Tools and materials

Tools you will need:

- Spanners (take a full set at once);

- Socket wrenches;

- Vise;

- Chisel;

- Hammer;

- Puller;

- Silent blocks.

There are several important nuances:

- It is strongly not recommended to take silent blocks from repair kits intended for models 2108-2112. You will simply waste your money because they are not suitable for the fourteenth VAZ model.

- The easiest way to purchase a puller is at auto parts stores. But you can ask your friends for it.

- You can make a device for pressing in a new silent block yourself. To do this you will need a 170mm M12 bolt, a bushing, a washer and a high nut. But if you have the opportunity to use a full-fledged, real tool, do just that.

What configurations are recommended to buy to replace daisies?

When the VAZ 2114 is factory equipped, a product is installed that is entered into the company catalog under the number 108-290-40-46. Speaking about the quality of the standard kit, I want to wish for the best, but this product is native to the silent block seat, therefore it has a number of advantages. If you purchase a new set in a salon, you should expect an amount of 500 rubles.

Silent block VAZ 2114

In addition to silent blocks or daisies, you will also need to purchase all the necessary fasteners, as well as washers to adjust the product in its seat.

Front arm

Replace the silent blocks on the front suspension arm of a VAZ 2114 with your own hands. To do this, try to strictly adhere to the instructions we offer.

- Place the car on the inspection hole.

- Remove the engine protection, if equipped.

- Unscrew the bolt nuts from the front arms.

- Using a 17 key, remove the fasteners of the front stabilizer strut, which secures it with the lever.

- Knock out the bolt.

- Loosen the wheel bolts, jack up the car and remove the wheels.

- Use a 24mm wrench to remove the brace nut. To avoid having to exert enormous force, first clean the fastener with a wire brush and treat it with WD40. This should help completely unscrew this nut.

- Then remove the two ball joint bolts from the steering knuckle to remove the arm.

- Problems often arise with this nut. It is rarely possible to remove it easily. A good way out of the situation is to remove the lever with a crab and a stretcher. To do this, slightly loosen the extension nut near the crab and remove the three bolts securing the crab and the body. Now remove the entire assembly and, in a more comfortable position, begin to unscrew the problematic nut. The most extreme method is heating or using a chisel.

- You managed to remove the lever. First of all, replace the silent block of the extension. Dismantling the old element is carried out using the most ordinary chisel. Be sure to clean the lugs and take a new suitable silent block.

- It's up to the vice. The silent blocks are pressed one by one into your lever. It is usually not possible to seat the element completely, so the lever should be placed on a flat floor or a sturdy table. The silent block must be installed using a hammer. A few accurate and fairly strong blows should be enough.

- Using the method without using a vice is very risky. Such measures are resorted to either by self-confident specialists or by those who do not mind experimenting with their car.

- Now we change it on the front lever. The first priority is to get rid of the old silent block. If it was completely broken, you just need to remove the bushing and remove the remaining rubber elements of the silent block from the eyes.

- If this method is not relevant, the silent tape will have to be pressed out. You already have a puller.

- The new element is pre-treated with water diluted with any soap, dish gel or simple liquid soap.

- Use the press-in tool to place the new part in its rightful place.

- The fastening bolts should be tightened gradually. The silent block can be twisted at the same time, so try to hold it with a screwdriver.

- Alas, the process of replacing silent blocks on the front lever is much more complicated than in the case of a stretcher.

A few more tips

It will also be useful for owners of cars of this model to know how to replace the silent blocks of the rear beam on a VAZ 2114. These rear suspension parts are more durable, but also need to be replaced after a certain period. It is best to position the car above the inspection hole, this will make it most convenient to perform the replacement. To perform the replacement, the beam must be moved down and slightly back.

To do this, they also lift the car with a jack, place it on a stand and dismantle the beam. It needs to be supported with a stand or a second jack. Worn silent blocks are removed and new ones are installed using a puller, but in some cases, the intervention of “brute” force and other auxiliary tools may be necessary. The installation of new VAZ 2114 parts is preceded by cleaning the eyes from rust and oxides, as well as treating them together with the hinge with soapy water.

