03.07.2019

| (Votes: 5, Rating: 4.2) |

Issues discussed in the material:

- What is an engine mount or mount?

- For what reason can an engine mount break?

- How to understand that the engine mount has become unusable

- How to change an engine mount

An engine mount is a support structure that maximally softens vibrations of the engine in the engine compartment of the car. An ideally functioning cushion should completely dampen any engine vibrations, preventing vibration from spreading throughout the body.

Types and types of engine mounts

Before checking anything, it is also necessary to understand the purpose of the part, what malfunctions of the element may occur, as well as what signs of failure. As you know, the engine weighs quite a lot and vibrates during operation. This means that if the internal combustion engine is rigidly attached to the car body, then all vibrations will be transmitted to the latter.

When driving over uneven surfaces, the mounting points of the power unit experience significant loads. A rigid attachment to the body will mean that the fasteners and their installation location will quickly begin to break. To ensure that the overall design is reliable and comfort is maintained, special supports are used to mount the internal combustion engine.

A cushion (engine support) is a part that serves to fix the power unit, prevents it from moving and dampens vibrations during operation. In essence, this is a real gasket, only quite large. It is placed between the engine and the car body, that is, it is attached both to the power unit and to the body itself. The number of pillows depends on the make and model of the car; there are from three to five.

If you open the hood, you can immediately see the top (right support). The rest are located on the underside of the motor. Again, placement points depend on the car model, engine and gearbox type. In most cases, engine mounts consist of a rubber housing and metal fasteners.

Sometimes polyurethane is used instead of rubber, which is more wear-resistant. In expensive cars, more complex and modern options are installed - hydraulic ones. The vibration damping efficiency is naturally much higher.

Such supports consist of two chambers, between which a membrane is located. Either propylene glycol or a special liquid (gel) is used as a filler in the chambers. During operation, depending on road conditions (for example, on uneven surfaces), it flows from one chamber to another through special channels, and the overall rigidity of the cushion dynamically changes thanks to this design.

There are different types of hydraulic supports:

- Electronically controlled. The computer changes the rigidity of the support by receiving and processing signals - vibrations, the strength of which changes depending on the situation. The liquid inside such a pillow often contains metal particles and the density changes under the influence of a magnetic field. Thanks to such technologies, it is possible to achieve maximum comfort in the car interior, regardless of engine operating mode and road conditions;

- With mechanical control. A simpler option. Technical characteristics are set at the assembly stage. It depends on them in what mode the maximum benefit will be: at idle or at different engine operating modes.

Of course, high-tech devices are installed on very expensive cars. On budget options, and even more so on old Soviet models, simple rubber-metal supports are installed. In case of breakdown or wear (usually they last about 100,000 km), they are simply replaced. And the hydraulics can be repaired. And even on your own. However, before removing the mounts, you need to know how to check the engine gel mount, rubber mount, etc.

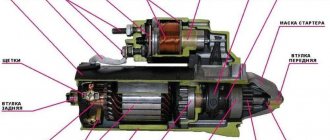

Device and diagnostics

The design of the hydraulic part of the engine mount is simple. Inside it, under the main load-bearing rubber stop (like a support without hydraulics), there are two compartment chambers located one above the other, filled with liquid. The chambers are separated by a rubber damping wall-membrane, but they also communicate with each other through a small hole - a throttling flow. At small vibration amplitudes the membrane resists the vibrations, at large amplitudes the flow channel comes into operation. In essence, such a support has two “sub-ranges” in which it exhibits different damping characteristics.

Despite the fact that the liquid in a failed support is usually black with rubber dust, the hydraulic part of the support rarely suffers from physical wear - as a rule, the rubber block is the first to give out, losing elasticity with age due to partial detachments from the metal, micro-tears and cracks.

