Speed sensor drive 2114

AutoNews / Reviews / Tests

Replacing the Speed Sensor Drive VAZ 2114

The procedure for replacing the speed sensor on a VAZ 2114

To measure speed while driving, cars with internal combustion engines equipped with carburetors were equipped with a mechanically driven speedometer. This drive was located in the gearbox housing. Through a rotating cable, the readings were sent to a speed indicator located on the dashboard. Electric speedometers began to be installed on the VAZ 2114 with an injector. Speed data is transmitted to them from speed sensors based on new operating principles. Modern DS use the Hall effect.

Speed sensor VAZ 2114

Connection procedure and possible malfunctions of the VAZ 2114 speed sensor

The DS on the VAZ 2114 is installed in the receiving socket of the speedometer drive in the upper part of the manual transmission housing. It can be accessed both from above, with the hood open, and from below the car, when installing it on the inspection hole.

DS performs several functions, such as:

In connection with the tasks performed, it is connected to the controller and speedometer through a mounting block in the engine department. In the electronic circuit, the DS is activated through a fuse installed in the cabin on the heater fan relay.

If there are defects in the speed sensor strip, the following signals light up on the car's on-board display:

The occurrence of similar errors calls on the driver to pay attention to this area in the electrical circuit of the motor, and often their prerequisite is the absence or oxidation of contacts. However, if secondary signs of DS failure appear, then there is a need to check or replace it. These signs may include:

These signs may appear during failures in other car systems, for example, in the fuel system, but if an error appears on the computer screen and any of the listed signs at the same time, you should check the performance of the DS.

Replacing the VAZ 2109/14 speedometer drive and their modifications

Hello everyone, in this video I will talk about replacing the drive

speedometer for injection modifications at the front...

Speedometer drive 2110 2115

Video summary on replacing the speed sensor

on

VAZ

2110-2112 cars with an injection engine. Personal experience….

Replacing the VAZ 2109 speedometer drive due to gear wear

The drive also fails due to wear of the paired gears. In this case, its repair is carried out without removing the gearbox according to the following scheme:

- the car is placed on an inspection hole or overpass;

- using a socket wrench, unscrew the fixing bolt that secures the drive housing and gearbox;

- remove the case (it should be pryed off with a screwdriver);

- remove the gears and change them.

It is important to immediately count the number of teeth on the old gears. New parts must have the same number

Otherwise, the speedometer will provide incorrect information both in terms of mileage and speed. When inspecting the housing, you can see oil leaks on it, which indicates the need to replace the o-ring. It is pushed out after the driven gear is removed. It is recommended that after all replacements, wash the drive parts using clean kerosene, and then reassemble the unit in the reverse order.

Replacing the VAZ 2114 speed sensor with your own hands

After the contacts, wires and the DS itself have been tested and it has been determined that the device does not work, you need to make a decision about replacing it. For a car owner who is not a car repair specialist, this work is easy to do, but still, you need to look into the car repair and operation department and see how to change the speed sensor on a VAZ 2114.

Before work, you need to prepare the necessary tool. Keys for “10”, “14” and “21” will be useful. In addition, you will need a rag to clean the manual transmission housing in the DS area from dirt and oil.

You also need to purchase a new speed sensor for the VAZ 2114 in advance. It has a catalog number - 2111-3843010. The average cost for a speed sensor 2114 is about three hundred rubles.

On a VAZ 2114, replacing the speed sensor is possible from above, without entering the pit. But the adsorber and the inlet corrugated pipe from the air filter make it inconvenient to work with. Even if you remove them, it may still not be so easy to unscrew the DS. Experienced specialists advise stopping by the pit. DS will be at your fingertips. It is located on the body of the box above the universal joint of the rocker next to the dipstick for checking the oil level in the box.

This must be done with caution, because its body is made of plastic and can be damaged during installation. There is such a negative experience; in all instructions, experts warn about taking precautions when installing the DS, so that you do not have to interrupt the repair and go to the store for a new sensor.

