The gearbox in VAZ 2110 cars is one of the most involved dynamic elements. Because of this, the unit often becomes loose, which makes operating the car inconvenient. A shaking gear shift lever is a fairly common occurrence in domestic cars. There are two ways to combat this defect: constantly adjust the gearbox or make the rocker short-stroke - the process can be done independently. You can also purchase a gearbox repair kit from another VAZ model, which initially comes with a short-throw driveshaft.

This is what the installed short-stroke rocker looks like on a VAZ 2110 car.

What is so good about a short-stroke rocker? Firstly, it guarantees reliable operation of the gearbox over a long period of time. Secondly, the short-stroke version helps to increase the clarity of VAZ gear changes, including in the 2110 model. This is quite enough to make the operation of the power plant more comfortable, because smoothness, stroke and clarity of gear shifting are important for the gearbox.

Replacing the drawstring cuff

Replacing the backstage seals of a VAZ 2110

First you need to arm yourself with the necessary set of tools, which includes:

- Set of keys (10, 13);

- An ordinary awl or other sharp metal object;

- Screwdriver;

- Hook;

- Plastic stopper.

The oil seal must be replaced in a viewing pit or overpass. If this is not possible, then an option with a lift will do. In addition, there is another option, which involves placing two spare tires flat under the car, like stops. Two strong boards are placed on them, and the car drives onto a makeshift overpass. Simple and brilliant.

Advice. If a motorist drives into a hole or other device, he must take care of the safety rules. In particular, it is necessary to secure the vehicle using the parking brake and wheel chocks.

Replacing the gearbox seal of a VAZ 2110

Let's start the replacement process:

- The slide on a vase is almost always covered with a special rubber boot. If the cuff is faulty, then this same boot will be covered in oil, which will once again indicate the need for replacement;

- We take the wide part of the anther and bend it;

- We see the cardan located at the bottom;

- We disconnect this same cardan from the rod and lever, thus gaining access to the cuff (we use a 13 key in our work);

- The nut is turned out completely, which allows you to loosen the connection between the cardan and the lever;

- The lever is removed from the cardan;

- First or third gear is engaged;

- The cardan is completely disconnected from the rocker;

- The cardan is removed;

- Now you should remove the rubber boot.

Replacing the rocker seal on a VAZ 2110 gearbox

We see the cuff itself, which is located in a certain recess. This is where the rocker seal fits into the gearbox and needs to be removed from this recess.

Note. It is almost impossible to remove the cuff from the rod without using a special tool. An awl and a special hook will help in the work.

Making a short-stroke slide with your own hands

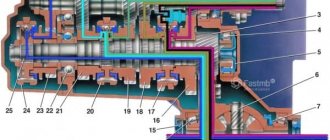

The diagram shows in detail where you need to cut with a grinder, and where you need to cook.

So, let's begin the modernization process:

- We raise the place of attachment of the piece of iron that goes from the gearbox to the lever inside the VAZ 2110 interior.

- You can do without dismantling the rocker, the main thing is to disassemble the ball joint.

- Now we need to ensure that the plastic paws release the ball.

To do this, you need to unclench the metal ring. We disconnect the rod and carefully drag it inside through the cover, which is responsible for protecting it from dirt. It will be much more convenient to work if the clamp near the gearbox is loosened. Adjustment is made using this lever.

Guided by the diagram, we cut off the parts using a grinder. It is necessary to weld a piece of metal pipe with a wall thickness of about 3 millimeters into the rod. To avoid skew, it is necessary to use identical pieces. The rod can be lengthened by 2-4 centimeters. All that remains is to raise the hinge with a hook, which serves to prevent an erroneous shift to reverse gear 2110.

- We change the gearbox shifter on a VAZ-2110 with our own hands - is there any point in using a repair kit?

Replacement is carried out according to the same scheme. Only instead of welding, a freelance short-stroke rocker from another car is installed. Replacement is a more expensive solution, so doing it yourself is problematic. If you have experience working with gearboxes, then replacing and purchasing a new part will cost about 1,000 rubles.

Why the reverse gear on the VAZ 2109 does not engage. Learning how to repair a gearbox

- the car is running), the clamp on the rocker is loosened, and the lever is moved to where it should be according to the schedule. The clamp is tightened, the success of the adjustment is checked with the engine running;

- If the knob is not set to reverse speed, the adjustment is made in first gear. The lever is moved to position 1, the clamp is loosened again, the rocker drive rotates against the clock until the gear shift lever hits the reverse speed lock.

