What is a coolant temperature sensor (CTS)

An example of the appearance of coolant temperature sensors for various cars.

The coolant sensor is a small device that determines the temperature of the coolant in the system. When it heats up, it sends a signal to turn on the fan to reduce it.

The main thing the coolant temperature sensor is responsible for is turning on the fan. If it is faulty, the fan will not turn on. Accordingly, the antifreeze may boil and the engine may overheat.

On injection engines, an incorrectly working (or not working at all) sensor will lead to the fact that the ignition timing will be set incorrectly by the electronic control unit, more fuel will be consumed, and the load on the engine will increase.

In addition, this device has other, equally important functions, the performance of which determines the performance of the engine as a whole. Therefore, a malfunction of the coolant temperature sensor affects many things, which means it needs to be found and repaired in a timely manner.

Purpose of the device

DTOZH should not be confused with an antifreeze level controller. If the first is intended to detect the temperature of the power unit, then the second is used to control the volume of consumables - refrigerant. Based on the DTOZH readings, the control unit detects temperature changes and transmits data to the on-board computer about the state in which the engine is operating. Using the controller, engine warm-up, overheating, and the optimal temperature of the operating internal combustion engine are determined. Pulses transmitted to the control module determine the functionality of the internal combustion engine control system as a whole.

The engine temperature determines the following nuances:

- fuel consumption per 100 km;

- volume and quality of gases;

- ignition of the air-fuel mixture;

- optimal operation of the gearbox.

All these factors are controlled by a control device, which, based on the information received, determines the optimal operating mode of the engine. Therefore, the performance of the temperature sensor is important for the vehicle. If the device is faulty and sends incorrect pulses to the control module, this can lead to problems.

How does DTOZh affect the operation of the internal combustion engine?

Based on the parameters supplied to the control device, the module performs the following functions:

- Enrichment of the air-fuel mixture or its depletion. If the controller detects that the temperature is too low, it will begin to increase the duration of the signal sent to the injectors, which helps to enrich the fuel mixture. In accordance with the normalization of the temperature regime, the fuel is gradually depleted, which prevents possible excessive consumption of gasoline and reduces the volume of exhaust gases. If the sensor breaks down, it can regularly lower the temperature in the engine, which will lead to fuel contamination and increased consumption.

- The control unit sets the ignition. It can be early or late. If the temperature increases, the control module adjusts the ignition timing to reduce exhaust toxicity.

- Thanks to DTOZH, proper recirculation of gases is performed during warming up. The recirculation valve closes tightly when the power unit warms up. If the car’s engine is still cold, then recirculation will cause fluctuations in idle speed and random engine stops.

- With the help of DTOZH, the control unit purges the filtration system, which traps fuel vapors. To achieve better machine controllability, the carbon filter element is not purged until the engine is completely warmed up.

- Locking of the gearbox torque converter when the internal combustion engine warms up. The control module should not limit the operation of the device until the machine warms up.

- The ECU controls the operation of the unit's cooling fan. Based on the temperature controller readings, the module activates and deactivates the ventilation device to correctly select the temperature of the unit. If the DTOZ gives incorrect impulses, there is a possibility of the motor overheating.

We recommend: Replacing rear brake pads on VAZ-2110, 2111, 2112

Main tasks and functions of DTOZH

As a rule, the system contains several coolant temperature sensors - from two to five. In a standard scheme with two, one is responsible for the operation of the fan, and the second transmits data to the control panel. Additional coolant temperature sensors are used for other purposes.

Generally speaking, here are the main tasks facing the coolant temperature sensor:

- Fuel enrichment. When the coolant temperature is low, the sensor sends a signal to the control unit. As a result, fuel injection increases. This is necessary for the engine to operate stably at idle speed. Conversely, as the temperature increases, the injectors reduce fuel injection. If the sensor does not give a timely signal about the increased temperature, then as a result the fuel becomes over-enriched. This is extra fuel consumption, effort expended on it, and exhaust pollution.

- Increasing the number of revolutions at startup. This is necessary so that the engine does not stall at the start.

- Adjusting the exhaust recirculation valve. During engine starting, this valve must be closed before the system reaches normal operating temperature. Otherwise, the machine will work unstably or even stall.

- Setting the ignition angle. Fuel consumption, the amount of harmful emissions, power plant parameters, etc. depend on the correct or incorrect ignition angle.

In addition, to one degree or another, the coolant temperature gauge sensor is responsible for the condition of the filter that captures fuel vapors, and also prevents the torque converter clutch in the gearbox from blocking until the engine is completely warmed up.

