Vase stand supports

Shock absorber supports are necessary to improve the quality of the connections between the shock absorber and the vehicle suspension. Shock absorber mounts and shock absorbers in particular can be subject to a variety of shock loads and vibrations. For this reason, replacing the VAZ 2110 strut bearings and shock absorbers together contributes to better wheel grip on the road, and the car’s handling becomes better. In addition, the service life of shock absorbers increases, and the body is reliably protected from destruction and impacts. In a word, replacing the strut support of a VAZ 2110 is a responsible and important process.

Replacing the support bearing on VAZ-2110, 2111, 2112

Support bearings are designed to reduce body loads transmitted from the vehicle wheels through the shock absorber struts.

They are components of the upper supports of the front shock absorbers. The support bearings are located in the upper inner surface of the “cups” located in the engine compartment above each of the wheels.

The design of the standard support bearing of the VAZ 2110 consists of the bearing itself (a thick rubber separator with steel balls built into it) and two protective rubber gaskets.

Basic faults

When a support bearing fails, a knock resembling dull blows appears in the front part of the car in the area of the pillars. Most often, such symptoms are observed when driving over uneven surfaces.

A knock indicates that the bearing has ceased to cope with its duties due to a violation of its integrity. This is caused by the destruction of its structure due to:

- exceeding the recommended resource;

- excessive dynamic loads;

- dirt and moisture getting inside the bearing.

However, knocking in the area of the racks may have other causes. To check the bearings and make sure that they are the ones knocking, lift the hood of the car, remove the cover of the supposed “glass”, and place your palm on the upper shock absorber support.

Rock the car up and down. If at the same time you hear the same knock and feel the corresponding vibration with your hand, immediately replace the bearing.

Symptoms of a problem

The most obvious sign indicating that it is time to change the part is a characteristic knocking sound that occurs in front of the car when making a turn. In some situations, the noise is accompanied by a slight vibration of the steering wheel.

However, the symptom described above does not always appear. In a VAZ model 2110, the inner part of the bearing protrudes slightly. The rod of the shock-absorbing unit passes through it, as noted at the beginning of the article. If the part is seriously worn out, then noticeable play appears, which causes the rack to wobble. All this disrupts the wheel alignment.

In the described case, a malfunction of the support element manifests itself as uneven driving in a straight line. Because of this, the driver is forced to constantly adjust the steering movement.

An incorrect camber angle sharply reduces the service life of the shock-absorbing support - in this case it lasts about 20 percent less than usual. In addition, the work resource is reduced:

- tires;

- steering rods;

- their tips;

- brake hoses, etc.

When to change

The service life of standard bearings for the VAZ 2110 is 100 thousand km, but given the state of our roads, it is better not to take risks and change the bearings after no more than 50 thousand km or 2-3 years of operation, especially if they are no longer factory.

Also, support bearings must be immediately replaced when their malfunction is diagnosed. Otherwise, in addition to the body, the supports themselves and the shock absorber struts will suffer.

It is recommended to replace two support bearings at once.

The cheapest support for the “ten” costs about 300 rubles . A good alternative to the original bearing models are products from other manufacturers, such as SS-20, ASOMI, TRACK or FENOX ( up to 800 rubles per piece ). They may have a modified design designed to meet certain consumer requirements.

You can also buy the entire upper support assembly. This will cost approximately 1200-3000 rubles per unit .

The cost of replacing one prop at a service station is about 500 rubles.

It is not necessary to overpay for the work of replacing support bearings. Having the necessary tools at hand, you can do this yourself.

Tools and tools:

- wheel wrench;

- car jack;

- a special puller for steering tips (as a last resort, a hammer and a small pry bar);

- wrenches 9, 13, 19;

- pliers;

- two spring ties.

Work order

- Park the machine on level ground. Jack up the body on the desired side. Remove the corresponding wheel.

- Unscrew the nut securing the steering tip (pliers) and unscrew it (19mm wrench).

- Using a special tip puller, press out the pin. If you don’t have such a tool, knock out the finger by carefully tapping it with a hammer from below and prying it up with a small pry bar from above. Be careful not to damage the threads on the finger.

- Unscrew the two nuts securing the lower part of the strut in the steering knuckle (19mm wrench). If you cannot unscrew them, treat the connections with anti-rust liquid.