Find the correct one in the fuse box, marked F21. He is 8th from the left; if it is burnt out, replace it; Raise the cover on the gearshift knob

There is a connector that is connected to the switch, you need to carefully disconnect it; The connector contacts are closed directly. If the missing gear appears, we change the switch, if not, we dig further; The connector is removed from the solenoid, and the voltage is measured in it

It should be 12 V, you can throw in a 5-watt light bulb to control it.

What is a short-stroke gearbox?

Here it is necessary to explain what the inconvenience is. Most often it affects VAZ owners with a manual transmission - not only old models 2107, 2106, 2108, 2109, but also more modern 2110, 2112, 2115, 2114. And it consists in too much time spent on gear shifting and the need for increased efforts to fix them. The reason for this is the non-optimal shape of the scenes, which is why such inconveniences arise.

Race car drivers were the first to encounter them; a lot depends on their gear shift time, and they try to minimize it. So they were the first to use a short-stroke rocker (SC), which allowed them to circumvent this drawback. And then a similar innovation spread to ordinary cars. For a better understanding of the subject of discussion, the photo shows a similar part for switching the gearbox of a VAZ 2108 car.

Gear shift drive rocker from Priora on VAZ 2110

| After the start of production of the Priora, the plant constantly refined the design of the car. So, starting around 2011, AvtoVAZ began equipping cars with a new type of gear shift drive. Thus, the Priora got its own gear knob (and not like on the “ten”), a rocker, a lever axis and other elements of the shift drive. Let's figure out what this modernization of the Priora gave and why this design is installed on the VAZ 2110. |

| 1 | Gear shift knob cover | 21700-1703124-00 |

| 2 | Lever | 21700-1703088-00 |

| 4 | Hinge bushing | 21700-1703226-00 |

| 5 | Thrust washer | 21700-1703371-00 |

| 17 | Control drive assembly | 21700-1703010-00 |

| 18 | Lever arm | 21700-1703082-00 |

| 19 | 21700-1703219-00 | Lever axis |

- No vibrations on the gearshift knob;

- New design of the gear knob with a gray insert to match the interior style.

- Owners who have installed new parts notice a gap between parts 17 and 20. The metal disks 16 are not pressed against the spacers 16 and the lever 20 tightly enough due to the bushing 18. The problem can be solved by shortening the bushing by 1-2 mm.

- Vibrations on the gearshift knob become less, but they do not disappear completely. They say that only cable shifters have no vibrations, but even there there is a rattling of the gearshift knob.

xn--2111-43da1a8c.xn--p1ai

Differences between a short-stroke link

The main differences can be seen even in photographs. We see that the short-stroke rocker has smaller dimensions, namely length. To reduce the stroke length at startup, the length of the transmission under the hinge should be increased. Due to this, we can not only get shorter gears, but also maintain the traction axis in its original position.

The photo shows a self-modernized backstage. As an alternative, you can use a part from other VAZ models.

It is worth understanding that after such tuning, you will need to put more effort when changing speeds. After upgrading, switching will resemble joystick control, which is undoubtedly a plus. In addition to the rocker, you can install a backlash-free cardan, which will also have a positive effect on the smooth operation of the gearbox.

Video instruction

Many inexperienced drivers begin to panic and talk about a breakdown of the gearbox, although in fact the culprit of the problem is the rocker.

Practice shows that replacement and repair are rare and not very common measures. Much more often, the current situation forces you to simply adjust the scenes.

But today we will talk not only about adjustment, but also talk about the features of modification, repair and replacement of this element.

Element location

Do-it-yourself short-throw scaffold

A similar device can be installed on any VAZ car (both classic and front-wheel drive) with your own hands; below are examples of how this is implemented.

Short-stroke link for classics

For production in this case you will need:

- a piece of pipe with a diameter of fifteen millimeters;

- nut from a classic ball nut;

- RPP from 2108;

- backstage repair kit 2108 (axle and two bushings);

- cardan from the steering mechanism 2104, 2105 or 2107.

The work is performed as follows:

- The ball from the bottom is cut off from the RPP;

- The lower part is sawed off so that a pipe can be inserted into it and scalded;

- The nut is welded to the pipe from below;

- The ball is placed in a convenient place;

- The cardan is attached to the gearshift lever.

