Print this article Font size 16

On any car, including the VAZ 2109, the coolant temperature sensor plays a huge role, since it largely ensures the proper, efficient operation of the engine cooling system.

Malfunctions

There are several main malfunctions that lead to failure of the coolant temperature sensor. Namely:

- There is an electrical contact inside the sensor that may break or become cracked. If the contact is broken, this leads to complete combustion of the regulator. If there are cracks, the sensor can still function, but the lack of proper contact does not allow accurate information about the coolant to be transmitted;

- Sensor insulation is broken. If the wiring insulation is poor, short circuits occur. They, in turn, cause the device to burn out;

- Wires break near the sensor. Because of this, the regulator cannot turn on the fan, which leads to overheating of the car.

In the summer, a failure in the operation of the diesel engine is rarely noticed, but in winter it becomes much more difficult to start the engine.

Signs of breakdown

How can you determine that the coolant temperature sensor has stopped working normally or has completely burned out?

- The cooling fan turns on randomly even at normal engine temperature. But in fact, the fan should only turn on when the power unit overheats.

- It's difficult to start the engine when it's hot. The cooling system is responsible for regulating the temperature, but a faulty sensor does not allow obtaining objective data and a signal to start a particular operating mode.

- Fuel consumption increases noticeably. This is caused by overloading the engine, which has to drive at elevated temperatures. Because of this, fuel consumption is increasing.

Before making final conclusions regarding the breakdown or malfunction of the DTOZH on the VAZ 21099, be sure to carry out verification activities.

Electronic engine control unit

The engine control unit is responsible for the operation of almost the entire car. In this part, hundreds of processes are calculated, all readings from sensors installed on the car are processed. Many people call the ECU a “computer” and it’s impossible to disagree with this. The unit, receiving readings from the sensors, processes them and controls the engine, adjusting the supply of fuel and air to the combustion chamber.

Location

The engine control unit on the VAZ 2109 is located under the glove compartment at the feet of the front passenger. You can see it by looking under the panel; the block is closed with a special plastic cover.

Signs of malfunction:

Problems with the operation of the sensor are most often associated with damage to the microcircuit, for example, burnout of a track or damage to one of the radio components, due to which one of the cylinders may fail, etc. It is quite difficult to judge the failure of the ECU based on its symptoms, since they are all similar to the failure of one of the sensors, so the malfunction of the unit can only be determined by diagnosing, disassembling, or replacing it with a known good one.

Examination

Today, VAZ 2109 car owners use two methods to check the condition of the coolant temperature sensor. Let's say right away that the second one is more reliable, but the first one is easier. Decide for yourself which of the methods presented below to use.

Verification method

Your actions

According to the table, check whether the resistance corresponds to that required at a particular temperature of coolant or boiling water.

Temperature (in degrees Celsius)

Resistance (Ohm)

If there are deviations from the norm, we conclude that the sensor no longer performs its functions properly and therefore requires mandatory replacement.

Replacement

Crankshaft position sensor

The crankshaft sensor (CPS) is one of the main sensors in the car system; if it breaks down, the engine will not even start. It takes readings from the position of the crankshaft, namely, it determines the top dead center of the piston. This is necessary so that the ECU understands when to send a signal to send a spark to the combustion chamber of a certain cylinder.

Location

The DPKV on the VAZ 2109 is located near the generator drive pulley; you can find the sensor by looking behind the oil filter; next to it there is a crankshaft sensor.

Signs of malfunction:

Replacement

It is not difficult to replace the DTOZH with your own hands on an injection VAZ 2109. Follow the step-by-step instructions to resolve any issues that may arise.

Removing the device

- First of all, check the condition of the fuses. It is not uncommon for them to burn out, which causes a failure of the coolant temperature sensor.

- Wait until the car has cooled down completely. Under no circumstances should you replace the DTOZH on a hot engine.

- Disconnect the wires going to your DTOZH. You just need to do this in a situation where, when you turn on the ignition, the temperature indicator needle begins to rise sharply and sometimes reaches the maximum level.

