What number of sandpaper to choose for sanding a car

There are markings on the back of rolls, sheets or special grinding wheels. It complies with Russian GOSTs of 1980 and 2005 (letter designation “M” or “N”) and ISO international standardization standards (letter “P” in the marking).

Drivers who service their cars themselves are not afraid of even painting the body. A complex procedure, however, requires a lot of knowledge, for example, what sandpaper numbers are needed for painting, sanding, and polishing a car. The topic is worth studying.

Material selection

Experienced builders recommend using sandpaper to sand putty. People call it “sandpaper” or “skin.” The quality of the work and the speed of its completion depend on what sandpaper the putty is rubbed with. The choice of material depends on the personal wishes of the master and the grain size of the sandpaper.

The main difference between abrasives is the degree of grain size. Large grains indicate the roughness of the material. The smaller the grain size, the finer the processing. The grain size is marked “P” with a number. For example, P150 is thinner than P50.

Sanding the walls after puttying should be done in two stages. The initial grouting should be done using coarse-grain sandpaper, and the final grouting should be done with fine-grain sandpaper.

Sanding a wall covered with putty does not present any difficulty for the master. The main thing is to choose the right sandpaper so as not to spoil the coating. Depending on the purpose, you need to use:

- skin marked P120 - for primary processing;

- sandpaper marked P100 - if there are visible irregularities on the wall. Abrasives with a lower parameter scratch the surface. They will simply erase thin putty;

- sandpaper marked P240 - to prepare the wall surface for painting. After treatment, the wall becomes perfectly smooth without a single mark on the surface. Skins with smaller grits will clog, so they are not recommended for home repairs.

For reference! Sandpaper with a fine grain diameter is used for finishing and finishing. Experts recommend using sandpaper marked P180. It sands well and does not scratch the surface.

Types of abrasive sandpaper

Sandpaper (sanding paper) is a grinding material used to impart a certain structure to the surface before painting and to bring it to shine and gloss after. Before you find out the number of sandpaper for painting a car, you need to understand the types of abrasive material. The division occurs along the base, onto which an abrasive is applied using glue or mastic.

The following types of skins are distinguished:

- Paper. This is the most common and economical option, allowing you to apply very fine crumbs to paper.

- On a fabric basis. This sandpaper is more elastic and wear-resistant, which affects the price.

- Combined. The combination of the two previous options has absorbed the best properties: flexibility - from a fabric base, the ability to apply fine abrasive - from a paper base.

Cloth-based sanding paper

How to minimize defects

To avoid possible shortcomings, it is necessary to use universal or finishing putty compounds. The first version of the mixture is laid in one layer on the prepared base, the second method is only suitable for use on the base layer.

Attention! Manufacturers of plasters indicate the consumption of the mixture on the packaging; on average, this figure for a layer thickness of 1 cm for one square meter is 10 kilograms.

Solutions have different compositions:

| Type of plaster | Description |

| Water-dispersed | They are easy to sand and adhere perfectly to the wall. |

| Polymer | They have high elasticity and strength. Easy to process, and the coating does not lose its properties. Acrylic based. |

| Plaster | They are the easiest to sand, but have low reliability, unlike other types. Can only be used in rooms with minimal humidity. |

| Cement | As they dry, they shrink, which reduces their strength and adhesion to the pre-coated soil on the wall. To avoid this, plasticizers are introduced into the solution, which leads to higher prices. |

| Oil-adhesive | Characterized by good adhesion. Suitable for painting. |

Also an important factor when choosing will be the company that produces the plaster mixtures. It is better to buy a high-quality gypsum or polymer composition than a poor water-dispersion one.

Grit markings

“Grains” - abrasive powder - have different characteristics:

- size;

- material of manufacture;

- application density per square inch.

These parameters help you choose the required sandpaper number for sanding your car.

Grit is measured in micrometers (µm). The gradation of sanding material is based on the size of the abrasive particles:

- Large. Numerical designation - from 12 to 80. Paper is used in rough preparatory work, primary processing of repaired areas. Coarse grain evens out chips and welds.

