Characteristics of the camshaft sensor

Before moving on to the question of checking the camshaft position sensor, you need to find out what kind of device it is, what it is needed for and on what principle it works.

This will help clarify the details of the audit in the future. A camshaft sensor is a device that records the angular position of a specified shaft at a specific point in time. The information obtained with its help is transmitted to the electronic engine control unit (ECU), and on its basis this control element issues commands for fuel injection and ignition of the air-fuel mixture in each cylinder at a specific point in time.

The operation of the camshaft position sensor is based on the Hall effect. So, directly on the camshaft there is a metal tooth, which, when the shaft rotates, changes the magnetic field in a nearby sensor. This tooth is called rapper. The sensor detects a change in the magnetic field, which is converted into a low voltage electrical signal. This signal is sent to the electronic control unit.

In fact, the camshaft position sensor only registers one position, corresponding to the position of the piston of the first cylinder at top dead center. Next, phased fuel injection is performed in the firing sequence of the cylinders. Typically this is a 1-3-4-2 system.

If the camshaft sensor fails (the electronic control unit receives incorrect information from it or does not receive it at all), then it is programmed to switch to emergency mode. It involves the use of pairwise-parallel (group) fuel supply to the engine. This leads to two negative consequences:

- A slight loss of engine power, especially when driving in critical modes (acceleration, driving under load).

- Increase in fuel consumption by approximately 10...20% (depending on engine power, its design features, as well as operating conditions).

As for diesel engines, camshaft position sensors are designed similarly, but there is one difference. It lies in the fact that the sensor records the position of not only the first cylinder, but all of them. This is done due to the fact that the drive disk has a separate tooth for each cylinder.

Thus, if a sensor fails, it makes sense to diagnose it as quickly as possible and, if necessary, replace it.

The operating mechanism of this part is based on the Hall effect. What does this device do? The Chevrolet Niva camshaft sensor controls the gas distribution device, its inclination according to the crankshaft. The signal is received by a system that controls the flow of gasoline and the operation of spark plugs.

The operation of the camshaft sensor is based on monitoring the potential difference between the carriers of the amount of electricity, and its work is associated with another crankshaft position analyzer. The camshaft sensor operates under the influence of the Ampere force acting on a current-carrying conductor in a magnetic field. Using a magnet, it creates a magnetic field that changes under the action of a special iron tooth on the camshaft wheel.

Thus, the part tells where the piston of the internal combustion engine cylinder is located, and the strokes of the cylinder cycle are performed one by one.

Recommended Tools to Fix P0343

- To read fault codes - FOXWELL NT301. For advanced troubleshooting, you may need a more advanced scanner.

- Car charger: with battery repair function or simple.

- To check the integrity of the wiring and sensor, use a regular digital multimeter or a more expensive device.

- For an extended check of the signal from the camshaft sensor, use an oscilloscope.

Let's take a closer look

Trouble code P0343 reads "Camshaft Position Sensor A Circuit High (Bank 1)." Often, in programs that work with an OBD-2 scanner, the name may have the English spelling “Camshaft Position Sensor “A” Circuit High Input (Bank 1)”.

Speeds

The Chevrolet Niva speed sensor helps to determine exactly how fast the car is moving. The received information is transmitted to the speedometer. In addition to this, it also performs such functions as:

- Controls fuel consumption

- Displays information on the dashboard

- In cars with automatic transmission, it is part of the system that is responsible for engine control.

If for some reason it fails, then further movement becomes difficult. The causes of failure may be contamination or oxidation. If the device stops working, first of all you need to check for the following problems:

- Contacts have oxidized

- There was a break in the electrical wiring

- Wire insulation is damaged

- There are mechanical damages

Diagnostics can be done both visually and using a multimeter. To do this, the sensor is removed, after which you need to connect the plus to the contacts, and the minus to the ground of the car. We switch the multimeter to power measurement mode and if it shows that the voltage has increased, then the element can be considered faulty.

To change it you need to disconnect the battery. When the car is de-energized, we find the sensor which is located on the rear cover of the transfer case. Disconnect the terminal from it and unscrew it with a wrench.

