How to check engine mounts on a VAZ 2114?

To diagnose the mechanism we need:

- A pair of jacks;

- Bar or board;

- Mount.

The check occurs in order:

- We drive the car onto a straight platform or into a garage with a flat floor.

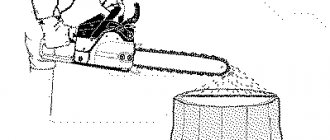

- Raise one of the front wheels using a jack. Then we place a second jack under the engine pan and press it against it, through a board or block, to relieve the tension on the cushions.

- We lie down under the car and inspect the engine mounts. There should be no cracks or tears on the rubber elements. Also, they should not be hardened or peeled off from the metal part.

When a visual inspection does not help to detect the problematic element, it is worth checking for the presence of play between the support and the body. To ensure a complete inspection, use a pry bar to tilt the mechanism to the side.

If problems are identified in the elements, then it is better to immediately begin replacing the engine mount, since the motor is not securely mounted and because of this, other pillows receive a load higher than that for which they are designed. Subsequently, they may also fail, which will further weaken the reliability of the structure.

Replacement of VAZ 2109 engine mounts, front, side and gearbox

Replacing all engine mounts...

Hello dear readers of the blog RtiIvaz.ru. Today's article will be devoted to replacing the front, side and gearbox engine mounts of a VAZ 2109 car. Factory engine mounts for the VAZ 2109 are quite reliable and last for quite a long time. This is due to the fact that high-quality materials were used in their production, and the technology of the production structure of rubber technical rubber products was also followed.

However, everything has its own lifespan during the operation of a car; the material of the rubber mounts ages due to natural wear and tear and then the car requires maintenance, for example, replacing the engine mounts of a VAZ 2109. In addition to the natural “age-related” wear of the part, there is also an emergency failure of the rubber engine mounts. This may be a consequence of an accident, hitting an obstacle, falling into an open sewer manhole, etc.

Replacing rubber cushions is necessary in cases of: vibration, knocking when starting the car and braking, as well as sudden acceleration, poor gear shifting. In addition, when the engine mounts sag, the operation of replacing the timing belt becomes difficult, since the sagging engine “fits” almost closely to the right mudguard, which makes it difficult to remove the timing belt cover and service the car engine.

When the engine sag significantly, the CV joints, the so-called axle shaft grenades, are loaded, as the geometry of their operation changes, which leads to a noticeable reduction in their service life. On many cars, a barely perceptible knock appears in the area of the rocker, which is associated with sagging of the engine and the gearbox slide hitting the body of the anti-roll bar.

As you can see, worn-out rubber mounts can bring a lot of trouble to car owners, and therefore replacing the VAZ 2109 engine mounts should be done as soon as possible. If faulty engine mounts are not replaced in time, parts of much greater value may fail.

To replace, purchase engine mounts with elastic rubber!…

To complete the work you will need an inspection hole or overpass. As a matter of principle, we do not consider a lift, since, as a rule, it is not available in the garages of our car enthusiasts. To complete the work you will also need: a new support/cushions, a hoist or jack, a set of socket heads and wrenches, spanners, a ratchet, and rust preventative (if necessary).

It’s worth mentioning right away that if only the front engine mount (boom) needs to be replaced, then this work can be done without a hole on any flat area.

Work diagram for replacing engine mounts of a VAZ 2109 car:

- The car is “driven” into the pit and secured with reliable stops.

- The terminal is removed from the battery for safe operation.

- A hoist cable is placed on the engine or a jack is placed under the pallet through a wooden support. If the cable starts, the hood is torn off to the maximum possible height and a homemade stop is placed using any available means.

- The engine protection is removed.

Replacement of the front central support of the VAZ 2109 engine (balds)…

VAZ 2109 front engine mount

Before starting work, you need to treat all support fasteners with an anti-rust solution, which will facilitate the replacement process itself. When lifting the engine, you must be careful not to damage wiring or piping elements, and do this work slowly. The socket head “undermines” all the mounting bolts of the cushion and the engine is raised, then it is most convenient to carry out the work with a ratchet wrench.

It is best to start replacing with a long bolt connecting the bracket on the body cross member to the support. Having given away the nut, you need to try to pull out the bolt, “playing” back and forth to do this with a hoist or a jack. As soon as the common center is “caught”, the bolt will come out with a light hand force. Having found this position, leave the bolt in the connection and remove the bolts securing the pillow to the engine block, after which, having removed all the bolts, remove the old support.