- Average. Indicated by symbols from 80 to 160, it is used for finishing body parts and final preparation for putty. From these grain size indicators, select the sandpaper number for painting the car.

- Small. The largest amount of abrasive powder ranging in size from 160 to 1400 is concentrated per square inch. Within these limits there is a number of sandpaper for polishing a car, which will be needed at the final stage of painting.

The photo shows a table of sandpaper grain sizes for different materials.

Table of abrasive grain sizes for different materials

The table shows that the numbers of sandpaper for cleaning after puttying a car range from 180 to 240.

There are markings on the back of rolls, sheets or special grinding wheels.

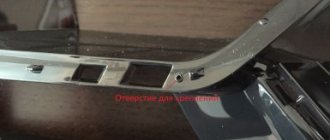

Sandpaper markings

It complies with Russian GOSTs of 1980 and 2005 (letter designation “M” or “N”) and ISO international standardization standards (letter “P” in the marking).

What is included in a full cycle repair and painting of a car?

If you had to deal with serious damage, which was also not repaired in a timely manner, you will most likely have to carry out a full cycle of repairs followed by painting. This process will be longer (especially if you need to remove rust) and requires the following materials:

- Epoxy primer

- Putty

- Corrosion-protective primer

- Ground leveler

- Finishing coating – enamel

- Finishing coating – base paints under varnish

Do not forget that the selection of products for preparing the surface of a car for painting also depends on the material from which the part being repaired is made (steel, galvanized steel, aluminum or plastic) and on the type of old paint coating (hard or soft).

Currently, many manufacturers make their car bodies from galvanized steel and aluminum. This provides higher corrosion resistance and durability, but at the same time requires the use of special materials for repairs. There are a number of products suitable for application to galvanized steel and aluminum.

Abrasives used

Manufacturers use stones, sand, shell rock and artificial polymer materials as crumbs (powder) for the base.

- Pomegranate. Natural origin gives softness and elasticity to emery, which is often used for processing wood.

- Silicon carbide. A common universal powder for working with paintwork and metal surfaces.

- Ceramic chips. A very durable material is needed to form products.

- Zircon corundum. Resistant abrasive is often made in the form of a belt for sanding machines.

- Alumina. The durability of the abrasive allows it to be used for sharpening cutting edges.

Silicon Carbide Sandpaper

When choosing sandpaper numbers for painting a car, pay attention to silicon carbide abrasive.

How to sand a car before painting

So, the preparatory work has been completed, now you should begin choosing materials for grinding. As a rule, silicon carbide or aluminum oxide plays the role of an abrasive for body work.

The question of which sandpaper to rub putty on a car consists, first of all, of choosing materials with a certain concentration of particles . The more there are, the faster the grinding procedure will occur. On the other hand, this same parameter also affects the uniformity of scratches that occur during work.

Pay attention to the number that refers to a specific material. As it decreases, the size of the abrasive increases.

How to sand properly with sandpaper

The technology is simple. The main thing is accuracy and patience. For sanding, you need to take different numbers of sandpaper for painting a car - from the finest to coarse sanding material.

Process Features

Carry out the work in a clean, dry, well-lit box. Do a wet cleaning, cover the floor and walls with plastic film.

Preparatory work

The final result of coloring directly depends on the preparatory stage:

- First, wash your car at a car wash.

- In the garage, remove all plastic, chrome parts that are not related to painting.

- Wash the car again with shampoo, wipe dry, and degrease with white spirit.

- Inspect the body, evaluate the scale of the work. It is possible that not the entire area will have to be cleaned, painted and sanded.

- Weld the places that need it and straighten it.

Then clean the room again.

Features of manual grinding

To make the work easier, prepare a sanding block in advance - a block with sandpaper holders. You can buy the device or make it yourself from available materials: a piece of wood, a hard sponge.