So, the DS has been replaced. After this, you need to check the operation of the engine and speedometer in all modes and make sure that the new DS is operating normally.

How to remove the speedometer drive with your own hands - instructions

VAZ 2110

- We support the anti-rollback shoes of the rear wheel, then we need to jack up the front of the car, and then install it on supports.

- On a model with a cable-driven speedometer, remove the fastening pin and disconnect the cable from the gear drive.

- Unscrew the fastening bolt and remove it together with the heat shield.

- Remove the drive with the gear from the crankcase and remove it from the seal ring.

- The gear can be removed from the gearbox housing; be sure to check the condition of the gear; if defects are detected, it must be replaced.

- If there are signs of wear or damage to the gear, the condition of the gear should be checked.

- To remove the gear, release it from the transmission. Then you need to unscrew the mounting bolt and remove the drive gear housing. Then you should remove the drive gear and remove all the adjusting washers.

VAZ 2107

- Using a “13” wrench, you need to unscrew the bolt of the clamp securing the exhaust pipe of the muffler.

- Take a 10mm wrench and unscrew the drive fastening nut.

- Using a 13mm wrench, unscrew the two nuts securing the cross member.

- Then you need to lower the rear of the transmission.

- The pipe section must be moved to the right and then the speedometer drive must be removed from the crankcase hole.

Speedometer drive: types and differences

A speedometer is an important element in cars, as well as several other vehicles, as it is necessary to monitor speed in order not to violate traffic rules. But this is not the last function of this device.

All possible speedometers have a high-speed magnetic unit; due to the rotation of the magnets, a flow is formed, it moves through the coil, thereby facilitating the induction of eddy currents. They thereby begin to create more magnetic fields. They interact with each other, the needle of the device moves along the frequency scale, with the help of this the magnet rotates.

All speedometers are divided into three categories.

Mechanical speedometers. In this type of speedometer, the process of speed measurement and indication occurs thanks to a mechanical device. A gear is used as sensors, which is connected to the secondary shaft of the gearbox; this is the speed unit with an arrow indicator and the drum counter. Previously, speedometers were used in the form of a drum and tape. But they stopped using them quite a long time ago.

Tags: VAZ 2109, speedometer drive, speed sensor, VAZ 2114

Comments 50

Thank you, it hasn’t been working for a long time, I’ll have to look into it, but I’m having the same problem. I tried somehow unscrewing the sensor, but it doesn’t come out and spins endlessly, and what did you hear, maybe it could fall into the box?

I honestly don’t know what could fall into the box.

Well, I read somewhere that when you pull out the drive, it looks like it might fall

I read the same thing, but I still don’t understand. Unless the plastic part comes off and falls into the box. I also read that 2 CV joints cannot be pulled out at the same time, as if something falls.

Damn, now I’m wondering whether to climb or not

Until you climb in you won't know)))

Until you climb in you won't know)))

I bought a sensor, installed it, to no avail, but I rocked the car without a sensor; this roller rotates on the drive

Thank you, it hasn’t been working for a long time, I’ll have to look into it, but I’m having the same problem. I tried somehow unscrewing the sensor, but it doesn’t come out and spins endlessly, and what did you hear, maybe it could fall into the box?

I fell today and it’s not visible at all (((ppts

I still didn’t dare to take it apart

In short, the speedometer drive fell through the differential housing (I’m not sure exactly) and fell into the clutch housing under the main pair... I didn’t dare to drive such a gearbox, lest a metal part get caught between the gears and break them... repairs would be expensive. although people said that when repairing the gearbox they found 4 pieces inside and nothing... from the previous owner to know))) but it’s better not to risk it

Remove the cable from the box and fry along the highway from 70 to 140, if there is no cod, then you will wave the cable, if it remains, then there is something wrong with the box.

