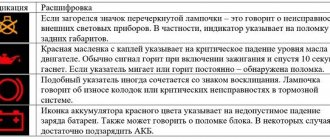

Error p2008 stands for “Intake manifold geometry variable valve control circuit malfunction, valve 1.” When an error is formed in the memory of the electronic engine control unit (ECU), the Check Engine light on the panel is activated, and the engine begins to idle unevenly and loses power at low speeds. In most cases, error code p2008 is eliminated by replacing the corresponding valve, but not always; there are a number of other reasons. In general, the error is not critical, and the machine can be operated with it.

IMRC valve - what is it and what is it for?

The IMRC (Intake Manifold Runner Control) system is designed to change the geometry of the intake manifold. Its functions are to increase engine power, reduce fuel consumption, and reduce exhaust toxicity. Changing the geometry is possible in two ways - using collectors with variable length or with variable cross-section. Let's consider the IMRC system using the example of the popular Ford Focus 2 car. Its collector geometry changes using the cross-section correction method.

The operating principle of the IMRC system and valves is as follows:

IMRC valve

- The intake duct of each engine cylinder is structurally divided into two. Inside one of these channels there is a swirl flap controlled by a vacuum drive.

- In turn, the vacuum drive is controlled by the IMRC solenoid valve.

- When the engine speed is low, the swirl flaps are closed, therefore, air enters the cylinders through only one channel.

- As a result, turbulence occurs in the cylinder, facilitating better formation of the air-fuel mixture. This helps to increase power at the bottom.

- When the engine load (speed) increases, the dampers open and air enters the cylinders through both channels. This helps increase engine power at high speeds.

Signals to open/close the valve are supplied from the computer.

conclusions

It is important to understand that the codes that appear, for example, Ford Mondeo error p132b, may not be displayed correctly, or the on-board computer itself may have various problems. Self-testing and decoding error codes are not always accurate compared to testing the on-board computer using special equipment.

Thus, if you feel that something serious is happening to your car, it is better to turn to professionals, or buy equipment that can read Ford Mondeo 4 errors with high accuracy.

Engine management system part 2

Poor road recognition

Poor road recognition

Signs of error code p2008

Symptoms of the formation of error code p2008 in the ECU memory:

- When the engine operates at low speeds, power is lost (up to approximately 3000 rpm). In particular, when driving in first and second gear.

- The car accelerates poorly and responds to pressing the gas pedal with a delay.

- When accelerating (gaining speed), the engine makes whining sounds.

- Vibration of the engine and the entire car body is observed, especially at low engine speeds.

- “When it’s hot,” jerks may be observed when the machine moves.

- Sometimes fuel consumption increases, especially if the car is operated in city driving mode (low engine speeds).

- The Check Engine light may not be on constantly, but may turn off periodically, or not light up at all.

Conditions for generating error p2008

The conditions for generating error p2008 may differ for different cars. So, for example, on a Chevrolet Captiva, the code is fixed within 1 second of a break in the IMRC valve circuit, provided that the car’s engine is running.

Ford Focus Club

Legend Owners Club!

- Links

- Unanswered messages

- Active topics

- Search

- our team

Error P2008, but throttle body and sensors are ok

- print version

Error P2008, but throttle body and sensors are ok

- Quote

#1

Post by alexl » Apr 25, 2022, 8:31 pm

Hello. Finally got around to it and I finally got involved here)

The story is like this. End of 2016, I haven’t driven it for a month, when I start it, the revs jump from 1000 to 3000, the engine doesn’t run smoothly. About 5 minutes later the check engine light came on. I check the resistance on the damper sensor coil - open. I ordered a regular one, replaced it, it drives like new, only the check light is on. I got to the diagnostics - error P2008, reset.

March 2022, 5000 rpm at 1st speed, then the same amount at 2nd, 4000 at third, and then I see the check light comes on. and I didn’t even reach the red zone((((I connect the ELM327 - it gives errors P2008, P0400. At the same time, the speed is normal at idle and when driving. I checked the resistance on the sensors - 30 ohms, everything is fine.

After 3000 km. I start it when it’s cold and it stably holds 2400 rpm at idle. And the most amazing thing is that the gasoline gauge shows 1, the arrow rests on the right edge, although the side of the computer. shows the correct distance to the gas station. Warmed up. The checks did not light up. The resistance on the sensors is normal. When driving, it still holds 2.4 turns. I drove for an hour, turned off the engine several times, drove to auto parts, and bought a flush for the damper. I start the engine again and the revs are normal, and the gas shows correctly.

