There are often situations when the driver does not know what to do if the silent blocks creak, so much so that sometimes they drown out the quietly working audio system. Especially on uneven roads, you can hear these grunts, unplanned by the manufacturer and completely unnecessary for the user. Probably none of us is able to ignore such a sound for a long time: even the most reserved person lacks any nerves.

And although many of the experienced drivers say that there is nothing particularly military about this: the wheel will not fly off, the car will not stop moving - everyone, even an inexperienced novice in the automotive business, strives to fix such flaws as quickly as possible.

What to do if silent blocks creak? The sequence of your further actions depends on the reason why the creaking itself appeared. There are not so many of them, so it is not so difficult to establish what caused it and eliminate this factor with your own hands. Especially if you are used to performing many routine repairs yourself. This material is devoted to how to do this.

Wear of silent blocks

This is one of the most likely causes of an unpleasant squeak. After all, what is this detail actually? A piece of thick rubber with metal inserts. And any rubber tends to dry out. In addition, silent compounds are constantly exposed to mechanical and other influences (for example, in winter, road chemicals play a role in destruction). As a result, the resource is exhausted earlier than planned.

When worn, creaking may be accompanied by deterioration in controllability and the appearance of vibration. Theoretically, the silent tape should last for 100 thousand km, but, given the state of our roads, it is rare that it can withstand 50. Replacement is carried out in an inspection pit or its equivalent; If the car has a crankcase protection, it must be removed before the procedure.

- The nuts that secure the front arms are turned out;

- Next in line for dismantling is the nut that secures the stabilizer to the lever;

- Get a bolt; manually it moves out reluctantly, so it is lightly tapped with a hammer;

- The bolts on the wheel are loosened, the corresponding side is jacked up, and the wheel is completely removed;

- The nuts on the braces are unscrewed. Before starting this step, they should be sprayed with WD-40;

- The ball joint is moved away from the steering knuckle, 2 more bolts are removed, and the lever is finally dismantled;

- The silent blocks are removed using a puller. Under no circumstances should it be replaced with a sledgehammer!;

- The eyes are cleaned of all deposits;

- Before pressing in the new silent, it is coated with any soap solution. Do not try to use oils and lubricants - they will corrode the rubber;

- Everything is installed in the reverse direction of disassembly. If the cause of the squeak was wear and tear, the sounds will disappear.

Necessary materials

To press this part into place at home, you will need the following tools:

- Mount;

- Jack;

- Set of wrenches;

- New hinges.

It is recommended to use machine oil or other types of lubricant as a lubricant.

Among other things, you will need special mandrels designed for pressing silent blocks; as an alternative, you can use a piece of pipe with the required diameter. You also need to get a press to press in a new rubber-metal hinge . When it comes to home use, an ordinary vice can serve as a press. In addition, you can stock up on a set of sledgehammers, but with this approach it is necessary to maintain high precision in the work.

Creak of new silent blocks

If you recently replaced these parts and notice that they are making noise, it may be because they are not yet in place. To speed up mutual grinding, it is worth spraying the assembly with silicone grease.

- If you have already driven about a thousand km, and the squeak has not gone away, most likely the mounting bolts are not tightened properly. Extraneous sound is removed as follows;

- The car is driven into the pit and jacked up;

- The fasteners on the silent blocks are weakened;

- Reliable stops are placed under the levers, and the jack is carefully released;

- The bolts are tightened all the way when the car is sagging under its own weight;

- If the squeaking does not go away, most likely you got a manufacturing defect in the silent blocks. In this case, you will have to return to replacing them.

Why does the car squeak on bumps?

Knocking or squeaking

on

bumps

it often appears due to faulty ball joints. In this case, you need to contact a car repair shop immediately, since the car can stop at any moment, and it will be impossible to do anything on the spot; you will have to call a tow truck. ... It's enough to rock the car.

Interesting materials:

Which ultrabook to choose in 2022? Which station wagon is better to choose under 500,000? Which insulation to choose for the facade? Which car is better to choose on a double-decker train? Which car to choose on a double-decker train? Which roller is better to choose? Which roller to choose for whitewashing the ceiling? Which DVR to choose in 2022? Which VR helmet to choose in 2022? Which car to choose under 300 thousand rubles?

Design features

None of the approaches described above will help Chevrolet Aveo owners. The original silent blocks on this model are made with slots in the rubber component. This design should theoretically provide a softer ride, although Aveo owners believe that this design does not provide any special differences in this parameter. But the creaking of the slots is constant: dirt gets clogged in them, preventing the part from working properly. A temporary solution: regularly wash the unit and generously spray it with WD-40.

However, the blissful silence lasts for 3-4 days at most, and in wet weather the creaking returns almost instantly. There is only one cardinal solution: replace the silent parts that were unfinished by the designers with parts from another car without unnecessary cutouts.

One of the proven options is a silent block from a Ford Mondeo born in 2000. It is identical in size to the corresponding Aveo part, is installed without difficulty and does not creak until it wears out naturally. And in order to less often think about what to do if silent blocks creak, you need to pay close attention to this unit. Firstly, install them according to the rules or use the services of a proven service. Secondly, periodically treat with penetrating oil - this will reduce the degree of inevitable friction. And thirdly, sometimes check what condition they are in and whether it’s time to change them.