Installed 3 cables did not help

You take it off the box and fry it. When I had a cable one, I had such a rustling noise from the new one. I immediately took it off and poured engine oil into it through a syringe, after 50 kilometers it was as it should be.

I immediately lubricated the cable for the high panel and installed a new one, maybe the bend was wrong. Well, I'll try to take it off completely tomorrow and drive it

You take it off the box and fry it. When I had a cable one, I had such a rustling noise from the new one. I immediately took it off and poured engine oil into it through a syringe, after 50 kilometers it was as it should be.

and I took out this rod. exactly the same as in video 2108, it says 11 teeth. teeth are all intact, box without feeler gauge

There could be a shitload of business here. If you're wrong about the cable, then take it off. Maybe you've never changed the oil in it?

I removed the cable, took out this gear (rod) and the oil is visible! you can even touch the oil in it with your finger

thank you, very useful info, I also need to change it, but I couldn’t get around to it, I thought I’d have to remove the box, thanks again

Try it, change it, 100 rubles)

Please give me a link to the video. It doesn't open here

I came across such a problem. I want to add something. The speed sensor drive (electronic or cable) consists of 2 parts - the drive gear (placed on the differential cone) and the driven gear (the one about which the video is). they come in 2 types (differing in the number of teeth). one type of plastic is gray, the second plastic is white or yellowish. they are not interchangeable! therefore, if you change the driven gear (rod), then only with the same one (count the teeth). But from personal experience I will say that if the driven gear turns, then replacing only it will not solve the problem (well, just for a short while). both of these craps can be changed, to do this you will have to remove and disassemble the box, press it off the differential and press on a new drive gear

Thanks for the addition. I wanted to add this in this video about the gear in the differential.

By the way, about the key for the 22-sensor, it’s plastic, it unscrews by hand (well, I’ve never seen one that’s tightened that much). and also about the licked teeth - they do not lick themselves, but become stained over time, but the licked ones indicate incorrect installation (the rod was pushed in by force so that the teeth become jammed). you need to insert it in neutral, slightly rolling the car back and forth, since when inserting the rod, the teeth of the rod may not fall between the teeth of the drive gear, but onto a cog. so they roll the car to turn the drive a little. By the way, I changed it without a pit, although it was also an injector.

It was necessary to make a video recording showing the checkpoint itself and the car))).

Next time for sure))))

I’m having the same problem right now (the check light is on, an error message is the speedometer. This crap itself was erased in the box, even though I bought a new sensor and installed it, it didn’t help. So you can change it, this rod, without taking off the box? Can you be more specific? Please)

Below in the comments I wrote how it is changing. And he said it in the video. The main thing is to climb into the hole, and then you’ll figure it out.

Procedure

Now let's figure out how to remove the drive when the speedometer on a VAZ 2109 does not work:

- To do this, release the cross member that secures the gearbox to the body, give back the nut that secures the drive

- Pry off the drive housing with a flat screwdriver (as in the photo below)

- By pressing the gearbox to the side (for example, with a piece of pipe) from the drive, we pull the drive out of it

- Then we check its serviceability

- To do this, twist the gear and see whether the groove for the speedometer cable begins to turn or not

- If the groove does not turn, then replace the speedometer drive

- When going to the store for a new drive, it’s better to take the old one with you as a sample just in case (you can confuse the number of teeth on its gear)

- And if you install a “foreign” (not the one you need) drive, then in no more than 100 meters it will break the box cover, because a mismatched gear pitch will simply turn the entire drive outward and result in serious damage to the gearbox

- To be able to use this gearbox in the future, it will be necessary to replace its rear cover and completely change the oil

- If the old one suddenly pours out, there will still be fragments and crumbs of the housing left in it, which can subsequently fall on a gear tooth or clog the oil channel

Now that you know how to determine what the reason is if the speedometer needle suddenly starts jumping and fix it with your own hands.