After another 1000 km I decided to flush the damper anyway. I took pictures, and it was almost clean! And after another 500 km I was driving calmly at 60 mph, the check light came on again, error P2008, the speed was normal. Fuel consumption, according to the on-board computer, is only decreasing.

How to check the IMRC valve

There are two methods to check IMRC valves. The first and simplest is directly on the engine, without removing it. To do this you need:

Checking the IMRC valve with a multimeter

- turn on the ignition (you don’t have to start the engine);

- remove and put back the terminal on the valve;

- if at the same time a click is heard from its operation, then the valve is working, along with the sound you will see how it opens and closes;

- accordingly, if there is no click or movement, the valve is faulty.

Before this, using a multimeter, you need to make sure that the power in the chip comes from the ECU.

The second method is to check the intake manifold geometry changing system valve with a multimeter. To do this, it is not necessary to remove it from the engine; you can do it right on the spot. By setting the tester to resistance measurement mode, you need to find out if there is a break in its winding. You need to use probes to check the resistance at its contacts. The resistance value of a working valve should be about 30...40 Ohms . If the display shows 0, it means the valve has failed and must be replaced.

In parallel with this, you can set the multimeter to dialing mode and similarly “ring” the connection between the contacts. If there is a sound signal during the test, it means the valve is working, otherwise it must be replaced.

The ignition order of cylinder 2 is broken

How to resolve OBD2 trouble code P0302.

Misfire or lack of ignition in the second cylinder.

Code interpretation: excessive (frequent) or random misfires in the second cylinder (fuel ignition timing in the cylinder).

Uncharacteristic engine operation is manifested by jerks - short in duration both at low and high speeds, cold or warm engine.

It is worth knowing that detection of error p0302 does not always cause a “Check Engine” emergency indication. However, in case of serious malfunctions or deviations from operating standards, “Check Engine” will not allow the engine to start.

The priority list for checking components and components for their integrity and serviceability:

- No contact or oxidation (corrosion) of connectors, terminal latches, short circuits.

- Breakdown of the module insulator or high-voltage wire.

- Spark plug malfunction.

- Coil failure.

- Nozzle clogged.

- Insufficient compression in the cylinder block.

- Air in fuel supply pipes.

- Damage or wear of the gasket on the cylinder head itself.

- Incorrect timing operation, chain wear.

- Malfunction of the oil separator.

- The ECM is faulty.

- ECU unit malfunction.

- Malfunction of sensors - detonation, crankshaft.

List of serious malfunctions for OBD-2 error p0302:

- Valve tappet failure.

- Camshaft cam wear.

- Wear of the valve and its end.

- “Drawdown” of the valve seat.

- broken ellipse of the pusher seat.

The influence of error p0302 on engine operation and the emission of combustible product

As a result of stress wear, the intake and exhaust operating cycle primarily suffers. As the vehicle's mileage increases, the gap on the intake valve increases, and on the exhaust valve, on the contrary, it will decrease (sit down). From this comes an understanding of the violation of the gap between the valve and the glass, as well as the pusher gaps. There are often cases of valve seat subsidence.

Incorrect combustion in the cylinders leads to combustion products (exhaust gas) becoming more toxic. An incompletely used product (fuel) increases the overall temperature at the outlet of the cylinder, while exceeding toxicity, rapid wear and rapid breakdown of the catalyst due to exceeding the maximum operating temperature - eight hundred degrees.

How to get rid of the error

Replacing IMRC valves

Error code p2008 - malfunction of the damper control circuit of the intake manifold geometry changing system (Intake Manifold Runner Control Circuit), can be solved by the following steps:

- replacing the damper of the intake manifold geometry changing system;

- IMRC solenoid valve replacement;

- replacement or restoration of electrical/signal wires;

- replacement or restoration of electrical contacts of the IMRC system.

After completing the repair work, you must remember to erase the error from the ECU memory. This often happens automatically, but not always. Therefore, it is better to do this forcibly using a pre-installed diagnostic program on your smartphone and an OBD2 scanner. The easiest option is to disconnect the negative terminal of the battery for 10...15 seconds so that the ECU reboots.

Conclusion

In most cases, error code p2008 is not critical, and the vehicle in which it occurred can be used in the future. However, it is necessary to understand that with this error, the engine will pull poorly at low speeds, and additional noise and vibration of the engine will be observed. Therefore, it is advisable to diagnose the error as quickly as possible and eliminate the reasons why it appeared.