After pressing them into the beam, it should be installed in its place. Taking this moment, inspect the remaining components and parts of the rear suspension, and if necessary, replace the elements that have become unusable. As you can see, the operation of replacing the rear silent blocks of a VAZ 2114 can be performed in your garage.

You should not be afraid even if you have no experience in carrying out such work; you need to acquire it at some point. If anything else is not clear, watch the video:

Rear suspension

Sometimes it is also necessary to replace the silent blocks on the rear suspension of a VAZ 2114 car. They are not as susceptible to wear as in the case of the front control arms, but the fact remains.

The sequence of your work in this situation will be as follows:

- If there is no lift, slightly loosen the bolts on the wheels, install a jack, raise the car and completely remove the wheel.

- It is advisable to place some supports under the beam. Both simple bricks and a second jack will do. It all depends on what you have at your disposal.

- Now you need to remove the bolts that are attached to the shock absorber and the car body.

- Proceed carefully to avoid damaging the threads.

- The bolts are knocked out, the beam moves down or slightly back. This will allow you to get to the desired silent blocks.

- They are dismantled with a puller.

- New suspension elements are installed in a similar way to the silent blocks of the front control arms. To help them sit in their nests better, use a soapy solution.

- Reassemble the entire disassembled structure in reverse order.

- During the disassembly and assembly process, pay attention to the remaining components to which you gain full or partial access.

- As practice shows, performing certain repairs allows you to study the condition of related components, assemblies and parts of the car, identify emerging problems in a timely manner and eliminate these breakdowns or what may lead to this.

Changing silent blocks on a VAZ 2114 is far from the most difficult type of car repair. Therefore, many car owners cope with this task with some ease with their own hands.

How to check silent blocks yourself?

If the driver does not have sufficient driving experience, it is better to diagnose any car mechanisms at a bus station. If you have sufficient driving experience, and therefore minor repairs, you can inspect the silent blocks yourself. To do this, you need to drive into the pit and assess the condition of the parts.

Silent block with signs of wear

An untimely replaced silent block leads to the following consequences:

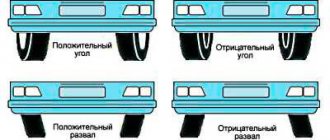

- Wheel alignment violation;

- Uneven tire wear;

- Knock in the front suspension.

These are signs that should prompt the idea of replacing silent blocks.

If during inspection cracks or tears were found on the rubber joint liner, it should be replaced. The replacement can be done at home - specialized tools or special skills are not required.

Let's take a closer look at the algorithm for replacing the silent blocks of the front levers of VAZ cars.

What is a silent block?

A silent block is a small part made of polyurethane or rubber; the kit includes two metal bushings. In other words, a silent block is a rubber-metal hinge that performs connecting and protective functions. It is used to complete parts of the front and rear suspension and gearbox. And if the rear silent blocks of a VAZ 2114 are replaced, then new ones of the appropriate brand and size of the product are purchased. Under no circumstances should you make any substitutions; every millimeter is important in the configuration of the machine.

Silent block VAZ

Stabilizer

This element of the VAZ-2114 front suspension is designed to reduce vehicle roll when cornering. The part does not have a complex device and consists of a flexible beam, as well as a pair of silicone silent blocks

. The element has a small stroke, which ensures vehicle stability on the road. Attached to the front side with the central part. The side parts are connected to the manipulators using a suspension. The stabilizer has a high resource. more than 100 thousand kilometers. Quiet units usually fail. But to replace them you need to completely remove the stabilizer. Below we will show you how to do this.

