02.10.2019

| (Votes: 2, Rating: 5) |

Issues discussed in the material:

- What could be the problem with the throttle sensor?

- How to troubleshoot throttle sensor yourself

- How to Troubleshoot a Throttle Sensor by Cleaning

There are no “minor little things” in the design of the car. Each unit performs its own function, and even a seemingly inexpensive part deserves attention. For example, if you do not pay attention to malfunctions of the throttle sensor in time, then there is a high probability that you will have to prepare for expensive engine repairs.

Purpose of the throttle position sensor

This sensor transmits data to the electronic engine control unit about the position of the bypass valve in a certain time period. The operation of this unit is based on the interaction of AC and DC converters.

The highest value of the total resistance of the converters is at the level of 8 ohms. The design of the remote sensing sensor has three contacts. The first and second contacts receive a current of about 5 V, and the third contact is connected to the controller and performs a signaling function.

DPD3 is located on the throttle body. The device receives signals about the opening and closing of the passage channel. The resistance index of the part changes to satisfy the following conditions:

- when the damper is open, the voltage on the third contact will exceed 4 V;

- if the air passage is blocked by the remote control damper, then at the 3rd contact the current does not exceed 0.7 V.

The device controls all fluctuations in contact voltage and thus regulates the supply of fuel necessary for the formation of the air-fuel mixture.

Due to a malfunction of the sensor, the voltage reading most often goes beyond the established limits. This leads to disruption of the normal operation of the internal combustion engine, which can ultimately lead to breakdown of the unit.

We recommend

“Expansion tank cap: we understand the design and purpose” More

Important: a malfunction of the sensor often causes a malfunction of the gearbox. Every car owner understands that restoring an engine and transmission is a process that requires a large investment of time and money. If symptoms indicating a breakdown appear, it is necessary to carry out a diagnosis.

Reasons for sensor failure

It is impossible to completely prevent breakdowns of units, parts, and electronic mechanisms of vehicles.

Possible reasons for failure of the TPS:

- Loss of contact between the slider and the resistive layer. The reason is that the tip is broken, causing scoring on the substrate. The throttle sensor may continue to function (not correctly) until the resistive layer is completely erased. As a result, the core fails completely.

- A linear increase in the voltage of the output signal is not provided due to a violation of the base deposition at the start of the slider stroke.

It is necessary to understand that not a single indicator on the instrument panel will indicate such a breakdown, and self-diagnosis of the car is not provided. The existence of a malfunction can only be assumed in the event of unstable operation of the motor in different operating modes.

Symptoms of a Malfunctioning Throttle Sensor

The following symptoms may indicate a malfunctioning throttle sensor:

- Unstable operation of the internal combustion engine at idle speed.

- The engine stalls when shifting the gearbox or when engaging neutral gear after other speeds.

- The car stalls at idle.

- When driving in different gears, there are jerks or dips in traction (most often such symptoms are felt when accelerating.

- Traction drops and acceleration of the car deteriorates (at the start, when driving uphill, when the car is fully loaded or when driving with a trailer).

- The Check Engine light on the dashboard lights up. If you connect scanning equipment in such a situation, you will receive error p0120 or with another code indicating a malfunction of the sensor in question.

- Failure of the throttle sensor leads to increasing fuel consumption by the car.

Please note that the listed symptoms can also be caused by a malfunction of other internal combustion engine components, for example, a breakdown of the damper itself. But despite this, you should start by checking the sensor.

Causes of malfunction

Improper operation of the throttle sensor may be caused by wear. It should be noted that the wear of various elements of this unit has different effects on the operation of the system.

If the coating on the conductor is worn off, the sensor will not be able to detect current readings.

Exceeding the design life of the moving parts of the sensor. If the gap between the sensor and the axle conductor exceeds a certain value, contact is lost between these parts. In this case, the malfunction indicator on the instrument panel will not light up. Such a breakdown can be assumed by the presence of interruptions in the operation of the motor in various modes.

Oxidation, contamination or corrosion of sensor contacts.