Drive repair

We only considered replacing the drive, if the speedometer does not work in the VAZ 21093, sometimes this is easier and cheaper to do:

- The speedometer drive is removed, as a rule, to replace its housing, or the sealing ring from under which lubricant flows, or the drive gear itself

- It can be removed without dismantling the gearbox assembly; for this purpose it is better to drive the car onto an overpass, inspection hole or lift

The repair procedure will look like this:

- Using a socket wrench, unscrew the bolt that secures the drive housing, pry it off with a screwdriver, then remove it

Unscrew the drive nut, remove it, then pry off the housing with a flat screwdriver and remove the drive

- Now we can remove the driven gear

- This gear is made of plastic, so it is important to carefully inspect it and if signs of wear are found, replace it immediately

We inspect the condition of the rubber seal (shown by the arrow), then remove and inspect the plastic gear

- In addition, it is important to pay attention to the condition of the mounting socket, where the tip of the flexible rod (cable) of the speedometer enters

- The socket should not have licked corners or be broken, otherwise such defects are the reason for replacing the gear

- It is also worth paying attention to the condition of the box body in the place where our drive is installed

- If traces of lubricant leaks are visible, then it will be necessary to replace the rubber ring of the drive seal, which is located on its body

- To remove it, you will need to remove the driven gear, then push the o-ring out of the groove

- All parts are then washed in clean kerosene

Of course, no one has canceled the service station services, if you are too lazy to tinker, although tinkering is probably not an applicable expression here (it only takes 10-20 minutes), and the price of their services suits you, then decide for yourself.

Replacing the cable

Almost everywhere, car owners are faced with the problem of speedometer failure, which is often caused by a faulty cable. To replace the cable, it is not at all necessary to go to a car service center, because you can easily cope with this task yourself, our instructions will help with this. So:

- Go down the car (on a pit or overpass), then you need to unscrew the cable from the drive of your speedometer, located on the side of the engine compartment, move the rubber cap up, and unscrew the nut on the cable

- After this, disconnect the cable

- To disconnect the cable from the speedometer, you must first remove the instrument panel from the dashboard

- At the same time, if your car has a low dashboard, then unscrew two bolts and carefully remove the visor, squeezing the spring-loaded clamps with your fingers

- Then you can remove the instrument cluster

- If the car has a high dashboard, then first you will need to remove the trim, then unscrew the instrument panel

- Then you should unscrew the cable nut from the speedometer from the back side and pull out the old cable through the engine compartment, remembering how it went through

- Because the next step will be laying (pulling) a new cable

- It will be much easier to insert the plug into the compartment bulkhead if you first lubricate it with oil, for example Lithol

Source

Reason 1. Broken wiring

In fact, a non-working speedometer does not affect the operation of the car in any way. However, when driving within the city, where dozens of control cameras are installed, it is difficult to track the speed without this device. Experienced drivers can easily determine speed “by feel” and by engine speed (via the tachometer). In any case, driving with a faulty device is unpleasant, given that it is always in front of the driver's eyes. One of the reasons why the speedometer on a VAZ 2114 does not work may be a broken wiring. To check for a possible malfunction, perform the steps described in detail in the video below.

Briefly, the process of dialing plus and minus looks like this:

The verification process does not take much time, but it gives a more detailed picture of the breakdown. If there are no results during the check and the lamp does not light up, the problem is a broken wiring. In this case, the malfunction can be eliminated by replacing the wiring leading to the speedometer or restoring it.

Reason 2. Failure of the speed sensor

The age of the car or its operation in poor road conditions leads to the fact that many components of the car are subject to wear faster. The speedometer sensor is also not reliable. The absence of speed readings on the dashboard can be associated with a malfunction of the element itself. Later VAZ models began to be equipped with speedometers of a new type - magnetic. Previously, all cars were equipped exclusively with mechanical devices. The serviceability of the mechanical device can be checked as follows:

Another option for diagnosing a mechanical variant is as follows:

Checking the magnetic type of the device is carried out according to a similar principle:

If the check showed that the sensors do not work, then you now know why the speedometer on the VAZ 2114 stopped working. If, during diagnostics, the speedometer needle twitches, the problem is different. In this case, the fault may lie in the dashboard itself.

