- 16.09.2021

- /

- Useful, How it works

- /

- Anna Krivoruchko

Spoilers, splitters, air intakes, body kits... These are just a small part of the “decorations” that flooded our streets in the 2000s. Perhaps, then in Russia the “golden” era of folk car tuning had begun, and crazy wings grew even where they seemed to have no place at all. Only a few guessed about their true purpose, and only the most abstruse design engineers could calculate and install the aerodynamic elements so that they would perform their direct function.

Now technologies that allow you to “calculate” a car in a few clicks have become more accessible. Computer modeling has become quite accurate, and wind tunnels are no longer associated only with the space industry. The pioneers in the field of automotive aerodynamic research, as always, were sports teams, but very soon the manufacturers of production cars took a closer look at the research results and adopted the experience of their enlightened comrades. Figurative cutting through the air is a whole art and we are talking here not only about forms that are pleasing to the eye, but also about what can only be felt in movement.

It turns out that aerodynamics can affect the noise in the car, the notorious acceleration of 0-100 km/h, and even fuel consumption. How it works? Let's figure it out together.

Drag coefficient

It turns out that air is a capricious and unpredictable substance. In calm weather you can even forget about its existence, but everything changes when you start moving. The weightless gas will turn into almost jelly as you accelerate. The car comes face to face with oncoming traffic, and in order to understand how effectively the car overcomes the endless air barrier, they came up with a rather ephemeral, but well-established value - the drag coefficient. This indicator is relative and needs to be compared with something, so gentlemen scientists chose a “standard”. And this is not some kind of clever figure, but a very ordinary cylinder. It should be the same diameter as the widest part of the car and the resistance that it encounters when moving is usually considered equal to 1. And when the resistance of the metal “sausage” is known, the tested car is placed in the same conditions. And if the car encounters half as much air resistance, then its drag coefficient will be equal to 0.5. But now this indicator is considered practically a “failure”. Although many representatives of “brick” aerodynamics are loved and respected on the roads. The drag coefficient of the brutal Gelandewagen, for example, is as much as 0.54. For comparison, the most aerodynamic car to date boasts a value of 0.189. This is a futuristic creation of the VAG concern - Volkswagen XL1.

Alfa Romeo Giulia

Some may not believe that this car has excellent aerodynamic characteristics, since the exterior of the classic Alfa Romeo Giulia is presented in the form of a square. But the legendary 1962 Alfa Romeo Giulia showed unique results in the wind tunnel. The drag coefficient was only 0.34, lower than even the more fluent-looking NSU Ro 80 (0.355), which did not come to market until five years later.

What does aerodynamic performance depend on?

In fact, there could be enough factors to fill a couple of full-length books. But you can still identify the main categories:

- front geometry;

- side geometry;

- rear geometry;

- bottom geometry;

- surface roughness.

In order for the car to encounter less air resistance, it is important that its flow flows around the car as smoothly as possible. When meeting an obstacle, the air flow first resists, and then nevertheless separates. One part of it passes the obstacle from above, the other from below, and the third and fourth parts from the side. Imagine that the air around the car is horizontal strings with springs along their entire length. When a car enters this striped space, this is what happens: first you need to force the obstacle to part. The larger the area of the area that first encountered the elastic obstacle, the more springs will have to be compressed at the same time in order to continue movement. When this happens, the threads begin to gradually distribute throughout the body and bottom.

The springs begin to compress further, and due to this, the threads rise along the radiator grille until they reach the hood. There is usually quite an impressive step there, so the spring needs to sharply compress even more. Then comes the turn of the windshield, which causes the coils to tighten even more. This continues until the body begins to smooth out and the spring has room to expand to its normal state. If the roof line gradually collapses and flows into the trunk, an imaginary spring will gradually unwind, and an equally imaginary thread will calmly outline the contour. But if a compressed spring suddenly loses support, it will first sharply unclench, and then oscillate until it uses up all the accumulated energy. Such chaotic movements at the moment of sudden loss of support perfectly visualize turbulence. At the moment of its occurrence, streams of so-called disturbed air are formed, which swirl and, thereby, create an area of low pressure. The simplest example of an area of increased turbulence is the end of a truck trailer. You can physically feel how you are “dragged” there if you drive past. It is also known from the school physics course that any object tends to move to where the pressure is less. This is what causes such an unpleasant effect. But while everything is clear with neighbors downstream, many people forget about the self-generated “vacuum”. If the air flow suddenly stops behind your car, the resulting turbulence will literally suck you back, preventing you from moving forward.