Diagnostics can be done both visually and using a multimeter. To do this, the sensor is removed, after which you need to connect the plus to the contacts, and the minus to the ground of the car. We switch the multimeter to power measurement mode and if it shows that the voltage has increased, then the element can be considered faulty.

Chevrolet Niva error codes: decoding and description of meanings

The popular Russian-made model is very widespread in the CIS countries due to its optimal cost and increased cross-country ability, which is critically important in the conditions of domestic operation. Motorists buy cars for off-road travel and small towns, where the quality of roads leaves much to be desired.

The disadvantages of the car include weak wiring - when the load increases to the design limit, on-board electronic systems often fail, which causes software failures. Chevy Niva error codes appear on the dashboard display or are detected using special equipment, but the common thing is that they all indicate a malfunction of a specific component.

Chevrolet Niva error diagnosis

The most reliable way to identify what is wrong with a car is to diagnose electrical appliances and equipment. The procedure allows you to accurately identify breakdowns and quickly repair your car.

There are two ways to detect a problem in a car.

The simplest procedure allows the motorist to independently identify the damaged area and repair the damage. Thanks to the successful firmware of the on-board computer, some errors are displayed on the standard display. In this case, nothing happens on its own - you will need to perform several steps manually:

If the manipulations are correct, one of the indicated codes will appear on the display, and each Niva Chevrolet error number will be responsible for its own section of the highway:

Removing the phase sensor

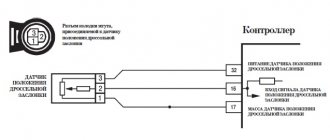

The Niva Chevrolet phase sensor operates on the Hall effect principle. It works as follows: there is a special pin on the camshaft and when it runs parallel to the end of the sensor, the sensor begins to transmit a voltage pulse to the existing controller, which should have the same position as the piston of the first cylinder in the compression position. That is, it is needed so that fuel injection and the order of operation of the engine’s cylinders correspond to each other.

In the event of a failure, it or its chain controller writes a special code into its memory and activates the alarm. And to remove it you need:

- Disconnect the battery

- Remove the decorative casing from the engine

- Disconnect the connector from the sensor

- We unscrew the bolt that secures it to the cylinder block.

- We remove the part from its seat

- Install the new one in reverse order

The part is removed from the engine to finally verify that there is a specific problem. On the cylinder head this structure is inserted into a special hole. Next, everything is screwed on with one bolt. It is enough to unscrew this connecting element, and then pull out the part and wipe it off with engine oil. The main thing is not to disconnect the block to which the additional wires are connected.

The ignition can be turned on after the multimeter is connected - to the middle contact, the ground of the car. The steel element is brought close to the end part of the part. For example, a regular key is perfect for this. All that remains is to monitor the readings that appear on the display. If everything is normal with the sensor, it reacts to the approach of any metal whose voltage is 02.-0.4 V. A high indicator is not taken into account.

If there are no changes in the tester’s performance, the device definitely needs to be changed. The main thing is to remember about the possibility of missing an o-ring even with new original spare parts. This part of the structure must be purchased separately, or an old one must be used.

- Disconnect the negative terminal from the battery

- We remove the decorative casing to gain access to the element we need

- We press the block and disconnect it from the sensor

- Unscrew the bolt that secures the part to the cylinder block

- We remove the part from the existing hole in the block head

- We change to a new element, doing all the steps in reverse order.

Also interesting: Engine twitching at idle: causes of malfunction "

It is recommended to replace it every five years, even if it is working properly. The replacement job takes about twenty minutes, everything will depend on what technical skills you have.

Self-diagnosis

The easiest and most common way to diagnose error codes on a VAZ Kalina is to search using the on-board network. The procedure looks like this.

Insert the key into the lock cylinder. Next, hold down the RESET key and, without releasing it, turn on the ignition. In this case, the device will automatically switch to diagnostic mode. At the same time, all the indications will light up, and the instrument arrows will make a full circle.

