The exhaust manifold is a structural element of the exhaust system designed to remove exhaust gases from individual cylinders into a common pipe. Another function of the exhaust manifold is to ensure efficient ventilation and filling of the combustion chambers.

The exhaust manifold is rigidly fixed to the cylinder head. At the outlet, it is connected to the catalytic converter or exhaust pipe. There is a gasket between the exhaust manifold and the cylinder head that prevents exhaust gases from leaking into the engine compartment. The exhaust manifold operates under very difficult conditions, characterized by high temperatures (up to 1300°C) and pressure.

There are two types of exhaust manifolds - solid and tubular. The one-piece manifold has short channels that are combined into a common chamber. Made from heat-resistant cast iron. A one-piece exhaust manifold has low efficiency in removing exhaust gases and purging the combustion chamber, because short channels create obstacles in the form of gas pulses from each cylinder. On the other hand, a one-piece exhaust manifold is easy to manufacture and has a low cost.

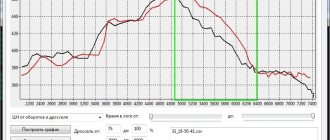

Modern passenger cars are mainly equipped with tubular exhaust manifolds, which are effective in the medium and high speed range and improve engine power characteristics. Tubular exhaust manifolds are made of stainless steel, less often of ceramics. To achieve the best parameters for removing exhaust gases and purging combustion chambers, the length, diameter of the pipes and their design (shape) must be optimized.

The movement of exhaust gases in the exhaust system is an oscillatory process. The short pipe of the exhaust manifold allows you to achieve a resonance effect, which provides the best purging of the combustion chambers at high engine speeds. With a long pipe, on the contrary, the resonant effect is achieved in the low rev range. In this case, long pipes prevent the return of exhaust gases to adjacent combustion chambers in which the exhaust valves have not yet closed.

The small diameter of the pipe ensures high exhaust gas speed, at which better inertial purging of the combustion chamber occurs and rated torque is achieved at low and medium speeds. On the other hand, small diameter pipes create additional resistance to flow at high engine speeds. Using a large diameter pipe, you get an increase in power at high speeds and a decrease in power at low speeds.

Currently, two designs of tubular exhaust manifolds are common:

4-1 or short manifold (four pipes connected into one pipe);

4-2-1 or long manifold (four pipes connected in pairs and then connected into one pipe).

The tubular exhaust manifold is an important element of car tuning. For one car, several designs of exhaust manifolds can be proposed and, accordingly, different effects can be achieved. The short manifold provides extra power in a narrow rpm range. A long manifold is more versatile, as it provides increased power and torque over a wide range of engine speeds.

Purpose of the intake manifold

This part is designed to ensure the supply of air and VTS to the engine cylinders while it is running. In modern power units, additional elements are installed on this part:

- Throttle valve (air valve);

- Air sensor;

- Carburetor (in carburetor modifications);

- Injectors (in injection internal combustion engines);

- A turbocharger whose impeller is driven by the exhaust manifold.

We offer a short video about the features of this element:

Intake manifold: frequently asked questions

About tuning instead of an epilogue...

When thinking about the exhaust manifold, one cannot ignore the topic of tuning, because this part quite often ends up on the list of those subject to modification.

As a rule, on the market you can find different configurations of this element for a specific model.

Exhaust manifolds allow you to achieve, for example, good performance at low speeds or in the mid-range - for every taste and color.

And in motorsports, they often do away with exhaust manifolds altogether, connecting the exhaust pipes directly to each cylinder.

I hope, dear readers, we have delved deep enough into the study of the exhaust manifold. In future publications we will continue to study the structure of the exhaust system of cars, don’t miss it!

Design and design of the intake manifold

One of the most important factors affecting the efficiency of the motor is the shape of the commutator. It is presented in the form of a series of pipes connected into one pipe. An air filter is installed at the end of the pipe.

The number of taps at the other end depends on the number of cylinders in the engine. The intake manifold is connected to the gas distribution mechanism in the area of the intake valves. One of the disadvantages of the VC is the condensation of fuel on its walls. To prevent this effect of electrostatic reaction, engineers have developed a pipe shape that creates turbulence inside the pipeline. For this reason, the inside of the pipes is deliberately left rough.

The shape of the collector pipes must have specific parameters. Firstly, the path should not have sharp corners. Because of this, fuel will remain on the surface of the pipes, which will lead to clogging of the cavity and change the air supply parameters.

Secondly, the most common intake tract problem that engineers continue to struggle with is the Helmholtz effect. When the intake valve opens, air rushes into the cylinder. After its closure, the flow continues to move by inertia, and then abruptly returns. Because of this, a resistance pressure is created, which interferes with the movement of the next portion in the second pipe.

These two reasons force automobile manufacturers to develop improved manifolds that would ensure smooth operation of the intake system.

Principle of operation

The suction manifold operates according to a very simple scheme. When the engine starts, the air valve opens. As the piston moves to bottom dead center on the suction stroke, a vacuum is created in the cavity. As soon as the intake valve opens, a portion of air moves at high speed into the vacated cavity.

During the suction stage, different processes occur depending on the type of fuel system:

- Single injection - another portion of air comes from the filter. It passes through the carburetor or cavity in which the fuel injector is installed (if the engine is equipped with an injection vehicle). In this cavity, air is mixed with fuel. Due to the vacuum in the cylinder, this portion is sucked through the raised valve of the intake system;

- Multipoint injection - individual fuel injectors are located in each manifold pipe. When the corresponding valve opens, air is supplied through the pipe suitable to it. At the same time, fuel is atomized.

- Direct injection - only air is sucked in. The valve lowers, the piston compresses the air in the cylinder. At the end of the compression stroke, fuel under pressure is supplied through the nozzle into the compressed medium. In diesel internal combustion engines, an identical process occurs, only the air is compressed more strongly.

All modern engines are equipped with an electronic system that controls the supply of air and fuel. Thanks to this, the motor operates more stably. The dimensions of the pipes are selected to match the parameters of the motor at the stage of manufacturing the power unit.

The principle of operation and features of the formation of a flow of a combustible mixture

The carburetor or fuel injectors spray fuel into the intake chamber of the manifold. Due to electrostatic forces, fuel droplets immediately scatter throughout the chamber and tend to settle on the walls of the collector or collect into larger droplets in the air. Both actions are undesirable because they lead to the formation of a mixture of uneven density. The better the fuel is atomized, the more intensely and completely it burns in the cylinders. To achieve the required turbulence and pressure in the manifold, and therefore correct fuel atomization, it is customary to leave the internal surfaces of the intake channels of the manifold and cylinder head unpolished. The surface should not be too rough, as excessive turbulence may occur, which will lead to an increase in pressure and a drop in engine power.

The equal-length intake manifold, developed for racing cars, has become standard on modern passenger car engines.

The intake manifold must have a strictly defined length, capacity and shape. All these parameters are calculated when developing the power unit. The intake manifold ends with air channels that direct air flow to the engine intake valves. In diesel engines and direct injection systems, the air flow is swirled and directed into the cylinder, where it mixes with fuel.

Collector pipe shape

This is a very important factor, which is given key importance when designing the intake system of a separate modification of engines. The pipes must have a specific cross-section, length and shape. Sharp corners and complex curvatures are not allowed.