- If no changes occur with the arrow, the fault is not with the sensor itself, but with the wire going to it.

- If the needle starts to drop when you turn on the ignition, the coolant temperature sensor has failed and needs to be replaced.

- There is no need to remove half of the units to get to the DTOZH. Access to the device is free, there should be no problems.

- Drain the coolant from the system. This is an excellent reason to at the same time change the antifreeze for a new one, if necessary. If the coolant is fresh, use a clean container to drain it.

- Disconnect the wiring from the sensor.

- Using a socket, unscrew the regulator so that it can be easily removed by hand.

- Clean the device landing area. This usually accumulates a decent amount of dirt and dust, which can cause the new antifreeze temperature sensor to not work correctly.

- To clean, use any rag that does not leave behind lint or threads.

- Treat the nest with a degreaser.

- Insert the new regulator. The mistake of many is that, supposedly to increase the reliability of the installation, they seal the sensor with sealant. You shouldn’t do this, because this way the DTOZH can only work worse.

- Replace the power cord. Only if the check shows that it has a break or is damaged, it is better to replace the wire immediately. We do not recommend repairing it with electrical tape.

- Pour coolant back into the system. Even if you changed the coolant a couple of months ago, it is better to replace it with a fresh one at the same time. It definitely won't get any worse.

- Start the engine and check the operation of the new TOZ sensor.

Replacing the DTOZ yourself is a fairly simple process. You don’t have to spend money on car service services, plus you’ll get the necessary experience in car repairs yourself.

The coolant temperature indicator in the instrument panel of VAZ 2108, 2109, 21099 cars and their modifications receives information about the coolant temperature in the cooling system from a sensor installed in the engine cylinder block.

Operating principle of the fuel level sensor

Depending on the principle of operation of the sensors, the malfunctions that may occur with them will differ slightly. Let's look at the operating diagram of each type of fuel level sensor.

Float lever FLS

The operating principle of a float-type level sensor is based on the use of a rheostat. A lever is attached to its central part, at the end of which there is a float. Depending on the fuel level in the tank, the float will move, moving the rheostat lever accordingly along the contact path. During such movement, the resistance will change, which is recorded by the vehicle's electrical system. Accordingly, the arrow on the instrument panel will move in accordance with the indicated resistance on the rheostat. By the way, at a certain position of the float, and therefore the resistance value on the rheostat, a warning lamp on the dashboard will light up, indicating that there is little fuel left in the tank and refueling is necessary.

Coolant temperature sensor for injection vehicles VAZ 2108, 2109, 21099

The coolant temperature sensor (DTOZH) is part of the engine control system (ECM) of injection vehicles VAZ 2108, 2109, 21099. Based on its readings, the control unit (ECU) determines the thermal state of the engine and calculates the required amount of fuel mixture for injection and ensuring normal operation.

Temperature sensor location

On VAZ 2108, 2109, 21099 cars with injection engines, the sensor is installed in the coolant outlet pipe between the thermostat and the block head.

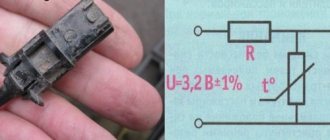

It is a thermistor - a resistor with a negative temperature coefficient, the resistance of which changes with increasing or decreasing temperature. When heated, the resistance decreases, when cooled it increases. For example, at plus 100 gr. – resistance 180 Ohms, at minus 40 – resistance 100700 Ohms. On one side of the sensor there are two contacts; on the other (located in the coolant flow) there is a sensitive element.

Operating principle of DTOZH VAZ 2108i, 2109i, 21099i

After turning the key in the ignition switch, the control unit supplies voltage to the DTOZH through a resistor with a constant resistance located inside the unit. Since the temperature sensor is a thermistor, the voltage supplied from the ECU will immediately change depending on the coolant temperature. Based on the voltage drop, the control unit calculates the engine temperature and, accordingly, the volume of fuel for injection. The voltage drop will be high when the engine is cold (more fuel) and low when the engine is warm (less fuel). As the engine warms up, the volume of fuel entering the engine cylinders decreases.