Don’t forget to mark the old cushion (its top) with any mark so that when installing a new rubber support you don’t have to “guess” how to install it correctly.

Then install a new rubber support, first just tightening the bolts so that everything matches everywhere, and then tighten them, but not completely. After preliminary tightening, release the hoist cable tension or lower the jack and perform final tightening of the bolts. Before assembly, clean the bolts (if there are traces of rust, then with a metal brush) and lightly lubricate the threads with any grease, for example Litol-24 or graphite lubricant.

Replacing the left (in the direction of travel of the car) side engine mount...

Side engine support for VAZ 2109

At the beginning of the checkpoint, the box is hooked with a hoist cable or jacked up for insurance.

When replacing three engine mounts on a VAZ 2109, the left mount is not located very conveniently for work and there are a number of difficulties when replacing it. The starter housing interferes with dismantling the fasteners, so there are two ways to proceed. Either release or remove the starter (a few minutes spent will make it much easier to replace the left side engine mount), or unscrew the studs securing the rubber support bracket from the “body” of the gearbox.

Often the studs come out on their own when the nuts are unscrewed, but if the stud remains in place, then to unscrew it, lock two nuts against each other, then unscrew the stud by the lower nut. There are usually no difficulties with the long bolt securing the cushion to the spar bracket, and if the rear support is not sagging, then the bolt comes out freely after unscrewing the nut.

When installing a new left engine mount, in order for the studs to accurately fit the threads of the gearbox, you need to lift the box slightly with a hoist or a jack. Then insert a long bolt, compress all the fasteners, lower the jack and then tighten everything completely. If the starter was released or removed, then everything is put in its place.

Replacing the rear rubber gearbox mount with a metal handle...

Engine mount VAZ 2109 rear gearbox

Using a hoist, the gearbox is engaged or a jack is placed below. Then the bolts of the cushion bracket connected to the gearbox and the support body itself at the point where it is attached to the body are “broken off”, then the power unit is raised slightly. Now the bolts are fully released and the box support is removed.

When installing a new pillow, you need to “play” a little with the jack to ensure that the holes line up exactly, this is especially important when installing the vertical bolts that secure the pillow. Often, due to some misalignment in these connections, the threads are broken during installation. When attaching these bolts, you need to center one of the holes with any conical object of suitable diameter, and insert the bolt into the second hole and “catch” the position when it moves freely along the thread. Then install the second vertical bolt. Having tightened all the bolts, then tighten them evenly, remove the jack and once again tighten all the bolts securing the rear gearbox mount.

Actually, that's all. The protection is put in place and this completes the replacement of the VAZ 2109 engine mounts. The entire work process, taking into account the preliminary removal and subsequent installation of protection, takes approximately 3 hours. You'll be lucky if nothing has soured anywhere, such as studs, bolts in the engine support bushings, and so on. Video:

Good luck to you and see you soon on the pages of the RtiIvaz.ru blog!

You can also check out other materials:

Adjusting valve clearances frets 2101-2107

Cooling system pipes for Kalina and Priora cars

The best 2109 of the last century

Radiator pipes

Engine mounts Kalina -1118

Replacing the front support

- Place the car on a level surface. Be sure to raise the handbrake or engage first gear. For safety, you can support the rear wheels.

- Remove the engine protection to gain access to the mounts.

- To remove the load from the support, place a jack under the oil pan and raise the engine. It is imperative to place a spacer between these elements in the form of a board.

- When the engine is supported by the jack, we inspect the mounting location of the cushion. We unscrew the bolt that connects the bracket to the support.

- After this, you can disconnect the pillow from the motor unit.

- We clean the fixation points and install the new part in the reverse order.

It is possible that in order to replace the front cushion, you will need to further lift the engine, since the mounting location of the old one has been worn out.

What influences the replacement

There are two main factors that force motorists to replace airbags.

- Natural wear and tear. Each pillow has its own service life, exceeding which is very rare. Often they don’t work it out for the second reason.

- Mechanical impacts leading to breakdowns. These are our roads, potholes, accidents, collisions with manholes, etc.