Sources:

https://videovaz.ru/vaz-2109/1572-zamena-sajlentblokov-perednej-podveski-vaz-2109 https://vaz-remont.ru/zamena-sajlentblokov-perednej-podveski-vaz-2109/ https:/ /carfrance.ru/perednyaya-podveska-vaz-2114-podrobnaya-sxema-remonta-opisanie/ https://www.syl.ru/article/335718/perednyaya-podveska-na-vazremont-zamena

How to change daisies on a VAZ 2114, watch the video, study the instructions

Are you planning to implement a solution to the question of how to change daisies on a VAZ 2114, you’ve already watched the video, now are you preparing a sequential instruction for yourself? Then you can pay attention to the following workflow structure

- The machine is installed on a lift or driven onto an overpass to provide access to the front suspension, the elements of which will be used for repair work. Usually, the approach to the silent block is also made difficult by the crankcase protection, which must first be dismantled.

- Next, work with fasteners is provided, but due to the fact that the car has mileage and has been used in different weather conditions, a situation may arise that all the nuts have soured, or the threads are covered with a layer of dirt. What to do? Take a rag or a wire brush with stiff bristles and clean all existing fasteners. If some nut does not give in, then you should use special lubricant WD 40. And start unscrewing the suspension nuts again.

- First, we unscrew the bolts on the wheels, put the car on a jack and stoppers, and then think about how to change the daisies on a VAZ 2114, having previously pressed them out.

- We continue to work with the support and its dismantling. Sometimes it can be difficult to remove the support from the steering knuckle.

- Using a chisel, we begin to press out the silent block itself. Sometimes even fire is used, but in this situation you need to be very careful.

- We thoroughly clean the freed bushing, and immerse the new silent block in water for several minutes and wash it several times with a soap solution. If you use a regular detergent, for example, for dishes, it’s okay, it will also help treat the new silent block. All that remains is to prepare for the climax, deciding confidently how to change the daisies on a VAZ 2114, and recording a video report if necessary.

- We install a vice - this is a good basis for pressing the chamomile. The process comes with a number of difficulties, because the part does not always quickly fit into its seat and force has to be used. A hammer will not hurt in this procedure. We make several precise and sharp blows, making the correct pressing of the part.

- We work carefully with the fasteners, which should be tightened gradually and consistently. We check the tightness of the nuts and make sure that the installation is correct.

- The rack is mounted in place and all final testing is done once the car is on its wheels.

Thus, the question of how to change daisies on a VAZ 2114 is relevant, and its solution is in demand among car enthusiasts. But, as they say: “it was smooth on paper, but they forgot about the ravines...”. So with car repairs, you can count on half a day of fussing in the garage, but it turns out that even a day is not enough to solve the problem of how to change daisies on a VAZ 2114, unforeseen difficulties and financial expenses will arise.

Symptoms of ball failure

First of all, the problem begins with a torn boot. Because of this, dirt, water and sand get inside. In this way they leach the fat from the ball mechanism. As a result, the element begins to work “dry”, and corrosion processes begin. In practice, this turns into loud knocks and squeaks from the suspension. Then the wheels will involuntarily change their trajectory. There will also be uneven wear on the tire tread. When turning the steering wheel the knocking noise increases. If you notice the problem in time, you can eliminate extraordinary consequences.

The gearshift lever and the rocker on the VAZ-2114 are rattling, what to do?

As you know, the gearbox is the main, and most importantly, irreplaceable link between the engine and the wheels of the car, because it is only because of it that the nature of the torque changes.

What gearbox is installed on the VAZ-2114?

Since the VAZ-2114 is equipped with a mechanical gearbox, the driver personally selects which gear to engage at what point in time (by changing the position of the driven gear relative to the driving gear - approx.), thereby ensuring the correct position of the lever in the cabin. However, during operation it happens that the handle begins to rattle, causing only discomfort to the car owner.

Below, in our article, we will look at the main causes of this problem, as well as ways to fix them.

Gearbox device

Diagram of the gear selection mechanism with decoding

First of all, before we undertake the repair or alteration of the gearshift knob, we need to learn more about its design (to figure out where the vibration comes from and how dangerous it is for the operation of the car as a whole - approx.), and also become familiar with its main elements.