- Under the hood there are three nuts securing the upper support to the body. Unscrew them (key 13).

- Remove the entire shock absorber.

- Using two spring ties, tighten the spring enough to relieve the load on the support.

- Unscrew the nut of the central fastening of the support to the rack (wrenches 9 and 22). Remove the support and disassemble it.

- Replace the support bearing in it with a new one.

- Carry out work on assembling the rack and installing it to the body and suspension in the reverse order. Replacing the second bearing is carried out in the same way.

Varieties

At the moment, VAZ 2110 cars are equipped with various types of bearings, which have their own design and functional features. Let's look at them.

| Bearing type | Peculiarities |

| With integrated inner or outer ring | Their peculiarity lies in the presence of special mounting holes provided by the manufacturers. This eliminates the need for additional flanges. Such bearings guarantee rotation of the units when using both the inner and outer rings |

| With detachable rings | In such bearings, the rings are mounted inside |

| With detachable externally mounted ring | The peculiarity of the element is that the outer ring can be separated if desired, and the inner ring seems to merge with the car body |

| Split Singles | There is no significant difference from the bearings under consideration, however, the rigidity of the rings is much higher. |

When choosing a bearing, you should focus on quality. This is the most important criterion when purchasing.

What to choose?

Now let's talk about what manufacturers are ready to offer us today.

If one bearing fails, both should still be replaced. Otherwise, uneven wear will occur, the car will begin to consume more fuel, etc.

- Regular ones. Purchasing them will cost you about 300-400 rubles apiece, depending on the region and store. Good design, solid resource.

- Cheap Chinese supports. You will pay about 300 rubles for them, but the quality literally screams not to buy.

- Foreign and domestic analogues. Here we advise you to pay special attention to such products as TRACK, ASOMI, SS20, Fenox. Good quality, more reliable resource compared to standard ones. But you have to pay for quality. Any of the presented bearings today will cost no more than 800 rubles per unit.

- If simply replacing the bearing is not enough, you will have to replace the entire upper support. You will spend about 1500-3000 rubles on this. And only on one support.

- Those who do not want to do the repairs themselves, considering the procedure for replacing the support bearing to be too complicated, can contact a service station. To replace one element you will pay at least 500 rubles.

Tuning and repair of VAZ 2110

I think everyone understands that with roads like ours, the chassis often requires repairs. Quite often after winter, when the snow has melted and the holes are not yet visible due to puddles, shock absorbers and support bearings often get damaged. Because of such situations, it is necessary to repair this component of the VAZ 2110 chassis. It is better to carry out repairs in a timely manner, since in the first stages it will result in you spending less money than if you cause a breakdown and it will lead to a more disastrous result.

This article will provide information so that you can replace the VAZ 2110 support bearings with your own hands. Moreover, we will do this in such a way that we do not have to adjust the wheel alignment. That is, we will not touch the camber bolts.

Replacing the front support bearing of a VAZ 2110

1. First of all, remove the cap on the hub, and then loosen the nut.

2. Now, put the assistant behind the wheel, let him keep his foot on the brake pedal. At this moment you must unscrew the nut, or rather tear it off. 3. Jack up the car and remove the wheel. 4. Remove the cotter pin from the steering tip, unscrew the nut and use a puller to press out the pin.

5. Press out the ball joint pin.

6. At this stage you need to release the brake hose; it is held on the strut clamp.

7. Next you need to remove the caliper from the brake disc. When it is unscrewed, hang it to the side so that it does not interfere with you, but at the same time does not strain the brake hose.

8. Now unscrew the 3 nuts holding the strut under the hood. Before doing this, I advise you to loosen the strut nut a little. This will make it easier for you to work with the stand further.

9. Unscrew the CV joint nut and remove the strut so that the CV joint comes out of the splines.

10. Now that the strut is removed, you will need a spring remover, called a spring puller. Having installed them on different sides of the spring, we begin to tighten the nuts on the pullers one by one. This will compress the spring. After the operation, unscrew the support bearing of the VAZ 2110.

11. We put a new one in place of the old support.

Everything is assembled back to the parsing algorithm.

As you can see, replacing the support bearing of a VAZ 2110 is not an entirely simple matter. But if you decide not to spend money on a service station and do this repair yourself, then following these instructions you should not have any difficulties.