The described process is illustrated by the following photographs:

Comparison of short and long stroke

Car enthusiasts describe the difference in options as fantastic. The renovation dramatically improves ergonomics. The amplitude of movements of the gear shift knob decreases by two to three times, but the force on its tip increases. The increase is quite acceptable, since gear shifting occurs in an unloaded state with the clutch depressed and does not require any serious effort.

Some experts believe that an increase in the shoulder leads to an increase in forces on the gearbox rods and to additional wear on the gearbox. There is no statistical confirmation of this point of view yet. Unfortunately, it is not possible to order a short-stroke configuration from the factory. You must install it yourself at your own risk. AvtoVAZ does not approve of such changes in the design of the Nine.

Independent modernization of the design associated with welding the levers lengthens them, and the height of the gearshift knob above the tunnel increases by about 5 cm. Such alteration requires welding work and the involvement of an experienced specialist, for whom cutting the levers using a grinder, installing a pipe and a strip of the appropriate section , and also welding the levers is not difficult.

The adjustment changes the ergonomics, but due to the reduction in the strokes of the shift knob, it is not perceived as a deterioration.

Is it difficult to change the slide yourself?

In order for the short-stroke rocker to feel the beauty of the absence of play and vibration in the lever, it must be installed correctly. If the installation is carried out in a car service, then there is nothing to worry about, but if you replace it yourself, you should treat it with full responsibility. The whole procedure is reminiscent of replacing a rocker seal - almost half of car owners face this operation. The characteristic creaking noise that is constantly present when changing gears speaks volumes about the need to replace the oil seal.

If we analyze in more detail the process of self-assembly of a short-stroke stage, we can highlight the following main stages of work.

- The lever housing cover is removed along with the handle with a simple and secure click.

- Using a size 13 wrench, loosen the clamp and remove the traction arm from the driveshaft.

- The reverse locking ball is released, for which it will be necessary to remove the locking ring.

- The retaining ring and lever are removed along with the ball and spring, placed in a separate housing.

- Now it will be possible to remove the lever along with the rod through the cabin. If necessary, they can be disabled in advance.

- Next, the cardan is removed, from which the boot is first pulled out and the bolt located on the left side is unscrewed.

- The new cardan is lubricated with lithol; When tightening the holder, do not be too zealous.

- The boom is also attached from the cab. Doing this work together will be much more convenient.

Further assembly is also not difficult. The rod is placed on the cardan shaft, after which it will be necessary to assemble the reverse locking mechanism. It's best to lubricate his ball beforehand. Next, before the final tightening of the fastening clamp, the final adjustment of the lever and the reversible locking system is carried out - in some cases the mechanism often does not coincide with the plate, so it will have to be removed and the existing hook adjusted. The process of installing the short-stroke stage on the Priora can be seen in the video:

Most car owners who, for one reason or another, decided to replace the standard rocker arm with a short stroke are satisfied with the speed and clarity of gear shifting. Considering the very low cost of such a retrofit, which can be done manually, adds to the benefits of a short-course stadium. Although the driver doesn't care how long it takes to shift into gear, the almost complete absence of extraneous noise and kickback is inevitably noticed by every driver.

Adjustment

Now let's talk about how you can adjust the link if it shows primary signs of malfunction.

- First of all, try by hook or by crook to engage first gear.

- Place the car on an overpass, turn on the handbrake, place additional supports under the wheels to avoid the car moving.

- Do not turn off first gear on the transmission.

- At the bottom, find the clamp that holds the rocker and secures it. To do this you will have to crawl under the hood. You shouldn't have any problems finding the gearbox. The clamp needs to be loosened.

- Now return to the salon. Your task is to move the box lever as far as possible to the left. If you start to pull the handle forward or backward, the drawstring will most likely come off. You don't need it.

- Get back under the car and tighten the clamp back.

- In many cases, simply shifting the rocker relative to the cardan shaft by literally a few millimeters is enough.

When adjusting, pay attention to the condition of the cardan shaft. It may require replacement if worn out

Finalization

Now many owners of the VAZ 2110 are discussing the possibility of refining and improving the gearbox by replacing the rocker from a standard one to a short-throw one.

The short walk is the result of independent tuning. Decide for yourself whether to carry out such work or not. But from the point of view of the efficiency of the gearbox, installing a short-throw rocker is only beneficial, since gears begin to shift more clearly.

To install a short walker for yourself, it is not necessary to completely dismantle the standard version.