It’s also worth considering that modern cars, in their geometry, vaguely resemble the shape of an airplane wing.

The underbody of your car is quite flat, and therefore there is relatively little turbulent flow, which cannot be said about the upper part of the body. This means that there is less air pressure above the roof than under the wheels. This causes the car to rise slightly above the road, and the higher the ground clearance, the stronger this effect. Airplanes similarly rely on air and generate lift from pressure differences. Of course, you won’t take off in a car, but it’s better not to forget about such tricks of the air, especially when you’re driving fast.

ALFA 40-60 HP Aerodinamica Castagna

The first show car in history and the first attempt to apply the principles of aerodynamics to cars was the ALFA aerodynamic car, released in 1914 (in those years the brand was not yet called Alfa Romeo).

See also: Unusual cars that came for inspection

The car was created by the Italian company Carrozzeria Castagna for Count Mario Ricotti. The car body was made in the form of a drop and rested on a classic frame.

Thanks to the aluminum body and the absence of a hood, the maximum speed of this concept was 120 km/h. When the car went into serial production, the speed was already 139 km/h. Unfortunately, the exact value of the aerodynamic air resistance of this car is unknown.

How aerodynamics affects a car's behavior

Aerodynamics begin to work when the car moves, but at low speeds it is almost impossible to feel it. But the faster you go, the more influence the environment will have on the car.

Noise

The faster you drive, the noisier the cabin becomes. And it's not just the tires that hum. To all the sounds that accompany daily driving, aerodynamic noise is also added. All the humming and groaning that is heard around is the sound with which the air “breaks” from the car body, and then “beats” into the windows and doors. The faster you drive, the more air will noisily “leak” from pillars, mirrors and other excessively protruding parts of the exterior, hence the increasing noise.

Overclocking

It’s not for nothing that I managed to call the airy mass jelly. After all, the air really resists movement in it with all its might. It works something like this: the force of air resistance increases in proportion to the square of the speed, which means that, all other things being equal, if you accelerate from 60 to 70 km/h, the resistance force will increase by about 35%, and if you accelerate to 100 km/h - by 180%. It turns out that the faster you go, the more power the car needs to overcome an air barrier. Accordingly, at high speeds, fuel consumption may increase significantly, and acceleration will seriously suffer, even if the nominal power reserve of the engine is not exhausted.

Controllability

Handling is greatly affected by the lift that occurs under the bottom of your car. At low speeds, the weight of the car is greater than the impact of the air from below, but at speeds above city speeds you can feel that the car begins to handle differently and react very nervously, for example, to side gusts of wind. This happens because the body rose slightly above the road, and part of the weight of the car took on a kind of air cushion. Therefore, the contact patch between the wheels and the road has become a little smaller, which results in unpleasant instability in control. This “critical” speed is different for all cars. Some “take off” at 100 km/h, while others are not afraid of a speed of 210. It also depends on the geometry of the body, the weight of the car itself, and what the car can oppose to the lifting force.

For what purposes is it required?

Almost every driver knows what the aerodynamics of a car may require. The streamlined shape of the body will result in less fuel consumption due to reduced drag. Such a car will not only help you save money every day, but will also reduce the amount of toxic chemicals in the environment. At first glance, it may seem that the answer is clear, but some details are still missing. Experienced specialists working in the field of aerodynamics try to finalize the shape of the car body, as well as perform the following series of actions:

• make calculations to correctly distribute the lifting force along the axes. This is extremely important, given the possible high-speed operation of modern cars;

• ensuring normal air circulation so that the engine and brake system are cooled in a timely manner;

• careful planning of the places from which air will be taken in and out to ensure a high-quality and efficient ventilation system in the cabin;

• make every effort to reduce noise in the cabin;

• optimization of the shapes of body parts to reduce contamination of glass, lighting fixtures and mirrors.

