There are a number of reasons why engine detonation problems may occur. Most often, there is a direct connection with the incorrect operation of the electrical circuit connecting the knock sensor and the electronic control unit (ECU), or with the sensor itself.

The knock sensor (DS) is part of the electronic engine control system. It is considered a fairly reliable component, but troubles also occur with it, requiring replacement of the element.

The knock sensor is mounted on the outside of the cylinder block wall and monitors the abnormal vibrations that occur when detonation occurs inside the engine. The DD generates a signal in the form of alternating current, with a certain amplitude and frequency, which directly depends on the vibrations of the cylinder block. If the operation of the sensor is disrupted, corresponding errors occur in the memory of the electronic unit. Typically, on a diagnostic scanner when connected to the ECU on domestic cars, you can see errors with codes P0325, 0326, 0327 and 0328. It is worth considering separately the error code P0327.

What does code P0327 mean?

A knock sensor (DS) is installed in the engine and is used to detect knock.

Detonation (from French détoner - “to explode” and Latin detonare - “to thunder”) is a combustion mode in which a shock wave propagates through a substance.

When detonation occurs, the sensor produces a voltage signal that is sent to the engine control unit (ECU). The ECU retards ignition timing to protect the engine.

Inside, the knock sensor is a piezoelectric crystal. This crystal is used to create alternating voltage when vibrated.

A knock sensor is a transducer, which is a device that converts changes in a physical quantity into an electrical signal. In other words, the DD does not receive a reference voltage from the ECU - it creates its own.

There are two main types of knock sensors. The first one was used in old cars and the second one is a resonant sensor used in modern cars.

P0327 indicates the knock sensor signal is low. This means that the controller has detected a problem with the DD or its circuit. Some vehicles may be equipped with two knock sensors. Trouble P0327 refers to the sensor on bank 1 (the side of the engine where cylinder number 1 is located).

Read more: What are Bank 1 and Bank 2, Sensor 1 and Sensor 2 (Bank 1, Bank 2, Sensor 1, Sensor 2)

Symptoms of error P0327

P0327 has the same symptoms as other knock sensor related errors. That is:

- The engine has noticeable problems with dynamics;

- The electronic control unit switches the car into emergency mode. On some engines, this can lead to the fact that the ECU will programmatically block the ability to increase revolutions above 3-5 thousand per minute, or prevent acceleration over 50 kilometers per hour;

- The engine may be unstable at idle. Often the engine starts to stall at idle if you do not maintain speed with the accelerator pedal.

Please note: Many cars in emergency mode begin to emit black smoke from the exhaust pipe due to a suboptimal air-fuel mixture - this can be attributed to another symptom of the P0327 error.

How to troubleshoot P0327?

The following step-by-step guide will help you resolve the P0327 code.

Inspect the sensor and its connections

Many problems can be easily found in the harness and connectors. Begin your diagnosis by visually inspecting the knock sensor and its wiring.

Check sensor output

To test an older style knock sensor, connect a digital multimeter set to AC voltage between the DD signal output wire and the housing.

Then tap the engine near the sensor. You should see an AC voltage reading on your multimeter. If not, the sensor is faulty and must be replaced.

To test a car with a resonant type sensor, you must connect a digital multimeter in the same way as in the example above. But instead of knocking on the cylinder block, you will be removing the fuel pump relay.

Start the engine, keep your foot on the brake. Raise the revs a little. When the car is starved of fuel, it begins to knock and you should see an AC voltage output from the sensor. If there is no voltage, the DD is faulty and must be replaced.

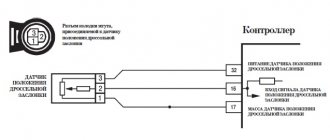

Check the diagram

If the knock sensor is good but P0327 is still present, you will need to check the sensor circuit. Using a multimeter set to Ohms (resistance), connect one probe to the DD connector and the other to the knock sensor input pin on the ECU. This checks the continuity of the circuit between the sensor and the control unit.

If the device shows “OL”, then there is an open circuit in the circuit that needs to be repaired. If not, the ECU is likely the problem and needs to be replaced.

While older style knock sensors are grounded through the sensor itself, resonant type sensors typically have a separate ground circuit.

In this case, use a multimeter to make sure that the ground wire is ok before blaming the ECU. Look at your vehicle's wiring diagram to determine which pin on the connector is power and which is ground.

Then connect the red lead of the multimeter to the positive terminal of the battery and the black lead to the ground on the connector. You should see a reading of about 12 volts, indicating a good ground. If this is not the case, you will need to look at the wiring diagram to determine the cause of the circuit failure.

