Share:

Engine coolant temperature sensor 405, 406, 409, 4213, 4216 (DTOZH) is the topic of this article. Here are the technical specifications, electrical diagram for connecting the engine coolant temperature sensor 405, 406, 409, 4213, 4216. Experimental data on the resistance of the coolant temperature sensor model 19.3828 are provided separately. The location on the engine where the DTOZH is located is indicated. Engine malfunctions caused by a breakdown of the DTOZh and methods for their determination are described. The replacement of engine coolant temperature sensor 405, 406, 409, 4213, 4216 is described.

- 8.1 — Checking the coolant temperature sensor using the self-diagnosis function;

- Video - replacing the coolant temperature sensor (DTOZH) on the 405, 406, 409, 4213, 4216 engine:

What temperature sensor is on the gazelle 405 engine

This article provides a complete description coolant temperature sensor - DTOZH. Its technical characteristics and electrical connection diagram are given. The location on the engine where the coolant temperature sensor . Engine malfunctions caused by a breakdown of the DTOZh and methods for their determination are described. The sequence of its replacement is outlined. With this material, studying the coolant temperature sensor will become much easier.

Crankshaft position sensor

DPKV is the sensor responsible for spark formation. It receives readings about the position of the crankshaft and transmits them to the controller, which sends a signal to form a spark in the desired cylinder. If the sensor fails, the car will not start.

Signs of malfunction:

- No spark;

- The engine does not start or troits;

- Loss of power;

Purpose and principle of operation of the engine temperature sensor

The device is designed to measure the temperature of the engine coolant at different times of the year, under different weather conditions and send its data, converting it into a unit of voltage, to the ECU. Thanks to DTOZH, the car’s computer starts the engine, keeps it in working condition, and turns on the fan for cooling. The information received from the coolant temperature sensor allows the ECU to determine the engine temperature and, using the program, calculate the required amount of fuel required to be supplied by the injector to the cylinders.

There are several types of engine coolant temperature sensors according to their purpose:

- DTOZH for supplying information to the temperature indicator on the instrument readout.

- Temperature sensor that supplies data to the electronic propulsion control unit.

- Device for emergency overheating of engine coolant. It sends its data to the red control light located on the engine temperature gauge.

- The coolant temperature sensor ensures the operation of the engine cooling fan.

- An air temperature sensor that supplies the computer with information about the temperature in the receiver of the injection engine.

The device is a semiconductor zener diode, powered by a constant voltage (5 volts) from the ECU.

The output voltage of the device changes with the temperature of the antifreeze. As the heat of the antifreeze increases, the output “U” of the device increases.

The operating principle of the DTOZH is the ability to change the resistance of the sensing element depending on changes in the temperature of the surrounding coolant. And naturally, this changes the output voltage coming from the device to the computer, which controls the operation of the motor. Using this data, the ECU calculates parameters for the operation of the injectors. Based on this, this is a very important device in the engine control system, especially during its startup.

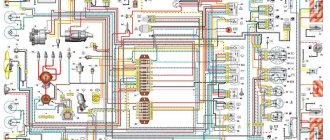

Various circuits depending on the engine

The ZMZ 402 carburetor engines were the very first to be installed on the Gazelle. For the operation of the internal combustion engine ignition system, it was necessary to supply power to the ignition coil, distributor and switch. The next one to enter the series was also in a carburetor version.

But it no longer had a coil, distributor and switch; instead, an electronic ignition control unit was installed.

Later, Gazelles began to be equipped with a ZMZ 405 injection engine, which instead of a carburetor had a distributed injection system.

This is what the ZMZ 405 engine looks like

The engine wiring on this engine is completely different - the control unit has become common to both the ignition system and distributed injection. have their own electrical circuit, and it differs depending on the type of internal combustion engine installed: Cummins or UMZ-A274. The Gazelle Next has been equipped with a new 2.7 liter engine since the end of 2014.

Where is the coolant temperature sensor (DTOZH) ZMZ 405 located?

The coolant (air) temperature sensor is designed to convert the engine coolant (air) temperature into DC voltage. Information from the coolant temperature sensor allows you to adjust the basic engine control parameters depending on its thermal state.

In addition, it allows you to adjust the basic engine control parameters depending on the air temperature in the engine throttle chamber.

The coolant temperature sensor (DTOZH) ZMZ 405 is a semiconductor zener diode, which is powered by a constant operating current from a stabilized source of the control unit; the output voltage of the sensor varies depending on the ambient temperature. As the temperature increases, the output voltage of the sensor increases.

Coolant temperature sensor device

This section contains complete information about the DTOZ of power units 405, 406, 409, 4213, 4216, located on UAZ and Gazelle vehicles.