When replacement is required

There are several factors you should know about replacing engine components.

| Situation | Peculiarities |

| Body vibration | If you feel vibration in the body, you should definitely check the condition of the supports. This effect can be caused by various reasons, but pillows are one of the main |

| Replacing the timing belt | When replacing a belt, removing its cover can be very difficult, since the engine is almost tightly pressed to the right mudguard of the front wheel. You have to remove the pillow in order to fully carry out repairs. |

| The engine sags, loads the CV joints | Due to the impact of the engine weight on CV joints, their geometry changes, which leads to a significant reduction in the service life of the elements. The resource is reduced, it is necessary to carry out replacements ahead of schedule |

| There is a knocking noise in the backstage area | It may be barely noticeable. But its presence indicates that the engine has sagged. Consequently, the supports do not work properly and need to be replaced |

If you do not replace the supports in a timely manner, this will lead to more serious consequences and expensive repair of the breakdown. Therefore, it is better to replace the pillows when primary signs of wear are detected. To do this, we additionally recommend periodic inspection of the unit.

Replacing the left support

- The beginning of the replacement actions coincides with the previous example, but in this case we place the jack under the gearbox.

- When the support is freed from the load, unscrew the bolt securing it to the body.

- Then unscrew the two bolts that attach the cushion to the gearbox housing.

- We also clean the contact area and install a new part.

Inspect the condition of the bolts before installing the support; they may need to be replaced.

Features of the pillows used

There are several nuances that you should know about the supports in general, as well as about the engine mounts used on the VAZ 2109 model.

- When developing the design of supports that serve to reduce engine vibrations, manufacturers take into account the loads absorbed by the supports;

- These elements are under constant influence of loads, the magnitude of which varies;

- One constant load is the weight of the engine. But when the car starts, another load arises;

- When the car moves in reverse, the supports take on negative forces;

- When sharply accelerating or braking, when a wheel hits a pothole, or when hitting an obstacle, these same negative forces arise. The front, rear and side engine mounts are responsible for extinguishing them;

- To make cushions for the VAZ 2109, special natural rubber, high-grade SKI-3 rubber is used. In addition to rubber components, the supports include steel elements and heavy-duty adhesive;

- The VAZ 2109 engine mounts are capable of withstanding temperature loads in the range from -40 to +70 degrees Celsius.

In order for the pillows to meet all the requirements for them, experts recommend choosing products from the manufacturer or companies that were recommended by the VAZ 2109 manufacturer.

Replacing the rear support

- Just like with the left cushion, we need to place a jack under the gearbox.

- First, unscrew the bolts securing the support to the car body, and then to the box body.

- We clean the mounting area and install a new part.

Having finished the work, we check the correctness of the actions performed and the reliability of the connections. Afterwards you can start the engine.

What is this?

If we talk about the VAZ 2114 model, then there are three supports, two of which are intended directly for the gearbox, and another one for the engine itself.

The main purpose of pillows is to reduce vibrations.

When the car drives, serious vibrations occur, which are transmitted to the body from the power unit. To ensure the necessary level of comfort while driving and not to be distracted by extraneous noise or shaking, special supports are mounted on the car. If you remove them, driving a VAZ 2114 can be compared to riding an old wooden cart.

Causes of malfunctions

The most important problem that pillows face is the loss of elasticity of the material. This is due to the fact that the supports are made of rubber. Over time and with use, these elements lose their original characteristics. Various factors accelerate the wear process of bearings:

- Regular exercise;

- Long service life;

- Cold;

- Heat;

- Temperature changes, etc.

If elasticity decreases, this entails the formation of cracks and delamination of the material.

Replacement is purely a matter of time. But the procedure for changing the front and all other pillows should be carried out on time. If you drive for a long time with worn out bearings, this will result in a negative impact on engine performance. Then the repair will cost much more than the cost of new supports.

The main advice is to periodically check the condition of the supports for wear. If you detect a fault in a timely manner, you can replace it yourself and significantly save on car repairs.

Price issue

If you do everything correctly and in a timely manner, then your costs will be insignificant. You will have to purchase new supports and contact a car service. Of course, it is quite possible to do it on your own. This is a matter of desire and availability of appropriate skills.

How much will it cost to replace engine mounts? We suggest that you familiarize yourself with the current prices for the VAZ 2114.

Detail

Minimum cost

average price

Set of three supports

There is no need to pay someone, since the replacement can be done by yourself.

What are the features of pillows on a VAZ 2109 car?

