Torsion bar suspension appeared on cars back in the 30s of the last century. Similar suspensions based on an elastic element that works in torsion were used not only in passenger cars, but also on heavy armored vehicles and trucks. Lightness, strength, compactness - everything about it. We will analyze what a torsion bar is and the principle of its operation using the following example.

What is a torsion bar in a car?

A torsion bar is a metal rod of round, square or composite cross-section, one end of which is rigidly fixed to the body, and the other is attached to the suspension arm. Thus, when hitting an obstacle, it twists around its axis. The most common example of a torsion bar on a car is any anti-roll bar.

The diameter of the elastic element is precisely calculated for the given characteristics of the car, and according to the type of arrangement, the torsion bar can be longitudinal or transverse. The composition of the steel from which it is made plays an important role in the work. The metal must be moderately pliable and elastic, but at the same time withstand hundreds of thousands of twists. To protect against corrosion, the surface is coated with a special elastic paint or polymer.

An example of the use of torsion bar semi-independent suspension in a passenger car is some models from Peugeot, Renault, Citroen, pickups and SUVs from Toyota, Isuzu, and Mazda.

Disadvantages of torsion bars

- Oversteer. Almost all cars that have this suspension are prone to this. The driver must be especially careful when turning, because at this moment the vehicle may simply turn in the other direction. On ZAZ cars at low speeds, this problem becomes especially noticeable.

- The processing and production technology of torsion bars are quite complex processes in themselves. But otherwise, manufacturers cannot provide the required level of material elasticity and high strength. It cannot be done without special procedures to harden the surface, otherwise the metal will not be resistant to cracks appearing on the surface. Plastic deposits are also used. But even this does not stop those who use torsion bars to provide a higher level of comfort while moving in a wide variety of terrain.

- There are needle bearings where the arms are attached to the ends of the torsion beam. This system has a somewhat limited mileage resource. Through cracks in gaskets and seals, dirt, water and dust enter the bearings, which is why the bearings themselves fail faster. At the same time, driving intensity and style do not play a special role in this. Much more important is the impact of aggressive environments plus the aging of the rubber material.

Operating principle of air brakes Brake fluids

But, thanks to the high level of modern service, the problem is easy to solve by changing only the bearings or seals. Sometimes repairs are needed, replacing the torsion beam, but this is only in the worst case scenario.

The history of torsion bar suspension

Since its appearance in the 1930s on Citroen cars, the torsion bar in the suspension has been used by almost all major manufacturers: Renault, Peugeot, Chrysler, Ford, ZIL, Mazda, LuAZ and others. First of all, I was attracted by the compactness and simplicity of both the front and rear suspension of the car. Thanks to this, it became possible to create a compact front-wheel drive car, for example the Citroen 2CV or Renault 16. The service life of metal rods was also higher for shock absorbers and springs of that time, and the concept of controllability differed from modern ideas about the standard behavior of a car.

Currently, torsion bar suspension continues to be widely used on French cars. For example, the Citroen Xsara successfully combines a torsion bar in the rear beam and a modern MacPherson beam in the front.

Trailing arm suspension

Its structure is as follows: one or two elastic elements are located across the body, and trailing arms are attached to them. This design was used, as a rule, for the rear suspension of small cars, but is not currently used.

It was first used on the Volkswagen Beetle; its front part had such a device. One of the cars with a rear trailing arm suspension was Renault 16. This car is interesting because it had a different wheelbase on the left and right. The reason is that the design of its rear axle used two torsion bars, located one behind the other.

The principle of operation of torsion bar suspension

An elastic metal rod is placed longitudinally in the car frame or transversely between the suspension arms. The ends of the torsion bar are equipped with a splined connection for reliable fixation and are adjustable. To do this, the initial angle of installation of the rod is changed by several degrees, which increases or decreases the elastic torsional force.

Under load, the force from the wheel is transferred to the lever, which in turn begins to twist the elastic element until the limit value is reached. After removing the load, the wheel returns to its original position. The design of the torsion bar in this case is similar to a spring suspension when the metal strip is compressed. But unlike a spring, a torsion bar reacts faster to various irregularities and provides a better smooth ride.