Car mechanics and painters call the first stage of cleaning the body matting. It is more convenient to polish large areas using a grinding machine, but where the tool cannot be reached, it is better to grind by hand. The number of sandpaper for matting a car is P220-240.

After this procedure, dents, scratches, and other defects are clearly exposed. Use sandpaper number P120: it will smooth out scratches, sharp edges of paint, and completely remove rust.

The goal of the procedure at this stage is not a smooth surface. For better adhesion of the putty to the body metal, uniform micro-scratches should remain on the latter.

Don't forget to remove debris with a vacuum cleaner. When the surface is prepared, putty it and let it dry. Select the appropriate number of sandpaper for sanding after puttying the car, go over all the panels.

Matting tools

To easily matte your car, sanding and polishing tools are useful. The choice depends on the area of the surface to be painted. For a complete repaint of the body, a sanding machine will be an indispensable assistant. An economical alternative for smooth surfaces are sandpaper blocks, also known as planes. With their help, it is easier to manually process the surface of the car.

Manual matting is required in difficult and uneven areas. When matting embossed parts, Scotch Brites are useful. These are flexible and elastic felt-based abrasives that allow you to process hard-to-reach areas without changing shape. They differ in the degree of aggressiveness of the material in color - from red for rough work to green for polishing.

Manual matting

When manually processing the surface when matting, adhesive tape or flexible sandpaper is used. These materials make it possible to efficiently process complex relief areas. In this case, it is important to remember about the change in the sanding trajectory during bending and take it into account for uniform matting.

When working with abrasives manually, sanding with water greatly simplifies matting. A wet sponge is used to wet the body. An important condition for high-quality processing is the purity of the water, so it should be changed frequently. Adding liquid soap to the water will help to avoid varnish and shagreen smudges. After matting, the surface is washed with plenty of running water and wiped dry with a lint-free cloth.

Attention! The use of wet manual matting technology is contraindicated when working with polyester putty, which absorbs moisture and leads to corrosion.

Matting with a plane

When manually matting smooth surfaces, it is more convenient to secure the abrasive on a plane. This is a wooden block that is convenient to hold during the matting process. When working, you should securely fasten the sandpaper and regularly change the direction of the plane for uniform polishing.

Important! Keep in mind that when working with a plane, finer abrasives are used than when machine sanding in the same places.

Matting a car using a sander

The universal choice of sanding machine for matting a car body is an eccentric, also known as an orbital sander. The grinder will significantly speed up matting work in the following cases:

- complete removal of old paintwork;

- processing of transition zones of individual sections of the body before painting;

- leveling putty areas;

- removing the shipping primer.

Use the sander effectively on all flat surfaces. For high coating hardness, surface grinders or special attachments with mineral abrasives are used. When machining, it is important to ensure that the pump and dust removal hose are in good working order. To prevent clogging of the abrasive, it is recommended to periodically tap the sole of the machine. When working, it is unacceptable to put pressure on the machine and allow the surface to overheat. Also, bent, curved or thin parts should not be machine matted.

Matting of the car body and parts is necessary at all stages of applying protective and paint coatings. To work, you will need a set of abrasives of different grain sizes. Different elements of the body are processed with different tools - smooth surfaces can be sanded with a grinder, thin metal must be processed with a plane, and hard-to-reach places can only be polished by hand.

A few additional tips

High-quality sanding is perhaps the main preparatory moment before painting. Here experience and intuition play a big role.

Tips from experienced car mechanics:

- If you do not need to sand the entire body, cover the area near the repair area with masking tape.

- When planning areas for restoration, do not be afraid to cover an area wider than the defect.

- Before sanding, treat the putty with black developer, this will show you where to add more putty.

- Always stock and work with coarse, medium and fine grit sandpapers.

- You need to grind metal and putty with different physical effort: the primer layer is always softer and will simply be erased from excessive enthusiasm.

- Start with coarse sandpaper, then increase the number of sandpaper for sanding a car by 80-100 units.

While working, remove dust and do wet cleaning.

