Based on the principles of organizing its work, a car engine has long turned into a computerized installation. There is a central processor with various types of memory and developed peripherals with sensors and actuators. One source of incoming information is the intake air temperature sensor (IAT). It plays a significant role in optimizing combustion in the cylinders.

Purpose and location

The temperature sensor is designed to monitor the temperature of air coming from the environment. Depending on the air temperature, the state of the air-fuel mixture and its flash point in the cylinder changes. If the air on the street cools or heats up excessively, the vehicle's driving behavior may differ significantly. The sensor reacts to temperature changes and sends a signal to the control unit to change the current operating parameters.

Therefore, the direct function of the intake air temperature sensor is to measure current parameters. Indirectly, it is designed to increase or decrease the volume of the supplied fuel mixture in accordance with external factors.

This temperature sensor is installed in the vehicle's air supply system. As a rule, it is located in close proximity to the air filter or on its housing; in some models it may be located in the intake manifold.

Rice. 1. Air sensor installation location

The location method involves directing the sensitive element into the air stream. Therefore, the installation location must provide for clear fixation, since if the sensor moves in the mounting hole, you will get unclear readings.

DTVV: what kind of sensor is it and what does it affect?

The car has long turned into a tangle of wires and other electronic systems. One of them sets the operation of the engine, each element of which is important for proper functioning. The intake air sensor is an important component, malfunctions of which will affect the correct operation of the engine.

What is an intake air sensor

The composition of the air-fuel mixture is adjusted using the intake air sensor (hereinafter referred to as DTVV).

The control system uses data received from the DTVV to estimate air density and balance the air mixture.

Design and principle of operation

To better understand possible malfunctions and malfunctions, it is necessary to understand its structure and operating principle.

Rice. 2. Intake air temperature sensor design

Structurally, the temperature sensor for monitoring intake air consists of:

- Contact connector – for connecting the temperature sensor to the internal electrical circuit;

- Housings – designed to protect against mechanical damage and the effects of external factors on electronic components;

- Sensing element - to record the temperature of the incoming air, a thermistor is used, which can be located either in an open cap or in a sealed flask.

- Landing fitting - an element equipped with a thread for screwing into the air temperature control point.

Please note that to ensure a tight fit of the sensor to the mounted surface, there is an o-ring between them. Otherwise, air will leak from the system.

The operating principle of the intake air temperature sensor is based on the readings of a negative temperature coefficient thermistor. In accordance with clause 23 of GOST 21414-75, this is a nonlinear element whose ohmic resistance decreases as the thermistor itself heats up. The position of the sensor is selected so that the sensor interacts with the moving air directly, otherwise the operation proceeds as follows:

Rice. 3. Operating principle of the intake air temperature sensor

As you can see in the figure above, when the flow of air sucked into the system moves, it directly affects the sensor, flowing around the thermistor. When the engine starts, the air in the pipe will be cold and when interacting with the thermistor, its resistance will be within a few kOhms. If the air temperature in the system increases, the sensor resistance will begin to decrease, the voltage drop will decrease and the current will increase. As soon as the parameter reaches the set limit, a current sufficient to command the control unit will begin to flow in the control circuit.

If cold air passes through, a weighting effect occurs, which requires the injection of a larger volume of fuel into the cylinder to maintain normal operation. As the temperature rises, the sensor will react with a proportional decrease in resistance, and the control unit will give a command to narrow the injectors and reduce the volume of injected fuel. In this way, the operation of the motor is adjusted, depending on the temperature of the supplied air. However, the system may malfunction, significantly affecting the operation of the vehicle.

Intake air temperature

Intake air temperature is used by the engine control unit to make two major adjustments to the operation of the internal combustion engine.

The principle of measuring the temperature of the air entering the combustion chambers is in many ways similar to the principle of measuring the temperature of the coolant. In both cases, the resistance of the sensors changes depending on the temperature applied to them.

As the temperature rises, the voltage on the air temperature sensor decreases and the ECU, based on this data, makes adjustments to the fuel supply process and to the algorithm for changing the ignition timing. It follows from this that the sensor plays an important role in the engine control process.

Signs and causes of malfunction

For timely detection of problems associated with both the sensor itself and the operation of the air supply system. The most common symptoms of a faulty temperature sensor are:

- The internal combustion engine does not start well in conditions of low ambient temperature;

- The engine malfunctions at idle;

- Noticeable excess of fuel consumption;

- There are noticeable interruptions in the operation of the motor;

- Turn on the indicator lights on the dashboard or display a message on the on-board computer.

The cause of such factors can be various malfunctions, both in the sensor itself and in the accompanying elements of the air supply system. Among the reasons that motorists often identify are:

- Short circuit in the sensor circuit;

- Oxidation of contacts, which makes a noticeable correction to the measured value;

- Clogged sensor element - dust particles can circulate through the system along with the intake air and settle in the thermistor area;

- Mechanical damage to the housing or other auxiliary elements, which affects the accuracy of measurements;

- Open circuit in the sensor measuring circuit.

Also note that the reason may be a clogged filter and a deterioration in the permeability of the system. But to determine a specific malfunction, it is necessary to carry out diagnostics.

Tags

intake air intake air how much air comes in heated air has airflow from the passage of air through the intake air will become air flow rate. intake air air density and intake air temperature intake air temperature intake air temperature intake air mass buying a car car engine in a car in a car brands of cars car arches outside

Engine ohmmeter is pressure check dmr

Diagnostics and replacement

To check the functionality of the temperature sensor, you can use either simple methods available at home or resort to the help of a service station. If you decide to diagnose the device yourself, you will need to acquire at least a simple multimeter. The verification process consists of the following steps:

- Disconnect the power cord from the intake air temperature sensor contact block.

Rice. 4. Disconnect the power cord from the sensor contact block

- Using a multimeter, measure the resistance value of the sensor when it is cold.

Rice.

5. Measure the resistance of the sensor with a multimeter. If the engine has just been turned off and you do not know the temperature value, you can remove the sensor and force it to cool.

- Then, using a household hair dryer or, if the design of the sensitive element is made of metal, heat the thermistor over the gas burner.

Rice. 6. Heat the sensor with a household hair dryer

- Re-measure the resistance to electric current at the sensor terminals.

Rice. 7. Remeasure the resistance of the heated sensor

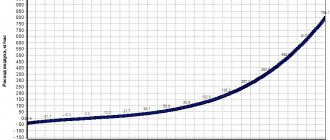

- Compare the measurement results with the table for your sensor model

For example, consider a series of temperatures for a sensor from Lada Priora, shown in the table below:

Table: dependence of sensor resistance on temperature

| Intake air temperature, °C | Resistance, kOhm |

| –40 | 39,2 |

| –30 | 23 |

| –20 | 13,9 |

| –10 | 8,6 |

| 0 | 5,5 |

| +10 | 3,6 |

| +20 | 2,4 |

| +30 | 1,7 |

| +40 | 1,2 |

| +50 | 0,84 |

| +60 | 0,6 |

| +70 | 0,45 |

| +80 | 0,34 |

| +90 | 0,26 |

| +100 | 0,2 |

| +110 | 0,16 |

| +120 | 0,13 |

As you can see, when measuring the resistance of a cold sensor whose temperature is 0 °C, the multimeter will produce 5.5 kOhm. If the sensor is heated to +70 °C, the resistance will be about 450 Ohms. Otherwise, the device is faulty and cannot display the air temperature correctly and requires replacement.

To replace a failed temperature sensor, you need to follow a few simple steps. Disconnect the power cord from the sensor and unscrew it from its seat.

Rice. 8. Unscrew the sensor using a wrench

Install the new temperature sensor into the seat and screw it tightly into the housing. Connect the connector to the contact block - the device is ready for use.

Positive Temperature Coefficient Air Temperature Sensor

PTC air temperature sensors are rarely used (mainly on Renault vehicles). Such a sensor is a thermistor, whose resistance increases with increasing temperature.

The methods for testing such sensors do not differ from those described above for sensors with a negative coefficient. The only difference is the dependence of the resistance and voltage of the sensor on temperature, which are shown in the following table.

Source: press.ocenin.ru

How to choose a new sensor?

An ordinary motorist can spend a lot of time searching for the desired intake air sensor in online store catalogs, getting lost in the existing abundance of offers. Since an incorrectly selected device may not only refuse to interact with the car’s systems, but also not fit into the mounting hole.

Therefore, when choosing, be sure to consider:

- Make of the car and specific model;

- Year of its release;

- The type and functional features of the engine installed in the car.

This approach will minimize the likelihood of error and provide the seller with the maximum necessary information. But, if you are a beginner and have little understanding of such issues, it will be much easier to select the right model using the VIN code.

The VIN code is a unique code unique to your device. If you select a new sensor for replacement using the VIN code, then the likelihood of an error is reduced to zero. This is the most accurate method for selecting equipment for your car. However, if the choice of product depends on several manufacturers, it is worth considering the most famous of them.

Among foreign companies producing intake air temperature sensors, Japanese and German manufacturers have the best quality. Among which are Denso, Bosch, Borsehung, but the price of such models also belongs to the premium segment. If you are looking for a more democratic option, then pay attention to the domestic company Energomash, the Taiwanese company Vika or the Italian Facet.