For greater clarity, I suggest watching a video in which the support bearing of the front strut of a VAZ 2110 is replaced:

Replacement

You made the right decision by replacing the support. An inspection was carried out, and it showed that there was no way without replacement.

To work you will need a certain set of tools:

- Balloon wrench;

- A pair of spring ties;

- Pliers;

- 19, 13 and 9 mm wrenches;

- Jack;

- Puller for steering tips;

- If you don't have a puller, then take a small pry bar and a hammer.

We recommend using a puller, as it ensures simpler and more accurate work.

Dismantling works

Everything is ready, so you can proceed directly to the repair work.

- Choose a level area for the car. A regular garage should be enough.

- Raise the front of the car on the side where you plan to replace the first bearing. For this you will need a jack. Then remove the wheel.

- Using pliers, the fastening nut of the steering tips is uncoiled and then removed using a 19 mm wrench.

- The finger is pressed out using a puller. If you couldn’t find the puller, then carefully tap the finger from below with a hammer, prying it up with a pry bar from below. Make sure that the thread on the finger is not damaged. Otherwise you will have to change it too. This is why a puller is the best solution.

- Again, use a 19 mm wrench to unscrew the nuts on the bottom of the steering knuckle strut. There are two of them. Sometimes they get stuck and become rusty. Use WD40 to loosen it.

- We move to the engine compartment, where you will find three mounting nuts that hold the upper support to the body. They are dismantled with a key number 13.

- Unload the support by tightening the spring with two ties.

- Remove the central mounting nut that holds the support to the post. You will need two keys - 22 and 9.

- Remove the support and disassemble the assembly.

- Remove the bearing and then install a new one in its place.

- Carry out the assembly procedure in reverse order.

- By analogy, replace the support on the side of the second front wheel. The procedure there is no different from the one performed above.

After completing the replacement, drive out onto a flat section of the road and drive a little. Then you need to ride on an uneven surface.

If everything is fine, there are no extraneous noises or knocks, all that remains is to go to a service station, where they will adjust the position of the wheel angle.

How to replace the front support bearing and strut on a VAZ 2110

The support bearing of the VAZ 2110 is one of the important parts of the chassis. Thanks to it, the shock absorber can easily rotate around its own axis without pushing through the upper part of the mount. This ensures the durability of the suspension itself and also guarantees comfortable driving.

With proper operation, the part should fail only after 70-100 thousand km. However, situations arise when repairs will be required sooner. You can learn how to recognize a malfunction in time, diagnose a breakdown, or professionally replace a VAZ 2110 support bearing with your own hands from this article.

Causes of failure and how to check the support bearing of a VAZ 2110

The original supporter is capable of traveling 70-100 thousand km. But if used incorrectly, failure will occur earlier. For example, a breakdown can occur due to:

- dynamic driving style;

- ignoring the features of the roadway;

- liquid getting inside the part, which will wash out all the lubricant from the bearing.

The main symptoms of a malfunction will be:

- knocking noise when driving on rough roads;

- vibrations on the steering wheel when it rotates while driving;

- slow reaction to driver actions.

How to check the support:

Below is a video with verification recommendations:

Creak when turning the steering wheel in the area of the front wheel of a VAZ 2111:

How to check the support bearing of a VAZ 2110 strut:

vazoved

I drive a LADA VESTA CROSS, Moscow

Then there will simply be no one to pay the fines! This is a Korean 7 in 1 car tablet video recorder for Android..

I forgot about fines and Yandex Navigator.

There is FULL HD shooting, radar detector and GPS with 32 satellites. I got it at a reasonable price for just a few thousand here >>>> MORE...

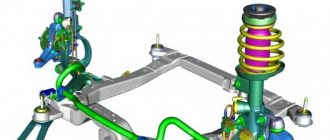

Diagram and design of the unit

This photo shows a diagram of the front suspension of the car with a list of main elements:

Why do you need support?

Replacing the upper strut support of a VAZ 2110

The shock absorber support is also called a shock absorber pad or a shock absorber pad. Due to this part, the shock absorber and its rod are attached to the car body.

Note! When a car moves, it is often exposed to the impact force of potholes and potholes in the road. In this case, it is extremely important to reduce these shock loads, which should not reach the car body.

