On a modern car, several systems and a large number of sensors simultaneously monitor the operation of the engine and adjust its behavior when internal and external parameters change.

If any malfunctions or irregularities appear in the operation of the internal combustion engine, they are recorded by the control unit (ECU) and stored in memory. These errors may appear as lights on your dashboard. Most often we are talking about Check Engine.

One of the errors that motorists may encounter when connecting to the ECU with a scanner is P0113. You should know what it means, what symptoms it is accompanied by and how to eliminate it on your own.

How does a mechanic diagnose a P0113 code?

When diagnosing this error, the mechanic will do the following:

- Reads all stored data and error codes using an OBD-II scanner to find out when and under what circumstances the P0113 error code appeared

- Clear error codes from the computer's memory and test drive the vehicle to see if P0113 appears again

- Visually inspect the intake air temperature sensor and associated electrical wires and connector

- Disconnect the intake air temperature sensor connector and observe the sensor readings in real time using a scanner. This will help determine if there is a short circuit inside the sensor or in the associated wires or connector

If no problem is found, the mechanic will continue diagnosing by following the vehicle manufacturer's procedure.

What does the error mean?

When the P0113 error occurs, the first thing that interests the motorist is its meaning.

Error P0113, stored in the ECU memory, indicates a failure on the part of the intake air temperature controller. Namely, a high signal level is observed.

This is a sensor that monitors the temperature of the air entering directly into the engine for further formation of the air-fuel mixture.

Some vehicles use a separate sensor to perform these tasks. But most often it is an integral component of another controller. This could be an absolute pressure sensor or a mass air flow controller. Inside them there is a sensor that controls the pressure.

Structurally, the element is located in the air pipe. It's actually a thermistor. Depending on the temperature of the incoming air, the resistance of the controller changes. The control unit reacts to this and monitors the signals and behavior of the device. This allows:

- change the width of the pulse supplied to the engine injectors;

- change the ignition timing;

- influence the volume of supplied fuel;

- control stable idle speed, etc.

This sensor is also often called IAT (Intake Air Temperature).

The sensor parameters are most important at the moment the power unit starts. Working together with the coolant sensor, based on their resistance, the ECU receives accurate information and determines the optimal time for injection. This eliminates problems specifically during a hot start of the internal combustion engine.

If resistance data is transmitted incorrectly, error P0113 appears. If information is not transmitted at all, then error P0110 will pop up.

The error code in question indicates that the current incoming air density is higher than the maximum set level. That is, the temperature of the air that is sucked into the engine is low. This is usually due to a malfunction of the controller or its breakdown.

How to fix

In most cases, a malfunction in the sensor's power supply circuit is to blame for the error. However, you must first make sure that the sensor itself is working.

The scheme for checking and identifying problems with the sensor is as follows.

- You need to check the serviceability of the IAT sensor itself. To do this, you need to use an ohmmeter or multimeter, as well as a source of air of different temperatures, for example, a household hair dryer. The multimeter must be connected to the sensor to measure the resistance, after which you need to supply air at different temperatures, adjusting it by switching the modes of the hair dryer. If the resistance readings do not change in different modes, then the sensor itself is not working correctly, that is, it is broken or dirty.

- In such a case, you can simply replace the sensor with a new one, but you can try to revive it by cleaning. This can be done using special cleaning products, for example, the most popular of them - carb cleaner. To clean, you will have to dismantle the sensor, thoroughly treat it with cleaner, and then reinstall it. After the procedure, it is necessary to re-diagnose the sensor using an ohmmeter (multimeter) and a hair dryer. If nothing has changed in the device readings, the sensor will have to be replaced with a new one.

- Troubleshooting in the power supply circuit should begin when, during preliminary diagnostics, it has been established that the sensor itself is operational, that is, the resistance changes in different temperature conditions of the air supply. To find the problem, you will have to carefully inspect the power connectors, as well as the wiring for breaks or oxidation. If a problem is detected, it must be eliminated by changing the corresponding element.

Often the P0113 error is accompanied by other errors with codes P0111, P0112 or P0114. All of them are also associated with malfunctions of the intake air temperature sensor. In this case, the presence of additional errors can help determine the cause of the malfunction without diagnosing, since all errors are related to specific sensor problems.

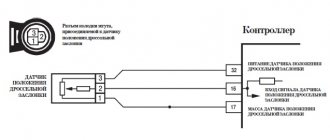

IAT connection diagram

The electrical circuit for DTVV is shown below:

The sensor is calibrated and produces a voltage proportional to the air temperature. Higher temperatures result in higher voltage being applied to the ECU because the internal resistance of the IAT decreases as it heats up.

Errors associated with high circuit input signal are mainly caused by faulty generators that create excess voltage. Although there may be other reasons, such as short circuits that "leave" current into a particular system from other, unrelated systems operating at higher voltages.

