Have you started to notice a strange knocking noise coming from the engine compartment? When driving on an uneven road with potholes and bumps, the sound appears, but when accelerating or on a flat road it disappears?

Most likely, the engine fasteners are broken, which means it’s time to look under the hood. And if the knocking is accompanied by strong vibration of the body, there is a problem with the engine mounts. What are they and what are they for?

The VAZ 2114 car is equipped with three rubber cushions, two of which support the gearbox, and one serves as a support for the engine.

The direct purpose of rubber supports is to reduce vibrations. When the car moves, strong vibrations occur, transmitted from the engine to the body. To make the ride as comfortable as possible, and the driver not to be distracted by extraneous noise and jolts, airbags are installed.

Without rubber softeners, driving a car would be like riding a cart, just as noisy and shaking.

How to check engine mounts on a VAZ 2114?

To diagnose the mechanism we need:

- A pair of jacks;

- Bar or board;

- Mount.

The check occurs in order:

- We drive the car onto a straight platform or into a garage with a flat floor.

- Raise one of the front wheels using a jack. Then we place a second jack under the engine pan and press it against it, through a board or block, to relieve the tension on the cushions.

- We lie down under the car and inspect the engine mounts. There should be no cracks or tears on the rubber elements. Also, they should not be hardened or peeled off from the metal part.

When a visual inspection does not help to detect the problematic element, it is worth checking for the presence of play between the support and the body. To ensure a complete inspection, use a pry bar to tilt the mechanism to the side.

If problems are identified in the elements, then it is better to immediately begin replacing the engine mount, since the motor is not securely mounted and because of this, other pillows receive a load higher than that for which they are designed. Subsequently, they may also fail, which will further weaken the reliability of the structure.

Engine mount malfunctions

The main damage to a pillow is loss of elasticity. The support is made of rubber, which loses its properties with prolonged use.

This is due to constant loads accompanied by changing weather conditions (cold, heat). In the future, the pillow will begin to deteriorate: it will crack and delaminate.

To prevent destruction of the rubber support, it is necessary to inspect it regularly. If damage is detected, the part should be replaced, otherwise strong vibration and extraneous knocking will be felt in the cabin, which will soon affect the operation of the engine.

It is better to replace the airbags in a timely manner than to later spend money on expensive repairs or purchasing a new engine.

The cost of engine mounts depends on the manufacturer, the minimum price for the front support is from 600 rubles, the rear and left ones are 500 rubles each. Average prices start at 1,200 rubles for the front, and 900 rubles for the rear and left.

It is possible to buy a set of three pillows from 3,500 rubles.

To replace engine mounts at a car service center, you will be asked for 1,500 rubles, but you can replace them yourself.

Replacing the front support

- Place the car on a level surface. Be sure to raise the handbrake or engage first gear. For safety, you can support the rear wheels.

- Remove the engine protection to gain access to the mounts.

- To remove the load from the support, place a jack under the oil pan and raise the engine. It is imperative to place a spacer between these elements in the form of a board.

- When the engine is supported by the jack, we inspect the mounting location of the cushion. We unscrew the bolt that connects the bracket to the support.

- After this, you can disconnect the pillow from the motor unit.

- We clean the fixation points and install the new part in the reverse order.

It is possible that in order to replace the front cushion, you will need to further lift the engine, since the mounting location of the old one has been worn out.

SIGNS OF WEAR

Since the function of the engine mount is to dampen vibrations, if they are noticeable even at idle, this indicates a problem.

Among other signs of wear on the airbags on the VAZ 2114:

- Vibration of the gearshift lever. This indicates that all motor vibrations are transmitted to the box.

- If you open the hood, strong vibrations of the engine are visible.

- Uneven car operation. The fact is that when the silent blocks are heavily worn, the crankcase begins to move slightly relative to the clutch. Because of this, the crankshaft position sensor (CPS) constantly produces different signals. The ECU is forced to mistakenly “catch” the revolutions to eliminate the imbalance.

Replacing the left support

- The beginning of the replacement actions coincides with the previous example, but in this case we place the jack under the gearbox.

- When the support is freed from the load, unscrew the bolt securing it to the body.

- Then unscrew the two bolts that attach the cushion to the gearbox housing.

- We also clean the contact area and install a new part.

Inspect the condition of the bolts before installing the support; they may need to be replaced.

