The tenth family of the Tolyatti auto giant was equipped with injection engines. The first releases of cars were with 8-valve heads, and subsequent ones with 16-valve heads. Both engines were equipped with electronic control units (hereinafter referred to as ECU). The main controller collects readings from several sensors and adjusts the balanced operation of the engine (hereinafter referred to as the internal combustion engine). The temperature sensor on the VAZ 2110 is also responsible for interacting with the computer, and if it malfunctions, the “Check Engine” signal lights up, which in English means “Check the engine.” Next, we will tell you where the temperature sensor is located on the VAZ 2110, how to check and change it.

Attention! The injection "tens" have 2 coolant sensors. One for the arrow on the dashboard, and the second for exchanging data with the ECU and turning on the radiator fan. It's called DTOZH. The article is dedicated to him.

Principle of operation

The mechanism of action of the temperature sensor on the VAZ 2110–2112 family is based on changing resistance parameters depending on the ambient temperature t°C. In essence, we have before us an electronic resistor with a negative temperature coefficient. That is, the lower the t°C, the higher the resistance of the device, and vice versa.

Table 1. Operating temperatures and parameters of DTOZH

| Temperature, t°C | Resistance, Ohm |

| 100 | 177 |

| 40 | 1459 |

| 25 | 2796 |

| 0 | 9420 |

| −20 | 28680 |

| −40 | 100700 |

The presented values can be used to check the sensor with a tester. More on this below.

What function does DTOZH perform in the ECU system?

There is no damper (choke) on injection machines. Now the fuel is enriched or leaned by the control unit using the t°C values coming from the DTOZH. In addition, the main controller monitors the operating temperature of the engine and gives a command to turn on the fan if it overheats.

VAZ 2114, VAZ 2115

On these cars, GM 2112-3851010-01 can be used as a DTOZH. The location of the device is between the cylinder head and the thermostat.

To check, it is recommended to dismantle the element (open-end wrench size 19). To do this, you need to wait until the engine cools down, reset the negative voltage on the battery and drain the antifreeze.

After this, you need to dismantle the device and check it by heating the liquid, a thermometer and a multimeter.

The following parameters must be present.

Table 2.

| Temperature, 0C | Resistance, Ohm | Voltage, V |

| +30 | 1350-1880 | 8 |

| +50 | 585-820 | 7,6 |

| +70 | 280-390 | 6,85 |

| +90 | 155-196 | 5,6 |

| +110 | 87-109 | 4,7 |

If there is a discrepancy in the readings, the device must be replaced.

Causes and symptoms of malfunction

Service workshop technicians say that in 90% of cases, the breakdown of the temperature sensor on a VAZ and other brands of cars occurs due to natural causes. Most often, a break in the internal contacts of the resistor occurs. As a result, the DTOZh sends incorrect parameters to the ECU, for example, engine starting t° within 0 °C. The control unit considers the engine cold and gives a command to another sensor - the mass air flow sensor - to reduce the air supply, that is, to enrich the mixture. Therefore, a warmed-up engine begins to work strangely, “excitedly” with failures. Here are 3 more most common reasons for the incorrect operation of the DTOZH:

- The seal of the sensor housing is broken.

- There was a break in the electrical wires.

- The power supply has fallen off.

In the above cases, the ECU does not see the DTS system, so it attracts the driver’s attention with a “Check Engine” signal on the dashboard. In this case, the operation of the car becomes unusual:

- the engine starts with difficulty and tends to stall;

- the speed fluctuates even on a warm engine;

- strong detonation is felt;

- the former power is lost.

In addition, fuel consumption increases, and dark smoke comes out of the exhaust pipe. It is necessary to make a diagnosis. To do this, you can go to a car service center, or install a special application on your smartphone and buy a Bluetooth adapter.

Air flow control

The location of the mass air flow sensor (MAF) is on the air duct running from the filter to the throttle valve. The device consists of 3 elements located inside the air flow. The first one measures the temperature of the incoming stream, and the other 2 heat up to a certain degree. The stronger the flow passing through the air sensors of the VAZ-2110, the more intensely they are cooled. The controller that supplies the voltage determines the air flow by the energy spent on heating the 2 elements in relation to the temperature of the first meter.

There is another design of the MAF device with a silicon mesh and two elements; it operates on the same principle. The marking of the first type is 2112-1130010, the second - 21083-1130010. Receiving signals from these devices, the processor makes a calculation and changes the duration of fuel injection for the VAZ-2110. The following signs indicate a sensor failure:

- the engine stalls when switching from high speed to idle;

- unstable operation at idle;

- difficulties arise when starting the engine;

- increased fuel consumption.

