Actually, it stands but doesn’t really show anything. The indicator from VAZ is installed, but the temperature sensor is from Renault Rapid. The resistance of the pointer and the sensor are different - as a result, the pointer, roughly speaking, shows the average temperature on the moon. The VAZ sensor doesn’t seem to fit (purely visually the diameter is larger + thread for a cone).

Now, actually, the question for knowledgeable people is which sensor to install instead of the standard one so that the indicator readings are correct.

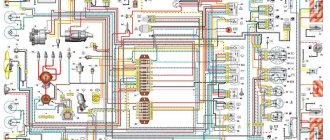

Well, some photos and a wiring diagram for all this. Perhaps it will be useful.

The white wire and the white and black wire go to the indicator light bulb (I connected it like this - white and black - to ground, and the white wire - to the dimensions on the dragonfly. It turns out that the light is turned on - the indicator lights up)

Green - to the temperature sensor, which is located on the engine (located on the left side behind the pump closer to the cabin)

Orange to any positive from the ignition switch (do not throw directly on the battery, otherwise it will work constantly, regardless of whether the ignition is on). You shouldn’t connect it to the white wire either - as soon as you turn on the dimensions, it will lie (mine constantly showed a temperature of 120 degrees)

I also installed the original expansion tank, instead of the VAZ garbage.

The coolant temperature sensor (CTS) is an important element of the engine management system that monitors the coolant temperature in the cooling system. The engine control unit receives information from the DTOZH and, in accordance with it, adjusts the composition of the fuel-air mixture, crankshaft speed, and ignition timing.

Design and principle of operation of the coolant temperature sensor

The “progenitor” of the modern coolant temperature sensor was a thermal relay

, which was installed on some engines (for example, in the K-Jetronic distributed injection system). The thermal relay contact is open - the engine is warming up, the contact is closed - the engine is operating at its normal temperature.

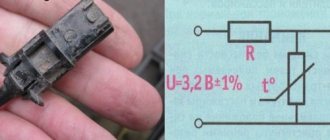

Currently, the basis of the coolant temperature sensor is a thermistor

(a resistor that measures resistance depending on temperature). The coolant temperature is monitored continuously. The material used to make a thermistor is usually nickel or cobalt oxide. The peculiarity of these compounds is that as the temperature increases, the number of free electrons increases and, accordingly, the resistance decreases.

Most often, the thermistor, which is located inside the DTOZH, has a negative temperature coefficient

. The sensor has maximum resistance when the engine is cold. A voltage (5V) is applied to the coolant temperature sensor, and as the resistance changes, it decreases. The engine control unit records voltage changes and, in accordance with it, determines the coolant temperature.

What it is

A standard coolant sensor is a device that is used to measure the antifreeze present in an internal combustion engine. The recorded parameters of the sensor are returned using signals to the engine control unit, which in turn uses this data to adjust the required amount of fuel and a certain ignition angle.

In some car models, the alarm can be used to switch to an electric ventilation cooling system. Let's say this is how the car coolant temperature sensor works in the VAZ-1117 (and number 1119) Lada Kalina, Lada Priora and Granta, Lanos, Toyota Camry (Toyota).

Photo - temperature sensor

Where is the coolant temperature sensor located?

The thermistor is located inside a protective heat-conducting housing, and on the housing itself there is a thread for attaching the sensor, as well as an electrical connector. Typically, the DTOZH is screwed into the exhaust pipe of the cylinder head. Some engines have two sensors at once: one records the temperature at the engine outlet, the second - from the radiator.

The coolant temperature sensor is positioned so that its tip has direct contact with the coolant. Accordingly, if there is little antifreeze in the system, then the DTO indicators may be inaccurate.

Operating principle and functions of the device

The design and operating principle of the temperature meter have changed little since its first use on a car. Due to modern materials used in the manufacture of the sensor, it has decreased in size, and the accuracy of the readings has increased. The device is a thermal variable resistor enclosed inside a metal case with a threaded tip. When heated, the thermoelement reduces the resistance of the electrical circuit, which allows the electronic control unit (otherwise known as the controller, ECU) to determine the temperature of the coolant.

The following functions depend on the operation of the temperature sensor:

- Traditionally, the coolant temperature indicator operates from meter signals.