In addition to starting, based on the temperature sensor readings, the control unit adjusts engine idle speed, decides to enrich the fuel mixture at medium and high load modes, changes the ignition timing in one direction or another, and turns the cooling system fan on and off.

If the temperature sensor goes out of order, it does not allow the ECU to correctly calculate the dose of fuel required by the engine at the moment, and this in turn leads to the inability to start the engine, especially in cold weather, interruptions in its operation at idle and while driving, and increased fuel consumption. In addition, a malfunction of the DTOZH may be one of the reasons for engine overheating (untimely switching on of the cooling system fan) or, conversely, its prolonged warming up.

In some cases, if a temperature sensor malfunctions, the engine control system switches to backup mode. In this case, at startup, the ECU considers the engine temperature to be zero, the calculation of the dependence of the volume of injected fuel on engine warming up will be carried out based on the time it is running, and not on the readings of the temperature sensor, the cooling system fan will be constantly on. The light on the instrument panel lights up and the self-diagnosis system writes an error code into the memory of the control unit.

You should not immediately replace the sensor with a new one; you must first check the sensor connection connector and the wires leading to it. If a malfunction occurs on the way, you can remove the connector from the sensor and drive to the repair site in the ECM backup mode.

VAZ 2108, 2109, 21099 – DTOZH 2112-3851010 (23.3828).

Notes and additions

— A resistor is an element of an electrical circuit that has resistance. They allow you to control and regulate the voltage and strength of the electric current passing through them. The unit of resistance is Ohm.

Where is the fuel level sensor located?

To understand why the fuel sensor shows incorrectly or does not work at all, you need to find out where it is located. True, there is no special secret here, because naturally it is located directly in the fuel tank. The only difference that may be is the version of its execution. Depending on the design, it can be built into the fuel module, which is a single device consisting of a fuel sensor, check valve, fuel pump and filter (for injection engines), or installed separately in the middle/side of the gas tank separately, or screwed into a separate device by a separate device. tank if it is a diesel car.

Recent comments

- Mechanik on Carburetor starting device 2108, 21081, 21083 Solex Check the fuel level in the carburetor float chamber. Plus check if the fuel pump is pumping.

- Boris on Carburetor starter 2108, 21081, 21083 Solex After gas does not work on gasoline. The engine starts for 2-3 seconds and stalls. Half a minute later the same thing.

- Boris on Carburetor starter 2108, 21081, 21083 Solex engine starts but stalls after 2-3 seconds. after 0.5 minutes the same thing

- Andrey on Replacing thresholds on a VAZ 2108 Thank you, useful article. I also have to change the threshold on the eighth road.

Causes of errors

The main reason why the fuel level may be displayed incorrectly on the instrument panel is long-term operation of the sensor.

Most often, the device is replaced with a similar one from another car model, for example, VAZ 21099, 2110. After the replacement, some drivers notice that the data is displayed incorrectly. Most often this happens if the sensor was removed from an earlier version of the car and installed on a later one, for example, from 2109 to 2110 model. In addition, incorrect data may also appear after installing the Europanel.

VAZ 2109: coolant temperature sensor and its malfunctions

Coolant temperature sensor

In a VAZ 2109 car, the coolant temperature sensor plays a very important role. Without it, the system will not function properly, which can lead to overheating or hypothermia of the machine. Therefore, if any problems are observed with the sensor, they need to be diagnosed in advance so that later it is not too late. On a VAZ 2109, you can easily check the coolant temperature sensor on your own.

Location

To repair or replace the coolant temperature sensor, the first thing you need to know is its location.

In VAZ 2109 cars, the DTOZH is located between the thermostat and the cylinder head. The device has two contacts, one of which serves for ECU readings, and the second turns on the fan.

It is also worth noting that near the DTOZH there is a single-contact sensor, which are often confused with each other.

The main function of the DTOZH is to cool the liquid. The colder it is, the richer the air-fuel mixture entering the engine will be.