Causes of error P0327

There are several main reasons that lead to error P0327:

The knock sensor is not installed correctly or has defects that prevent it from transmitting information correctly, for example, oxidation of the contacts or poor fastening;- Problems with the data transmission circuit from the knock sensor to the electronic control unit, which can be caused by broken wires, a short circuit due to worn insulation, or other defects;

- Failure of the knock sensor;

- The software of the electronic control unit works with defects that form error P0327 in the device memory.

To fix the problem, you need to step by step check the possible faults indicated above.

Codes related to P0327

- P0324 - Knock Sensor Module Performance.

- P0325 - Knock Sensor Circuit Bank 1.

- P0326 - Knock Sensor Performance.

- P0328 - Knock Sensor Circuit High Voltage, Bank 1.

- P0330 - Knock Sensor Circuit Bank 2.

- P0332 - Knock Sensor Circuit Low Voltage, Bank 2.

- P0333 - Knock Sensor Circuit High Voltage, Bank 2.

Previous post Error P1602 - low voltage on the control unit (ECU)

Next entry Knock sensor - purpose, types, design, where it is located, how to check

Causes

Before troubleshooting error P0327 on VAZ cars, you need to understand why it may appear and what leads to its display on the diagnostic scanner.

Experts identify several most likely and common reasons:

- The knock sensor was initially installed incorrectly or has certain damage or defects. Because of this, the controller cannot correctly transmit data to the ECU. Quite often this is due to poor fastening or oxidation of contacts.

- There are problems in the electrical circuit through which information is transmitted to the computer from the knock sensor. This may be due to broken wiring, short circuit or worn wire insulation.

- It's just that the knock sensor has failed. It stopped working, and therefore the ECU writes an error to the memory, and the normal functionality of the engine is disrupted.

- There are problems with the ECU software. These defects provoke the appearance of the error in question in the equipment memory.

To deal with the problems, you should follow the step-by-step instructions and check several possible characteristic faults described above.

How to change a knock sensor

The process of replacing DD with VAZ 2114–2115, 2110–2112, as well as Priora, Grant and Kalina, is quite similar. For all of the listed cars, the knock sensor is located on the outside of the cylinder block, under the 2nd and 3rd spark plugs. Here are the step-by-step instructions:

Then we connect the battery. Using a diagnostic scanner or mobile application, we remove the error.

Description and meaning of error P0327

This diagnostic trouble code (DTC) is a generic powertrain code, which means it applies to OBD-II equipped vehicles. While general, specific repair steps may vary depending on the make/model. The knock sensor tells the engine computer when one or more of your engine's cylinders are knocking, that is, exploding the air/fuel mixture in a way that produces less power and can damage the engine if extended. The computer uses this information to adjust the engine so that it does not knock. If your knocksensor on bank #1 produces a low output voltage (perhaps below 0.5V), then it will trigger a P0327 DTC. This P0327 code may appear intermittently or stay on continuously. Other knock sensor related DTCs include p0325, P0326, P0328, p0329, p0330, p0331, P0332, P0333, and p0334.

Trouble P0328 Knock Sensor Circuit 1 Input High (Bank 1 or Separate Sensor)

The structure of the flat engine knock sensor (non-resonant type) allows vibration detection over a wide frequency range: approximately 6 to 15 kHz. Knock sensors are installed on the cylinder block and are designed to detect engine knock. The sensor consists of a piezoelectric element that generates voltage when deformed. Voltage is generated when the cylinder block vibrates due to detonation. The occurrence of engine knock can be eliminated by delaying the ignition timing.

Signs of an error

The error manifests itself when the engine is warm - in order for fuel detonation to occur, the fuel must be warmed up and able to detonate. Problems with the sensor lead to deterioration in vehicle behavior:

The reason for the deterioration in performance is a command from the electronic control unit to switch to emergency engine operation when the signal from the knock sensor is low. The ECU specifically limits the engine's capabilities to avoid burning out valves and pistons as a result of excessive detonation. On some vehicles, emergency operation may limit the maximum speed to 3-5 thousand rpm and the maximum speed to 50 km/h.

How to fix error code P0327

Please note: Before you begin troubleshooting P0327, you must ensure that the problem was not caused by a temporary software glitch. To do this, use a diagnostic scanner (or by removing the negative terminal of the battery for 15 seconds) to reset the errors recorded in the computer, and then create the conditions for the formation of a malfunction with code P0327.

Let’s take a step-by-step look at how it’s easier to start checking for possible faults in order to find and fix the problem as soon as possible:

If none of the methods listed above was able to detect the cause of error P0327, you will have to use a special diagnostic stand to check the electronic control unit. Perhaps the problem lies in its software.