Note that in the case of short circuits, there are likely to be other seemingly unrelated fault codes present.

Diagnosing a "high input" code will always involve thorough testing of the charging system as a first step, followed by isolating the circuit from all other possible voltage sources while checking resistance, continuity, and voltage reference.

How to eliminate an error in the incoming air temperature

Often, when car owners take readings from a car scanner, the display of which displays the code p0113, after receiving the decoding, they immediately look for the location of this sensor and rush to replace it with a new one. Although it is not always reasonable to do this, because there is no 100% certainty that error p0113 will go away after replacing the air pressure sensor or mass air flow sensor. Therefore, it often happens that I changed it, but the error does not go away - what should I do?

Tips for eliminating P0113 high signal level of the incoming air sensor are quite simple:

First you need to check the resistance of the IAT sensor at different air temperatures. This can be done using a hairdryer or a tank of warm water and a multimeter. Although the numerical ratio is different for each sensor model, it should always change proportionally. Therefore, even if you do not have a table with the technical characteristics of the sensor (°C/kOhm) at hand, it is important that the resistance changes proportionally with respect to temperature.

The next step is to check the contacts in the connector and the wiring of the sensor for air entering the engine (possibly oxidation or a break).

cleaning of the sensitive element with a carb cleaner can help eliminate error p0113 , since crankcase gases could heavily “clog” it with oil deposits.

And only if the above procedures did not help eliminate the problem, should you replace the air sensor , which, as a rule, is built into the flow meter or is a pressure sensor located on the intake manifold. Therefore, if error P0113 appears on your car, be it a VAZ, Ford, Audi or Subaru, then the first thing you should do is listen to the recommendations and start by checking the DBP and cleaning the sensor, since the price for some car models is quite steep.

Source

Probable Causes

Error P0113 hides certain reasons that led to the recording of the corresponding code in the memory of the control unit.

The main reason lies in a problem with the temperature sensor. But the occurrence of an error may be due to various malfunctions. The main ones are:

- breakdown of the temperature sensor, its complete failure;

- contamination of the controller with oil particles, which reduces sensitivity;

- loss of contact in the connector;

- broken wiring in the electrical circuit.

Statistics show that most often the reason lies in a short circuit in the circuit or in the sensor housing.

Much less often the device becomes contaminated with oil and other deposits, which entails a decrease in the sensitivity of the sensor.

Symptoms

An error such as P0113 does not have pronounced and characteristic symptoms by which it could be accurately diagnosed. These are, rather, indirect signs that force the motorist to connect a scanner to the computer and read the errors in the memory.

You can suspect problems with the intake air temperature controller based on the following symptoms:

- the Check Engine light comes on on the dashboard;

- The ECU switches the engine to emergency or safe operating mode;

- fuel consumption indicators are increasing;

- If the car is all-wheel drive, the rear axle may spontaneously disengage.

If you continue to operate the car in such conditions, the wear of the valves and piston group increases. It is better to fix the problem as quickly as possible.

Yes, the symptoms discussed do not indicate that the intake air sensor has failed. But this is a reason to read the errors and look at their codes.

On what cars does it appear?

Error P0113 itself is quite universal. It may appear on cars produced by VAZ, companies such as Toyota or Honda.

It is only important to note that an error such as P0113 occurs on a car where there is an electronic control unit and the sensor itself that controls the intake air temperature parameters. This is almost any modern car, starting from the already outdated VAZ 2112 or VAZ 2114, and ending with more recent models such as Ford Focus 2, Ford Transit, Chevrolet Lacetti, Lada Kalina, Priora and Grant. For all of them, seeing code P0113 on the scanner is not a surprise.

Motorists note that error P0113 appeared on various models of Volswagen, Honda, Nissan, BMW and Mercedes.

Regardless of which vehicle the P0113 error occurred on, it should be eliminated. For this, there is a certain algorithm of actions and recommendations from specialists.

Conditions for generating an error

Such an error can only appear when certain conditions, a certain scenario, are met.

The error is recorded in the ECU when the engine starts. When starting the internal combustion engine, the ECU reads data from all sensors. If the air passing through the air duct has a density higher than the allowable value and this continues for more than 1.5 minutes, the check engine light will illuminate on the instrument panel.

If this is an accidental error, then after 4 normal starts the indicator on the instrument panel will go out. But the error itself will still be in the ECU memory. It is automatically erased only after 40 successful engine starts.

Possible consequences of ignoring

You can get to your home or the nearest technical station, but there is no need to delay the troubleshooting process. Ultimately, this is fraught with a reduction in the operational life of the power plant due to the rapid wear of parts of the cylinder-piston group. Possible engine repair costs cannot be compared with the price of the sensor or payment for services to eliminate other causes of its failure.

Overhaul is expensive!