Calculation of the strength of supports for the VAZ 2109 engine is carried out taking into account the magnitude of the loads acting on the structure. Regardless of the state of the car - whether it is moving or standing still, the devices are constantly in operation. The weight of the unit is concentrated on them. The loads on the supports change periodically: one load occurs at the start, and the opposite force occurs when the car moves backwards. Sharp braking or acceleration, encountering an obstacle, or a wheel falling into a pothole cause the emergence of negative forces that the supports are able to absorb. The products are made from natural rubber, high-grade rubber SKI-3, high-quality steel and special glue. Pillows can easily withstand temperature fluctuations from (-45) to (+70) degrees Celsius. This means that for the VAZ 2109 engine mounts should be used only those produced by the manufacturer. They are manufactured in strict compliance with technology and supplied to specialized auto shops. You need to purchase them from well-established suppliers who have many positive reviews from customers.

Previous posts from the category: VAZ 2109

Your starter has failed on a VAZ 2109 , 2110. You bought a new one and decided to replace the old one, but you don’t know how to replace it

starter for VAZ

2109 , 2110 for cars with your own hands.

No problem, we will help you figure it out and eliminate this gap. Replacement

wheel bearing VAZ

2109

Replacement

Wheel bearing VAZ

2109 is a painstaking task, so you need to stock up on the necessary tools and patience.

We carry out the work on a flat surface or in a hole. Installing a new crankshaft oil seal on a VAZ 2109

Replacement

the crankshaft oil seal on the VAZ

2109 is carried out with the timing belt previously removed.

We need to remove the crankshaft toothed pulley by prying it off on both sides with screwdrivers. Replacing the front struts on a VAZ 2109

Replacing the front pillars of vases 2109

or repairing the front struts of a VAZ

2109

is an inevitable process when they wear out. The shock absorber strut must also be removed if the support bearing or spring wears out. Work is usually carried out in a viewing hole or on a level area with the front of the car raised.

Knock in the rear suspension of the Nine and excessive swaying of the car on uneven roads? Replacement

rear pillars of the VAZ

2109 is inevitable for you.

But the devil is not as terrible as he is painted. First, let's look at what the rear pillar actually consists of. Replacing engine mounts on a VAZ 2109 is necessary when extraneous noise and vibrations appear. With their help, the engine noise is reduced, since the amount of vibration transmitted to the body is reduced several times. Repairing an old nine at a service center is too expensive. And the design of the machine is so simple that it allows you to carry out minor repairs and maintenance yourself, without resorting to the services of expensive craftsmen.

Replacement

Now we move on to replacing elements. Doing it yourself or contacting a car service is purely your personal decision.

For the VAZ 2109, the use of three supports is provided:

- Front;

- Rear;

- Left side.

The replacement of each of them should be discussed separately, since the processes differ from each other.

Replacing the rear cushion

- Find a suitable place to carry out repairs. You will need a pit or overpass.

- Place the car there, secure it with stops, and put the car on the handbrake.

- Disconnect the negative terminal from the car battery.

- Using a 17mm spanner, unscrew the nut that holds the cushion to the body.

- Using a 17 socket, remove the mounting nuts of the support bracket to the gearbox. There are 3 of them in total.

- Remove all the bolts and remove the old engine mount.

- Install a new motor element and reassemble the unit.

Dismantling works

Side left pillow

Left element

- Provide yourself with free access to the bottom of your VAZ 2109.

- Secure the vehicle with jack stands and the handbrake.

- Disconnect the minus from the battery.

- Remove the left engine splash guard.

- Using a 17mm spanner, remove the nut that holds the cushion to the body.

- Using a 17 socket, unscrew the 3 mounting nuts of the support bracket, removing them from the gearbox.

- After removing the mounting bolts, replace the worn engine mount with a new one.

- Carry out the reassembly procedure. Stick to strict consistency.

When to replace

Before carrying out repairs, you need to completely inspect all motor mounts and identify those that need replacement. They cannot be repaired - these are elements that cannot be restored. And if they are broken, then only installing new ones will help. Replacement of VAZ-2109 engine mounts is carried out in the following cases:

- In the presence of strong body vibrations. If you feel vibration, you need to diagnose the supports. This behavior of the car can be caused by various reasons. But the failure of the pillows is the main one.

- In the case when the timing belt is being replaced and it is not possible to remove the cover that protects the compartment, it is necessary to completely dismantle the cushion in order to slightly lift and move the engine to the side.

- If the mass of the motor has a strong effect on the CV joints, and their geometry changes significantly, this leads to the fact that the life of the cushions is reduced.

- Sometimes an almost imperceptible knock appears near the scenes. This is the first sign that the engine has sunk. In other words, the engine mounts are not working correctly.