Replacing the mass air flow sensor control device is not difficult; you need to disconnect the wires, remove the old sensor from the air duct and install a new one.

Where is DTOZH located?

All front-wheel drive VAZ cars received a transverse internal combustion engine. If you look down, between the cylinder head and the air filter housing, you can see the location of the DTOZH. It is built into the coolant flange pipe and looks in the direction of travel, that is, towards the radiator. A block with two wires fits into it. (A little lower, directly in the block, there is another coolant temperature sensor. Thanks to it, we can see the t°C level on the dashboard. 1 white-green wire goes to the device).

Determining the position of the crankshaft

The task of this element is to determine the location of the pistons, along which the controller produces a spark in one or another cylinder. On VAZ-2110 cars, the 8-valve injector and subsequent models, the sensor is located near the crankshaft toothed pulley. In earlier dozens with a carburetor, the devices could be located inside a mechanical ignition distributor. Then they were called Hall sensors and controlled the position of the pistons by rotating the camshaft.

The device is a magnet with a small coil that generates electrical impulses when a metal mass approaches, the role of which is played by the teeth of a pulley.

The magnetic Hall meter of the VAZ-2110 is the most important element in engine operation, and if the sensor fails, the engine will not even start.

Fortunately, the device is very reliable and operates for a long time. Replacement is simple and does not require a description.

Which sensor to choose

Independent automotive industry experts and service workshop specialists are of the opinion that it is better to buy original spare parts or branded analogues. The latter are selected according to codes in special combination programs. The coolant temperature sensor, VAZ 2110–2112 family, has serial number 21120–3851010–00. Sometimes at the end, instead of 00, you can see: 01, 02, 03. This indicates that the device was made at one of the related AvtoVAZ enterprises.

Table 2. Price of the original DTOZH and its foreign analogues

| Manufacturer | Number | Amount, rub. |

| GM AvtoVAZ | 21120–3851010–00 | 250 |

| AvtoVAZ | 21120–3851010–82 | 165 |

| Magneti marelli | 1719 16011 150 | 355 |

| Hella | 6PT 009 107–271 | 735 |

| Eps | 1.830.098 | 1080 |

Sources: autopiter.ru, exist.ru.

Interesting fact. Some owners buy exclusively foreign spare parts for their “tens”. The same shock absorbers, struts, springs, timing belts, electrical equipment and other parts “from there” last much longer.

CO functions

The cooling system is responsible for removing excess heat that is generated during operation of the power unit. If the engine overheats, the consequences can be catastrophic.

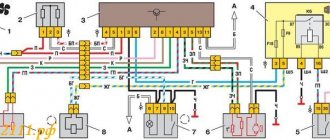

Cooling system diagram

In addition to heat removal, CO additionally performs several other functions:

- Helps accelerate engine warming up to optimal operating temperature;

- Warms the air inside the cabin;

- Cools the lubrication system;

- Cools exhaust gases.

In total, three types of cooling systems can be used on cars:

- Air. The cooling process is carried out by blowing air over the units;

- Liquid. The coolant is a special liquid - water, antifreeze or antifreeze;

- Combined. Both types of cooling are mixed in one system.

antifreeze or antifreeze acts as a cooler .

How to check

There are many cases in history when the owner installs a new spare part, but it does not work. Therefore, after purchasing a temperature sensor, it is recommended to measure the resistance before installing it on the same VAZ or another car. To do this you will need a multimeter (tester). We convert it to an ohmmeter. At room temperature (+23 °C, +25 °C), the readings should be around 2780 Ohms (as in table No. 1). If you lower the DTOZH into a glass of boiling water (+100 °C), hold it for a while and take readings, a result in the range of 175–180 Ohms should appear on the tester screen. This means the purchase is in good condition. Can be installed on a car.

How to replace the coolant temperature sensor on a VAZ 2110-VAZ 2112?

Attention! Before you buy a new sensor, look at the markings on the old one and exactly the same markings on the new one, buy, if you buy any other sensor, it may simply not give you readings or simply show them to be incorrect, besides, it comes with with a new sensor, check if necessary, a new copper washer is included, if it is not there, buy it separately, for clarity, in the picture below this washer is marked with a red arrow, but there is only one but! This sensor, shown in the photo below, does not at all relate to these sensors, which we will break down with you today, as follows from the photo below, which is taken for illustration only, so that you understand that it is intended for a copper block and where it can be on the counter!

Dismantling: 1) First, check which elements prevent access to this sensor, here is an example of an interfering air filter housing, think about how to remove it or not, read about how to remove it in the article: “replacing the air filter housing in a VAZ.”