Engine coolant temperature sensors have one or more output terminals:

- DTOZH device with one terminal:

- Device with two terminals:

- Temperature sensor with three leads:

- Engine Coolant Temperature Sensor with 4 Terminals:

The engine coolant temperature sensor consists of a metal housing, inside of which semiconductor temperature-sensitive elements are located. At the lower tip of the device body, inside at the ends of the metal rods, there is a thermistor. At the top of the device there is a plastic connection block with two output terminals in the form of flat plates. On the metal part of the device body there is a hexagonal projection for a 19 key. Under the hexagon there is a socket for a gasket. Below the gasket socket there is a thread M 12 x 1.5.

Replacing wiring

Advice: replacing functional control devices on the panel due to new connectors is not justified.

Therefore, when integrating new wiring, the connection diagram in the connecting terminals only changes, and for alignment you should use the wiring diagram of the new power unit.

It is certainly not impractical to change the entire electrical wiring of the Gazelle when replacing the engine from 402 to 406.

The fact is that on newer versions of Gazelles, the connection diagram of certain devices also changed:

Modifications of the coolant temperature sensor (DTOZH) ZMZ 405

According to all catalogs, the main sensor comes with the number 19.3828, but when I was faced with the fact that it was time to change it, it turned out that there were different sensors from the factory. I’ll say right away that I had 40.5226 in my receiver, and 19.3828 on the thermostat.

- Mikas 5.4, 7.1, SOATE, VS5.6 19.3828 - black 40.5226 - brown

- An analogue of these sensors is produced by LUZAR (LS 0306 406-3851010), Fenox (19.3828000), AutoTrade (42.3828)

- Mikas -11, SOATE, VS8 40.5215 - gray Analogues 234.3828 - black 421.3828 - black

All these analogs are suitable when replacing the original ZMZ 405 sensor.

Original solution

What if you don’t go shopping and waste time and money, but buy a donor car for disassembly? For example, Volga 3102 produced in 1999-2004. We don’t need fairly well-maintained cars in garage storage because of the high price; it’s better to focus on the remodeling budget, choosing the available options. You can still buy a donor car from the original owners at a reasonable price

Important! Since we are interested in the electrical part, it is quite acceptable to purchase a car with defects. And although we will not take everything, modernize

Technical characteristics of DTOZH

This section provides comprehensive technical characteristics of the coolant temperature sensor 19.3828 for engines 405, 406, 409, 4213, 4216, UAZ and Gazelle cars.

- Power supply 5-12 V

- I = 0.5-5.0 Ma

- Street heat spectrum -40 – +125 0C

- R = 24-27 kOhm

- It has a direct ratio of the exhaust U to the heat of the propulsion

- Its sensitivity is 10mV/0C

- Calibration data: -600C:2.13B – calibration violation, line failure

- -400C:2.33B

- -300C:2.43B – frozen engine

- -200C:2.53B

- 00C:2.73B

- +200C:2.93B – cooled engine

- +400C:3.13B

- +700C:3.43B – heated engine

- +800C:3.53B

- +900C:3.63B

- +1050C:3.83B – overheated propulsion

- +1250C:3.93B – calibration damage, communication failure

Engine coolant temperature sensor malfunctions

This section lists possible engine malfunctions caused by a breakdown of the DTOZH.

| Engine temperature sensor faults 409 | Remedies |

| 1. Increased speed of free rotation of the heated motor. The indicator lights up when the engine is running. Checking the ECU notes the failure code 21 or 22. | Check the integrity of lines 45 and 30D of the device |

| 2. Low or high level of the DTOZh signal. The check lamp lights up when the electrical power is connected. The ECU diagnostic itself notes fault codes 17 or 18. | Check the integrity of lines 44 and 30V of the air temperature device |

| 3. When the engine has cooled down, it will not start (it doesn’t matter if it starts). The check light does not light (there is no system failure) | The device is poorly configured. Check the setting and change the meter |

| 4. When starting the engine, the spark plugs are heavily flooded. The engine does not start. The DTOZH shows the engine temperature lower than the air temperature. | Replace temperature sensor |

| 5. When starting the engine, the spark plugs are dry. The engine doesn't catch. DTOZH shows a temperature higher than the air temperature. | Incorrect calibration of the coolant temperature sensor. Replace the device. |

Fault diagnosis

Checking the functionality of the sensor can be done in two stages.

According to external manifestations without dismantling

If the engine does not start at low temperatures, one of the reasons may be a breakdown of the DTOZH. The control unit does not receive information that the engine is overcooled and does not adjust the injection volume. The “Check” indicator on the instrument panel does not light up, since there are no problems with the system itself.

Detonation of a warm engine is also a possible symptom of a faulty temperature sensor. It will also cause an increase in idle speed.

If you have a measuring device, you should check the ECM error codes: indications of a DTOZ malfunction will be readings 21 and 22.