It is these problems that are dealt with by the shock absorber supports and the shock absorbers themselves, which are secured not directly, but through supports. They can be seen when you open the hood of the car. As a rule, they are located on the right and left above the wheels of the car. In frequent cases, the shock absorber support may consist of a rubber gasket that absorbs impacts with vibrations, and a bearing of different shapes. As a rule, everything depends on the design features of the arrangement of parts. In the support, a rolling bearing is necessary to reduce the friction force of the shock absorber rod when turning the machine.

About replacing an assembled part

If there are leaks on the shock absorber, the entire strut needs to be replaced. To do this, you need to carry out the disassembly process:

- Hang up and dismantle the wheel;

- Loosen the top fastenings;

- Remove the brake caliper with hose;

- Disconnect the steering tip and CV joint;

- Disconnect the steering knuckle;

- Dismantle the unit;

- Replace the brake disc, spring and other elements on the new strut, and then reassemble.

It is important to remember that after such a procedure it is necessary to adjust the wheel alignment, because when dismantling the shock absorber, the camber bolts are disconnected.

Buyer's choice: cost of support bearing VAZ 2110, its manufacturers and articles

There are many different options on the market. It is advisable to take original parts - article number: RS-67499 or 2110-2902820-RU. The width of the part is 144 mm, length – 148 mm, and height – 62 mm with a weight of 1260 grams.

However, there are plenty of other options with good reviews. Among the well-proven products are parts from the Balakovo plant, as well as products from the Asomi company. The price fluctuates between 750 – 1800 rubles. When choosing a spare part, you should pay attention to the quality of the processing of the edges of the part, as well as the packaging. In addition, the part must have certificates of conformity and quality certificates.

Which support bearing should you choose?

In any situation, experts recommend choosing original spare parts produced by the car manufacturer. In the case of the 2110th model, look for bearings whose article number is 2110-2902820-RU. International designation – RS-67499.

The element has the following dimensions:

- weight – 1.26 kg;

- outer diameter – 148 millimeters;

- internal – 144 mm;

- part height – 62 mm.

It is also permissible to use products produced by a plant located in Balakovo. The article number of this bearing is BRT 2110-2902820RU.

Asomi has good analogues (110.2902.820-31), however, their cost is quite high - more than 900 rubles.

How to find out that the support bearing is broken

In the vast majority of cases, the support bearing fails due to severe contamination. Therefore, if you often drive in bad weather or travel on almost complete off-road conditions, this part will break down much more often than when using the car in the city.

What symptoms indicate bearing failure? There are several of them:

- knocking of the front suspension when driving even on small uneven sections of the road;

- an unpleasant grinding or crunching sound when turning the steering wheel in any direction;

- clicks that can occur even while driving on a flat road.

Replacement of the VAZ-2110 support bearing should be carried out immediately after detecting any of these symptoms. Otherwise, the safety of car operation is significantly reduced, the risk of rapid tire wear increases, the support struts fail, the restoration of which will cost much more.

The procedure for replacing a bearing on a VAZ-2110

In order to cope with the replacement of a part relatively quickly, you will need to prepare in advance all the necessary tools - a standard set of keys, a spring tie, a mechanical steering wheel end puller and a jack. In addition, it is important to choose the right support bearing itself, which must meet the specifications of your car.

The replacement procedure does not take as much time as it might seem at first glance, and includes several main steps:

- We install the car on a perfectly flat, hard surface and dismantle the hub cap;

- Unscrew the CV joint nut using a wrench or a special socket. At this point, you will need help to press the brake pedal at the same time;

- lift the car using a jack and remove the wheel;

- remove the cotter pin of the steering tip nut using a special puller, then completely unscrew it;

- remove the finger, which will have to be pressed out with very noticeable force;

- unscrew the bolts holding the ball joint and dismantle it;

- remove the brake hose, after which you need to unscrew the bolts holding the caliper and move it slightly to the side. This will allow you to reach the bearing without interference;

- pull out the CV joint, compress the spring using the tie mentioned above and remove the support bearing;

- Carefully install a new support to replace the worn one, after which we reassemble in the reverse order.

Step-by-step instructions for removing the assembly

Before the procedure, you should stock up on the necessary tools.

To work you will need:

- jack, trestle or lifting mechanism;

- a set of standard wrenches with socket heads from 12 to 28;

- several screwdrivers, including Phillips and flathead;

- two ties for removing the spring;

- engine oil.