It is important to understand that the liquid and, in general, the entire hydraulic part in the rubber-hydraulic support does not play a leading role, but an auxiliary one. The mass of the engine, as is the case with conventional rubber mounts, is supported by a powerful elastic rubber element. And if for some reason the liquid leaves the support (which sometimes happens due to a break in the elastic bottom or due to a leak in the rolling of parts of the body), then a catastrophe will not occur - except that the level of vibrations in the body will increase. And it’s not a fact that even throughout the entire speed range - the defect is usually more noticeable at idle.

However, it is still not worth delaying the replacement of the support - the increased amplitude of the engine’s swing causes it, when starting or gaining speed under load, to hit the stationary elements of the engine compartment, which can damage various pipes, hoses, and wires. And the rest, usually still quite alive, the supports begin to wear out intensively after the death of the leading, hydraulic one.

1 / 3 2 / 3 3 / 3

If you take the support by the working part (the one to which the bracket connecting it to the engine is screwed) and swing it (by the support in its pure form or by the engine itself), then you will not feel its “hydraulic essence” in any way - only ordinary rubber elasticity. Therefore, visually, faults in the rubber-hydraulic cushion are usually impossible to detect. Well, with the exception of cases where liquid is openly leaking from it... Both the new support and the dead one respond with a certain elasticity to a manually applied force - without experience or at least comparison with a similar machine with a known good support, finding the problem alone is difficult for a non-specialist, although an experienced mechanic can do it it's easy.

Therefore, to diagnose the serviceability of the airbag in garage conditions, it is necessary to observe the behavior of the support in conditions close to working conditions, when the assistant accelerates under load (turning on the “D” mode or slightly releasing the clutch on the handbrake). The amplitude of the engine swing and the possible contact of the central axial fastener with the support of its holder (body) is controlled, which is unacceptable:

Repair of rubber-hydraulic bearings is not practiced. They are non-separable and there are no spare parts for them on sale. Although there is a garage practice of replacing supports with similar ones (we will not use the term “similar”) from other models and even brands of cars. The fastenings at the supports are redone - holes are re-drilled, adapter plates are made, etc.

In principle, when using supports from another car with an engine of comparable power and weight, such tricks are generally workable and are acceptable out of desperation. It’s just that it is extremely undesirable to use cushions from transversely mounted ones on longitudinally located motors, and vice versa - the shear and compression loads are calculated completely differently, and such supports do not work correctly if installed incorrectly - they either do not dampen vibrations or are quickly destroyed.

Excursion into the materiel

For the first time, measures to reduce engine vibration were taken back in 1932 on Plymouth cars produced by the Chrysler Corporation. At the suggestion of lead engineer Frederik Zeder, rubber gaskets began to be installed between the engine and the frame. Owners of old Soviet-made cars, for example, the Moskvich model, can still see something similar today.

Engine mounts (also called engine mounts) today come in several types:

Rubber-metal. They consist of two metal plates and a rubber cushion placed between them. Some manufacturers use polyurethane instead of rubber, which is more durable. In addition, the structure can be reinforced with springs to improve shock absorption. These supports are either collapsible or non-dismountable. Widely used due to simplicity and low cost of production. The service life of rubber-metal supports is 100,000 kilometers.

Of course, those car enthusiasts who prefer to do everything with their own hands for one reason or another most often deal with rubber-metal cushions. This especially applies to owners of domestic vehicles. The number of supports depends on the type of engine. For example, the eight-valve engine of a VAZ 2110 car uses two side valves and one rear valve. And on the sixteen-valve version there will already be five supports. Those who are planning to replace the engine mount on a VAZ with their own hands should take this fact into account.