Location

Sensor check

VAZ 21093 coolant temperature sensor

There are two ways to check. To check the temperature sensor in the first way, you should:

- Connect the negative end of the voltmeter to the engine.

- Turn on the ignition.

- Using a voltmeter, determine what voltage is generated while driving a car.

- It is important that this voltage is at least 12 V (with a charged battery).

Note: otherwise you will have to either repair or replace the sensor with a new one.

VAZ 21093 coolant sensor

The second verification method is more reliable. To implement it you need:

- Set the multimeter to voltmeter mode. The voltage should be measured in the range from 100 Ohms to 10 kOhms.

- Take a thermometer that can change the temperature up to 100 degrees and above.

- Lower the sensor into a container with coolant.

- Warm it up. In this case, you should constantly monitor the temperature, which a thermometer will help with.

- Measure the resistance of the sensor at different temperatures.

Note: This method can be slightly modified. Pour boiling water into the container and immerse only the working part of the sensor in it. Monitor the resistance of the sensor as the water cools.

Idle speed control

The idle speed sensor is a DC motor with a “cap” on its shaft that acts as a valve. This valve closes the channel in the throttle valve, thereby opening or closing the air supply to idle. The IAC only works at idle and at high speeds, when the throttle valve is open, it does not participate.

Location

The VAZ 2109 idle speed regulator is located on the throttle valve on the reverse side.

Signs of malfunction:

Possible sensor malfunctions

VAZ 2109 coolant

The temperature sensor is usually installed between the cylinder head and the thermostat. It has two contacts. Each of them performs its specific function. So, the first one is needed to give readings to the control unit. The second one turns on the fan.

Note: next to it there is a single-contact sensor, which is usually confused with the second one.

The main purpose of the sensor is to cool the liquid, since the colder it is, the richer the fuel mixture. However, in some cases the sensor does not function well. Let's look at possible problems:

- The electrical contact located inside the sensor is torn or has a small crack. In the first case, the sensor burns out completely. In the second, it continues to work, but due to poor contact it gives incorrect or inaccurate data.

- Insulation violation. If the wiring is poorly insulated, this can lead to a small short circuit, and as a result, the sensor burns out.

- Broken wires near the sensor. As a result, the sensor loses the ability to influence the fan. Therefore, the second one does not turn on when it needs to. The result is overheating of the car.

At the same time, the machine can operate for some time without a sensor. Having not received a response from him, the computer automatically injects liquid with zero temperature into the system. In the summer, sensor failure will be faintly noticeable. However, in winter this problem is very noticeable - in cold weather starting will be very difficult.

Signs of trouble

VAZ 2109 cooling system

The following signs indicate that a new sensor is needed:

- The cooling fan may turn on at any time, even if the engine is not overheated. Although it should only work when it is needed, that is, when the engine is overheated.

- It is difficult to start the car when the engine is hot. The cooling system is supposed to regulate the temperature, but due to a faulty sensor, it does not receive a replacement signal.

- The car spends much more fuel than it did before. It just gets overloaded and continues to drive with a hot engine. Actually, this is why she spends extra gasoline.

Why does the sensor fail?

Causes:

- There are several contacts inside the DTOZH. Sometimes one of the conductors may become cracked, and then there is poor contact with the electronic control unit. The regulator stops transmitting readings correctly.

- If the insulation of the conductors is broken, a short circuit occurs. The temperature readings begin to fluctuate. The controller cannot process the signal.

- If the wires are broken, the fan does not start. Given the increased temperature of the liquid in the cooling system, the engine may stall.

Replacing the sensor

VAZ 2109 cooling

There is a DTO on every car. As a rule, its replacement is carried out on all machines according to the same principle. To replace it with “nine”, you should:

- Check fuses. They may be faulty. As a rule, if the fuses are blown, then the sensor will not be able to function normally.

Note: Any repair work on the machine can only be carried out after it has completely cooled down.