Source

What sandpaper should I use to clean my car before painting? read and memorize

Our part is primed and, at first glance, is now definitely ready for painting. However, taking a closer look, we will still see some shortcomings on it: uneven soil layer, areas of dry pollination, shagreen. To completely level the surface and give it the necessary roughness, the primer must be sanded before painting. Only then will the paint lay on the surface in an even layer, and, no less important, will it adhere well to the surface of the soil.

Today you will find out

Quality control of alignment during grinding

A developing coating is used to control the quality of alignment.

As a developing coating, you can spray a thin layer of primer in a contrasting color. For such purposes, it is better to dilute the soil with a large amount of thinner and apply a light spray that will not affect the thickness of the repair layer. Next, the soil should dry.

More often, a special developing powder or aerosol is used, which sprays a matte, quick-drying layer.

The developing coating can be used both to identify pits and to monitor the removal of scratches from a larger abrasive after changing to fine-grit sanding paper. After sanding, the development coating remains in the recesses and scratches. So you can see that some place requires adding putty or additional sanding. It should be noted once again that during the final stages of leveling with sanding paper P180-P220, the pressure on the sanding block should be minimal.

We recommend: What are the main reasons for engine overheating on a VAZ-2109

Checking the surface with moisture

A good way to check the surface during the final stages of sanding is to check it with moisture. Simply spray a thin layer of degreasing liquid onto the surface to be leveled. Before the liquid evaporates, you can carefully look at how the surface reflects from an acute angle. Even minor waves and holes will be visible, the location of which can be remembered or marked and immediately re-leveled, or added putty or primer, and then sanded. This way you can control the leveling process down to the slightest unevenness.

Grinding methods. Advantages and disadvantages

There are two ways to process filler primer for painting:

Both methods have their advantages and disadvantages.

The “wet” method is most popular in private workshops, and there are still cases of treating not only soils, but also putties with water (hello to future rust and bubbles). Here, many craftsmen are skeptical about the very possibility of using “dry” technology for preparing surfaces for painting.

The main reason is that in such workshops both sanding and painting are most often carried out in the same room, so when using dry technology the rooms become very dusty, and removing all this dust is problematic. During wet processing, dust emission is minimal, and work can be carried out in any well-ventilated area.

In addition, with manual processing there is a much lower risk of violating the integrity of the primer layer, and the sandpaper itself is used very sparingly and becomes less “greasy” even when processing soft soils (we are now talking about the advantages of wet technology exclusively for processing soils, since dry technology is used for processing putty - the only correct option).

There are basically only two disadvantages of this technology - low labor productivity and a long time for soil to dry after grinding. Dry technology does not have these disadvantages.

In fact, Western European stations have long abandoned the use of water when preparing surfaces for painting. The fact is that discharging water contaminated with grinding products into the sewer system is dangerous from an environmental point of view. In addition, working in damp conditions is harmful to worker health.

But the main argument is that the dry grinding process has significantly higher productivity compared to wet grinding. A vacuum cleaner and an eccentric sander are several times more effective than hands with a sanding block and a bucket of water, you can be sure. And the access of moisture to the metal and putties is completely excluded, which means the likelihood of such defects as swelling, cracking of the layer, and others is minimized.

The disadvantages of the dry method include the need for expensive equipment for grinding, good ventilation of the entire room, or the presence of specially equipped workplaces equipped with at least a slatted floor.

It is clear that this is not achievable everywhere, so both “dry” and “wet” soil treatment are allowed. Which method to choose depends on the conditions of your workshop and the availability of equipment with dust extraction.

How to sand, with water or dry?

- It is better not to sand putty with water; it can absorb moisture (but not too much, as many people think). If water was used when sanding putty or primer, it is better to dry the surface with an infrared lamp. Sanding putty with water doesn't make much sense. Control over the condition of the surface is lost, and a developing coating cannot be used.

- When using sanding paper finer than P400 by hand (usually in preparation for painting or before polishing), the paper will quickly become clogged with material residue. These residues can clump and act as an abrasive. In this case, water is used, which helps keep the surface and paper clean. Sanding with water always helps the sanding paper last 3 to 5 times longer. In addition, water during sanding prevents the formation of dust.