2) Moving on, remember that we told you that the coolant system needs to be drained, so use the article called "Changing the Coolant in Your Car" which explains how to drain the coolant, but you may not need to drain the sensor for replacement, just a little dirt in the engine as a whole, do whatever you see fit, both ways will help you replace either of the two sensors on your car as normal.

3) So, after draining the liquid, select the sensor to be replaced and do not forget to remove the negative clamp from the battery (read about how to remove the clamp “here in this article”), after selecting, disconnect everything that is connected to the sensor that you are going to change (see . photo below)

After disconnecting the sensor (also look at the photo below, they are clearly visible), unscrew the sensor and remove it from the car, replace it with a new sensor, if the coolant is not drained from the system, the note below says carefully

Attention! If you decide not to remove the coolant, but simply replace the sensor, the first thing to do is take the second sensor in your hands and twist the old sensor a little, when you can turn it by hand, move the key to the side and manually the sensor begins to turn, do it slowly and hold the sensor by the hole because you won't be sure when you unscrew it and the fluid will start to flow out around the edges of the sensor, after unscrewing the sensor take it out and put a new one in its place, the fluid will flow out a little if you do it right, finally, Screw the new sensor all the way in and check if it works by cranking the engine and seeing if all the symptoms go away or not!

Once the sensor is installed, everything is done in the reverse order of disassembly, but be sure to apply sealant (this is up to you) to the edges of the sensor as shown in the photo below (the bottom photo shows a different sensor, just for clarification), but if you have already finished the sensor and you don't have anything to leak, don't forget to lubricate the edges.

Checking the coolant temperature sensor:

We check the sensors, as we said, are identical, they just have slightly different readings, check the container or lift it (a glass is convenient or just a kettle can be used) and heat it to a certain temperature (the temperature to which the container can be heated. shown in the pictures below, for example, warm it up up to 100 degrees and check with a thermometer, lower the sensor into heated water (but only the part that was wrapped in the holes in the engine, the sensor contacts do not need to be lowered into the water), then connect the wires to the sensor and check its resistance with an ohmmeter.

Replacement

Before repairs, it is necessary to carry out a number of preparatory measures. First, you should choose a level area for the machine. It can be in the garage, it can be outdoors. Secondly, prepare the tool: open-end and ring wrenches (19 mm, 13 mm, 10 mm, 8 mm). You will also need a capacious medical syringe of 100–250 ml, a 15–20 cm dropper tube and a 0.5–1 liter jar (so as not to drain the antifreeze/antifreeze). The sequence of actions is as follows:

- We wait until the engine cools down completely.

- Use a syringe to pump out the coolant from the expansion tank (100–200 ml).

- Unscrew the negative terminal of the battery (10–13 mm wrench).

- Unscrew the air filter housing fasteners (8 mm wrench).

- Carefully tilt the “pan” to the right.

- Disconnect the power supply from the DTOZH.

- We unscrew the sensor (19 mm wrench).

- We clean the landing area from dirt.

- We screw in the new DTOZH.

The assembly must be done in reverse chronology. There is no need to use sealant, since the copper O-ring fits perfectly and seals the connection. Let's start the engine. We check its operation and inspect the repair area for antifreeze leaks. The entire event takes 15–20 minutes.

Articles

For oxygen sensors, the designation 21120-3850010 was first used. Then an article appeared with the numbers 1118 (see photo). It appears to be a new type of sensor. It will be easier to use BOSCH articles.

Exhaust system of VAZ-21120 engine

We list the article numbers of the remaining sensors:

- Mass air flow sensor (21124 or 21120): 21083-1130010-01, -10, -20;

- Mass air flow sensor (motor 21120 with ECU January 4.1): 2112-1130010, -01;

- DPDZ: 2112-1148200;

- РХХ: 2112-1148300-02;

- DPKV: 2112-3847010, -01, -03, -04;

- DTOZH: 2112-3851010, -01, -02, -05;

- Speed sensor: 2110-3843010-13, -18;

- DPRV: 2112-3706040, -02, -03;

- DD: 2112-3855020, -01, -02, -03;

- Oil pressure sensor: 2106-3829010, -01, -02;

- Antifreeze level sensor: 2110-3839310-10, -11, -12, -13, -14;

- Coolant temperature indicator sensor: 2101-3808600, -02, 2106-3828010.

The last three sensors are not connected to the ECU. However, a rough road sensor (2123-1413130) can be connected. It affects the operation of the engine, although it is attached to the body.

In general, on VAZ-2112 hatchbacks, sensors may be different from those indicated in the list. But then we are talking about an 8-valve engine. And everything that we indicated applies to 16 valves, here is a diagram of this engine.