It’s no secret that the VAZ-2114 is a front-wheel drive car, with front drive wheels; accordingly, the gearbox itself is perpendicular to the direction of movement of the car (this means that the “box” lever does not enter the cabin directly from its body, but through the rocker – approx.) . The same cannot be said about representatives of the “classic” AvtoVAZ family, where the rattling of the gearbox lever may indicate problems with the transmission itself.

Causes of gearbox bouncing

- The connection bushing is the wrong size.

- The handle gasket is missing.

- Inconsistency of parts that border each other.

All of the above problems can be caused by one small metal bushing that connects the rods under the lever. Therefore, the rattling of the handle may appear due to the appearance of a gap in it, or poor contact between two connections. All this leads to impacts of the bushing against the metal of the body, which contributes to the appearance of noise and rattling of the handle.

This is what the old bushing looks like.

On some VAZ-2114 models, such connections were wrapped with a rubber gasket to avoid such malfunctions.

Removing the gearshift lever

Before you begin dismantling the handle, you need to carefully examine the entire space next to it and understand how it comes apart. There is nothing complicated about this, the main thing is to follow our instructions exactly:

- If there are additional armrests and other elements installed independently, we dismantle them so as not to damage them during the work.

- Carefully remove the casing (plastic or leather - approx.) so as not to tear or break it.

Dismantling should be carried out carefully so as not to break anything. - Now that all the interior decoration is visible, let's move directly to the backstage.

To do this, using a key set to “13”, unscrew the nut securing the lever. If the lever does not budge, you can treat the surface with WD-40. - After this, you can dismantle the lever with the same bushing, and carry out work to eliminate rattling and vibration.

The old bushing is marked with a red marker.

Vibration Elimination Process

After you have the bushing with the lever in your hands, carefully inspect it visually for visible damage and signs of wear. Because if they are available, you may have to buy the same spare element, so that a little later you won’t have to do the work of dismantling, repairing and adjusting it.

The new bushing looks much better

The procedure for repair work with the bushing

- First of all, we dismantle the plastic cover on the bushing in such a way as to free its metal base.

Disassembled gear lever bushing - We inspect it for traces of friction, which will indicate a discrepancy in its size (when the bushing is several millimeters longer, usually 2-3 mm - approx.).

We went to the store and measured the new bushing there and compared it with ours! - If the above facts are confirmed, then this reason can be corrected by simply grinding off the excess by hand using a file.

- Next, we move on to repairing the lever itself, and if there is any damage, friction, etc. on its body, we simply wrap this area with ordinary electrical tape in order to fix it more tightly in place and provide it with the tightest contact.

Thanks to such simple and simple procedures, vibrations and rattling of the gearbox lever can be eliminated in no more than half an hour of your time, and the result of the work performed will please you for a much longer time.

conclusions

Replacing daisies on a VAZ-2114 car is a fairly simple and not complicated process that every motorist can handle. Of course, if the operation seems too difficult, it is recommended to contact a car service, but you should not waste money and time when you can do everything yourself.

Particular attention should be paid to the process of selecting spare parts, which are not always of high quality.

So, we need: - a car; - a garage, preferably with a vice and a pit; - new silents and daisies; - a gas burner or blowtorch; - soap and water; - a small piece of pipe so that the silent block fits into it along the length and diameter; - hammer, chisel; - various keys. If there is a hole, good. If not, it’s worse, but not fatal. We unscrew the lower arm - the nut securing it to the body, the extension nut and the stabilizer link, two ball bolts.

To unscrew it is better to use larger heads and a lever.

You will have to puff, but everything can be solved. If the extension nut does not unscrew in this place, you can unscrew the crab. Then clamp it in a vice and unscrew it.

We clamp the removed lever in a vice and burn out the old silent block with fire. You can, of course, try to squeeze it out, but it’s easier with fire.

We uproot the old unnecessary rubber band and throw it away

You should get a hole like this. If there is anything left there, clean it.

Now we press in the new silent block. We soap both it and the hole. Don't skimp on soap! It's cheap. We load it all into a vice, press it a little and fill the collar in a circle with a screwdriver. It won't work the first time, but don't despair. The silent should go in about halfway.