Replacing engine mounts for VAZ Lada 2115 in auto repair shops in Moscow

18 car repair companies

- TTS Motors

- Pyatnitskoe highway, 2

- +7 (495) 24… show all

- Lexus on the market

Skladochnaya street, building 1, building 9 +7 (495) 24... show all

- Garimotors

st. Lyublinskaya, building 1, building 1A +7 (495) 76... show all

- Motorway

Ostapovsky proezd street, building 17, building 4 +7 (495) 98... show all

- Lorant

Kolskaya street, building 14, building 5 +7 (495) 76... show all

- Auto-rad

st. Novokhokhlovskaya 11 building 2 +7 (495) 25... show all

- Nivus

st. Avtozavodskaya 16, building 2, building 16 +7 (495) 62... show all

- Auto complex

Biryusinka street, 1/18, building 4 +7 (968) 51... show all

- Ddcar

st. Vavilova, 13a +7 (495) 12… show all

- Technical center gm east

Green Avenue, building 3A, building 1 +7 (499) 39... show all

- LR-west

Ryabinovaya street, building 28A, building 2 +7 (495) 21... show all

- Tolex tuning Lexus on Taganka

street 2nd Mashinostroeniya street, building 27, building 2 +7 (495) 24... show all

Popular companies

Replacing the rear support

- Just like with the left cushion, we need to place a jack under the gearbox.

- First, unscrew the bolts securing the support to the car body, and then to the box body.

- We clean the mounting area and install a new part.

Having finished the work, we check the correctness of the actions performed and the reliability of the connections. Afterwards you can start the engine.

Self-replacement

Before replacing the pillows, it is necessary to diagnose their condition. The condition of any silent blocks is checked with a mount: with its help you need to influence the support, simulating the movements of the engine during operation. If:

- rubber ruptures are visible,

- the bushing of the silent block touches the joints,

- the motor moves easily when pressed and hits the protection,

- the support bracket is broken,

the part needs to be replaced. Even if the signs of wear are not so noticeable (for example, the rubber is cracked but not torn), it is better to replace them as a set. Silent blocks lose their elasticity over time and begin to perform their functions poorly.

There are regular and reinforced supports for the VAZ 2114 on sale. The second type uses a harder rubber compound, but they are more durable only in quiet driving mode. Fans of sharp starts and braking will have to change any of them every 15-20 thousand; for other drivers they can last 50 thousand kilometers. This is the answer to the question of how long the supports last.

Front engine support VAZ 2114

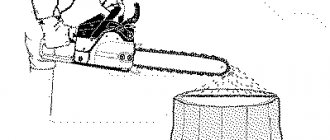

On a VAZ 2114, the supports can be replaced independently, without contacting a car service center. It is more convenient to use a pit or overpass, but you can do without them. To do this, the car is jacked up and placed on supports (bricks or tree stumps). If crankcase protection is installed, it must be removed.

Replacing the front support. You need to jack up the oil pan. First, use a 17mm head to unscrew the 4 bolts securing the bracket to the crankcase, then the silent block bolt. To remove the bolt, you need to use a jack to get it into a position where the engine will not put all its weight on it. When installing a spare part, it is important to lubricate the silent block bolt well: not only the threaded part, but also the body. It is in contact with the metal sleeve, so it can stick.

Side engine support VAZ 2114

Replacing the right support is similar, with the difference that it is better to jack the gearbox housing rather than the engine. Another option is to install a jack in the area of the oil filter housing. It is attached to the crankcase with three bolts. Another trick is that the right pillow needs to be changed by two people. Without a side stop, the motor moves up, not down. The jack will not help here, so an assistant must press on it so that the silent block bolt can be secured.

Replacement of the rear support is the most difficult task if done without a pit or lift, requiring some skill in performing auto mechanic work and perseverance. It is located at the connection between the engine and gearbox, so you will have to work in a confined space. In addition, when unscrewing the bolts from the body, the key may rest against the gearbox housing.

What can happen if faulty supports are not replaced?

What happens if you do not pay attention to possible malfunctions of the engine mounts? At first, when vibration and knocking are unnoticeable, nothing critical will happen. But with the destruction of the engine mounts, the power unit will begin to transmit vibrations to chassis parts and they will begin to fail much faster; this could have happened under the same operating conditions. Also, the engine can hit elements of the engine compartment and lead to damage to various pipes, hoses, wires and other parts. And the condition of the engine itself may suffer due to constant impacts that are not dampened by anything.

How to extend the life of engine mounts

Engine mounts work hardest when the engine vibrates the most. This is primarily starting from a stop, accelerating and braking. Accordingly, a driving mode with a soft start and less sudden acceleration and stopping prolongs the life of the engine mounts.

Of course, these parts last longer on good roads, but this factor is very difficult for us to influence. As well as for launches in sub-zero temperatures, when the rubber hardens and tolerates vibrations less well. But in general, we can say that a careful and quiet ride can extend the life of many parts, including engine mounts.

Replacement

As already mentioned, there are three rubber supports on the “fourteenth”:

Front cushion

- It is necessary to drive the car onto the overpass and make sure that it does not move. To do this, put the handbrake on and engage first gear.

- We remove the crankcase and engine protection, freeing access to the support.

- If the car is not new, to make work easier, all fasteners should be treated with anti-rust solution, and before assembly, all bolts should be cleaned with the same solution.

- Raise the engine slightly using a jack. It is recommended to place a wooden beam or board between them to prevent damage to the part. We carry out the lifting very carefully, avoiding damage to the fan housing and radiator.

- On the body cross member we find a long bolt connecting the bracket to the support and unscrew it.

- We unscrew the mounting bolts connecting the support to the engine block.

- We remove the damaged pillow.

- We install a new one and assemble everything in reverse order.

Left pillow

To replace the left airbag, you need to equip yourself with a cable.

- Using a cable, we hook up the gearbox and place a jack under it.

- If the starter is an old type (large size), remove it.

- Find the bolt that holds the support to the bracket and unscrew it.

- We remove the pillow.

- Install the new pillow by performing the steps in reverse order. Before firmly tightening the bolts, check that everything is in place.

Back cushion

To replace the right airbag you will also need a cable.

- Similar to replacing the left airbag, you need to hook up the gearbox with a cable and place a jack under it for safety.

- We loosen the bolts connecting the gearbox and the cushion.

- We also loosen the 2 nuts on the body that hold the cushion.

- Raise the gearbox with a jack and unscrew these 2 nuts.

- We unscrew the bolts from the box that secure the mountings of the pillow.

- Remove the rubber support.

- We install a new pillow, to do this we do what is written above in reverse order. Don't forget to clean off any rust before screwing in the bolts.

Design and technological features

Since in the “fourteenth” model the entire load from the engine falls on the front suspension, accordingly, the chassis is made of materials with an increased margin of safety, and its design must strictly comply with established standards. Durable rubber mounts of the VAZ-2114 engine are used as a damper for vibrations of the power unit under various loads.

Since high demands are placed on this part, it is extremely important to purchase only original and certified supports, since only they are suitable for use in our conditions. In the design of the front part of the car frame and its suspension, the engine mount is one of the important elements, while its independent replacement is quite within the capabilities of a car owner who has even the most minimal concepts in plumbing

In the design of the front part of the car frame and its suspension, the engine mount is one of the important elements, while its independent replacement is quite within the capabilities of a car owner who has even the most minimal concepts in plumbing.

The main thing in the repair process is to complete the entire technological sequence of actions, then the installed part will serve for a long period of time.

What signs indicate a torn engine mount?

The engine support (engine mount) is designed to reduce vibration loads and oscillatory movements of the internal combustion engine in the engine compartment, as well as to minimize the transfer of such loads to the vehicle body. In other words, the engine is attached to the load-bearing elements of the car body not directly, but with the help of special supports, which are also called cushions.

Next, we will talk about what signs indicate that the power unit mount is torn, as well as how to diagnose and check engine mounts.

Typical faults

If, while driving a car, a characteristic knocking noise has become clearly audible from under the hood, more precisely, from under the lower part of the engine or in the transmission area, if noise and vibration increase during the switching from 2nd to 4th gear, then this may be associated with malfunctions in the suspension or engine operation.

Depending on the condition of the road surface, these sounds may become louder. If the car is operated for a long time under conditions of severe loads or temperature changes, then all this does not have the best effect on the condition of the engine mounts. Over time, rubber loses its elasticity. In addition, the pillow may delaminate or crack, or even collapse.

But it is worth considering that the service life of these parts is quite long - more than 100,000 km. The supports are subjected to high loads when the vehicle starts and during braking. If the car owner likes to drive fast enough, with sharp jerks at the start, then the supports will not last their intended period.

Also among the typical faults is the breakdown of a metal aluminum bracket. This often happens when hitting a different obstacle. If there are oil leaks in the engine, it will definitely get onto the rubber part of the support. This lubricant can corrode the silent block and the support will fail. Coolant also does not have the best effect on the rubber part of the cushion. Breakdowns in the system must be eliminated immediately.

In addition to the cracked cylinder head, antifreeze from the expansion tank will also get onto the rubber parts. This will not have the best effect on their resource. It is important to remember that operating vehicles with broken mounts is not only unpleasant, but in some cases unsafe.

When to check engine mounts

How do you even understand that you need engine mount diagnostics? Signs of malfunction of this part are as follows:

Damaged engine mount

- vibration, possibly strong, that you feel on the steering wheel or body of the car;

- knocking noises from the engine compartment that can be heard even at idle;

- transmission jolts while driving (especially with automatic transmissions);

- impacts under the hood when driving over uneven surfaces;

- increasing vibrations, shocks, knocking when starting and braking.

Therefore, if your car “kicks”, “shakes”, “knocks”, especially when changing engine modes, shifting the gearbox, starting from a stop and braking to a stop, then the problem is probably in the engine mount.

Complete disassembly of the VAZ 2108 engine

General information

To secure the crankshaft from turning, screw the two flywheel mounting bolts into the holes in the crankshaft flange and insert a large screwdriver or spudger between them.

Location of the cylinder head mounting bolts.

Warning for operation 46

Do not jam a screwdriver or other tools between the cylinder head and the cylinder block. To remove the head from the block, insert a screwdriver under the exhaust manifold. Using it as a lever, lift the head.

To remove the oil filter, use a special wrench. If there is no key and you cannot unscrew the filter by hand, pierce its housing with a screwdriver and unscrew the filter, using the screwdriver as a lever.

Location of connecting rod nuts (white arrows) and main bearing cap bolts (red arrows).

64.

Remove the upper main bearing shells from the cylinder block beds. Remove the support half-rings from the middle support.

When disassembling the engine, we recommend replacing the liners

| Engine appearance 1- carburetor 2 - valve cover 3 - cylinder head 4 - front cover 5 - water pump 6 - generator 7 - crankshaft pulley 8 - oil pump 9 - drain plug 10 - oil sump 11 - oil filter 12 - cylinder block 13 - flywheel 14 - fuel pump Be sure to support the flywheel. [td]General information | ||

How to change supports

To replace, you will need to purchase front, left and rear airbags. Experts advise replacing the entire set during repairs, since after replacing one part, another one may break after a while. The average cost of parts is 2000 rubles. If you have the necessary tools, you can do the repair yourself and save on car service.

List of tools

To replace the pillows we will need:

- 2 good jacks;

- metalworking tools;

- scrap;

- steel rope;

- glue.

Tip: At some stages you will need to lift a lot of weight, so it would be a good idea to invite a neighbor or a fellow car enthusiast here.

Replacing the front airbag

The repair of each support has its own characteristics. Replacing the front airbag is carried out as follows:

- Put the car in 1st gear or the handbrake so that it does not move.

- To gain access to the support, remove the upper engine protection.

- Raise the engine with a jack. To avoid damaging its lower part or other elements, place a wooden board underneath.

- When we have freed the support from the load, we can unscrew the bolt that connects it to the bracket.

- We unscrew the bolts connecting the pillow to the motor.

Removing the bolt that secures the cushion to the engine - We remove the old part and install the new one.

Replacement result

After assembling all the parts, you should check whether the replacement was carried out correctly. To do this, you need to start the car and drive the car on a rough road.

If no more knocks bother you, and the car doesn’t shake like a tractor, then the job was done correctly. Otherwise, you should check whether you have placed the pillows evenly.

In order to extend the service life of the engine mounts, you should check that the bolts are well tightened and periodically remove dirt from them. Only regular monitoring will help delay the occurrence of engine mount malfunctions.

Source

Checking the backlash

This option is used if there is a malfunction of the engine mount, all the signs are there, but nothing could be detected visually. It is necessary to check for play in the attachment of the engine mounts to the body.

For a full inspection, experts recommend using a stick or pry bar to rock the pillows from side to side. If you can find a large amount of play in the places where the engine mount is attached to the body, then you can carry out independent repairs. But you can also go to a service station and fix the problem there.

Vibrations on the car body at idle and while driving indicate that the engine mounts are out of order or damaged. Signs of malfunction (Ford Focus 2 as well) may be different. Ford Focus cars use two supports. The right one is hydraulic, the left one is the gearbox support. In case of damage, it is recommended to replace both elements.

Naturally, you can replace only the damaged one and the vibrations will go away, but the new support will be subjected to significantly greater loads and will fail much earlier than its intended life. As a replacement, it is worth purchasing original parts. Inexpensive analogues last less than 20 thousand kilometers.

Source