It is worth noting that sometimes the solution found for one problem may be contradictory for the implementation of another problem. For example, when the drag indicator decreases, this leads to improved streamlining. But at the same time, the vehicle’s former resistance to wind gusts from the side begins to be lost. Therefore, manufacturers have to constantly find a compromise solution.

Why are spoilers needed?

If we really can’t get away from the air and its whims, then it’s worth trying to turn its abilities for good. That's what automakers thought before and continue to think so now. The main innovators and ideological inspirers, as always, are the sports divisions of automobile concerns. There they refine the shape of the bottom, and make special body kits, and invent exhaust systems using the Richelieu lace technique. But it will not be possible to fit all these effective innovations into one serial civilian vehicle - it is too expensive and difficult. You have to choose the simplest, most reliable and effective way to adjust the behavior of the car in the air flow. And if drag and increased noise can be overcome only by completely rebuilding the body, then you can deal with “take-offs” differently. Front splitters and rear wings (spoilers) are suitable for this. The splitter helps reduce the ground clearance and literally cut off some of the air that gets under the car at speed. This helps reduce lift.

The spoiler smoothes the flow of air coming off the roof and rear window of the car. But in addition to “straightening” the flow, a properly selected wing converts air resistance into downforce. It turns out that the air meets the surface of the wing at such an angle that part of the drag force is directed towards the road surface. Thanks to the rigid attachment of the spoiler to the body, the rear of the car has no choice but to press down to the ground under the influence of the air flow. This helps maintain controllability, and in rear-wheel drive it also helps deliver power to the drive wheels. By the way, there are also front wings, but only in the world of professional motorsport.

As you can see, aerodynamics is a complex thing. And making friends with her can be difficult, even with almost limitless resources. After all, even a tiny error in calculations can lead to an effect that is strictly opposite to what was expected. Yes, there are talented mechanics who can transform a car by fitting just a couple of strips, but, for the most part, all non-factory attachments rather enhance the appearance of the car, rather than its habits. Let's be honest: after all, we love with our eyes, and all the attributes of a real sports car will certainly force their owner to follow them with their eyes.

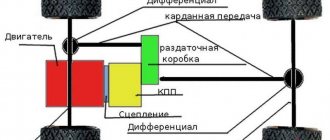

Front engine, front wheel drive

In such cars, all the power is concentrated in the front. To eliminate the negative effect of air masses, it is necessary to acquire a front splitter, which is often called a “bumper lip”.

Another useful part for creating downforce is a deflector on the bumper (also installed on the front of the car).

These two do enough to give the car extra downforce and reduce power loss.

Tesla Model S

The Tesla Model S is an electric car that changed the history of the auto industry, setting the entire automotive world on a new path. And all this thanks to the foresight of the company's head, Elon Musk, and designer Franz von Holzhausen, who developed a five-seater sedan with a drag coefficient of 0.24.

For comparison, in 2012 this value represented the overall world record for mass production cars. Mercedes S-Class cars had this coefficient. Thanks to the stunning body shape, Tesla cars can travel 400-500 kilometers in ideal conditions.

Audi 80

Audi, starting in the 1980s, began to set its own high standards for aerodynamic performance, imposing a new bar on other automakers. Thus, first the Audi 100 C3 was presented, which showed an air resistance coefficient of 0.30 cd in the wind tunnel, and then in 1986 the Audi 80 B3 (“barrel”) was presented, which showed a drag coefficient of 0.29. For reference: already in 1987, the new Opel Omega A model had an aerodynamic drag coefficient of 0.28. The 1980s can easily be called the decade of aerodynamics in the auto industry.