Video “Replacing the speed indicator cable”

This video shows how to remove the low tidy and replace the cable on a VAZ 2109 (the author of the video is Engine Repair! And interesting!).

The speedometer of this car model is equipped with a mechanical drive. The installation of gears, including the drive gear, is carried out on the secondary shaft of the box. The transmission of torque to the speedometer, which is located on the dashboard, is provided by a flexible shaft.

One of the features of the car model is that the equipment can have either a high or low dashboard, which in turn means that when purchasing a flexible shaft, you need to make sure that its length is suitable for your car.

Reason 3. Failure of the dashboard

If on the VAZ 2114 model on the instrument panel none of the indicators equipped on it work (speedometer, mileage indicator, tachometer, fuel quantity and coolant temperature indicators), then the first thing the car owner needs to do is check the integrity of fuse F3 , which is located in the mounting block under the hood. Another option why the tidy does not work is that the tracks on the board have burned out. The situation is not critical, because in this model it is removable and is cheap. Also, do not discount the option of a power outage to the panel. In this situation, it is better to contact an experienced auto electrician.

If there is no panel light, check the brightness adjustment. The minimum brightness of the backlight may have been accidentally set.

Source

What is the Hall effect

It lies in the fact that during the interaction of magnetic and electric fields, when the electric field flows in a certain way through the magnetic field in which the semiconductor wafer is located, a potential difference appears on it, the so-called Hall voltage.

This effect has gained practical application in DS because when moving, this voltage is converted into a pulse-frequency signal, which is transmitted to the controller. The higher the speed, the higher the frequency of the signal. It is calculated that the DS emits 6004 pulses per kilometer of travel. Based on the interval between these pulses, the controller calculates the speed of the machine.

Examination

If problems arise with the speed sensor, first of all you need to check the wiring for broken or oxidized contacts.

Since the wiring is not secured by anything, interruptions in the operation of the DS are often associated with the wires. If inspection shows that the wiring is normal, then it is necessary to diagnose the sensor itself.

You can check it using a multimeter turned on in voltage measurement mode. To do this, you don’t have to remove it from the car, but simply jack up the wheel and engage 4th gear.

The sensor itself has three terminals: the side ones are ground and the “positive” terminal for supplying voltage to the element. And the central one is pulse, through which signals are sent to the speedometer and ECU.

We connect the multimeter probes to the mass and pulse terminals. Then we ask the assistant to spin the wheel, and we ourselves look at the readings.

If during rotation the voltage value “jumps”, and the higher the speed, the more often “jumps” will occur, then the DC is working properly and the wiring should be checked.

In the same way, you can check the functionality of the new sensor after its installation.

Speed sensor in the general scheme of sensors and devices

It doesn’t take long to guess where the speed sensor is located on a VAZ 2114. After all, it also performs the function of determining the speed of movement. Structurally, the speedometer drive remained in the same place, therefore the VAZ 2114 speed sensor is located on top of the manual transmission, in the area of the right CV joint. The best access to the DS can be obtained from below, if you place the car on an inspection hole.

The connection diagram for the VAZ 2114 speed sensor is quite simple. In the general electrical circuit of the car, it is powered through the middle fuse, rated 7.5 A, which is located on the heater fan relay in the passenger compartment. On the instrument cluster in the front instrument panel, the output plug with the address - “DS” and the “engine control controller” has the same number - “9”.