If the pillows are not replaced, this will result in more serious consequences and expensive repairs. Therefore, it is necessary to replace the pillows as soon as the first signs of their breakdown are discovered. It is impossible to delay repairs, as this will lead to destruction of body elements, damage to the engine and deterioration in the comfort of the driver and all passengers.

Additional engine support for VAZ 2114 8 valves

Well.

I’ll install this one for myself. Material from the site “Behind the wheel”, April 2000 https://www.zr.ru/arch37411.html FOURTH POINT OF FOUNDATION

Many owners of VAZ models of the “tenth” family are annoyed by the unpleasant vibrations of the power unit, which are transmitted primarily to the front seat cushions and the gear lever. Non-standard additional support will help dampen these vibrations. It is attached on one side to the cross member, on the other - to the clutch housing. On injection models, you will have to move the ignition module closer to the radiator. A special bracket is included for this purpose. The approximate price of the set is 750-900 rubles.

I also thought about this topic. There is only one thing that stops it: in a side impact on the front fender with guy wires installed on the cups, there is a chance that both cups will move.

I also thought about this topic. There is only one thing that stops it: in a side impact on the front fender with guy wires installed on the cups, there is a chance that both cups will move.

Well, it doesn’t say there that it is attached like a guy wire to glasses.

It is attached on one side to the cross member, on the other - to the clutch housing

Did no one really bet?

I also thought about this topic. There is only one thing that stops it: in a side impact on the front fender with guy wires installed on the cups, there is a chance that both cups will move. I’m not going to fight, of course, but anything can happen. But the idea is good with an additional engine mount.

Yeah, but with a safety cage the whole body will move, so why put it on?! Mixed? That's funny to me.

Yeah, but with a safety cage the whole body will move, so why put it on?! Mixed?

I have a brace with an additional engine support (engine mount rod) - it’s a good thing.

What does it look like? Can you post a photo? What is the price of such a thing?

I also thought about this topic. There is only one thing that stops it: in a side impact on the front fender with guy wires installed on the cups, there is a chance that both cups will move.

But in the “Frequently Asked Questions” on the Tehnomaster website they write: ___________ Question: Is it true that during a side impact on a car with an installed brace, both front suspension supports are deformed? Answer: No. Our guy bars are designed in such a way that they fold up in the event of a side impact.

As you can see in this photo, the second post has not deformed and its location has not changed.

The brace has folded in the fastening points.

and in the middle of the connecting crossbar (in the adjustment unit). _____________

True, they don’t have a photo there.

They gave me this crap. a yellow piece of iron with a squiggle on the engine support (technomaster) so in the end I gave it to my father from him 99ya and it stood up fine after certain modifications.

This banner says that it is for VAZ2114, but in reality it is not so. 1. Using a grinder, I cut off one support on the cup by about 3 cm, so that the body number would not be blocked, or it would have to be removed before the technical inspection. 2. I cut three holes on the right support near the extension with a router, otherwise it won’t fit. 3. The adsorber bracket is in the way.

Unregulated ones are installed on new cars. On used cars there are problems with the alignment of the mounting holes on the cups (the body is already “mounted”). The ear, to raise the engine, you need to remove it. The generator mount also needs to be unscrewed; a support plate is placed between it and the engine. It allows you to remove the longitudinal “sausage” of the engine (transmitted to the gearshift lever), while freely moving to the sides and up and down.

You have to do some magic with the adsorber bracket - it only fits on one pin. Installation of this device does not in any way affect the warranty - the product is certified by AvtoVAZ OJSC.

Information on icons and features

You can not

start topics You

cannot

reply to messages You

cannot

edit your messages You

cannot

delete your messages You

cannot

vote in polls You

can

attach files You

can

download files

Source

Description of engine mounts

In the VAZ 2109, in fact, like in others, there are two engine mounts. They are two rubber salen blocks. These elements reduce vibration and engine noise on the vehicle body. In addition, with their help, the engine is held in the engine compartment. As for the cost of these parts, there is a wide price range on this issue. For domestically produced cars, you can purchase these parts from 300 to 1500 rubles per piece

The manufacturer is of no small importance. It is best to purchase products that are produced by the manufacturer of a particular car. It is generally accepted that they are a guarantor of excellent quality and enormous wear resistance of parts for their line of engines

Of course, the cost of original spare parts is much higher. Let's take a closer look at the malfunctions in engine mounts that every car enthusiast can encounter.