Design features

A rigid engine mount contributes to the transmission of noise into the car interior and increases the load on the internal combustion engine parts, since the body inevitably “plays” when driving over uneven surfaces. Therefore, vibration-damping materials are used in the design of the pillows. In modern automotive industry, several types of support designs are used:

- rubber-metal cushion. The units are fastened to metal elements, between which there is a layer of rubber. The silent blocks used in car suspensions have an identical design. This type of pillow is the most common because it has a long resource and low production cost. Some types of rubber-metal supports use springs to increase rigidity, as well as buffer elements to reduce shock loads. Rubber alloy or polyurethane is used as a damping material;

- hydraulic cushion. The operating principle is close to the operation of shock absorbers. The design of hydraulic mounts is more progressive, since it allows vibration damping to be adapted to the changing amplitude of engine and gearbox vibrations. The device assumes the presence of a working fluid, a membrane, upper (working) and lower (expansion) chambers, as well as a throttling channel. At idle speed, vibrations of the internal combustion engine are dampened by a membrane. As the speed increases, the rigidity of the membrane is not enough, so vibration damping begins to be carried out by hydraulic fluid. Thanks to this principle of operation, the cushion remains soft at idle, changing hardness only as engine speed increases.

We will not consider the design of electromagnetic and electrovacuum engine mounts, since they are found only on luxury cars, where replacing an engine mount with your own hands is a phenomenon bordering on science fiction.

Where is the engine mount located and what does it look like?

Mounts can mount the engine to a subframe, frame, or directly to the car body. The photo shows the main types of supports, so even a novice car enthusiast can find an internal combustion engine support on his car by analogy. To securely fix the motor, at least 3 pillows are used. The most commonly used scheme is with three lower and two upper supports.

Why is it needed?

The engine of any car is attached to the body through special elastic cushions. They are needed to smooth out vibrations, taking them upon themselves. Thanks to them, vibration is practically not transmitted to the body and is not noticeable inside the cabin. The car's engine simultaneously receives protection from adverse consequences, such as impacts when the wheels fall into a hole or pothole in the roadway.

A hydraulic cushion is a device that can provide the most suitable conditions for stable engine operation. Because it itself adapts to the intensity of vibration.

At low vibrations the cushion is soft, but as it increases it becomes harder to better dampen the vibrations of the machine.

Signs and causes of engine mounting problems

The main symptoms of faulty engine mountings are as follows:

- strong vibration on the steering wheel when the engine is running;

- knocking in the gearbox installation area when driving over uneven surfaces;

- jerks in the transmission while driving and changing gears at high speed;

- knocking under the hood when overcoming a rough road, as well as at idle and when the load changes while the engine is running;

When these signs appear, it is worth diagnosing the pillows. You can do this yourself.

Typical faults

If, while driving a car, a characteristic knocking noise has become clearly audible from under the hood, more precisely, from under the lower part of the engine or in the transmission area, if noise and vibration increase during the switching from 2nd to 4th gear, then this may be associated with malfunctions in the suspension or engine operation. Depending on the condition of the road surface, these sounds may become louder.

If the car is operated for a long time under conditions of severe loads or temperature changes, then all this does not have the best effect on the condition of the engine mounts. Over time, rubber loses its elasticity. In addition, the pillow may delaminate or crack, or even collapse.

But it is worth considering that the service life of these parts is quite long - more than 100,000 km. The supports are subjected to high loads when the vehicle starts and during braking. If the car owner likes to drive fast enough, with sharp jerks at the start, then the supports will not last their intended period.

Also among the typical faults is the breakdown of a metal aluminum bracket. This often happens when hitting a different obstacle. If there are oil leaks in the engine, it will definitely get onto the rubber part of the support. This lubricant can corrode the silent block and the support will fail.

Coolant also does not have the best effect on the rubber part of the cushion. Breakdowns in the system must be eliminated immediately. Do not overheat the engine. In addition to the cracked cylinder head, antifreeze from the expansion tank will also get onto the rubber parts. This will not have the best effect on their resource.

Torn engine mount: signs

Like any other part, the power plant support also has a limited service life and eventually fails. On average, airbags on modern cars are designed to last at least 100-120 thousand km, although in practice these elements may need to be replaced both earlier and much later than this period.

Usually the cause of problems is the rubber insert, which simply cracks and breaks under load. Less often, cracks appear in the metal part of the support, the installation sites of fasteners are broken, etc.