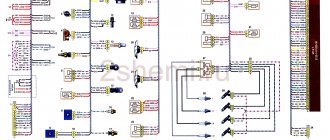

VAZ 2114 speed sensor diagram

What does the speed sensor affect? It is directly connected to the controller and electronic speedometer. When in working order, the DS provides the necessary information about the current speed, ensures normal operation of the idle speed controller and maintains engine speed in optimal mode through the generation of adequate signals to the ECU.

Since electronic devices are subject to various external influences that lead to failures in the overall system, one must be attentive to preventive inspections and monitoring their performance. So, there is an opinion that if the speedometer on a VAZ 2114 does not work, then the speed sensor has definitely failed. However, there are methods for monitoring the electronic speedometer. Using special equipment on the stand, you can determine its performance.

Three measurements are taken at speeds - 40, 80 and 120 km/h:

Functions

It is incorrect to assume that the DS serves solely to transmit information regarding the current speed of the vehicle. In fact, this device has several tasks.

- Transferring information to the dashboard, namely the speedometer, about the speed of the car.

- Supports optimal functioning of the idle air control.

- Transferring data to the electronic control unit in order to maintain optimal speed depending on the travel mode.

The DS is connected to the speedometer and controller using a mounting block located in the engine compartment. And inside the car, directly on the heater fan relay, there is a sensor fuse.

Errors and symptoms

If the device starts to work incorrectly or breaks down, you should pay attention to the on-board computer screen. Diagnostics of errors will determine that the DS has stopped functioning properly and measures should be taken to eliminate the breakdown

| Error code | What does it mean |

| P0500 | This error indicates that the computer does not receive a signal from the speed sensor. |

| P0503 | This error code informs about the receipt of an unstable signal from the DS, which is intermittent. |

If these error codes appear on the dashboard, you should definitely inspect the electrical circuit for oxidation or damage to the integrity of the contacts. Often it is because of this that the DS stops transmitting information.

But there are other signs by which you can determine that the DS is out of order:

- On the dashboard, the speedometer shows incorrect speed data or the needle does not move at all;

- With a slight acceleration, the speed floats, the engine switches off on its own;

- Fuel consumption increases;

- Engine power is noticeably reduced.

These signs may be signals of problems with other systems. But if you find one of the characteristic signs of a DS failure, plus one of two error codes appears on the on-board computer, then the problem lies precisely in the speed sensor.

Functionality check

Do not rush to replace the device until you are sure that the faulty sensor is the culprit of the problem.

The check is performed in several ways. Decide for yourself which one you prefer.

Checking the operation of the DS

Before doing this, be sure to check the condition of the wiring and contacts. If they are oxidized or rusted, or there are breaks in the circuit, then the DS itself may well be operational. You just need to return the wiring and contacts to a functional state. If the check shows that everything is intact and there are no problems with the contacts, then diagnose the speed sensor.

- If you don’t want to remove the DS, then place the car on a level surface, secure it with blocks and lift the left front wheel with a jack. Connect the voltmeter to the contacts of the sensor and begin to rotate the wheel with your hands. At the same time, look at the voltmeter data. If the voltage increases with frequency in proportion to the increase in wheel speed, the DS operates normally.

- Another method also does not require removing the measuring device. But for this you will need a test lamp. Use a jack to lift the left front wheel and connect the test lamp to the DC contacts. After this, manually rotate the wheel. If the lamp lights up, the sensor is working well.

- The third method involves dismantling the sensor and then checking the input and output voltage. The device for measuring the indicators will be a voltmeter.

- The fourth method is actively used by those who prefer to repair their car with their own hands. Here you have to check the sensor drive. To do this, lift the wheel using a jack and remove the sensor. Feel for the DS drive, and then begin to rotate the wheel. You can feel with your fingers that the drive rotates. If there are no jams, everything rotates evenly, then the drive is in good condition.

If a malfunction of the DS is detected, the only correct solution is to remove it and replace it with a new sensor.

Having determined that your DS has already served its purpose, you can begin the replacement procedure.