Where to buy car accessories

Spare parts and other products for the car are easily available for purchase at auto stores in your city. But there is another option that has recently received significant improvements. You no longer need to wait a long time for a parcel from China: the AliExpress online store now offers the opportunity to ship from transshipment warehouses located in various countries. For example, when ordering, you can specify the “Delivery from the Russian Federation” option.

Follow the links and choose:

| 12V car alarm, engine start/stop button, anti-theft system | Universal 10mm Oil Temperature Gauge for Cars | Automotive Electric Throttle Actuator Controller |

| Backlit Tire Pressure Gauge, High Precision Digital Meter | Set of screwdrivers for removing seals | 20 pcs crimp clamps with pliers |

Other control devices

The remaining sensors are also connected to the controller and perform important functions. Failure of any of them leads to an increase in fuel consumption, loss of acceleration dynamics or unstable operation of the power unit. Here is their list:

- throttle position detector;

- knock sensor;

- speed meter;

- oxygen sensor;

- phase detector.

The element that determines the angle of rotation of the throttle valve is installed on its body and is directly connected to the axis. The task is to facilitate the supply of excess fuel to the cylinders when the accelerator pedal is pressed sharply. The principle of operation is similar to the accelerator pump in a carburetor, only of the electronic type. The device often fails, especially after washing the engine.

The knock sensor located on the front side of the cylinder block functions much more reliably. Unlike other devices, it generates a signal independently, acting on the principle of a piezoelectric element. The stronger the detonation flashes in the cylinders, the more voltage is supplied to the controller, and it regulates the ignition angle, trying to extinguish detonation. If necessary, change with a wrench.

List of error codes issued that indicate a malfunction of the temperature sensor:

Codes 0112 and 0113 identify problems with the MVR associated with low and high temperatures, respectively. Don't rush to buy a new sensor. Since the element is an ordinary thermistor that changes resistance values depending on temperature.

Error codes for mass air flow sensor on VAZ 2110

It is very easy to check it with a multimeter by removing it from the VAZ and immersing it in water brought to the boiling point, measure the resistance as the liquid cools and compare it with the table values. If everything is normal, the problem may be caused by a clogged sensor or contacts.

Codes 0115 and 0116 indicate that the coolant regulator readings are incorrect. This may also be due to sensor failure, short circuit, or other problems discussed earlier in the article.

Codes 0117 and 0118, finally, indicate that the temperature recorded by the VAZ 2110 TOZH meter is outside the normal range. A seven on the end means the values are too low, and an eight on the end means they are too high. In this case, it is worth checking the entire cooling system, including the regulator itself.

Engine operating temperature on the VAZ-2110 - is there a difference?

Engine operating temperature on the instrument panel.

The factory provides normal engine operating temperatures ranging from 87 to 103 degrees. Maintaining the temperature within these limits can be greatly influenced by certain issues related to the performance and quality of the cooling system elements. Let's look at each of them briefly.

Cooling radiator

Clogged honeycombs of the engine cooling radiator.

Cleaning the radiator regularly will ensure normal engine operation and will help prevent antifreeze from boiling.

When checking the condition of the radiator, we pay special attention to the presence of leaks and the integrity of the honeycombs, the absence of cracks in the tanks and the condition of the pipes

water pump

Antifreeze leaking from under the pump.

Maintaining the normal operating temperature of the antifreeze also depends on the efficiency of the pump. The main pump malfunctions include bearing failure, leakage and destruction of the pump impeller.

This can occur as a result of both physical damage to the impeller and destruction as a result of cavitation processes. Cavitation is most often caused by the use of low-quality antifreeze or untimely replacement.

Thermostat

Thermostat location under the hood.

For example, the engine may not warm up to the legal 87–90 degrees due to a stuck valve. However, most often thermostat malfunctions occur due to the quality of the thermoelement. Despite the fact that each thermostat is marked on the body, which indicates the valve response temperature, the indicated temperature does not always correspond to reality.

So, at the specified operating temperature of 85 degrees, the thermostat can pass liquid in a large circle already when warming up to 75–80 degrees. As a result, the temperature will not correspond to the norm, the engine will not be able to warm up to the optimal value. The only solution is to test the thermostat before installation. To do this, the thermostat body is placed in a vessel with water and heated to the specified temperature, periodically checking the condition of the valve. A discrepancy between the thermostat response temperature, even by 3–5 degrees, will not allow you to obtain the optimal operating temperature while driving.

Sensors, ECU firmware and fan

The temperature sensor is located near the thermostat housing.

The sensor sends an electrical impulse to the electronic control unit, which in turn gives a command to start the cooling fan. The normal temperature at which the fan should start is 105 degrees. If the sensor readings are incorrect, the fan will start earlier (in this case the antifreeze will not warm up to normal) or later

Then the engine may overheat and the antifreeze may boil, especially antifreeze of poor quality.