You should pay attention to the arrows and indicators - if any diode does not light up, you need to check the device for which the element is responsible. On the right steering column lever there is a button for scrolling through the options - you need to scroll to the required position (error codes). Next, the display will show the general error number; to reset the index, you need to hold RES for three seconds.

Note! The indicated sequence is relevant for Lada Kalina of the first and second modifications.

The position of the error codes will show one of the indices on the display:

- “2” – there is a surge in the BS power supply – a possible short circuit in the wiring;

- “3” – rupture of lines, or failure of the float inside the gas tank;

- error 4 Lada Kalina says that the coolant temperature sensor is broken or malfunctioning;

- “5” – the thermometer has gone astray, the element may be damaged or the circuit may be broken;

- “6” – exceeding the maximum permissible temperature of the internal combustion engine block, while the acoustic alarm is working;

- “7” – exceeding the permissible pressure thresholds inside the oil line;

- “8” - on a Lada Kalina car, error 8 appears when there is a malfunction of the calipers or a breakdown in the hydraulic drive line;

- “9” – critical voltage drop in the battery;

- “E” – incorrect reading or display of the EEPROM information module.

To return to the original part, it is enough to hold RES for 30 s. The disadvantage of this method is minimal accuracy - the procedure shows in which direction to look for a breakdown, but not a specific node. So, it is possible to understand exactly where the failure occurred only by the following method.

Location of fuse and relay blocks Lada 4×4

https://www.youtube.com/watch?v=zPTu4cmH_3g

There are several typical signs that indicate that the camshaft position sensor has failed. It is immediately necessary to clarify that the symptoms listed below may indicate completely different malfunctions. Therefore, it makes sense to perform additional diagnostics.

- Problems with starting the engine, under any conditions - “cold”, “hot” and in other modes. This usually results in having to crank the starter longer.

- Unstable engine operation, “floating” operating and idle engine speeds.

- “Dips” in the movement of the car; when you press the accelerator pedal, it does not respond immediately, the dynamic characteristics of the car are lost (it accelerates poorly, does not pull, especially when loaded and when moving uphill).

- When the accelerator pedal is released, the engine stalls.

- Increased fuel consumption (by 10...20%).

- The Check Engine warning light on the instrument panel activates. It is necessary to perform additional diagnostics using an electronic scanner (for example, an ELM 327 device or its equivalent). In this case, typical errors regarding the operation of the sensor are numbers P0340, P0342, P0343.

In fact, the camshaft position sensor is a fairly simple and reliable device, so it rarely fails. More often, its wiring is damaged - the wires fray, the insulation on them is damaged, the so-called “chip”, the place where the sensor is connected to the car circuit, fails.

However, for cars that run on gasoline, the problems described above are not so clearly expressed. But a failed camshaft position sensor will cause many problems for owners of cars equipped with gas equipment, in particular the fourth generation. The malfunctions and problems described above can appear on such machines “in all their glory.”

To check the camshaft position sensor, you need to know where it is located. As a rule, on eight-valve engines the DPRV is usually mounted at the end of the cylinder head. On sixteen-valve engines it is also mounted on the cylinder head, usually in close proximity to the first cylinder.

As for popular domestic VAZ cars, their owners call such units phase sensors. Their location in these motors is similar. So, on eight-valve engines, the sensor is located on the left side of the cylinder head (when viewed in the direction of travel of the car). On sixteen-valve engines - on the right front part of the engine.

The easiest way to check the camshaft sensor is to connect a car scanner or a computer with an installed program corresponding to the make of the car to the diagnostic connector of the car. If the element is faulty, then after starting the engine the device will display the following error codes:

- P0340 – there is no signal from the camshaft position detector;

- P0341 – valve timing does not coincide with the compression/intake strokes of the cylinder-piston group;

- P0342 – the signal level in the electrical circuit of the DPRV is too low;

- P0343 – the signal level from the meter exceeds the norm;

- P0339 – an intermittent signal is received from the sensor.