Features of the torsion system

Using torsion bars, it is quite difficult to obtain an independent suspension system that would fully provide the required level of comfort.

Partly, it is for this reason that the parts are not yet widely used. But, if the torsion bar structure is still present, the system becomes quite free. Rotating shock-absorbing arms at the end of the beam will achieve better results. Thanks to this solution, the user can get a smoother ride while driving and independence of the wheels. This suspension will be a particularly effective solution on large cars, where it will constantly experience quite serious loads.

Types of torsion bar suspensions

Designers have a new technical tool for implementing various vehicle layout schemes. Therefore, now you can find fully independent and semi-independent suspensions, which are equipped with cars of various classes.

Front independent

This type has become common on racing cars (for example, Porsche), commercial trucks and SUVs. To fasten the wheel and hub assembly, double levers are used, and the role of a spring is played by a torsion bar located along the body. By adjusting its length, thickness and installation angle, you can raise or lower the body and adjust the suspension for specific road conditions.

In addition to the main torsion bar, shock absorbers are installed to dampen vibrations and a stabilizer bar. In terms of handling, a car with an independent front suspension is not inferior to, and sometimes even superior to, a car with a MacPherson-type shock absorber strut.

Rear independent

The rear independent torsion bar suspension differs from the same front one. A typical representative of a car with such a design is Renault 16. It featured a design with two transverse elastic rods, one of them being behind the other. Accordingly, the mounting points for the suspension arms of the left and right wheels were slightly shifted relative to each other.

The result was a very compact and durable suspension, the luggage compartment was increased, but handling remained unimportant due to the different base of the rear wheels. Another example of rear independent suspension is the use of trailing bars and separate control arms for the left and right wheels. This scheme is not widely used on passenger cars, but it is often found on passenger trailers and special equipment.

Rear semi-independent

A hybrid design that combines the elastic properties of a torsion bar and a rigid cross beam. In this case, two trailing arms are connected by one elastic element, so when one wheel is compressed, the force is partially transferred to the second. This does not give complete freedom to both wheels, but the handling and behavior of the car on the road is noticeably improved in comparison with a completely dependent one.

The U-shaped torsion beam always works in combination with a spring and shock absorber. Currently widely used on all budget front-wheel drive cars - VAZ, Toyota, Volkswagen, Renault and many others.

Advice! To find out exactly what type of suspension your car has, just look under the car. The long torsion bars cannot be confused with anything else.

Semi-independent rear

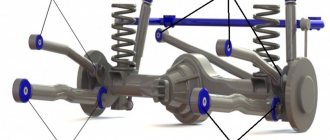

This type of suspension is based on a torsion beam, which has a U-shape. The trailing arms are located one on each side. The beam connects them together. The levers are attached with one side to the body, and the other to the wheel hub.

The beam resists bending well. At the same time, its shape does not prevent it from curling at all. The wheels may move slightly in the vertical plane relative to each other. The location of the torsion beam can be seen in the figure below.

Semi-independent suspension is used in budget cars with front-wheel drive. This is due to the simplicity of the design and low price of such machines.

Pros and cons of torsion bar suspension

Despite the fact that such torsion bars have been successfully used on cars for a long time, this type of suspension has many distinctive features that hinder mass implementation.

Let's start with the advantages:

- compact placement under the bottom or within the frame;

- ease of operation and maintenance of the elastic element;

- light weight of the entire assembly;

- the ability to manually adjust to the required operating conditions (change in ground clearance);

- simple repair and replacement with a new torsion bar (special tools may be required);

- service life is designed for the entire life of the machine;

- good ride quality on bad roads;

- high load capacity.

Most of these properties were relevant in the middle of the last century, when simplicity and reliability of design were required from a passenger car, while other qualities faded into the background.