- Disconnect the wire from the DTOZH. This should only be done if, when the ignition is turned on, the temperature needle quickly rises up (often it reaches the maximum possible value). If during its disconnection no changes occurred with the arrow, then the problem is not in the sensor, but in the wire.

- At the same time, if this arrow drops during ignition, then the sensor is out of order, so it urgently needs to be replaced.

- Access to the sensor is free, that is, you can get to it easily and quickly, while removing a minimum of engine parts.

- Drain the antifreeze, as it can change during the work.

How to check the fuel level sensor

The first thing to do when checking any fuel level sensor is to check whether power is supplied to it through the fuse.

If the design of the car does not allow open access to the sensor, then you need to use the car's electrical circuit and connect to the corresponding terminals on the blocks. To do this you will need to use pieces of wire. If there is access (usually through the trunk or under the rear seat), then you need to disconnect the chip from the sensor and then use an electronic multimeter to check or test. To understand which contacts you need to connect to, use the wiring diagram, but if you are dealing with a conventional resistive level sensor of an injection car, then as a guide you can look at the cross-section of the wires suitable for the block - the wires for the fuel pump are always thicker than for the sensor. In general terms, the verification algorithm will be as follows:

If there is no power, first you need to check the integrity of the fuse, and then the integrity of the plus and minus wires. When there is power, but the fuel sensor shows incorrect data, you need to continue checking and make sure what the problem is - in the sensor or wiring.

Checking the fuel level sensor using the universal method

After checking whether power is supplied from the fuse to the fuel sensor, it is necessary to check both the operation of the sensor itself and the signals sent from it to the potentiometer on the dashboard, that is, the fuel level device.

There are three wires between the fuel sensor and the potentiometer used in cars with a carburetor engine. One of which is “ground”, the second is the resistance signal wire going to the device, and the third is the signal wire to the critical fuel level warning lamp!

There are four wires between the sensors and potentiometers on injection motors. The first is “ground”, the second is power to the fuel pump, the third is signal, the fourth is to signal lamp. There are also three wires between the electronic sensors and the device. The first two are power and ground, and the third is a signal going to the control unit, which will indicate the amount of fuel on the digital display of the dashboard.

When checking a float or tubular fuel level sensor, it makes sense to start with a universal method. It is performed in two versions - when the arrow is constantly at the beginning of the scale and when the arrow is constantly at the end of the scale. Let's start with the first one. To do this you need:

If after this the arrow on the device moves to the end of the scale, the fuel level sensor is faulty. If the arrow remains in place, you need to check the integrity of the signal wire, that is, “ring” it.

If the arrow is constantly at the end of the scale, then the sensor is checked according to the following algorithm:

For more accurate diagnostics, it is better to check the fuel level sensor when it is removed.

During dismantling, make sure that debris from the cap or seal rim does not fall into the fuel tank. Therefore, before dismantling, it is advisable to wipe off the dust and dirt on the fuel module cover with a rag.

How to check a lever fuel level sensor with a multimeter

We will consider a specific example of how to check a float-type lever fuel level sensor in a removed state based on the VAZ-2108, VAZ-2109 and VAZ-21099 cars. The verification algorithm will be as follows:

In addition to measuring the fuel level sensor with a multimeter, you also need to perform a visual check of it. In particular, you need to check the functionality by making sure that the wires and connectors do not have mechanical damage. It is also necessary to inspect the presence of oxides and/or debris on the variable resistance, and the strip with contacts is securely fastened and soldered to the terminals. You also need to check the contact density, that is, how tightly the “tongue” fits the variable resistance. If necessary, it will need to be bent (just be careful!).

On other cars (or when using other sensors), the verification algorithm will be the same, but you must first know the nominal value of the resistance of the installed sensors. This can be found in the instructions for them or in the technical documentation for the car (manual).

Please note that if the fuel level sensor is working, but the indicator on the dashboard still does not work correctly or does not work at all, it means that the indicator itself is faulty. Often repairs involve replacing (or adding) a trim resistor. This is required in order to correct the failed resistance on the device itself.