Since the vast majority of car enthusiasts do not have scanners and laptops with software at their disposal, a more affordable method is practiced - checking with a digital multimeter. Diagnostics is carried out in 3 stages:

- Visual inspection of the wiring and continuity of the circuit for breaks.

- Measuring the outgoing current at the control contact of the DPRV.

- Testing functionality by approaching a metal object.

In practice, engine failure and immobilization of the vehicle are consequences that owners rarely encounter. The engine continues to operate, but small deviations occur that make normal operation impossible.

There are several important symptoms, although they may also indicate problems in other mechanisms:

- Natural increase in fuel consumption.

- Check Engine is an indicator that does not always light up when there are problems. But drivers notice flashes in this part of the system if the crankshaft speed increases to 3000 rpm or more.

- Reduced power of the power unit. When the load is increased, the effect becomes especially noticeable. This applies to trailer towing, sudden acceleration and lifting.

- After pressing the gas pedal, there is not dynamic acceleration, but a series of short jerks. The speed gain occurs at a slow pace.

- While driving, the engine cannot operate stably at idle speed. This problem occurs in cars of any year of manufacture - 2011, 2012.

The air-fuel mixture will be enriched if there is a malfunction in the device. Because of this, gasoline consumption is higher, and engine operation is no longer stable.

For other car models, additional symptoms of malfunction are acceptable:

- failure of the power plant due to lack of sparking;

- the appearance of additional noise;

- difficulties with automated gear shifting if an automatic transmission is used;

- difficulties when starting the engine cold;

- The engine starts without problems, but stalls while driving - this is what the 2123 model most often encounters.

At the same time, the part has a long service life. 80-100 thousand kilometers is a standard resource for domestic cars. In the case of imported ones, the figures reach 150 thousand km. You can focus on the indicated periods when faults are only being looked for.

Driving with a faulty sensor is acceptable, but not for long. Wear on spark plugs and other components increases due to the following factors:

- Electronic errors.

- Enrichment of the fuel mixture.

- Engine jerking.

They look for problems on their own, or decide to send the vehicle for diagnostics. It's easy to choose the right option.

1 — engine control system fuse box; 2 — windshield wiper relay; 3 — fuse blocks; 4 — relay block of the engine control system.

The fourth relay block is located above the gas pedal.

| F1 (30A) | Right electric fan relay contacts |

| F2 (30A) | Left electric fan relay contacts |

| F3 (15A) | Relay windings of the right and left electric fans, controller, injectors, ignition coil |

| F4 (15A) | Heating elements for control and diagnostic oxygen concentration sensors, phase sensor, mass air flow sensor, canister purge valve |

| №1 | Ignition relay |

| №2 | Main relay |

| №3 | Right cooling fan relay |

| №4 | Left cooling fan relay |

| №5 | Fuel pump relay (fuel) |

| №6 | Fuel pump fuse F5, 15A |

On some vehicle versions, a starter relay may be located under the additional unit next to the ignition relay.

Symptoms of malfunction

The main driver symptom of P0343 is the MIL (Malfunction Indicator Light). It is also called Check engine or simply “check light”.

They can also appear as:

The vehicle will most likely run with this trouble code. But it may be difficult to start, and there may also be a drop in power and unstable engine operation. To avoid damage to other engine components, if this code is detected, it is recommended that the problem be repaired as soon as possible.

More information about testing and troubleshooting

The Niva Chevrolet camshaft sensor creates stable engine operation. The work is based on the Hall effect. Thanks to it, the tilt of the gas distribution device is controlled according to the crankshaft. The system that controls the operation of the spark plugs and the flow of gasoline receives a corresponding signal.

And it’s also interesting: “Niva” is marvelous: how the legendary VAZ model became a beauty and turned into an SUV | — Chelyabinsk news

It works based on monitoring the potential difference of the required electricity, and is associated with the operation of the crankshaft position analyzer. Simply put, it informs the location of the piston of the internal combustion engine cylinder, while all cylinder stroke cycles occur sequentially. If it stops working, the device and indicator turn on, thanks to which a mixture of air and fuel occurs, dosing is suspended and the reserve mode is activated. Replacement is recommended every five years. If it is faulty, the on-board computer will display the following errors, PO343, PO342, PO340.