One way or another, the following symptoms usually indicate a malfunction of the engine mounts:

- The engine itself runs smoothly, but the driver feels a clear increase in vibrations in the body, on the steering wheel, on the gearshift knob, etc.;

- When you start moving from a standstill, as well as during braking, you can hear clicking or muffled knocking in the engine compartment;

- When driving on an uneven road, impacts are heard from the front of the car; in many cases such impacts are felt on the gearshift lever; shifting gears with a manual transmission at this moment can be difficult;

To check the engine mounts, it is not necessary to immediately go to a service station and drive the car to a stand. Usually, a fault can be identified and localized on your own, even if you do not have much experience in car repair and maintenance.

The simplest method of initial diagnosis is to rock the engine with your hands in the engine compartment, after which you can localize a torn or cracked support by knocking.

To carry out a more detailed check, you first need to find out in advance where exactly the supports are located on a particular model. Then the elements available for review will need to be pre-inspected. Cracks, breaks and other damage are usually visible and easily visible.

For a full visual assessment of the lower airbags, you need to be prepared for the fact that the car will need to be parked in a garage with an inspection hole, driven onto an overpass, or using a lift.

If a superficial diagnosis shows nothing, then the assistant should be used again. One person uses a pry bar to move the support, while the other watches for tears in the rubber insert at the very moment the support moves. It happens that some cracks are not immediately visible without rocking.

As for the replacement itself, replacing the top cushion is quite simple. The car needs to be jacked up, the old cushion removed and a new one installed. If you have to change the lower supports, it is also important to consider that the engine goes down after removing this cushion. This means that you will need an additional support that supports the internal combustion engine, allowing you to direct the cushion and properly secure this element.

Signs of wear on engine mounts

- Engine vibration at idle.

- Extraneous knocks while driving, felt in the engine compartment or under the gearbox.

- Jerks during dynamic acceleration of the car.

- Knocks in the engine compartment when starting or stopping the engine.

- Difficulty shifting gears.

On cars with hydraulic supports, in addition, acceleration dynamics may deteriorate. Visually, faulty airbags can be identified by delamination and ruptures of rubber dampers or breakage of aluminum brackets. An experienced specialist can also visually identify a sagging pillow by how severely its damper is deformed.

What can happen if faulty supports are not replaced?

What happens if you do not pay attention to possible malfunctions of the engine mounts? At first, when vibration and knocking are unnoticeable, nothing critical will happen. But with the destruction of the engine mounts, the power unit will begin to transmit vibrations to chassis parts and they will begin to fail much faster; this could have happened under the same operating conditions. Also, the engine can hit elements of the engine compartment and lead to damage to various pipes, hoses, wires and other parts. And the condition of the engine itself may suffer due to constant impacts that are not dampened by anything.

How to extend the life of engine mounts

Engine mounts work hardest when the engine vibrates the most. This is primarily starting from a stop, accelerating and braking. Accordingly, a driving mode with a soft start and less sudden acceleration and stopping prolongs the life of the engine mounts.

Of course, these parts last longer on good roads, but this factor is very difficult for us to influence. As well as for launches in sub-zero temperatures, when the rubber hardens and tolerates vibrations less well. But in general, we can say that a careful and quiet ride can extend the life of many parts, including engine mounts.

Source

Checking engine mounts yourself

Making such a diagnosis is not at all difficult. Even if the car is equipped with hydraulic cushions. The main thing is to know how to check the right engine mount correctly, and also diagnose the others. This can be done in several ways, which are best used in conjunction with each other to make a more accurate diagnosis.

- The first method is good for hydraulic supports. Having placed the car on a flat surface, you need to open the hood and start the engine. Then try to move slightly.

If the mountings are faulty, the engine will move from its place. In this case, characteristic sounds will be clearly audible. A similar check can be done with the engine not running, if you insert a pry bar or stick between the engine and the car body and try to shake the power unit from side to side.

- The second way to check is this. With the engine running, you need to engage the gear and move away a few centimeters. On different types of gearboxes, when the airbags malfunction, characteristic jerking may be felt.