- Timely activation of forced engine cooling fans when the antifreeze reaches the set temperature threshold (about 100 °C).

- Enriching the air-fuel mixture and increasing idle speed on a cold engine.

- While driving, the controller collects readings from all sensors and, on this basis, forms the ratio of fuel and air in the mixture. The temperature meter is also involved in this process.

The design of a modern car may provide for the installation of several heating meters responsible for certain functions. Their location varies:

- on the upper pipe leading from the cylinder block to the radiator;

- in the thermostat housing;

- in the cylinder head;

- directly into the radiator.

It is not difficult to distinguish thermocouples from other types of sensors. All devices built into the engine cooling system and connected by wires to the controller are designed for temperature measurements. The only point: when you start looking for the location of the temperature meter for the purpose of checking, do not confuse the device with the knock sensor built directly into the cylinder block. When a machine has several thermal elements, their functions are usually distributed as follows:

- a meter built into the pipe is involved in preparing the fuel mixture for the engine;

- a device located in the radiator ensures that a cooling fan (or two) is turned on;

- The sensor in the cylinder head is responsible for the coolant temperature gauge.

Most low- and mid-price cars use one temperature sensor that performs all functions simultaneously. It is usually located on the thermostat housing or on the upper radiator hose.

Signs of DTOZH malfunction

Like any other sensor, the DTOZH can fail, causing engine malfunctions. The first signs by which you can recognize a breakdown of the coolant temperature sensor:

- problems starting the engine in cold weather,

- bad exhaust on a cold engine,

- increased fuel consumption, etc.

Most often, if such symptoms occur, replacing the coolant temperature sensor is not necessary.

. Most likely, the problem is a loose or damaged contact, damaged wiring, or a coolant leak. Therefore, first you should conduct a visual inspection of the sensor for damage or corrosion.

Self-diagnosis methods

How to check the coolant temperature sensor? Before removing and replacing the sensor, you need to make sure that it is the problem that is causing the problem. Checking the coolant temperature sensor can be done at home; there are several ways to do this.

First, let's describe the first method - how to check a temperature sensor by placing it in water:

- First, you need to place the thermometer in a container of cold water. Alternatively, you can use a kettle. It is advisable to use an electronic device, since you will need to measure the temperature at elevated temperatures.

- Then you need to connect a tester to the controller - a multimeter, which needs to be set to resistance measurement mode.

- Then the DTOZH itself is installed in the kettle.

- Take readings from the regulator and write them down on a piece of paper.

- Next, the container is placed on the stove and heated, while you must take the resistance values of the DTOZH when reaching the main heating points - 15, 15, 20, 25 degrees, etc.

- After this, it is necessary to compare the obtained values with those given in the table.

Photo gallery “DIY diagnostics”

1. Regulator resistance measurement

2. Table of dependence of the DTOZ parameters

In the event that the readings differ from the most optimal, this indicates a breakdown of the regulator, and accordingly, it will need to be changed. There is another diagnostic option. How to check the coolant temperature gauge without a thermometer?

The principle of this method is that when heated, the temperature of the water will be a maximum of 100 degrees, no more. Therefore, this point can be taken as the main value and the resistance can be measured. When the water boils, the regulator's resistance level should be about 177 ohms. If we take into account the errors, then this figure can be approximately 190-210 Ohms.

Actions of the car owner in case of sensor failure

If the regulator is not working correctly, then you have several options:

- make sure that the problem is not a broken wiring; if so, then the damaged circuit must be restored;

- check the contacts for oxidation - to do this, the power wire must be disconnected and the contacts cleaned;

- if these actions do not help, then the only solution is replacement.

Checking the coolant temperature sensor

If the inspection does not produce results, it is necessary to measure the resistance and voltage of the sensor at different temperatures

. After starting a cold engine, as it warms up, the resistance should drop (or increase in the case of a positive temperature coefficient of the sensor) in accordance with normal values.