Connecting scanners or computers equipped with special software is the best option for identifying most faults. The main thing is to choose software that matches the current car brand.

If the camshaft sensor is faulty, the following error options appear:

- P0339. In this case, intermittent signals are received from the sensors.

- P0343. The signal is at a high level, but it exceeds the norm.

- P0342. The signal level for the electrical circuit is too low.

- P0341. The compression/intake strokes of the cylinder-piston group differ from the current valve timing.

- P0340. There is no position locator signal.

Most buyers do not have scanners or laptops with software. Therefore, a simpler method is to check with a multimeter.

In total, there are no more than 3 stages in such diagnostics:

- The wiring is subjected to visual inspection. Next, the circuit is rung to check for a break.

- The outgoing current is measured at the control contact of the sensor. There is definitely a malfunction if there is something wrong with it.

- Check functionality by approaching a metal object.

During the first stage, the most important thing is to make sure that the wiring remains intact and that the contact of the connecting block is reliable enough. Conducting cables should be inspected additionally to ensure that there is no melting of the insulation or cracks or kinks. Using a multimeter it is easy to make calls and search for a break. An additional responsibility is cleansing from oxidation. This is the first sign of problems.

After diagnosing the entire system, you can move on to the sensor itself. Standard alligator clips are easily replaced with wires with needles. The main thing is to correctly determine the location of the two power contacts and the third wire going to the controller. The voltage between the bus ground and the contact is checked by turning on the power. The signal should remain at normal level.

If the values obtained are higher or lower than normal, the sensor must be replaced.

The part is completely removed from the engine in order to perform final diagnostics and make a final decision.

Before testing the sensor using a multimeter or other electronic tools, you must check its mechanical integrity. In particular, it is installed in a housing with an O-ring, ensuring its secure fastening. We need to check its condition. It would also be useful to check the integrity of the sensor body, whether there are cracks or other damage on it. It is advisable to check the drive disk to see if the teeth are damaged or if there are metal shavings on the sensor body or nearby.

On the Internet you can find information that supposedly the DPRV can be determined to work by simply checking its magnetic properties. In particular, bring a small metal part to its end (the working sensitive part), which should “stick” to the sensor. In fact, this is not the case, and a non-working DPRV may or may not have magnetic properties. Accordingly, verification must be performed using other methods.

There are two main ways to test the camshaft position sensor - using an electronic multimeter and using an oscilloscope. The first method is simpler and faster, but the second is more accurate and provides more diagnostic information.

Reasons for the error

There are only three main causes of engine error p0340:

Sometimes the cause of error p0340 is incorrect installation of the sensor. However, this is a rather rare case, since it only has one seat. Perhaps the fastening is not strong enough (small tightening torque, which is why the sensor can vibrate when driving) or there is a large gap between the working (sensitive) part of the sensor and the so-called rapper - a tooth on the indicator wheel located on the camshaft.

Air flow

The air flow of the Niva Chevrolet is controlled using a hot-wire sensor, which is located between the hose of the intake pipe and the air filter. The magnitude of the direct current depends on the direction and amount of moving air that passes through it. In the event of a system malfunction, a code is stored in memory and the alarm is activated.

To replace, you need to prepare a 10mm wrench and a screwdriver and do the following:

- Disconnect the connector from the sensor

- Loosen the air pipe clamp

- We unscrew the bolts that secure the sensor and the o-ring

- Installing a new one

Oxygen

The Chevrolet Niva oxygen sensor is also called a lambda probe; it is located in the exhaust gas system on the receiving pipe. The oxygen contained in the exhaust gas interacts with it, thereby creating a potential difference at the outlet. It varies from approximately 0.1 to 0.9 V. For it to function normally, its temperature must be at least 360 degrees.

https://www.youtube.com/watch?v=SqqIBAU8osQ

The Chevrolet Niva oxygen sensor is also called a lambda probe; it is located in the exhaust gas system on the receiving pipe. The oxygen contained in the exhaust gas interacts with it, thereby creating a potential difference at the outlet. It varies from approximately 0.1 to 0.9 V. For it to function normally, its temperature must be at least 360 degrees.