- When sanding with water, the sanding paper should have a finer abrasive than when sanding dry. Sanding with water is more aggressive.

- When grinding with fine abrasive and water, the cross grinding method is used. The next pass is made 90 degrees from the previous one. First, sand the entire area in one direction only, then the entire area in another, perpendicular direction (see illustrations above).

We recommend: Do-it-yourself instructions for changing engine oil

How to rub putty - sandpaper, a block and a little patience

The issue of how to grout putty must be approached with the utmost seriousness. The finishing layer of this finishing material must be perfectly even and smooth - especially if the surfaces are being prepared for painting.

You can level the surface of a putty wall manually or using special grinding machines. The first method, of course, is preferable, since it allows you to remove flaws even in the most inaccessible places, and the quality of work when using it will be higher. Experienced craftsmen recommend using the machine method only if the area is very large. However, you can’t do without manual work here either; in some places the master will still have to “go through” the sandpaper.

Repair of serious element damage

Plastic is quite short-lived and easily susceptible to certain types of damage, for example, scratches, chips, cracks, and in some cases it may simply burst. Serious damage can be repaired by two methods: using welding or gluing the part. Welding the bumper, although a more reliable method, can bring you a lot of trouble. First of all, you must have a set of necessary tools. You will have to purchase a special soldering iron, electrodes, a hair dryer, special scissors, etc. Apparently, the method is far from cheap.

If you decide to repair your car's bumper using the gluing method, it will cost you much less. To do this, just purchase a special repair kit at any car store. It includes about 2 meters of reinforcing fiberglass, epoxy resin and hardener. The extended kits also include putty for plastic, sandpaper and a reservoir for mixing components.

They cost about 50-60 dollars, so each of you can afford to buy them. If you find rips, cracks or holes on your car's bumper, apply reinforcing fiberglass to its outside. To make the repair coating more durable, it is advisable to glue 3-4 layers of material.

When applying the first layer, calculate it so that it is 4-5 cm wider than the damage itself. The next layer should overlap the first by 6-7 cm. Next, you need to thoroughly sand the gluing line. Then, as the base hardens, apply putty to the back of the part. After waiting 25-30 minutes, sand the area.

Dry method

If we are proponents of the progressive dry sanding method, we can do most of the work using a sander. However, we still cannot completely avoid “manual labor”.

Firstly, there are quite a lot of areas on the car body that you simply cannot reach with a machine. Secondly, those areas of soil that are applied to the putty areas must first be sanded by hand in order to “outline” the plane and even out the unevenness of the layer. To do this we need a sanding block and an abrasive strip such as P320 .

If the thickness of the layer allows, you can use a slightly coarser abrasive, for example 240 or P280, this allows, in some cases, to “cut” the plane more efficiently. But you need to sand carefully so as not to break through the filler, and then you definitely need to repaint it with a P320 gradation (this can be done on a machine). Remember the hundred units rule!

If the primer is applied to a flat, unputtyed surface, leveling by sanding is not necessary.

In order to facilitate finishing of the surface, it is recommended to apply a developing coating to the primed area before sanding. Both dry and sprayed development can be used.

If you use a sprayed development coating (sometimes leftover base enamel is used for this), then it can be applied to the surface only after the primer has completely dried. Otherwise, this may negatively affect the strength of the soil; it becomes looser and more prone to shrinkage, and when sanding it clogs the sandpaper.

The grinding itself must be performed with diagonal movements so that the irregularities are “cut down” evenly over the entire area.

Apply dry development coating

We sand the surface with a hand sander and a P320 abrasive strip. Grinding should be done with diagonal movements so that the unevenness is “cut off” evenly over the entire plane.

After the leveling has been completed by grinding, you can begin finishing the surface. With this operation we will remove directional marks remaining after manual grinding and create on the surface the necessary roughness for the adhesion of the coating enamel.