On a modern vehicle, the disadvantages of a torsion bar become obvious:

- adjusting and replacing the torsion bar requires certain qualifications and tools;

- the complexity of producing elastic rods, their high cost in comparison with classic springs and leaf springs;

- support needle bearings require regular replacement or adjustment;

- do not tolerate fast driving on broken roads;

- sharp turns require careful and collected driving;

- Even a working torsion bar can burst due to improper use.

Conclusion

Manufacturers around the world are working hard to improve torsion bar suspensions and reduce their production costs.

Modern equipment and unique computer programs are actively involved in the creation process. According to some experts, in the coming years, torsion bar suspension will be able to catch up with the popularity of its competitors.

But at present, most manufacturers are not yet committing to the mass introduction of torsion bars. We have already discussed the reasons for this decision above.

But in any case, there is hope that over time this trend will change, because torsion bar suspension is truly a unique development that requires special attention.

The use of torsion bars in the modern automotive industry

Torsion bars in suspension are most common in armored vehicles, tracked vehicles and heavy trucks. The determining factor was the ability of the torsion bar to withstand very heavy loads and at the same time take up little space in the transmission compartment. Controllability and the cost of manufacturing the suspension in this case fade into the background. All modern tanks and armored personnel carriers are built according to this scheme.

The second area of use for torsion bars is light commercial vehicles. The determining factor here is the volume of the cargo compartment and the carrying capacity. Therefore, the most compact and simple rear suspension came in handy. Today this type can be seen on: Peugeot Partner, Citroen Berlingo, Renault Megane, Renault Kangu.

Approximate cost of servicing this type of suspension. The cost of the most elastic rod for budget class cars is about 6-7 thousand rubles, holders and silent blocks will cost another 700-1000 rubles. A service replacement will cost another couple of thousand, but you can do all the work yourself if you have a special key and a puller.

Advice! Not all services undertake this work, so the cost may vary greatly from the indicated one. As a rule, the most reasonable prices are from official dealers.

see also

The history of the appearance of torsion bar suspension dates back to the 30s of the last century; thanks to numerous improvements, it remains relevant to this day and is successfully used not only in civilian, but also in military equipment. Moreover, the technology is in demand not by some modest companies, but is in service with companies recognized as industry leaders, such as Volkswagen, Ferrari, Citroen, Toyota, Jaguar, etc. At one time, domestic manufacturers also appreciated the torsion bar suspension and tested it for the first time on the legendary Zaporozhets , in which the front suspension includes a pair of square torsion bars. In view of this state of affairs, it would be useful to take a closer look at what a torsion bar suspension is and why interest in it has turned out to be so persistent.

The basic element of a torsion bar suspension is a torsion bar (from the French torsion - twisting), an element made in the form of a cylindrical rod of increased elasticity, working to twist in one direction. The shape of the torsion bar is not subject to a single standard, so in cross section it is mainly square or round. Another less common option is a plate torsion bar, which has a multilayer structure, also designed for torsion provided by the joint operation of several plates.

In order to increase torsional springiness, the steel used in the production of torsion bars undergoes complex multi-stage heat treatment. Thanks to this, intense torsional stresses and significant twist angles do not create problems for the suspension. Both ends of the torsion bar are movable, which is achieved through the use of bearings and splined joints to accommodate changes caused by workloads.

The torsion beam located under the body can occupy both longitudinal and transverse positions. The longitudinal version is found mainly in trucks, where the chassis is constantly subject to significant loads. Transverse torsion bar suspension is installed on passenger cars, especially rear-wheel drive ones.

Torsion shafts have different thicknesses, which affects the performance and softness of the suspension. To avoid rusting, the torsion bar is protected with durable anti-corrosion paint or rubberized.

Do-it-yourself torsion bar suspension adjustment

The need to adjust the torsion bar tension arises due to their uneven wear or after each replacement. Visually, this parameter is determined by measuring from the ground to the car body or at control points specified by the manufacturer in the operating manual. The inspection frequency for SUVs is every 10 thousand km.

You can do a simple tightening of torsion bars with your own hands. To do this, you will need an inspection hole or a lift, a ruler (calipers), a jack, and a set of keys.

Important! You can tighten the tensioner nut only with the car raised, measuring the change in ground clearance each time.