Location of fuse and relay blocks Lada 4×4

If during the inspection it turns out that the camshaft position sensor itself has failed, then it must be replaced. As a rule, these units are non-repairable, since their body is sealed and cannot be disassembled. The sensor is inexpensive, and the replacement procedure is simple, and even a novice car enthusiast can handle it.

The sensor replacement algorithm is as follows:

- With the engine not running, disconnect the negative terminal from the battery.

- Disconnect the “chip” from the camshaft position sensor (as when checking).

- Depending on the vehicle model, it is necessary to remove parts that prevent access to the sensor. For example, on modern cars like the Lada Vesta, it is necessary to remove the bracket for auxiliary units.

- Using a wrench, unscrew one or two mounting bolts, depending on the type of fastening. The size of the wrench can be different, usually for VAZs it is a 10 mm wrench.

- After dismantling the mount, you must similarly remove the sensor from its seat.

- Installing a new sensor is performed in reverse order.

- Connect the negative terminal to the battery.

Replacing this part is relatively easy. The on-board computer registers errors such as P0340, PO342, PO343.

Error P0340 appears on the self-diagnosis system if the crankshaft rotates. Code P0342 - the camshaft electrical circuit shows a low signal and code P0343, accordingly, shows a high signal. It is necessary to check the wiring - for this purpose it is good to use an oscilloscope or other testing device.

Mechanical specialists, even if the sensor is in good working order, still recommend changing it every 4-5 years - such prevention will protect you from breakdowns and accidents, especially since the part is very cheap despite its importance. After all, the semiconductors inside the sensor react poorly to temperature fluctuations - remember your school physics course.

Also interesting: Niva Chevrolet installation of air conditioning - Auto magazine MyDucato

There is a special offer on our website. You can get a free consultation with our corporate lawyer by simply submitting your question in the form below.

The preparatory stage will require the collection of certain tools:

- additional lighting, if required;

- Phillips screwdriver;

- rags;

- new controller;

- key to 10.

The sequence of actions is described as simply as possible:

- First open the hood.

- The tie from the rubber pipe of the air duct must be released.

- We remove the air duct itself.

- The controller is easy to find in the first part of the block.

- Remove the terminals and unscrew the bolt. The main thing is that the phase is maintained.

- All that remains is to remove the sensor and replace it with a new part.

- We put on the terminals and mount the air duct pipe back.

Error P1602

P1602 (Court Controller, Power Loss) is another common Chevrolet Niva error.

Code P1602 is entered if the following conditions are met:

The codes should be cleared using a scan tool. If the code is entered again, check the power supply circuit from the battery to pin “12” of the controller.

What errors have you encountered on Chevrolet Niva? You will find other reference information on ChevyNiva here.

Keywords: Niva on-board computer | Niva engine | esud niva

Share on social networks:

Found an error? Select it and press Ctrl+Enter..

Fuel level

The Niva Chevrolet fuel level sensor determines the remaining fuel in the tank and transmits the readings to the dashboard. It is located in the fuel tank. Its breakdown can lead to the car stopping at the most inopportune moment, so the driver will not know how much fuel is actually in the tank. Therefore, if there are problems with it, it is better to replace it as soon as possible, this can be done like this:

- The right side of the rear seat rises

- A fluffy rag is folded back

- Unscrew two screws on the fuel pump hatch

- Removing the hatch

- Disconnect the two pipes and terminals

- Unscrew 8 screws

- Carefully remove the fuel pump and replace the required element

All work is done within 10 minutes.

FakeHeader

Comments 37

Yes, you can set everything without marks at all, use a screwdriver for the lower part, but it’s more difficult to use the upper part, you have to remove the cover

When replacing the kV rear oil seal, remove the flywheel. And sometimes they put it wrong. Then think about why problems appear

first think about what you wrote

I understand this perfectly well; on the former 11th, the marks on the timing belt did not coincide with the mark on the flywheel. On my Priora I only look at the kv mark by looking at the flywheel

Class. Continue in the same spirit, as long as no one follows you. No offense, but the mark on the flywheel is only for minimal imbalance and does not affect the timing in any way.

Idle move

The Chevrolet Niva idle speed sensor ensures the supply of air to the engine during idling. When a signal is received by the ECU, the sensor moves the valve, changing the flow hole in the air valve. If it fails, it will not be possible to repair it, since it has a non-demountable design.

To replace it, you need to prepare a thirteen socket wrench, pliers and a Phillips screwdriver and do the following:

- Unscrew the mounting bolts and remove the housing from the throttle valve

- Disconnect the wiring connector of the engine regulator

- Unscrew a couple of screws on the throttle body

- Removing the regulator

- Remove the O-ring from the existing hole.

To summarize, we can conclude that the failure of any of the above elements can seriously affect the operation of the car, therefore, in the event of a malfunction, you need to replace a new part as soon as possible. All replacement work can be carried out independently.

How to replace a spark plug?

Replacing the spark plug is a simple task and you can do it at home. Before changing spark plugs, make sure the engine temperature is low.

Step 1: Open the hood and locate the spark plug

Open the hood and you will see several wires running in the engine compartment. The spark plugs are located in the engine at the end of these wires.

Pull the wire and you will see the spark plug installed.

Step 3: Remove the candle

Insert the spark plug wrench and turn to loosen the spark plug

Remove the old spark plug and note its condition

Step 4. Install a new spark plug

Using the same spark plug wrench, install the new spark plug and tighten it correctly. Then connect the wire as it was before. All is ready.

Meter design and location

The operating principle of the DPRV is based on the Hall effect - the sensor reacts to the approach of a metal mass by changing the voltage on the signal wire. The design of the device is similar to another element - the crankshaft position detector. Inside the plastic case there is a coil where the 12 V on-board voltage is constantly supplied.

The meter is installed on the engine cylinder head in close proximity to the camshaft. The latter is equipped with a special plate or gear, whose rotation affects the DPRV. The work algorithm looks like this:

- After turning on the ignition and starting the engine, a supply voltage of 12 V is supplied to the sensor. Through the third signal wire, the element supplies the controller with a voltage of 90–95% of the original one.

- When the protrusion on the rotating part of the camshaft passes next to the DPRV housing, the voltage at the signal contact drops to 0.2–0.4 volts, depending on the design of the device and the vehicle model.

- When the voltage drops, the electronic unit clearly “sees” the valve timing, promptly supplies the fuel mixture to the engine cylinders and directs the spark discharge to the desired spark plug.

When the meter is faulty, the electronics are unable to control the operation of the gas distribution mechanism. In such cases, the control unit goes into error and is guided by the signals of other meters. Spark generation and fuel supply are adjusted according to the programmed program, which affects the operation of the power unit.

Peripheral system used (2000)

- 70-71 – the channel size diagnostic valve is faulty (jammed);

- 100 – break in the PDZ line;

- 101 – similar value to the previous paragraph;

- 102/103 – short circuit of the remote control control line;

- 105 – control unit failure;

- 122/123 – incorrect pedal position signal;

- 127/128 – similar to the above code;

- 187/188 – excessively rich or lean mixture at idle;

- 135 – sensors A and B, designed to control the position of the remote control, do not respond correctly;

- 138 – similar value for the corresponding accelerator lever position sensors;

- 176 – throttle drive position failure;

- 178 – complete failure of adaptation of the above block;

- 187/188 – incorrect mixture formation;

- 270/271 – lack of reaction of DK2 to enrichment or depletion of the mixture after the catalyst;

- 301/304/307/310 – short circuit of the ignition coil for all cylinders, respectively;

- 500/501 – incorrect generator power readings.

More information about testing and troubleshooting

Practice shows that a malfunction of the camshaft position sensor does not lead to engine failure and immobilization of the vehicle. The engine continues to operate with some deviations that interfere with the normal operation of the car. Symptoms of DPRV failure are quite vague and similar to problems with other measuring elements:

- Unstable engine operation at idle and while driving.

- Instead of dynamic acceleration, after pressing the gas pedal, there is a series of small jerks and a sluggish increase in speed.

- The power of the power unit decreases. The effect becomes noticeable when the load increases - on a hill, sharp acceleration, while towing a trailer.

- The Check Engine light on the dashboard does not always come on. But many drivers note that if the meter is faulty, the display flashes after the crankshaft speed increases to 3000 rpm or more.

- Fuel consumption is naturally increasing.

If the measuring element is faulty, the control unit prepares and supplies an enriched air-fuel mixture to the cylinders. This results in an increase in gasoline consumption and unstable idling. Jerks and drops in power are caused by untimely supply of a spark - the controller “does not see” the end of the compression stroke in the cylinder and cannot clearly determine the ignition timing.

On various car models, additional symptoms of a malfunctioning camshaft sensor are noted:

- the engine suddenly stalls while driving, but starts without problems;

- cold starting of the engine becomes difficult;

- on cars equipped with a robotic gearbox, difficulties arise with automatic gear shifting;

- the engine “troits” - skipping ignition cycles is heard, sometimes popping sounds are observed in the exhaust manifold;

- On some cars, the power plant fails due to lack of sparking.

Driving with a broken air pressure sensor is acceptable for a short period. Jerking, rich fuel mixture and electronic errors accelerate the wear of spark plugs and engine parts. After detecting the listed symptoms, you should send the car for diagnostics or find the source of the problem yourself.

Read news about the new Niva

- The modernized Lada Niva Legend (4x4) 2021 was shown on the Internet

- Lada 4×4 Bronto - sales stopped, new details » Lada.Online - all the most interesting and useful about LADA cars

- Description of the instrument panel Lada 4×4 (VAZ 2121, 2131) » Lada.Online - all the most interesting and useful about LADA cars

- Chevrolet Niva gasoline consumption per 100 km

- Buy LADA (VAZ) 2131 (4×4) 2022 in Rostov-on-Don, low price for Lada 2131 (4×4) 2022 on the Avto.ru website

- Fuses Niva 21214 injector «

- The new large Lada 4×4 Niva “Bigster” 2021-2022 based on the Dacia Bigster was shown for the first time. The SUV has changed beyond recognition

- New Niva Chevrolet Lux 2022 - review of GLC equipment

On which cars is this problem most common?

The problem with code P0343 can occur on different machines, but there are always statistics on which brands this error occurs more often. Here is a list of some of them:

- Audi (Audi a4, Audi TT)

- BMW

- Cadillac (Cadillac SRX)

- Chery (Chery Amulet, Jagi, M11, Tiggo)

- Chevrolet (Chevrolet Avalanche, Aveo, Lacetti, Traverse)

- Chrysler

- Citroen (Citroen C4)

- Dodge (Dodge Ram)

- Ford

- Geely (Geely MK)

- Hyundai (Hyundai Accent)

- Kia (Kia Rio, Sportage)

- Lexus

- Mercedes

- Opel (Opel Corsa)

- Peugeot (Peugeot 308)

- Skoda (Skoda Octavia)

- Toyota (Toyota Camry)

- Volkswagen (VW Beatle, Jetta, Passat, Tiguan)

- VAZ 2110, 2111, 2112, 2114, 2115

- Volga Chrysler, 31105

- Gazelle Chrysler, 405

- Lada Vesta, Granta, Kalina, Largus, Niva, Priora

- UAZ Patriot

With fault code P0343, you can sometimes encounter other errors. The most common are: P0030, P0036, P0124, P0332, P0335, P0336, P0340, P0341, P0342, P0345, P0346, P0347, P0348, P0349, P0365, P0366, P0367, P0368, P0369, P039 0, P0391, P0392, P0393 , P0394, P0606, P2122, P2138.