The operation of the engine and other systems on the second generation Ford Focus is controlled by an electronic computer. If any malfunction occurs, the check engine light on the dashboard lights up. After this, you can read the error code and find out what the problem is. What does error p2008 mean on Ford Focus 2? What malfunction does it indicate and how to fix it? Let's try to figure it out.

This malfunction indicates a malfunction of the valve responsible for changing the length of the intake manifold (Intake Manifold Runner Control). Error p2008 most often appears on 1.8-liter power units, which were installed on the second generation Focus and other cars from the model range. We have already mentioned how it is deciphered earlier.

What signs of machine operation indicate that this particular malfunction exists? Engine malfunctions appear gradually. When operating temperature is reached, the car begins to drive very slowly, and characteristic jerking can be observed. Error p2008 indicates that the intake manifold length change valve is not working correctly.

On which cars is this problem most common?

The problem with code P2008 can occur on different machines, but there are always statistics on which brands this error occurs more often. Here is a list of some of them:

- Audi (Audi a4, Audi a6, Audi q7)

- Chevrolet (Chevrolet Captiva, Cobalt, Cruze)

- Chrysler (Chrysler Pacifica)

- Dodge (Dodge Journey)

- Ford (Ford Galaxy, Mondeo, Focus, C-Max, S-Max)

- Jeep

- Land Rover (Land Rover Freelander)

- Mazda (Mazda 3)

- Mercedes

- Nissan (Nissan Beetle, Note)

- Opel (Opel Insignia, Corsa)

- Skoda (Skoda Octavia)

- Ssangyong (Sanyeng Aktion, Kyron)

- Subaru

- Toyota (Toyota Avensis)

- Volkswagen (Volkswagen Jetta, Passat, Touareg, Tiguan)

- Volvo (Volvo s40, s80, v50)

With fault code P2008, you can sometimes encounter other errors. The most common ones are: P0010, P0243, P0245, P0444, P200A, P2004, P2011, P2015, P2017.

How to fix the problem

The most correct solution when error p2008 occurs on a second-generation Ford Focus is to replace the corresponding valve.

However, the original part is quite expensive. Is there any way to save money and find an alternative? Fortunately, repairing this breakdown can cost pennies. The fact is that you can find a suitable valve in a VAZ spare parts store. For example, a similar part from the “five” fits perfectly on the second generation Ford Focus. Its cost ranges from 100 to 120 rubles.

After this you need to start replacing. You can do this yourself if you have minimal skills and knowledge. If there is no repair experience, then it is better to ask someone you know to help.

So, the work to replace the valve looks like this:

- open the hood and remove the engine cover;

- on the right side of the power unit near the shield the part we need will be located;

- remove the silicone tubes and terminals from the block;

- remove all fastening nuts;

- disconnect and pull out the valve block.

Now you need to proceed directly to the replacement. If the valves fail, both of them must be replaced. When only one valve is broken, the second one can be left in place. In order to check the serviceability of the part, it is necessary to connect power to the valve. If a click appears, then everything is in order. The absence of any sounds indicates that the valve can be discarded.

So, we unscrew the old valve and prepare a new one for installation, which must be purchased in advance at the Zhiguli store. In order to connect the new valve, you need to remove the wire chip from the old part and solder a small wire to it. You need to attach a couple of terminals to it. Next, the resulting structure needs to be wrapped with heat shrink for the wires.

This completes the replacement of the faulty valve. Next, you need to assemble everything in reverse order and put all the parts in place. First, the block is installed, and silicone tubes are connected to the valves. We carry out all the other work and install the engine cover. After this, you need to start the engine and let it run for a while. The check can be removed from the dashboard by resetting all errors. Thus, you can quickly and inexpensively solve the problem associated with the appearance of a malfunction in the 2008 Ford Focus 2.

Interesting read:

- Replacing steering rods for Ford Focus 2.

Problems in the service menu on older cars are common. Some codes indicate the need for powertrain control tests, while others indicate serious problems. P2008 error Ford Focus 2 is one of the chronic diseases of cars of previous years equipped with a 1.8 liter gasoline engine. In this article we will find out what the P2008 error is and what its symptoms are. We will give recommendations for “technical treatment”.

Features of self-diagnosis

Owners of Ford cars can independently diagnose their car; the on-board computer was created for this purpose so that they can understand what trouble has happened to the car without opening the hood. But self-diagnosis also involves a certain risk due to the fact that the test is carried out by a computer. Electronics also break down, glitch and freeze. No one can give a 100% guarantee that the computer will do its job correctly and will not let the driver down when testing the car.