And of course, one of the most important functions is turning on the fan to cool the antifreeze. Often, modern cars use a dedicated sensor for this function that does nothing else. The remaining functions are assigned to others.

Like a boat

The service life and frequency of maintenance of ship engines or generator sets are assessed in engine hours, and not in the kilometers familiar to motorists. But why track the engine hours of cars? This makes sense when the mileage is short and the engine works a lot - at low, below 15 km/h, average speed. In other words, this is driving in traffic jams or with prolonged idling (idling). Motor oil ages faster and needs to be changed more often. It is undesirable for the engine to run for more than 300 hours on one oil fill; an hour meter will help with this.

The price of the device is 300–350 rubles in the “counter only” version and 400–450 rubles if the counter is combined with a clock. Installation is extremely simple: we connect the meter to two wires on which voltage appears when the ignition is turned on. The result is shown with an accuracy of one hour by seven-segment indicators. There are other types of hour meters - with mechanical drums, like the odometer in old cars, and with liquid crystal displays. The price of these and other devices in the “marine” version exceeds 1000 rubles.

The hour meter is connected to the “minus” and “plus” after the ignition switch. This quite aesthetic device with an LED indicator begins to give readings immediately after starting the engine.

The temperature meter can be designed for outside air or for the engine.

Where is DTOZH located?

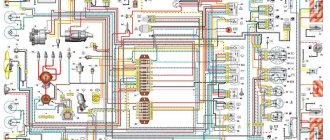

Location of the coolant sensor in the VAZ 2111, 2110

The location of the coolant temperature sensor is not known to every driver. But since it is not so difficult to change it yourself in the event of a breakdown, it will be more profitable to know these places. They are located in the radiator housing or in the “jacket” of the cooling system. The exact location depends on the make and model of the car, but there is one thing in common: it is installed close to the thermostat so that the result is as accurate as possible.

Here are the main places where the coolant temperature sensor may be located:

- thermostat housing;

- cylinder head;

- upper radiator hose.

It makes no sense to place the device far from the thermostat and the above-mentioned components. If located at a remote location, it will not be able to transmit data accurately. The resistance of the DTOZH directly depends on the heating of the motor - the higher the temperature, the higher the resistance and vice versa.

Installation on the engine

Making a sensor for an alarm with your own hands is still half the battle. You need to install it correctly and connect it to the system. In order for the thermistor to show the engine temperature as accurately as possible, the best place for it is the cylinder block.

The latter cools down later than all other parts, so the signal to turn on the starter will arrive in a timely manner. With a different arrangement, the system mistakenly believes that the engine has already cooled down and will start it more often, which leads to excessive fuel consumption.

The easiest way to mount your sensor is on the thermostat or radiator pipe. In the first case, it will show a more realistic temperature, in the second, it will be easier to connect in parallel with the hood closing sensor. The fastening method is the same:

- attach the homemade thermistor to the metal surface of the pipe;

- secure it with electrical tape;

- insulate the outside with heat-insulating material and fix it with the same electrical tape.

The proprietary sensor should be installed on any metal part of the engine (cylinder block, cylinder head, valve box cover) where there is a protruding pin with an M6 thread. If there are none, you can make a transition piece and secure it into the blind threaded hole of the eye bolt.

Types of coolant temperature sensors

There are two large types of DTOZH:

- mechanical;

- digital.

The mechanical coolant temperature sensor is simple and acts directly. Using electrical signals, it transmits resistance change parameters to the temperature indicator on the instrument panel and to the relay that turns on the fans. Such devices are installed on carburetor engines, for example, on old domestic cars.

Digital sensors are used in modern cars with injection-type engines. Outwardly, it is similar to a mechanical one, but the operating principle is different. The signals it reads are not sent directly to the fan and the scale on the parting panel, but to the electronic control unit. The processor located on the block analyzes all the signals and decides where to send them next.

DTOZH are also divided into magnetic, bimetallic and capillary. It is easy to distinguish the first from the second. The arrow of the magnetic indicator oscillates and “bounces” when displaying values, while the bimetallic one moves smoothly and gradually. Capillary ones are not used anywhere today.

Algorithm of actions

At the service station, mechanics will do the work following the procedure. Remove the sensor from the engine, immerse it in liquid, changing it using

diagnostic equipment, its temperature. Heated water for a working sensor shows a voltage decrease of 2.5 Volts over 5 minutes. A different result obtained serves as a condition for disposing of the sensor and installing a new one.

It is reasonable to check the mechanical cooler, that is, the fan, at a service station. The car engine begins to boil due to his fault. Let the experts check at what above-zero temperature the fan turns on and off.

Operating principle of the antifreeze temperature sensor

The operating principle of the coolant temperature sensor is based on the physical properties of the material from which it is made. The working element of the device is sensitive to heat; in addition to it, the device also contains electrically conductive contacts.

So, its resistance changes depending on the temperature, the data is recorded and transmitted further. As was already written above, for mechanical DTOZ the signal is transmitted directly - to the scale on the dashboard and the fan relay, and for digital ones - to the electronic control unit, which already distributes the signals and sends them to their destination.

How to connect the power connector of the central unit with six contacts?

- The red wire is the plus of the 12 Volt power supply. The wiring connection must be made to the place with the positive terminal of the battery.

- The yellow wire is the output to ignition supply Number 1. It must be connected to the place where the ignition terminal is located (IGN1; 15 to 1). Ignition control, inlet.

- The green wire is the accessory activation control output. It must be connected to ACC (Accessories terminal), located in the ignition switch.

- The blue wire is an additional control input hole. The blue wire must be connected to the correct terminal located in the ignition switch. The terminal is selected in relation to the output functioning algorithm or to the brake pedal for cars that have a start button. When it becomes necessary to measure polarity, an auxiliary relay should be used.

- The black and yellow wire is the input channel for manipulating the starter blocking function when activating the starter's security and protective modes.

vote

Article rating

Signs of a malfunctioning coolant temperature sensor

Since the DTOZH is responsible for many functions in the car, its malfunction will lead to various problems in the operation of the entire system. Here are some signs of a malfunctioning coolant temperature sensor:

- instability of engine operation - troits, stalls;

- idle speed range from 200 to 1500 per minute, sudden jumps;

- difficulty starting the engine;

- sudden turning on of the cooling fan in cold weather;

- unreasonable increase in fuel consumption;

- dark, black smoke from the exhaust pipe.

These alarming symptoms may also indicate other problems in the car, but the first thing you should pay attention to is the sensor.

Diagnostics and troubleshooting

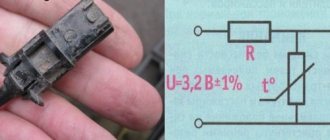

In practice, temperature sensors for automotive power units are structurally simple. There's nothing to break there. The electrical wires connecting the sensor to the ECU can affect the operation. Wires that have become oxidized and stuck together due to overheating will show incorrect values.

We should not forget about the prolonged heating of semiconductors. It is observed among German manufacturers whose cars are equipped with turbocharged engines.

It is not difficult to detect faulty temperature sensors. In 90% of cases, the cause is discovered by visually inspecting the power plant. The fault can easily be found in the electrical wiring connections. Distorts the passage of current due to oxidation and deposits. Simply remove it and the sensor will begin to give correct readings.

If corrosion spots are found, the wires should be cleaned. Microscopic cracks in the sensor body will certainly lead to errors in its operation. There is no point in repairing the sensor. Replaced with a new one.

But there are breakdowns that can be repaired at service stations (service stations). These include:

- The device located on the panel is faulty. Shows the coolant temperature as if it were receiving data from a working sensor.

- The engine does not want to start despite the summer heat outside.

- The dashboard shows excessive fuel consumption and high carbon dioxide content. Informs about catalyst malfunctions.

- The engine overheats when the forced radiator airflow is turned on.

These are the moments where the help of qualified workers with special diagnostic equipment is mandatory.

The main causes of DTOZh malfunction

There may be several reasons for the failure of the DTOZ. Here are the main ones:

- Poor quality refrigerant. Poor coolant leads to the formation of plaque, deposits, and corrosion in the cooling system. If the main working element of the sensor becomes covered with plaque, this will deteriorate its quality. As a result, incorrect signals will be given. For example, the coolant temperature sensor readings are lower than they actually are. This leads to the fact that the fan will turn on at the wrong time, and the engine will overheat.

- Poor quality sensor. If the first reason does not occur very often in reality, then the poor quality of the device itself - alas, quite often. On sale you can find sensors from unknown manufacturers. And the factory ones, similar to those installed on a car from the assembly line, for some reason last several times less.

- Radiator leak. It can occur as a result of a broken thread or a loose sensor. The thread can be stripped quite easily, since the metal of the radiator is quite soft. But you shouldn’t under-twist either. Leaks can also be caused by worn gaskets.

- Electrical failures. This reason will cause the sensor to malfunction. And anything can cause it: from oxidized contacts to a power surge.

The operation of the DTOZh is also directly affected by the thermostat. Any failures or malfunctions in its operation can lead to incorrect operation of the sensor too.

Examination

You can check the performance of the DTOZH yourself. But before removing this element, you should check the following:

- Check the electrical connection. Often the contacts can be dirty and oxidized. In this case, you just need to clean the contacts with sandpaper.

- Check the wires coming from the device. If a break in one or both wires is detected, repair the fault using the usual connection followed by isolating the connection point.

- Using a tester, check the integrity of the fuses. If a faulty element is detected, replace it with a functional one.

If the described malfunctions are not found, it is necessary to start checking the DTOZH itself. To do this, it must be dismantled. It is worth remembering that when dismantling this element, coolant will leak.

To dismantle the sensor you must:

- Allow the engine to cool.

- Disconnect the “−” terminal from the battery.

- If necessary, drain some of the antifreeze.

- Disconnect the connector from the sensor.

- Unscrew the part using an open-end wrench to “19”.

Before checking the element for malfunction, it must be cleaned of dirt and inspected. If cracks are detected in the housing, the part cannot be repaired - it must be replaced with a new one.

There are several types of DTOZH inspection. All of them are based on determining performance by resistance.

Method 1

It is based on a conventional resistance test. This method will only indicate that the element does not have an internal short circuit, or that the thermistor is not damaged. The test begins by connecting the tester probes to the terminals of the device under test. Optimal data can be considered indicators from 9400 to 5600 Ohms. It is also worth checking the sensor for a short circuit in the housing. To do this, you need to set the tester to dialing mode. Next, one probe of the tester is connected to the body, and the other in turn to each sensor terminal. The absence of a reaction from the tester will indicate the integrity of the element.

Method 2

This method is the most accurate performance check. To carry out the test, you will need a container of water, two wires, a regular home thermometer and a tester. First you need to connect the prepared pieces of wire to the sensor terminals. This can be done using twisting or a soldering iron.

Next you need:

- Place a container of water on the stove.

- Place the sensor and thermometer in the container.

- Connect the sensor leads to the tester terminals.

During the test, the tester must be set to resistance determination mode. As the water in the container gradually heats up, the resistance of the sensor should change. The tester readings must be checked against the temperature of the thermometer. The exact ratio of the readings must be checked with the table below.

It should be remembered that such a test without using a thermometer will not show the correct data, since only resistance information will be given. A faulty but functional sensor installed after such a test will produce false data to the ECU.

If the device showed correct data during the test, it is recommended to check other elements that are part of the cooling system and determine the engine temperature.

How to check DTOZH

Checking the sensor with a multimeter

The easiest way to check the coolant sensor is with a multimeter. Before you begin, it should be noted that different cars will have different resistance ratings at low and high temperatures. Therefore you need to know him. The vehicle manual will give you the exact answer.

The verification procedure itself is extremely simple. The sensor needs to be unscrewed and a multimeter connected to its contacts. Heat the water to a certain temperature specified in the manual (this is necessary so that you have something to compare it with), and lower the device into it.

If the indicator does not coincide with what is indicated in the manual, then the problem is in the sensor. If it matches, it means it’s working properly and the electronics or thermostat are to blame.

Replacement, including with your own hands

If you have accurately determined that the sensor has failed, then replacing it is not so difficult, even for an inexperienced driver. As a rule, its body goes under the “nut”, so it simply unscrews from its place. There are also plastic options that sit on two small bolts (however, this is rare).

Before changing it, you need to:

1) Disconnect the battery, this is mandatory to avoid ECU errors.

2) Drain “a little” of the coolant, as a rule, to the level of the sensor; at many service stations they simply unscrew it, some of the liquid comes out - then (after replacement) they add it to the level as needed.

3) Disconnect and remove the cable so as not to get it wet.

Afterwards we simply unscrew the sensor, usually it is a key either 13, 17, rarely 19.

We screw another one into this place - we tighten it, but not too much (and as the experts say, “tightly”, the main thing is not to break it), as a rule, rubber gaskets come with it.

Then we wipe off the stains, add coolant to the required level, connect the power and battery, start the car and check the operation. A very simple check, try to warm up the engine, then the sensor should turn on the cooling fan. We try to drive, sharp accelerations, as well as starting and stopping the engine - this needs to be done 3 to 5 times.

In conclusion, guys, the sensor is a simple but very important element; in my practice, there were several cases when the engine overheated precisely because of its malfunction. It costs a penny, and it’s not difficult to replace it yourself! Therefore, if signs of overheating begin to appear and the engine is not running stably, the first thing after the liquid level in the tank is to look at the sensor! Don't delay - engine repairs are very expensive!

Now let's watch a short video

That's all, sincerely your AUTOBLOGGER.

Similar news

Not found.