Having the tool available, you can get to work. Removal instructions are provided below:

- We drive the car onto a lift or overpass. You can also lift the wheel we need using a jack, which should be placed under specially reinforced areas of the body. You must first loosen the wheel mounts;

- Open the hood, where we loosen the three upper support fastenings;

- Now you need to loosen the central nut of the strut. It is not necessary to unscrew it completely so that the spring does not straighten;

- Remove the wheel rim;

- Now you need to unscrew the CV joint nut. To do this, you will need to lock the brake disc or your partner must press the pedal;

- Remove the brake hose fixation;

- Using a 17mm wrench, remove the two brake caliper bolts;

- Separate the brake pads and remove the caliper;

- 1. Unscrew and unscrew the steering tip nut with a 19 mm wrench;

- We disconnect it using a special puller;

- Using a 17 wrench, unscrew the ball fastenings;

- Remove the steering knuckle;

Replacing support bearings without removing struts on a Lada Granta

Hello. Chassis repair is perhaps the most common work that a car owner has to do, or more accurately, “our” car owner has to do. These constant knocks and squeaks seem impossible to completely “defeat”, and after one is put in order, another goes out of order. In general, this is not strange, given the state of the roads in Russia. Constant loads and driving on uneven roads have the most unfavorable effect on the chassis. In principle, it would probably be wrong to blame the roads alone; part of the problem certainly lies with the designers of AvtoVAZ, who, despite problems with the roads, continue to produce cars with flimsy suspension and chassis. Well, enough of the ranting, I think, we need to get to work.

Today, dear readers of VAZ Repair, you will learn how to replace the support bearings on a Lada Granta, and not just replace them, but replace them without removing the struts. I wonder how? Then continue reading.

I’ll say right away that before replacing the support bearings, you need to make sure that they are really faulty. Read about how to check support bearings here.

Those who have ever encountered the need to replace support bearings know that to perform this work it is necessary to remove the struts along with the springs, which certainly complicates the task. However, as you know, laziness sometimes works wonders; in addition to being the “engine of progress”, it also often allows you to make your life easier. This photo report will clearly demonstrate to you how to replace the support bearings without removing the strut and you will be able to see that sometimes laziness can work wonders :-). Joke!

To work you must have:

- Set of keys: “13, 14, 17, 22”;

- Hexagon (to fix the rod from twisting);

- Two jacks or supports for the car;

- Special spring ties;

- Actually, the support bearings themselves.

Cause and symptom of support bearing failure

It goes without saying that timely replacement, repair and, in general, any modernization of a car brings greater effect and success. In particular, if you are late in replacing the bearing, you can damage other important parts and components of the machine. The entire chassis can even fly off if you are not careful about your car. And then just a replacement won’t do, and you’ll have to do a major overhaul. The main cause of failure of this bearing is dirt. We conclude that if we drive often off-road, we will have to replace this component more often. The support bearing itself is practically not protected by anything. A symptom that the bearing has failed is a knocking sound. But to finally be sure that the reason lies in the support bearing, diagnostics by turning the steering wheel to the right and left will help.

Replacing support bearings on a Lada Granta without removing struts - step-by-step instructions

- We hang the wheel, then remove it.

- We unscrew the bolt securing the stabilizer strut, and then remove it so that it does not limit the travel of the strut.

- Next, take the hexagon and, holding the strut rod with it, loosen the fastening nut.

- We install the jack under the ball pin, and jack the rack, thereby removing the load from the second jack. At the same time, the stand will begin to “play” a little.

- We take the spring ties and attach them to the coils. We tighten the spring quite a bit, and then lower the jack installed under the ball. After these manipulations, the stand should go down.

- Now you need to unscrew the support bearing and rod; to do this, lower the rod down and pull out the “support” through the resulting void.

- We clean the rubber band and support cup from dirt. If you are going to install SS-20 supports, then the lower cup will not be useful to you.

Further assembly is carried out in reverse order. I recommend lubricating the bolts and nuts with “graphite” or at least working off, and after completing all the work, do not forget to tighten everything properly. We put the wheel in place and do the same with the second “support”, after which you can safely check the work. As you can see, in order to replace the support bearing on a Lada Granta, it is not at all necessary to completely dismantle the shock absorber struts.

That’s all I have, I hope this “life hack” will be very useful to someone and will significantly “make life easier.”