You can check the coolant temperature sensor yourself

Normal resistance and voltage readings for a NTC coolant temperature sensor

| Coolant temperature (°C) | Resistance (Ohm) | Voltage (V) |

| 4800 – 6600 | 4,00 – 4,50 | |

| 10 | 4000 | 3,75-4,00 |

| 20 | 2200 – 2800 | 3,00 – 3,50 |

| 30 | 1300 | 3,25 |

| 40 | 1000-1200 | 2,50 – 3,00 |

| 50 | 1000 | 2,5 |

| 60 | 800 | 2,00-2,50 |

| 80 | 270 – 380 | 1,00-1,30 |

| 110 | 0,5 | |

| open circuit | 5,0 ±0,1 | |

| short circuit to ground |

Normal resistance and voltage indicators for DTOZh with a positive temperature coefficient

AutoOt.ru » Car repair » Where is the coolant temperature sensor located?

Replacing the sensor

To begin repairing the coolant sensor, you need to determine its location. Most often it is installed near the thermostat or radiator; in some cases, the on-board computer uses readings from both sensors or one of them, depending on the make and model of the car. For example, this is how the sensor is located in Renault, Chevrolet, Citroen, Skoda, Chery, KIA, Subaru Impreza.

There are several ways to help you find out that the sensor needs to be replaced. If all other systems in your car are working, then the dashboard will indicate a malfunction using a light signal. If the car has computer control, then the problem can be determined by deciphering the combination on the monitor.

Photo - temperature sensor on the dashboard

Depending on the year of manufacture of the car, as well as its brand, many car enthusiasts note an increase in engine fuel costs. But at the same time, you need to understand that diesel cannot be defined this way (UAZ, PAZ and others). If you have a mechanic and not a computer control system, then here are the signals that you need to buy a new coolant temperature sensor:

- The car began to consume more fuel than usual;

- When the car starts and the engine reaches its maximum temperature, it stalls;

- There were problems starting up;

- Black smoke comes out of the muffler pipe.

Let's look at how to replace the G62 coolant temperature sensor on a Kia Sportage with a 2-liter engine. Similar instructions will also be useful when repairing Acura, BMW, Buick, Chevrolet, Ford, Toyota, Volkswagen, VAZ 2110/2112 injector, Renault Grand Scenic and others.

- To get to the sensor, you need to remove the air duct that cools the air filter housing and is connected to the radiator using two bolt connections and an air supply hose. Unscrew the bolts and remove the clamp, carefully remove the entire system. Disconnect the electrical wires from the sensor to correctly measure the resistance. Set the multimeter to ohmmeter mode and set the value to 1000 ohms. Connect the device pins to the positive and negative terminals. Normal resistance should be within 2700 Ohms when the motor is off. To check the sensor with the engine running, you need to move the tester away from the rotating parts of the car;

Photo - checking the sensor with a multimeter - Once you are sure that the temperature sensor needs repair, you need to disconnect it from the engine. To continue removal, you must first drain the antifreeze fluid from the radiator using the drain valve. Afterwards, check the radiator and sensor contacts again and unscrew the adjusting bolt as in the photo;

Photo - removing the sensor - Assembly is done in reverse form. It must be remembered that practically the main characteristic of the coolant temperature sensor is the material of the washer. If the washer is copper, then the thread of the alarm does not need to be treated with sealant; otherwise, be sure to lubricate the device.

Photo - copper temperature sensor

Advice from car enthusiasts on the forums: if for some reason you cannot immediately understand the coolant temperature sensor after a breakdown, then you can connect an additional one instead (such a connection may differ slightly in temperature from the main one).

Checking the temperature sensor is a simple procedure that even a novice car enthusiast can handle. The coolant temperature sensor (abbreviated as DTOZH) is a thermistor, that is, a resistor that changes the value of its internal resistance in accordance with the temperature where its actuator is placed. Most often, a multimeter is used for this (another name is a tester, “tseshka”), which is able to measure the value of electrical resistance in a circuit.

How to check the coolant temperature sensor?

In order to check the device, it must first be removed.

Dismantling is very simple:

- As a rule, the sensor is located on the cylinder head pipe and in order to remove it, you first need to remove the air filter;

- then the negative cable is removed from the battery;

- coolant is drained from the radiator;

- the wiring is disconnected from the device;

- using a suitable wrench (most often 19–21), the tightening is loosened, after which the sensor can be easily dismantled.

After the sensor has been removed, it is placed in a container with coolant and it is gradually heated. The process is accompanied by constant monitoring of the temperature and the readings of an ohmmeter, which is connected to the sensor.