To do this you need to perform several operations:

- You just need to disassemble the ball joint from the outside;

- Next, the metal ring of the support is opened and the legs made of plastic are spread apart;

- This is how the ball will come out;

- Now the rod is disconnected from the support, and a small piece of pipe and a piece of sheet metal of good strength are welded to the rod;

- Be sure to lift up the hinge with the hook, otherwise erroneous switching of speeds will not be avoided.

Installing a short drive will entail the need to apply more force when engaging a particular gear. But on the other hand, switching becomes clear and smooth. Therefore, decide for yourself which option would be better for you - standard or short-stroke.

Repair

Regardless of what exactly you do with the rocker - repair, adjust or change, you will still need to disassemble this unit.

Disassembly is performed as follows.

- Remove the cover from your gear shift knob.

- Place the car on a pit, or raise the front end with a jack.

- Remove the front console. It is held in place by mounting bolts.

- Now remove the curtain itself. To fix it, AvtoVAZ used 6 bolts in the case of the VAZ 2110 model.

- When carrying out dismantling work, be sure to examine the condition of all elements.

- By bending the boot, you will gain access to the support, oil seal and cardan shaft.

Changing the boot

Now regarding the repairs. There may be several recommendations in this regard, depending on the current state of the node and its components.

- At best, repairs will require the use of a repair kit for the backstage. It doesn't cost much.

- If the bushing is deformed, it will need to be replaced with a new one.

- Check the lever shaft bore for wear.

- Make sure there is no play in the driveshaft. Otherwise, a regular repair kit will no longer be enough, that is, a complete replacement of the entire backstage will be required.

- Often the culprit of extraneous noise and rattling when shifting gears in gearboxes is the rocker pad. Changing it is quite simple, and even a beginner can perform the operation.

Replacing the oil seal

Quite often, VAZ 2110 owners are faced with a situation where, after parking under the car, they find traces of oil. There are two options here - the oil filter has worn out or there are problems with the oil seal.

Airbag malfunctions

Understand that pillows

They have become unusable based on the amount of engine vibration. If it operates in normal mode, and the body begins to rattle, transmitting vibration to the steering rack, pedal block, and instrument panel, you can be sure that the reason for this is the wear of the pillows.

The greatest vibration is usually observed when the engine starts, as well as when it is turned off. When the rubber cushions are completely worn out, a knocking noise may appear caused by the contact of the engine elements and its supports.

Read:

To be more convincing, start the engine, open the hood and visually inspect the engine mounts and the cushions themselves. Replacing the VAZ 2110 clutch without removing the box and draining the oil. Place your palm on the motor and feel how much it vibrates.

The causes of failure of engine mounts can be:

- deformation due to spent life, mechanical or temperature effects;

- loss of elasticity due to “aging” of rubber and temperature changes;

- delamination or cracking caused by exposure to chemically active liquids.

Operating principle and manufacturing method

The VAZ 2109 short-throw gearbox came from professionals in motor racing; you will agree what kind of sport it is if a lot of time is spent shifting gears. What does such a scene give:

- Thanks exclusively to it, switching becomes much more pleasant for you, and the lever stroke is significantly reduced by almost half, the result obtained from the installation is simply incredible

- Therefore, smart people picked up this “theme” and launched it into the “masses”

- It turns out that today the VAZ 2109 short-stroke rocker is sold in almost every auto parts store

- Of course, the price is significantly inflated, but this is not an obstacle for most motorists

- There is nothing surprising here, because the rocker is worth it, I myself, like many car owners, was ready to buy it, I liked the short rocker of the VAZ 21093 gearbox so much.

- However, as soon as I saw its design and understood the main point of tuning, I changed my mind about paying for it, because it is possible to make one with your own hands in just half an hour of work

- What I got - see for yourself. Now I’ll tell you in a few words about how the whole mechanism works, also see the photo

Drawing of moving the upper point of the lever of a regular and short rocker

The diagram I have given will allow you to understand how the short-throw rocker on the VAZ 2109 works:

- The "O" - "F" line represents the low and high points of your standard lever set to neutral.

- In order for you to engage the gear, you will need to move the rod connected to the lever (point “B” is the point of their connection) to point “A”

- The handle of the gear shift lever will move to point “E”

- You understand that our task is to reduce the “E”-“F” switching distance that the handle travels

- And for this we need to increase the length of the lever to point “H”, which will allow us to raise the rod by the same distance (the segment “C”-“D” is equal to the segment “A”-“B”)

- It turns out that the lever that changes gears will have to travel a shorter distance; in this case, you won’t have to stretch or “search throughout the cabin” for the desired gear and its lever