Replacing the coolant temperature sensor on a VAZ 2109

The coolant temperature gauge sensor is an important device designed to measure the temperature of the coolant. This regulator, as well as the coolant level sensor, are included in the engine control system. This material will tell you how to check the coolant temperature sensor, what are the signs of a malfunction, and how to change and connect the regulator yourself.

We thank the specialists of the site avtozam.com for their help in writing this article.

Fuel level sensor repair

First of all, you need to understand that repairing the fuel level sensor is impossible without removing it from its seat.

If the resistive elements on the lever fuel level sensor are worn out, you can try to bend the “tongue”, which directly slides over them and transmits the current value to the monitoring device. At the same time, you can clean the contact tracks of the device. If the resistive track has worn out significantly, then repair is not possible and the FLS must only be replaced. If a board with a resistive track “walks” in its seat, it needs to be soldered again.

When there is a malfunction in the electrical circuit of the sensor, problems usually occur at the contacts. Accordingly, they need to be cleaned and tightened. It is also advisable to lubricate them with a special lubricant. If the wires are damaged, it is advisable to replace them with new ones (you can use a whole bundle). However, if the damage to the insulation is minor, you can use electrical tape or heat shrink for wires for repairs.

If the guide tube in the tubular sensor is dirty, it means that it needs to be cleaned and the deposits washed off using a spray with a cleaner. At the same time, you can also clean the signal wires located along the tube.

The disadvantage of the electronic fuel level sensor is its non-repairability. At least in a garage environment. Therefore, if this unit fails, contact a car service center or an official representative of your car manufacturer for help.

When to change?

If your car has a high signal level from the coolant temperature sensor, this may indicate a malfunction of the device. In the event of a breakdown, the device will need to be replaced. But before that, you need to know how to check the coolant temperature sensor; the symptoms of a malfunction are given below:

- If the electronic regulator fails or does not work correctly, then the operation of the engine as a whole will be disrupted, in particular, it will be very difficult to start the engine in cold weather.

- In the summer heat, the car engine already heats up to high temperatures. But if the DTOZH does not work correctly, then the engine will periodically lose “traction”, and over time, the malfunction can lead to increased gasoline consumption.

- Another diagnostic option is to measure the resistance indicator. Resistance can be measured with a digital multimeter. To do this, you need to dismantle the device and place it in a glass with antifreeze, and you will also need a thermometer. The container needs to be heated, and then measure the required indicator using a digital multimeter. At a coolant temperature of 100 degrees, the resistance value will be about 177 Ohms. At 20 degrees this figure will be equal to 3520 Ohms.

- If the DTOZH regularly shows overheating of the internal combustion engine of more than one hundred degrees, then check the condition of the antifreeze in the expansion tank. If everything is fine with the coolant and there are no signs of boiling, but the regulator continues to show too high a temperature, this may indicate a malfunction.

Diagnostics of DTOZH using a digital multimeter

Design and principle of operation

The DTOZh temperature sensor is a resistor (thermistor) that reacts to the temperature of the antifreeze in the engine cooling system. Information about the resistance of this element is transmitted to the ECU, which decides to change the settings in the engine operation.

The information obtained is used by the ECU to determine the steps of the idle speed regulator to optimally adjust the required volume of the fuel mixture.

The peculiarity of DTOZH is that in the cold its resistance increases, and when heated, on the contrary, it decreases.

So, when reaching 130 degrees Celsius, the resistance parameter is 70 Ohms, and at minus 40 degrees - 100.7 kOhms.

The thermistor is controlled by applying +5 V voltage to it from the controller.

The potential passes through a classical resistor with constant resistance (R).

The antifreeze heating level is calculated based on the voltage drop across the DTOZh with variable R (Ohm). In this case, the drop will be large on a cold engine, and low on a warm engine.

Engine temperature display: note to Nines owners

Each car engine is equipped with a device for measuring the temperature of the power unit. This component allows the driver to detect overheating in time and eliminate this problem. What is the fan switch on sensor on a VAZ 2109 with a carburetor engine, what is its structure and how to replace it - read on.