Instrument testing

The test is performed on the sensor removed from the motor using a milliammeter and voltmeter. The diagram shown in the figure is assembled:

The sensor is lowered into a container of boiling water, then at a given temperature (controlled by a thermometer), the voltage is measured. Its values should approximately correspond to the standard ones (temperature in degrees Celsius, voltage in volts):

- 100 — 3.73;

- 60 — 3.33;

- 25 — 2.98.

The part is rejected if the voltage on it is below 2.31 V (corresponding to a temperature of −60°C) or more than 3.98 V (readings for +125°).

Checking the ZMZ 405 coolant temperature sensor

Checking the coolant temperature sensor 19.3828. If codes 21 (low coolant temperature sensor signal level) or 22 (high coolant temperature sensor signal level) appear during diagnostics, assemble the sensor test circuit shown in Fig. 1. Using resistor 1, set the current in the circuit to 1...1.5 mA. Voltmeter 4 should show a voltage of 2.96…3.02 V at a temperature of +25°C. At a temperature of +90°C, the voltage should be within 3.6…3.7 V.

Theory

The main ambush for the client and the diagnostician lies in the following. On engines E-0, E-2, sensors come from the factory with a “square” connector, on E-3, E-4 with an oval connector. But that is not all. On E-0 and E-2, these sensors are also non-interchangeable and differ according to the type of ECU. But most importantly, DTOZH ZMZ 406, 405, 409 should be from Russian factories or brand manufacturers (Bosch). Relatively high-quality products are produced by two Kaluga and Autotrade. Sensors of glamorous pink color from Arzamas are “not that”. Sensors of all colors of the rainbow from the Middle Kingdom, “not at all.” What should be included according to the factory documentation:

- EURO-0, ECU MIKAS7.1 – DTOZH 19.3828, 42.3828 or 40.5226. The operating principle is a thermal diode. The sensor housing is black.

- EURO-2, ECU MIKAS-11VS8, SOATE – DTOZH 40.5215. Thermistor. The sensor housing is gray.

- EURO-3, EURO-4. Catalog number 40904.3828000. DTOZH 234.3828. Oval connector.

How to check the car engine coolant temperature sensor?

Possible methods for checking DTOZH are described in great detail here. To facilitate the study of verification methods, they are supported by photographs.

There are several options for checking the DTOZH:

- Using the self-diagnosis function built into the electronic engine control unit.

- On the motor;

- By removing the device from the car.

Checking the coolant temperature sensor using the self-diagnosis function.

This opportunity provided by the injection engine ECU must be taken advantage of first. To do this you need to do the following:

- On a muted power unit, you need to install a jumper between terminals No. 10 and No. 12:

- After this, turn on the ignition.

- The ECU turns on the self-diagnosis mode and displays code “12”. First, the “Check” light will blink once. This means the number “1”. Then there will be a short pause and the warning light will blink twice in a row. This means the number “2”. Code “12” will be repeated three times with short intervals.

- Then, after a short pause, the ECU will begin to display the fault codes in its memory. They will go one after another with a short pause. Fault codes are repeated three times. Their designation will be indicated by the signal lamp in the following sequence: one flashing number “1”; the number “2” blinks twice; three flashes the number “3” and so on. Each digit is displayed with a short pause. There is a longer pause between codes.

- If the computer detects a malfunction of the coolant temperature sensor, it will display the following codes:

Propulsion coolant temperature sensor errors 40900A: Error code Failure name 0116 The meter pulse goes beyond the allowed spectrum 0117 Low signal level DTOZH 0118 Instrument line signal high - If a malfunction of the DTOZH is detected, it must be replaced with a working one.

Checking the sensor on the engine

It is best to start checking with a cold engine.

- Measuring the coolant temperature

- We measure the resistance of the DTOZH, write it down

- We heat the engine to a temperature exactly noticeable according to the readings on the instrument readout (approximately 60oC)

- We measure the resistance of the coolant temperature sensor. Let's write it down.

- We do the same with another heating point.

- We compare the recorded data with the information in the table above. If the data differs greatly, it means the DTOZH is broken and needs to be changed.

Checking the coolant temperature sensor removed from the car

Using this method, you can more accurately perform measurements and, naturally, a more correct conclusion will be drawn about the DTOZH.

- Remove the coolant temperature sensor from the engine. Instead, install a plug or another sensor.

- Pour water into the vessel and place it on the heater.

- Place a thermometer in the vessel and heat the water to a temperature of 20oC.

- We measure the resistance at the sensor terminals and write it down.

- We do the same with two more control points.

- We compare the obtained readings with the data in the table: Certificate data resistance of the engine DTOZH.

Heat, Co Resistance, kOhm 128 0,08 100 0,177 90 0,241 80 0,332 70 0,467 60 0,667 50 0,973 45 1,188 40 1,459 35 1,802 30 2,238 25 2,796 20 3,520 15 4,450 10 5,670 5 7,280 9,420 -5 12,300 -10 16,180 -15 21,450 -20 28,680 -30 52,700 -40 100,707

If the data differs significantly, then the DTOZH has failed and needs to be replaced.