It is generally accepted that they are a guarantor of excellent quality and enormous wear resistance of parts for their line of engines. Of course, the cost of original spare parts is much higher. Let's take a closer look at the malfunctions in engine mounts that every car enthusiast can encounter.

What to look for when purchasing

Before purchasing, be sure to look at the quality of the product - there should be no damage to the metal parts - dents, cracks, paint damage. Rubber components should also not be damaged - no cuts or cracks on them are allowed.

If you plan to tune the engine, then you need to buy reinforced cushions - only they can withstand increased loads on the suspension. It is also recommended to supplement the design with at least one more support - this will significantly improve the operation of the car.

Signs of wear

Due to the presence of rubber inserts, the cushion loses elasticity during operation and can no longer dampen vibration, which is noticeably felt in the car interior.

Other signs of wear include:

- the appearance of a metallic sound under the hood;

- a periodically appearing sound reminiscent of a clock ticking;

- various damages that can be detected visually, such as cracks in the cushions.

Engine mounts are one of the most loaded parts in a car; they experience loads even if the car is stationary. Therefore, it is very important to pay attention to signs of wear and respond to malfunctions in a timely manner so that you do not have to later change the engine mount or repair the body.

Experts advise purchasing pillows only from a trusted manufacturer that provides a guarantee on the product. A low-quality part, firstly, will not cope with its task properly, and secondly, it will very quickly become unusable.

Ways to increase the rigidity of engine fixation on the body of a VAZ 2109

To prevent the VAZ 2109 cushion from being replaced frequently, and to increase the rigidity of the power unit, instead of the standard support, a more advanced part is installed, which has a rigid body and a rubber part inside.

Minimize the movement of the motor when braking, hitting bumps on the roads, or abruptly starting the car. With its help, you can avoid self-switching off the transmission. Increase the resource in the exhaust system and drive the drive wheels. Improve the design of the engine compartment. You can increase the rigidity of the motor by installing an additional fourth support . Its purpose is to connect the clutch housing to the cross member of the front suspension of the VAZ 2109. When installing the device, it is necessary to install a new bracket and find a place for the ignition module. The work procedure includes: Dismantling the VP for spark plugs. Disconnecting the wire connectors from the ignition module of the car. Disconnecting the clutch housing of this module from the cylinder block. The remaining three nuts securing the module are unscrewed, which is then removed. The ignition module takes a different place and new fasteners are installed. A bracket for mounting the fourth support is attached to the cross member of the front suspension. A bolt is installed in the hole on the terminal clamp, the nut is placed and screwed initially by two turns. The lower head of the rod is inserted into the support fixing eye. The bolt is installed in the eye and support, the nut is tightened. The size of the rod is adjusted until the holes in the clutch housing and on the upper head coincide. Another bolt is installed.

Problems when paying with bank cards

Sometimes difficulties may arise when paying with Visa/MasterCard bank cards. The most common of them:

- There is a restriction on the card for paying for online purchases

- A plastic card is not intended for making payments online.

- The plastic card is not activated for making payments online.

- There are not enough funds on the plastic card.

In order to solve these problems, you need to call or write to the technical support of the bank where you are served. Bank specialists will help you resolve them and make payments.

That's basically it. The entire process of paying for a book in PDF format on car repair on our website takes 1-2 minutes.

ATTENTION!

The electronic catalog of spare parts intended for reference purposes only!

Our company does not sell all spare parts presented in this list. If there is a “Cost” link in the right column, these spare parts are on active sale. Availability in warehouses for details and prices, see the product card. If there is no “Cost” link in the right column, we do not sell such parts and do not accept orders for them.

Diagnostics of the condition of engine mountings

Self-diagnosis of the condition of the engine mounts is not particularly difficult; you just need to open the hood and try to move the engine manually or using a lever. If it is noticeable that the engine sags or begins to fall on one side, then this indicates damage to the cushions that will need to be replaced.

If there are such malfunctions, the power unit is raised on special suspensions, the cushions are replaced with new ones, and then the engine and gearbox are fixed. It is difficult to carry out such repairs on your own, since you need to have appropriate lifts that can be used to fix and lift the engine in order to change worn out cushions.

As a preventative measure, you should maintain the suspension in good technical condition and prevent oil or antifreeze from coming into contact with the rubberized supports. In this case, such pillows will serve you for as long as possible, and the car owner will not need to go to a service center every 100 thousand kilometers and perform expensive engine repairs.