Procedure:

- Place the car on a level surface and equalize the tire pressure;

- rock the car to remove the residual load;

- we measure the distance, calculate how much the clearance needs to be changed;

- lift the car and loosen the torsion bar fastening nut;

- place initial position marks;

- Using a special wrench, rotate the shaft at the rate of 1 spline – 3 mm in height;

- tighten the nut and lower the car;

- We take measurements and repeat if necessary.

Torsion bar suspension, although somewhat unusual for the average car enthusiast, is quite widespread. Therefore, when choosing a car, you should always pay attention to this feature and take it into account during further operation. As practice shows, a modern torsion bar on a passenger vehicle is a reliable and repairable unit and there is no need to be afraid of it.

Where are they used today?

In recent years, torsion bar suspensions have become increasingly popular. As we already mentioned, in most cases they are installed on trucks and SUVs. But gradually the vector is shifting towards passenger cars.

Thus, torsion bars are installed on cars of the SMA, Lifan and Samand brands. In addition, torsion bar suspension is found on Peugeot 405, Citroen Xsara, Peugeot 405, Peugeot Partner, Citroen Xsara, Citroen AX, Citroen Berlingo, Peugeot 306, Peugeot 206, Citroen Xsara Picasso and a number of other models. Moreover, every year more and more new car brands join this group.

Video on the topic

Why is it needed?

Torsion bar suspension is an important option for any car, along with spring, spring, pneumatic and others.

Let us remind you that a car needs suspension in order to provide shock absorption when connecting the wheels of the car and its supporting system. The suspension performs another important function: it reduces the load on the wheels exerted by the road surface, stabilizing the position of the body when driving.

A little background

In the first half of the last century, around the 30s, an automobile manufacturer installed a design that was curious at that time on its Beatle model. As it turned out, it is a kind of prototype of a modern torsion bar suspension. This design was later improved by the scientist Ledvink from Czechoslovakia, and then was installed on Tatra cars.

Then Ferdinand Porsche became interested in it, and already in the 40s he reproduced this idea of the professor and introduced it into mass production under the name “KDF-Wagen”. Later, during the Second World War, this suspension was used in the design of tanks and other military equipment. In the post-war years, Renault and Citroen became interested in torsion bars. However, soon, despite the ease of operation, the production of torsion bars became much more difficult, so they abandoned it. Currently, torsion bar suspension is widely used on trucks and SUVs of some Japanese and American automakers.

Device

The torsion bar suspension consists of metal shafts. They work on the so-called torsion. So, one end of the shaft is fixed to the chassis, and the other to a special lever, which in turn is connected directly to the car’s axle. The torsion shaft is usually made of high-temperature steel. Due to its strength, this material can endure heavy loads without harm. The torsion beam (or shaft) can have two locations depending on the type of vehicle. For example, in passenger cars it is placed transversely. Most often, torsion bar suspension is found on rear-wheel drive passenger cars. On trucks, the beam has a longitudinal arrangement. However, despite the difference in location, the functions remain the same. Like other suspensions, the torsion bar affects the smoothness of movement, is responsible for adjusting the roll when turning, and reducing vibrations of the steered wheels. One

However, a torsion bar suspension in some cases also performs the function of automatic leveling with the help of an engine, which, in turn, tightens the torsion bar shafts to provide additional rigidity. This kind of design can be used when replacing a wheel. While all three wheels are lifting the car, the fourth one can be replaced without using a jack.

Advantages

Torsion bar suspension has some advantages over other types. For example, the service life of such a structure is much longer, and height adjustment is easier. This suspension is more compact and easier to maintain, which is the main advantage. If it becomes loose, it can be repaired using a standard wrench, which cannot be said about the spring suspension.

It differs from the classic spring one in that instead of springs, torsion bars are used in its design. extremely simple and at the same time effective. A torsion bar is an elastic shaft, one side of which is rigidly fixed to or, and the other side is connected to the wheel hub. In the case of a front-wheel drive car, the torsion bar is mounted on the lower wishbone.