Detonation

Detonation is an unauthorized ignition of the air-fuel mixture in the cylinders of the power unit. If the engine operates in this mode for a long time, this can lead to high vibrations, as well as high loads on the internal combustion engine components. Ultimately, this contributes to more accelerated wear of engine parts, in particular, we are talking about the pistons of the unit, cylinder head gasket, rings, etc. The engine knock sensor is mounted on the right side of the BC; it itself is a piezoelectric regulator.

The main components of the device are a quartz piezo component, as well as an inertial mass. When an internal combustion engine is running, many of its components vibrate. Due to detonation, higher vibrations are formed in the system, as a result of which the voltage amplitudes of electrical pulses in the power unit sharply increase. The impulses themselves are transmitted to the ECU.

In accordance with the signals received from the controller, the ECU adjusts the ignition timing until the detonation stops. If the element itself or one of the electrical circuits breaks down, the ECU will notify the car owner about this via a light indicator on the dashboard.

How to check the oil pressure sensor

If you have any suspicions about the performance of the pressure sensor, do not be lazy to check it. This can be done both at a service station and at home. But in the latter case, you will need to purchase a special pressure gauge. It costs about 300 rubles, but such a thing will be useful in the future. In addition to this, you will also need a slotted screwdriver, a 22 mm wrench and electrical tape.

To check the functionality of the sensor, you will need a special pressure gauge

- We lift the hood and find the fitting with the sensors.

- Using a slotted screwdriver, unscrew the bolt securing the power wire terminal to the emergency oil pressure sensor. We disconnect the wire and insulate its end (so as not to cause a short circuit during testing).

- Using a 22mm wrench, unscrew the emergency pressure sensor.

- In its place we screw in the pressure gauge fitting.

- Turn on the ignition, start the engine, wait until it warms up to operating temperature.

- We compare the readings of the pressure gauge and the indicator. If they differ significantly, we change the sensor.

To check the pressure, you need to screw the pressure gauge fitting into the mounting socket of the emergency oil pressure sensor

Video: checking the oil pressure in the system

Other faults

However, a deviation in the pressure value can be associated with both wiring faults and problems with the indicator itself. Don’t be lazy to carry out additional diagnostics. Her order is as follows.

This is interesting: How to burn a disc for a radio: formats, media types, common problems

Turn on the ignition. The pointer arrow should deviate to the right and then return to its original position. If the arrow does not deviate, use a slotted screwdriver to unscrew the screw securing the sensor power wire, disconnect it and touch ground. The arrow has deviated - there is a short circuit in the sensor's power supply wiring. If not, the problem should be looked for in the pressure indicator.

What is needed for remodeling

If you modernize it, it will be completely, including the injector, and for this you should take a closer look at the Digitronic gas-cylinder equipment. This HBO is praised by many, and it can be installed on Gazelle.

Many people know about the economical consumption of a car with LPG.

But there is one significant nuance - to equip a car with Digitronic, you need an injection engine, “tuned” to Euro-2 toxicity standards.

And then, modifications for the injector will not end there, because the following components and parts will be needed:

- The injection wiring on the Gazelle - 406 engine does not have it, not to mention the control unit;

- Intake system, including the manifold itself with the injector ramp, throttle position sensor, throttle pipe, idle air control and additional air regulator, connecting pipes and pipes;

In the photo - a diagram of the electrical equipment of the gasoline version of the ZMZ 406

Note! Wiring for Gazelle 406 is also available at disassembly sites. But its performance and reliability cannot be guaranteed.

- Injection camshafts. This point is controversial, since it is quite possible to leave carburetors on the car. The main difference between them is the lifting height, which affects the power;

- Electric fuel pump together with a fine fuel filter;

- Mass air flow sensor with connecting pipes;

- Air filter housing with bracket;

- Electric fan (but not required).

Replacing the engine coolant temperature sensor.

This section describes in great detail the sequence of replacing the DTOZH. Each operation is illustrated with a photograph.

- Loosen the nut with a 13mm wrench and remove the minus terminal from the battery

- Remove the terminal block from the temperature meter. On the ZMZ 409 engine, to do this, you need to press the locking spring and remove the terminal block.

- Before unscrewing the old coolant temperature sensor, you need to prepare a replacement. Place it nearby so that you can take it quickly without searching.

- Using a 19mm wrench, unscrew the old sensor:

- The engine coolant temperature sensor is being replaced with a new one.

- To do this, after removing the old device from the socket, immediately insert a new one, prepared in advance. We tighten it with a 19 key until it stops.

- We put the terminal block on the device:

- We connect the minus terminal of the electrical network to the battery: