It should be noted that if the car is moving at high speeds, there is, of course, no particular need for a working fan. But as soon as the speed of the car decreases, and also when the car is idling, you simply cannot do without a fan.

This device turns on automatically as soon as it receives a signal from the electronic control unit. This signal is based on data received from a temperature sensor, which is triggered when the coolant temperature rises to 103 degrees.

Finding possible causes of fan malfunction

The search for possible reasons why the fan on the VAZ-2114 does not work must first begin with the fan itself. To do this, disconnect the fan connector and connect it directly to the battery terminals, while maintaining the polarity. If the fan starts working, it means that it is fully operational and the reason lies in something else.

But if the fan still does not turn on after the above manipulations, you should check the condition of the sensor contacts and whether the wiring is intact. If in this case everything turned out to be fine, it’s time to check the fan relay and fuse. Both of these parts are located under the hood of the car, closer to the driver's side in a special mounting block.

It should be noted that fuses 20A and F4, responsible for the fan and sound signal, are double on the VAZ-2114. Therefore, if the reason for the fan not working lies precisely in the fuse, then the sound signal will not work. You can check the functionality of the fuse using the most common automotive tester.

But, unfortunately, you will have to tinker with the relay.

In order to confirm or rule out the relay problem, you should acquire a similar device that has been tested for performance. You need to temporarily install it in place of the old one and check whether the fan starts working. If in this case a miracle did not happen, we move on to inspecting the sensor.

After de-energizing the sensor, the fan should start in emergency mode and provide constant airflow. To do this, disconnect the sensor from the connector and turn on the car ignition. If the fan finally starts working, this indicates a sensor malfunction. The latter, by the way, cannot be repaired, which means it can only be replaced.

Replacement

Tools:

- socket wrench 10;

- socket wrench 8;

- screwdriver with a Phillips bit.

Execution order

- We park the car on a flat surface and immobilize it with the parking brake.

- Open the hood and disconnect the negative terminal.

- Using a 10mm wrench, unscrew the fastenings of the air filter housing.

- Using a screwdriver, loosen the air duct clamp on the air flow sensor and remove the corrugation.

- We unscrew the screws securing the cover of the air filter housing and remove the filter element.

- Using a size 8 wrench, unscrew the air intake mount and remove it.

- Using a 10mm wrench, then an 8mm wrench, unscrew the nuts securing the fan casing around the perimeter (6 pieces in total).

- Disconnect the wire block on the fan connector.

- Carefully remove the fan casing along with the drive.

- Using a 10mm wrench, unscrew the 3 bolts holding the electric motor to the casing.

- We put a new one in its place.

- We install the structure in place, fix it, and connect the connector.

- We carry out further installation in the reverse order.

When do you need to change the fan on a VAZ-2114

If the reason for the non-working fan lies in the fan itself, you can still try to repair this part. As a rule, the problem lies in the bearings. But sometimes it also happens that due to a break in the windings or a short circuit, the fan motor itself fails. If this happens, then it is better not to try to repair anything, but to replace this part.

By the way, driving a car with a non-working fan is strictly prohibited. As a result of this action, the coolant can warm up significantly, which will lead to complete destruction of the pipes and rubber hoses. Driving a short distance with the fan not working can also cause the cylinder head and valve cover gaskets to fail. But that's not all. Overheating of the engine can also destroy some elements of the piston group.

Operating principle of the cooling system

The cooling system on a car is a closed pipeline in which a special liquid circulates. It constantly transfers heat from the running engine to the radiator, where cool air lowers its temperature.

In hot weather, when driving slowly or during stops, without stopping the engine, the power plant may overheat. To avoid this trouble, the VAZ-2114 injector has an electric fan, which is turned on automatically by a special sensor when the engine reaches a critical temperature. On the model under consideration, the response threshold is 85 degrees. When the engine cools down, the thermostat stops the forced airflow.

The location of the fan on the VAZ-2114 injector is the engine compartment. It is screwed to the inside of the radiator. The unit in question consists of a blade and an electric motor enclosed in a frame casing. It is supplied with power and, indirectly (via the ECU), a temperature sensor.

What to do if the electric fan runs constantly?

Sometimes another problem arises. Many car enthusiasts are interested in why the fan on the VAZ 2114 is constantly running?

There are four possible causes of the malfunction:

- a short circuit has occurred in the electrical circuit;

- the electric fan relay has broken down;

- The temperature sensor needs to be replaced;

- The electronic unit is broken.

Most often, the fan starts to work continuously as a result of a shorted wire. The electrical circuit remains on regardless of the signals from the temperature sensor and relay.

To troubleshoot the problem, you need to ring each wire and find the fusion point. Sometimes it is noticeable even upon visual inspection.

If ringing does not help identify the malfunction, you need to check and replace the fan relay. The cost of the device is low. Therefore, for diagnostics it is easier to buy a new relay and install it in place of the old one.

If this does not help, then you need to check the operation of the temperature sensor. After all, it is he who is responsible for turning on and off the electric motor of the VAZ 2114 fan.

If all other elements of the system are working properly, you need to check the electronic module. It rarely fails. If the problem still occurs there, you will have to perform a complete error reset. Sometimes only a complete flashing helps. Not everyone can do this work on their own. Therefore, it is better to seek help from a car service center.