Wear of parts

The most likely and obvious cause is wear and tear. What to do in such a situation? First, a little hardware: the silent block is a dense piece of rubber with metal spacers. Rubber dries out over time and this is a normal process. They are also systematically exposed to mechanical and chemical stress. The most critical period is winter , when roads are often thickly sprinkled with reagents that corrode even the thickest rubber.

The creaking is the first sign. The driver can observe a deterioration in handling, coupled with the appearance of vibrations in the cabin. Theoretically, one silent block can withstand about 100 thousand kilometers, but calculations were carried out in the west, where the roads are incomparably better. Considering the condition of our coating, feel free to reduce the resource of the block by half. It is worth changing at the inspection hole, or its equivalent:

- Unscrew all the nuts that secure the front arms;

- remove the nut that secures the stabilizer to the lever;

- remove the bolt by gently tapping it with a hammer, since it comes out extremely reluctantly with your hands;

- Loosen all the bolts on the wheel, first jacking up the desired side. Afterwards the wheel is removed completely;

- unscrew the nuts on the braces, but before doing this, thoroughly “blow” them with WD-40;

- the ball is moved away from the steering knuckle, then 2 more bolts are unscrewed and the lever is finally removed from the car;

- Now silent blocks are removed using a puller, which in no case can be replaced with a sledgehammer;

- clean the eyes from any deposits;

- It is necessary to thoroughly lubricate the silent blocks before pressing with any solution with a high soap content. Oil and grease are contraindicated as they will likely corrode the rubber;

- The collection procedure is performed strictly in reverse order.

Nissan X-Trail › Logbook › How to press in silent blocks with your own hands?

I honestly admit, I stole it from here autochainik.ru/zapressovk…blokov-svoimi-rukami.html, I don’t claim authorship.

Someone just might need it. At least I will soon, because the mileage is almost 180. Every car owner has encountered the problem of wear and tear on parts of the car's chassis. Silent blocks are an important component of the suspension - they serve to dampen vibrations from one unit to another. Replace components as they wear out or every 100,000 km. Experienced drivers often press in silent blocks with their own hands, since failure is not difficult. Each driver is able to replace components at home with a small set of tools.

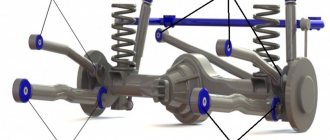

Special devices Replacing silent blocks is done by pressing them out of the suspension arm and pressing them in using special devices. The kit for pressing and pressing silent blocks can be universal or specialized. The first option is suitable for several types of cars, the second is selected for each car individually.

The most common and simple silent block remover consists of:

2 washers of different sizes; 1 long steel bolt; 1 nut; 1 steel tube. The pressing kit can be:

Mechanical - consists of threaded connections, and pressing is carried out using a wrench. Hydraulic – consists of: a hydraulic pump, a hydraulic cylinder, hoses and the unit itself. You can buy one puller or a whole set. Technical characteristics and methods of their use are indicated in the instructions.

Making it yourself To save money, you can make a device for replacing silents yourself at home using improvised materials.

Device for replacing silent blocks. This requires the following tools and materials:

bolt and nut (length and diameter at the discretion of the master); a cylinder of such diameter that the silent block fits there; several washers: one such that it closes the cylinder tightly, the rest are smaller in diameter than the silent block. After preparing the equipment you need to:

Cover one end of the cylinder with a washer and insert the bolt. On the other hand, put the washer on the silent block. Tighten the nut to press out. Ways to press in silent blocks There are several options for pressing in silent blocks.

Option with a vice Before pressing the component, it is necessary to clean the seats from rust and burrs with sandpaper. Then lubricate the eyes with Litol lubricant or liquid soap. Place the part on top of the lever, place a special mandrel on it, and use a vice to press the component into the socket.

Pressing in using a press Pressing in silent blocks can be done using a press puller with which the part was removed. You need to select the necessary attachment for pressing, lubricate the eye, install the part correctly and press it, periodically checking so that the component does not go awry.

Press-out tool To ensure that components need to be replaced, you need to do a visual inspection of the rubber parts. They must be intact, without deformation. There should be no play when the car is rocking. When the car is moving, wear will be revealed by knocking of the suspension, swaying of the body and unstable movement of the car.

To get a silent block at home, you need to:

Place the lever under the press on the stand where the silent block will go. Place a spacer on top to press out the bushing and press out the part. Using a vice instead of a press, you can squeeze out silent blocks using the same method. You can use a hydraulic jack. To do this, you will first need to weld a frame from a corner or channel in the form of a rectangle, which is larger in height than the jack. Insert the two spacers listed above and raise the jack until the silent block is pressed into the mandrel. You need to choose a more powerful jack - 10-15 tons, because lifts with 3-5 tons may not help. In the absence of special devices, a homemade or factory press puller is used, which squeezes out the part using a bolt, washers, nut and two extensions. All these components must be durable and reliable. Using such a device, you can press out without dismantling the hub and lever. Using brute force If none of the above devices are at hand, you can use an ordinary hammer and screwdriver or some thick sharpened pin to press out the silent blocks. It must be driven between the bushing and the silent block. As a result, the bushing of the part is deformed inward, after which it will be possible to pull out the rubber band and knock out the silent block.

Using brute force You can press out a part using a metal blade, a screwdriver and a hammer. To do this, you need to remove the inner sleeve and carefully saw through the silent block with a blade so as not to damage the lever. Then use a screwdriver to pull out the part.

To press a silent block using brute force, you need to insert the part into the eye, and hammer it into its seat with a sharp and strong blow of a hammer.

Disadvantages of this method:

The silent fits crookedly into the eyelet; bites the rubber parts of the part; The impact may damage the lever or silent block. After using this method, the component is often damaged and will need to be repressed.

Pressing in with the weight of the car Many motorists press in the silent parts with the weight of their own car.

To do this you need:

Install a screw or hydraulic jack under the vehicle. Remove the wheel. Install the lever with silent block under the car hub. Align the parts well and slowly lower the jack. Pressing by weight Due to the weight of the vehicle, the component will fit into the seat.

The creaking of new blocks

You can often come across the following point: new components that have just been installed make an unpleasant sound. Perhaps they didn't really fall into place. To speed up the grinding, they must be lubricated. A special silicone grease is provided for silent blocks. But before lubricating, do the following check:

- drive the car into the inspection hole and jack up the problem wheel(s);

- loosen the fasteners on the blocks;

- place reliable wooden stops under the levers and release the jack;

- When the car sinks under its own weight, tighten all the bolts until they stop.

If the creaking is still felt, then the component was originally defective from the manufacturer. In this case, simply lubricating the silent blocks will not work. They will have to be changed completely.

Design features

However, the question is “what to lubricate so as not to squeak?” will not help at all if you have a Chevrolet Aveo. The original blocks of the car are made in a cunning way: there are special slots in their rubber part. Theoretically, such a design feature should allow the car to move more smoothly, but in practice there are no significant differences, as the owners of the vehicle note.

These same slots systematically emit an unpleasant creak, which is why dirt constantly gets clogged inside them, preventing the normal operation of the structural element. The only temporary solution is to regularly wash the unit and thoroughly spray the components with WD-40. The effect lasts about 3-4 days if the weather is dry. During rain or snow, the effect disappears almost instantly. The only way to eliminate a factory defect is to completely replace the blocks with analogues without cutouts.

In this case, the best option would be components from a 2000 Ford Mondeo. In size, they completely coincide with those of Aveo, and they are installed without the slightest difficulty.

They serve faithfully until natural wear and tear. If you want to stop thinking about the potential creaking of units, treat the unit with the greatest possible attention:

- install them in strict accordance with the installation rules, or use the services of only trusted service centers;

- Periodically spray the blocks with penetrating oil to prevent friction;

- do a routine check of the mechanism at the time of natural wear. It’s better to change the part a little earlier and not “enjoy” the squeak.

FakeHeader

Comments 18

I'm interested in the price of the issue.) How much did the set of silent blocks cost?

I keep detailed records of all costs on this site. Look there for “Rear Suspension” and “Front Suspension”. Parts that end in “PU” are Polyurethane

Hello, Stanislav!) Great job! :) I’m very pleased with the approach!) This entry especially made me smile: “Thank you very much to vekmann for your help and patience! It’s not easy to bear my perfectionist antics :)))” I’m a perfectionist myself :)) I love it when the result of my work is close to ideal!) By the way, I have the same Legacy, ’90... only with mechanics. and the same color and also a sedan, only the headlights were intact... they were... I recently broke one:((

Thank you! But sometimes this perfectionism results in nothing but disappointment :)))

Hello, Stanislav!) Great job! :) I’m very pleased with the approach!) This entry especially made me smile: “Thank you very much to vekmann for your help and patience! It’s not easy to bear my perfectionist antics :)))” I’m a perfectionist myself :)) I love it when the result of my work is close to ideal!) By the way, I have the same Legacy, ’90... only with mechanics. and the same color and also a sedan, only the headlights were intact... they were... I recently broke one:((

There are plenty of headlights in Nakhodka on the drom. I took it there, though from a right-hand drive :(((

I also looked at the headlight on Drome. There are two offers for the left headlight I need, European. But the price of one of them is somehow dubious... it’s too cheap... 900 rubles in total. Mostly prices start from 2000 rubles. Doubts whether the parcel will arrive after payment for the order. And the other has defects: one fastening ear is soldered and a chip on the glass is caused by a stone. They are asking exactly 2000 rubles for such a headlight. PS I started writing something off-topic here along the way :)) Where can I write to you to discuss various issues regarding the car. so as not to clutter up comments on the main topic.)

Point to my nickname (stan31337) and select “Message”

Yes, damn it, 3 tons is not enough and he’s tired, that’s for sure)))

Yes, it still helps a lot! I'll try to press the bearing in with it tomorrow, maybe it will work