This does not mean that you need to go to a car service center in any case, as soon as a problem arises. Diagnostics performed by professional technicians usually come at a cost to the driver. And it doesn’t always turn out to be so obligatory.

Just keep in mind - if the computer shows a breakdown that you are sure does not exist, do not rush to buy a spare part. As we said, testing is a hint, not a guaranteed answer.

Signs of errors

Simple mistakes can appear at an early stage of the “disease” and not pose a serious threat. It is worse when the symptoms of the disease are hidden. The fact is that problems associated with the exhaust manifold flaps may not manifest themselves consistently. This state of affairs is due to the design feature of the IMRC vacuum valve.

Signs of a malfunction include:

- Regular loss of traction.

- Loss of dynamics: engine speed drops.

- The Check Engine light may come on intermittently.

- A slight increase in gasoline consumption, however.

- Jerks when hot are possible.

On a note! In all cases, including Ford Focus 2 cars with a 1.8 liter engine, the culprit is one of the 2 IMRC vacuum valves.

Unfortunately, upon visual inspection it is impossible to say that the valve has failed. Problems may be indicated by a clicking sound when removing the terminal block.

In this case, the ignition must be turned on. This is more of a folk method than one of the diagnostic methods.

What does error P2008 mean?

This error indicates a malfunction in the control circuit of the solenoid valve for changing the geometry of the engine intake manifold.

Symptoms of malfunction:

- Reduced engine thrust

- Drop in speed

- Jerking on a hot engine

- Increased fuel consumption

- Incorrect idle speed

There are two such valves on Ford Focus 2 cars. As a rule, one of them fails, but in some cases it happens that both at once. To check them, you need to remove the tube from it with the engine running. If air intake does not occur, the valve is considered faulty.

The price of a valve for changing the geometry of the intake manifold is around 4,000 rubles. It's quite expensive, especially if you change both. We recommend not to do this, as there is a more budget-friendly solution.

How to fix error p2008 on Ford Focus 2

If problems arise, specialists and service center technicians recommend replacing the failed valve. Owners of second-generation Ford Focus cars need to know that a vacuum valve is expensive. Having discovered the problem - error code P2008 using a multimeter, you can save on purchasing an expensive original part. You will need to buy a similar part from the fifth model Zhiguli from a spare parts store. It will cost you about 120 rubles, no more.

You can do the replacement yourself. To do this you need:

- Open the hood of the car and remove the power unit cover.

- The part is located on the right side of the motor.

- You will need to remove the silicone pipes and terminals from the problem unit.

- Loosen and then pull out the fastening nuts.

- Disconnect and remove the valve block.

Replace the failed valve. To do this, you will need to remove the chip from the wires of the problematic part and solder a small wire to which you attach a couple of terminals. The assembled unit is wrapped with shrink film for the wires. Thus, the P2008 Ford Focus 2 2.0 error is eliminated.

Checking the operating condition is done using a multimeter.

Resistance values should be within 30-40 Ohms with a permissible upward deviation of no more than 70-80 Ohms.

Errors in the service menu on Fords of previous years are common. Some codes may simply indicate the need to test the engine management system, while some of them indicate serious problems. Many owners of Ford Focus II, C Max, Mondeo and a number of other models with a 1.8 liter gasoline engine note the appearance of error P 2008 when scanning the system. What is this, how to remove and reset the error, without spending too much on repairs and replacing expensive original spare parts, we’ll figure it out right now.

Diagnosis and problem solving

Perform a thorough visual inspection of all wiring and lines. Look for damaged, burnt, disconnected or corroded wiring or connectors. Make repairs if necessary.

Check all vacuum lines for cracks, splits, hardening or perforations. Make sure all connections are tight and all vacuum check valves allow air flow in the specified direction only. Make repairs as needed.

If the P2008 code remains but there is no visible wiring damage, test the resistance, ground, and reference voltage with a volt-ohmmeter. Compare all readings obtained with the values specified in the manual. To ensure that all electrical values are within the ranges specified by the manufacturer.

Check the position switch and replace it if necessary. Observe the vacuum drive to see if it holds vacuum. If the vacuum drops, albeit slowly, the actuator is faulty and needs to be replaced.

Clear all codes after replacement, test drive to see if the code returns.

If you have an electric drive, use a scan tool to command the dampers to open fully from the fully closed position several times. To check for an unstable condition. The displayed signal voltage should always be the same in both the fully open and fully closed positions, no matter how many times the system is activated by the scanner.