There is a special table corresponding to the coolant temperature and ohmmeter readings.

| Temperature, °C | Resistance, Ohm | Voltage, V |

| 4800 — 6600 | 4,00 — 4,50 | |

| 10 | 4000 | 3,75-4,00 |

| 20 | 2200 — 2800 | 3,00 — 3,50 |

| 30 | 1300 | 3,25 |

| 40 | 1000-1200 | 2,50 — 3,00 |

| 50 | 1000 | 2,50 |

| 60 | 800 | 2,00-2,50 |

| 80 | 270 — 380 | 1,00-1,30 |

| 110 | 0,50 | |

| open circuit | 5,0 + 0,1 | |

| short circuit to ground |

When the readings from your device do not agree with the data from the table, the sensor must be replaced, since it can no longer be repaired.

If it turns out that the sensor is in working order, the fault needs to be looked for further. There may be some problem with the thermostat.

You can see an example of how to check the coolant temperature sensor by watching this video:

Signs of DTOZH malfunction

The liquid cooling sensor, like any other sensor, can have malfunctions that will someday lead to engine malfunctions.

The main signs that indicate a device failure:

- increased fuel consumption;

- poor exhaust when the engine is cold;

- Problems starting the engine in cold weather.

As a rule, if such problems occur, replacement of the sensor is not required. The problem may have arisen due to a loose or damaged contact, a wiring problem, or a leak of cooling fluid.

Sometimes a cold engine stalls and stalls, and its idle speed jumps from minimum to maximum values per minute, and after a few minutes or after a restart the situation is corrected.

This problem can occur due to a breakdown of the cooling fluid temperature sensor.

You can check the condition of the device using an ohmmeter. There is no need to unscrew it. It is not its resistance that is checked, but the mass sensor.

When the sensor is in order, the resistance tends to infinity, but if it is broken, then the resistance is 10 kOhm or less.

How to connect the coolant temperature sensor?

The sensor is installed very easily: it is screwed into the mounting socket, after which the thread is tightened and the wiring is connected, the air filter is put in place and the main air flow sensor power supply block is connected.

It is strictly forbidden to use sealant in this case. When the engine is running, the cooling system and metal elements become very hot, and the sealant may melt.

If this happens, the sealant will get into the antifreeze and the cooling system may fail.

Coolant temperature sensor connection diagram:

Replacing DTOZH, video:

How to remove the sensor

Mounting may vary, so again, look for information specific to your vehicle. But most often it is simply screwed into the thread. Then its body has a hexagonal shape. The sequence of actions is as follows:

- Disconnect the negative terminal of the battery. Find the sensor. Disconnect the wiring. Partially drain the antifreeze (if the sensor is located high enough, this can be skipped, check for the specific model). You also don’t have to do this if you find a plug (for example, a suitable bolt) and quickly put it in place of the removed part. Unscrew the sensor (if it is threaded), or unfasten it in another way provided for by the design.

Checking the coolant level

Many car owners often check the coolant level visually without using special instruments. You just need to look at the expansion tank.

If the engine is cold, the coolant should be between the maximum and minimum marks on the reservoir. When the engine is warm, the level of the substance may increase slightly.

If your car is in full working order, then when the antifreeze level decreases, the sensor immediately lets you know about it. The driver sees a special signal on the dashboard and adds antifreeze or coolant.

It is also contraindicated to add water alone. After all, antifreeze has special properties that protect cylinder heads from corrosion.

If checking the coolant temperature sensor does not show the coolant temperature. In this case, you better contact technical service.

In any car, everything is interconnected. The car system could fail for some related reason. For example, you could remove some part located with the sensor and place it incorrectly.

But it also happens that the problem is related specifically to the temperature sensor. The coolant level may be inconsistent or there may be a problem with the coolant level sensor.

The service can replace the sensor, and they provide a guarantee for its high-quality replacement and the correct assembly of all parts in the right places.

Thus, the coolant temperature sensor is a very important component of your car, which requires constant attention and care.

If repair of this device is necessary, then do it efficiently, without regretting the money spent. After repair, the engine will run smoothly, this will be especially noticeable at low speeds.

>