To finish the filler, we need a sander with a small eccentric stroke (optimally 3 mm) and a soft sole. The small stroke of the eccentric and the soft sole are due to the fact that the surface to be painted requires more delicate processing, so that we only follow the general contour of the part, knocking down the mark, but do not violate the shape and do not sand the filler.

Regarding the choice of abrasives for finishing:

- To apply acrylic enamel, it is enough to treat the surface with circles P320-P400 , applied sequentially;

- if a “base + varnish” coating is applied, the surface is treated with circles P400-P500 ;

- for some complex colors, such as light mother-of-pearl, if the manufacturer recommends completing the treatment with P600 grade material.

The main stages of preparing a car for painting

Well-organized actions represent a system and include the following steps:

- body defectiveness;

- welding work (if necessary);

- cleaning the car body;

- putty;

- surface grinding;

- body primer.

Let's look briefly at each stage.

Inspection and welding work

To identify all defects, even small ones, the body should be washed thoroughly. You cannot carry out preparatory activities for painting a dirty car! Only after assessing the condition of the car can you plan further work, including welding. They are necessary when identifying deep rust or completely rotten areas of the body. To do this, look at:

- bottom;

- racks;

- thresholds;

- wings;

- joints of body parts.

To replace worn parts you will need an angle grinder and a welding machine.

How to clean the body

First, all welding seams are leveled to the plane of the body using a grinder. The next stage is sanding the body. It is not necessary to do this by hand if you have an orbital sander and a special plane. Manual stripping is done where this equipment cannot reach.

We recommend: How to distinguish retreaded tires from new ones

Putty and body sanding work

Before applying the putty, you need to make the body matte so that not a single spot shines. To do this, sand it down with P220-260 sandpaper, then apply two-component coarse putty to all dents and chips. The choice of putty brand is up to the car enthusiast. Compliance with the instructions is mandatory! To remove minor defects, a universal putty is suitable, and for microcracks, a one-component acrylic putty applied to the primer.

Surface grinding

Further preparation for painting a car consists of sanding the treated surface of the body with a special machine and P80-120 sandpaper. By the way, developing powder is used to develop poorly filled areas. Correction is still possible at this stage. Then the surface is “finished” with sandpaper and abrasive P240-320, and the body, almost ready for painting, is degreased.

The final stage is primer

The most popular primer for the body before painting is acrylic, which will protect it from corrosion. They begin priming the car from those places where more putty was applied. The prepared composition is applied under pressure from a compressor in thin layers (necessarily after the previous layer has dried). Do not mix the primer in advance; its shelf life is 1-2 hours.

After priming, a thin layer of contrasting color paint is sprayed onto the body - the so-called developer. Then you need to sand again:

- for acrylic paint, use sandpaper P400-600;

- for metallics, P600-800 with gray scotch-brite P500-600 is suitable.

Orbital sander market overview

Any body repair is focused on creating a perfectly smooth new paintwork on the car. A grinding machine will help you mechanize your work in preparing the work area. The operating principle of the orbital device is to combine the rotation of the sole and the displacement of the orbit due to the eccentric by a diameter of 2 to 6 mm. The complex effect on the car body allows you to achieve a high abrasive result. The basic configuration of any grinder includes either an electric drive or an air drive from a compressor. Many craftsmen prefer the first option, because pneumatic equipment requires a large volume of air and a powerful compressor. The volume of the compressor is impressive, as is the energy consumption it consumes.

Pneumatic orbital sanders are a popular product among auto repair shops; for home use, an electrically driven device is sufficient.

Orbital grinding technology is selected according to the following parameters:

The basic equipment of the sander contains a 6-sided wrench, with which the sole is installed and removed. There is also a dust container, and sometimes a spare handle. Many models are equipped with a function for connecting to a vacuum cleaner.

To polish a car body, in addition to the orbital machine, the master will need consumables for it, namely abrasive wheels.

Do-it-yourself car painting. Photo report and description attached

Hello again, forum members