Once you've completed these steps, you'll almost certainly have your P2008 code figured out. But if the error persists, a faulty PCM may be causing the problem. However, PCM failure is an extremely rare occurrence and the most likely cause is an intermittent electrical problem.

What does error code P 2008 mean on Ford Focus 2

As we have already said, almost all 1.8-liter engines from Ford plants can issue error code 2008, not only on the second Focus. This applies not only to motors of this size, but the disease is mainly characteristic of them. In any reference book on error codes for Ford engines, you can find a decoding of code p2008: Intake Manifold Runner Control Circuit/Open. In Russian, this means that a problem has been identified with the intake manifold air damper control system.

Decoding the error code on the monitor

How to diagnose

First, turn on the ignition; do not start the engine. Hold down the button that resets the mileage. It is located on the dashboard of the car. This button must be pressed for several seconds and, continuing to hold it, move the key to the next position.

If you do everything correctly, “Test” will appear on the display.

As a result of such self-diagnosis, the computer will issue cipher codes that indicate certain breakdowns. Experts say it's not recommended to expect ultra-accurate results, but the test can be useful in many situations. If the machine is not working as it should, the first thing you need to do is diagnose it yourself.

Error P 2008, IMRC valve diagnostics

It will not be possible to visually determine the faulty valve, although when you reset the terminal block with the ignition on, you can navigate by the characteristic click. This is not a valid diagnostic method because the click may be weak. You can confidently talk about a non-working IMRC valve only if you check it with a multimeter in resistance measurement mode.

Multimeter readings for a faulty valve

The nominal resistance value for a vacuum valve is from 30 to 40 Ohms, the permissible deviation towards increasing resistance is a maximum of 70-80 Ohms. To measure, you just need to remove the terminal block by pressing the latch and install the tester probes on the valve contacts. A faulty valve must be replaced, although it can theoretically be repaired. To do this, you need to have a day of free time and a great desire to save money.

Normal valve resistance

Choosing an IMRC valve for Ford Focus, C-Max, Mondeo

Theoretically, to replace a valve, it is not necessary to buy the original, which costs a crazy 3-4 thousand hryvnia or $100-150 (a pair of valves on one strip). The original Ford valve code is 5243591. There are non-original valves with the same catalog number starting at $20. In addition, valves from Mazda L801-18-741 are excellent; they are three times cheaper and have identical parameters.

Mazda valve is perfect for Ford engines

Selecting valve analogues from third-party manufacturers

There are a number of analogues that are lower in price:

- HDE 57012001;

- ATS SEN43591;

- ERA 556131;

- Dorman 911-909;

- BWD IRS106.

Chinese analogues that are bought out of extreme need:

- Ruei RU13513FF2;

- ZZVF ZV13313;

- Dominant FO52043591.

Economy option.

VAZ valve Desperate and economical (or zealous) owners of second-generation Focuses sometimes use EPHH vacuum valves from the VAZ 2105 (does not work from 2107). The price, of course, is significantly lower and is available in every VAZ spare parts store, but complaints arise about the quality of work. In any case, no one is forcing you to buy an expensive original, although this is the most reliable option and guarantees that the error will be reset immediately after installing the new valve.

Interesting on the topic: Review of the 2022 Toyota Corolla sedan. All the details

Vacuum valve replacement

Replacing the valve takes a few minutes

. Replacing the valve with your own hands is absolutely easy; to do this, you just need to unscrew the bar with the valves, remove the contact blocks and, having previously marked them, remove the vacuum hoses. After this, you can start replacing. Reviews from owners often suggest that it is better to replace the valves in pairs, although the manufacturer is silent on this matter. After replacement, we reset the error by removing the negative terminal of the battery for 10-15 minutes.

Original Ford valve

After reinstalling the terminal and replacing the IMRC valve, the P2008 error will be cleared and normal engine operation will be restored. Good luck with all the repairs and full tanks of good gasoline!

Sources used:

- https://m.etlib.ru/blog/1273-oshibka-p2008-chto-znachit-prichiny-i-ustranenie

- https://fordprof.ru/focus-2/p2008-oshibka-ford-focus-2.html

- https://poliryi.ru/obsluzhivanie-i-remont/oshibka-r2008-na-ford-fokus-2-simptomy-i-sposoby-ustraneniya.html

- https://i-love-mycar.com/oshibka-p-2008-ford-fokus/