It would also be useful to install a button to force the fan to start and turn off on the VAZ 2114.

This solution can be very useful if the breakdown occurs somewhere on the highway far from the city. In this case, using the button on the instrument panel, you can force the fan to cool the engine.

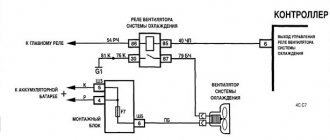

All cars with an injection engine have an electric fan, not a mechanical one. With mechanics, everything was simpler... The fan motor is connected to the network through a relay, and the signal to this relay is supplied by the ECU . Additionally, there is a fuse in the motor circuit, and the antifreeze temperature sensor (ATS) is connected directly to the ECU. If the cooling fan does not work, you can do one trick on the VAZ-2114: turn off the DTOZh sensor and start the engine. And if the fan starts spinning, the problem must be looked for in the sensor.

To avoid having to examine the wiring inside and out, just watch one video. Everything here has already been done.

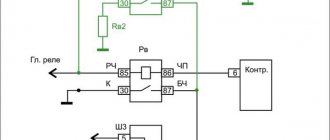

Electric circuit

So, you have made sure that the propeller itself is spinning, that is, the directly connected motor is working. In this case, it is necessary to do the wiring, inspect all connecting blocks and terminals for poor contact.

The first thing you should pay attention to is the fuse. A 20 ampere protective device is installed on the VAZ injector discussed in this article. It is not difficult to find it - look in the block located under the hood - the one designated as F4 is responsible for the fan. In fact, the device rarely burns out, since it does not experience constant high loads. It is very simple to make sure that the element is in good working order - turn on the ignition and press the horn. The signal is also fed through F4, and therefore, if it burns out, you will not receive sound.

Conclusions: what exactly should be done if the fan does not work (action algorithm)

First, check whether the “plus” is connected to one of the terminals in the connector. Then connect the connector from ground to check the serviceability of the electric motor. In some cases, you can observe this:

- Both fuse F5 and the additional fuse are working;

- The fan relay operates as expected;

- The DTOZh sensor is working;

- The motor can only be turned on by applying a potential of “0 Volt”.

There will be only one conclusion: the ground contact has come loose, which ends the entire power line. This means you will need to contact an auto electrician. All other faults can be overcome by yourself.

Element F5 may burn out as a result of the horn closing. But then “+12” is not called up on the connector, which should immediately alert you.

Using an electromagnetic relay

Using a simple relay will slightly complicate the circuit, but will relieve the temperature sensor from the presence of high current. A large current will flow through the relay contacts. It is cheaper and easier to replace the relay than the temperature sensor to turn on the electric fan. To carry out the upgrade, you will need a wire and a relay with a bracket for mounting to the body.

Disconnect the temperature sensor, and the wires that were on it must be connected to the normally open pair of contacts of our relay. Half the job is done, the power part is ready. Now control. We connect one terminal of the temperature sensor to ground, but connect the second to the relay coil.

From the second terminal of the coil you need to stretch the wire to the positive terminal of the battery. It is advisable that the connection be made through a fuse, the operating current of which can be 1 Ampere. The coil consumes a small amount of current, so the worst thing that can happen is a short circuit in the wiring. Subsequently, you can connect a forced activation button in parallel with the temperature sensor, which you will install in the car interior.

Forced fan activation using the SpeedFan program

Another way to improve the performance of a cooler is to use special software, which includes the free SpeedFan utility. To overclock the fan using this application, you must:

- Download and install SpeedFan on your laptop. The installation file takes about 3 MB, so low-speed Internet is suitable for downloading.

- Launch the program via a shortcut on the desktop, and then in the “Settings” tab change the interface language to Russian.

- Go to the “Indicators” menu and set the fan power as a percentage. Here you can view data on the temperature of the hard drive, motherboard and all processor cores.

- In the “Temperature” window, located in the “Configuration” section, specify the temperature for the HDD, CPU and motherboard that the cooler will support. In the “Alarm” line, you can set the temperature value, when exceeded, the program will notify the user about system overheating. This will allow you to respond faster to critical situations.

There are other programs that allow you to force the laptop fan to start. Thus, using the AMD OverDrive utility, you can make changes to the operation of a PC cooler built on an AMD processor. The Riva Tunes application has been developed for Intel processors.

Price issue

Before dealing with a radiator that isn't working, it's important for many to know the cost of the components and labor.

A new element will cost about 1.5-2.5 thousand rubles today, depending on the model and region. The cost of replacement at a service station will be from 400 rubles or more. Although you don't need to spend money on this, since replacing it yourself will take no more than half an hour. And there is nothing particularly difficult here.

temperature sensor

What should the engine temperature be?

According to the international automobile convention of December 1, 1992, where 92 representatives of the auto industry gathered, it was decided to establish a single standard for engine operating temperature.

This indicator is 90 degrees Celsius with a maximum permissible deviation of no more than 3 degrees Celsius.

Circuit diagram for turning on the cooling fan But, taking into account the region of operation and the ambient temperature, this temperature tends to rise. It is for this purpose that automakers came up with a cooling system fan, which provides additional cooling of the fluid in the system. It is driven by a temperature sensor, which detects it in the engine and is located directly on the power unit.

[custom_ads_shortcode1]