We also recommend reading the article on how to replace engine mounts (mounts) with your own hands. From this article you will learn about the available methods and features of replacing the support cushions of the power unit.

- To check the lower supports you will need an inspection hole, a jack and a wooden block about half a meter high. Having lifted one wheel and replaced the jack with a block, you need to inspect the bottom of the cushion for cracks, ruptures, and leaks of hydraulic fluid. Of course, before this it is necessary to take safety measures to prevent the car from moving from its place (a wheel chock under the rear wheel, etc.).

In order for the supports to last as long as possible, you need to monitor your driving style. The principle “higher speed - fewer holes” must be thrown out of your head forever. In addition, engine mounts are more likely to fail if you move off frequently and abruptly. In a word, the fewer sharp fluctuations in the internal combustion engine, the less often you will have to check the serviceability of the engine mounts.

Checking rubber-metal engine mounts

The first method , which will help determine the malfunction, is the simplest, but the least informative. Open the hood, ask the assistant to start the engine, and then slowly move away, driving literally 10 centimeters, then turn on the reverse gear and move back. If the engine changes its position as a result of changing vehicle driving modes, or it vibrates too much, most likely the problem is in the airbags. This method is best suited for checking the right, or upper, engine mount - it is clearly visible under the hood. However, several airbags or a problem with the lower support may fail at once, so it’s worth moving on to the next option.

The second method will help make sure that the integrity has been damaged and check the condition of all the pillows . It will require a pit or overpass, a jack, a support or prop, a pry bar or a strong lever. Then follow the algorithm.

- Raise the front of the car with a jack (if you have a rear engine, then the rear).

- Secure the raised vehicle with jack stands or a support/block.

- Use the released jack to support the engine and remove its weight from the mounts.

- Inspect the engine mounts for damage.

Useful tips

Motorists recommend replacing the support in warm weather. In winter, the pillow becomes very dull, and can only be removed after preheating (using a hairdryer or blowtorch). If the support does not come out, it is recommended to use VD-40 type lubricant or its equivalent from. Regular lubricant will not work for this.

Often dust and moisture enter the cavity of the old cushion, resulting in corrosion processes occurring on the cylinder. It is not possible to remove the pillow. If you are replacing the rear support, pay attention to the direction indicated by the arrow on the part. It must be installed in the direction of travel of the vehicle. Otherwise, there is a risk that the element will not withstand the load and will break.

Features of the procedure for replacing motor mounts

It is necessary to ensure easy access to the cushions, so in addition to wrenches, you will also need a good jack. Let's look at the list of measures to replace a defective cushion using the example of a rubber-metal product:

- Loosen the nut securing the airbag to the body.

- Jack up the engine and remove the bolt.

- Unscrew and remove the faulty support.

- We install a new one and tighten it.

- Jack up the engine and insert the mounting bolt.

- Tighten the bolt and lower the motor.

Note! If the vibration, on the contrary, increased after installing new cushions when the car was warmed up and running, then the supports need to be centered. To do this, you need to loosen all the bolts securing the pillows and tighten them evenly until the vibration disappears.

Self-replacement

If a visual inspection reveals problems in the pillow, it should be replaced as quickly as possible. Start by purchasing a new part. It should be noted that it is better not to buy this spare part for disassembly, even if it is in good condition. In this case, saving money may cause more harm than good. Ideally, it would be to buy an original part.

- Remove the terminals from the battery. Raise the car to a height that will allow access to the engine from below. In this case, you can use a jack and wooden blocks as support.

- Raise the engine with a jack to release the load on the required part.

- Remove the bolts that secure the cushion to the engine and body.

- Place the new part in place, guiding it properly into place. Tighten the mounting bolts well. It's best to tighten them while the engine is running to avoid excessive vibration in the future.

- Once you have finished installing the cushion, put all the dismantled parts back in place.

In each individual case, it may be that there is no convenient access to replace the part. In this case, try to remove those components that prevent you from making a replacement.

Sometimes this operation may require another person to help guide the motor while you push the part into place. If we are talking about the top cushion, then, as a rule, it will not be difficult to inspect it and, if necessary, replace it. It will be possible to do without a hole.

Periodically check the condition of the engine mounts on your car. As you can see, this is not at all difficult, but it can help avoid many problems in the future and provide you with a comfortable ride in any conditions. Remember that a car feels when it is being looked at and then thanks its owner for a long and good service.

Where is it located?

Not every driver knows thoroughly how the car works, and now many don’t know it at all. Therefore, not everyone knows about the presence of hydraulic supports and their location. Simply by lifting the hood lid, without crawling under the car from below, the most you can see is the top cushion.

In each model and brand of machine, the supports are located differently, and their number also differs significantly. This is mainly due to the different placement of engines in different brands and models, as well as the different placement of gearboxes. It is most important that the cushions are securely fastened to prevent them from moving when the motor is running.

Most often, hydraulic mounts are located at three points at the bottom of the engine and at two points at the top. The engine hydraulic mount is right, left and center, respectively. Exactly the same supports can support the gearbox; here it is important for the owner to understand where the engine ends and the gearbox begins.

When driving a car along our far from ideal highways and roads, it puts an increased load on the engine mounting elements.

Therefore, rigidly attaching the motor to the housing can break the fasteners and the fasteners themselves. To counter this, hydraulic support cushions were created. How does a hydraulic engine mount work? It is designed to provide a soft yet secure attachment. Serves as a kind of gasket between the body and the engine, which protects both parts from damage.

Suppressing vibrations and preventing the motor from moving on the one hand, and on the other – protecting the motor from impacts coming from the wheels. There are from three to five such supports. Modern cars are equipped with both hydraulic mounts and rubber-metal cushions.

I won’t go into detail about rubber-metal ones; their design is simpler, but hydraulic shock absorbers are much better. Since the rubber-metal ones are not able to adapt to the load and have constant rigidity.

The pillow consists of two rubber containers. What liquid is used in the pillows? They are filled with propylene glycol (or other suitable liquid), between which there is a membrane. The essence of the action is similar to the work of a shock absorber. Vibration causes this fluid to move from one chamber to another.

Due to the membrane, vibrations are smoothed out at idle speed, as in a flexible support. With an increase in speed and, accordingly, vibration, which cannot be extinguished due to the membrane. Here the liquid begins to be poured into the lower container from the upper. Due to this, the rigidity of the pillow increases.

When vibrations decrease, the liquid is poured back, and softness is restored.

What we see after replacing engine mounts

Having installed new original power plant mounts, we naturally feel a significantly lower level of vibration. And not only! After the repair, the gears engage more clearly, the comfort of movement on a dirt road increases noticeably, and the engine becomes 1-3 cm higher. But the vibrations of the manual gearbox lever do not always go away.

Sources

- https://KrutiMotor.ru/proverka-podushek-dvigatelya/

- https://www.kolesa.ru/article/gidroopora-dvigatelya-kak-ustroena-kak-ee-diagnostirovat-i-mozhno-li-remontirovat

- https://tuning-mg.ru/ustrojstvo/iznos-podushek-dvigatelya.html

- https://avtika.ru/kak-proverit-podushki-pod-dvigatel/

- https://bibika.pro/kak-proverit-podushki-dvigatelya-vse-ob-avto/

- https://autobann.su/diagnostika-podushek-dvigatelya.html

Malfunctions

Now let’s look at the faults, in order to understand what signs the check is based on, I’ll list them too. Pillow malfunctions are as follows:

- Structural deformations

- Peeling of rubber from metal

- Breaks or cracks in containers with filler

Signs of a faulty airbag are as follows:

- Vibration noticeable in the cabin

- Engine bouncing when the car brakes

- Vibrations radiating into the steering wheel or gear knob

- Knocking out speeds

- Shocks when shifting gears

- On rough roads, knocking noises occur, very similar to a malfunction in the chassis.

That's all the diagnostics are.

If there are no such problems, then everything is fine with them.