If such a malfunction is detected, to restore normal operation of the unit, it will be necessary to replace it. Non-contact sensors are considered more reliable, since their design does not contain rubbing elements.

Preventive measures

The DZ has a long service life and rarely breaks down. But mechanical damage to the housing itself may occur, or repair work must be carried out in the engine system. Then it or its components can be replaced. The sensor is always in the risk zone. It cannot be repaired and often needs to be replaced with a new one.

To prevent damage to this unit, it must be cleaned regularly. According to the manufacturer's recommendation, this should be done when changing the oil or after 20,000 km. mileage If these recommended preventive measures are taken, then the throttle valve and its sensor can serve the car owner for more than one year and subsequently will not need to be replaced.

Similar news:

- Diagnostics and troubleshooting of the mass sensor...

- Causes and solutions to the problem of squealing car brakes

- Causes of strong engine vibrations at idle

- Selection of spark plugs by car make, by VIN code

- Fuel consumption of Chrysler Sebring

- Fuel rail pressure tester

- Design and principle of operation of an automatic transmission

- Characteristics of the rotary engine, its pros and cons

What are the effects of TPS malfunctions?

If signs of a malfunction of the throttle sensor appear, then, first of all, this may affect the operation of the engine when the gear is in neutral. Injection engines do not have a system that controls the engine at neutral speed, as is provided in carburetor units. The electronics regulate the number of revolutions of the power unit solely based on data from the damper sensor. Thus, incorrect operation of the TPS leads to unstable operation of the internal combustion engine.

Increased fuel consumption. The TPS produces an incorrect signal, which the motor control electronics interprets as a closed damper position, but in fact it is open. It turns out that the engine operates stably in normal mode, but spends more fuel mixture.

- When accelerating, you feel dips and the car jerks violently.

- The position of the gas pedal does not change, but the engine jerks, and after the gas is released, it stalls.

- You feel a loss of traction (the car “does not pull”).

- The indicator lights up to indicate a breakdown.

- P2135 – error in throttle position sensor

In addition to the above error, the diagnostic scanner can also show other codes indicating incorrect operation of the remote control or its sensor: P0120, 0122, 0123, 0220, 0223, 0222, 01578.

To diagnose, it is necessary to measure the pulse voltage from the sensor, the wiring resistance, and also check the ground pin on the control unit.

Causes of problems with the damper sensor:

- Poor ground contact. To eliminate the malfunction, you need to clean the contacts or eliminate existing breaks.

- Relay failure. To eliminate the malfunction, you need to install a new part (to replace it, it is better to choose a relay from a reliable manufacturer with a current of 40 A).

- Poor condition of the sensor's electrical outputs. Sometimes you need to bend them in the connector to fix the problem.

- There is a short circuit between 1 and 2 contacts of the VTA. To identify the problem, it is necessary to measure the voltages in this area.

- Malfunction of the electromechanical throttle mechanism (EMDU). Repair in this case consists of replacing the unit.

We recommend

“How to wash car windows: options for solving the problem” Read more

Error P2135 appears due to improper operation of the throttle sensor as a result of severe wear of parts, poor pin contact or short circuit. In this case, you need to replace the spare part. On Russian-made machines that use wiring from the Tolyatti plant, the cause of such an error is often poor-quality insulation.

Once the faulty throttle sensor has been replaced, you will need to reset the error code using your diagnostic computer. In some cases, to erase the error, it is enough to disconnect the negative terminal of the battery, wait 10 minutes and install it back.

Infiniti G25 Spherical Horse › Logbook › Why adapt the throttle?

Oh, reader!

Hello from the couch! This article is supposed to eliminate the illiteracy of the masses. I'm tired of answering everyone separately in comments or in PM. So let's discuss and close the topic once and for all.

Let's start in order. 1) Why do chokes get dirty?

The reason here is banal. The crankcase ventilation tubes, PCV valve(s) and other troubles are connected to the inlet. Through all this happiness, oil vapors get into the intake (whether you like it or not). But that is not all. Through the air filter (no matter how cool it is), dust microparticles enter the intake tract.

All this happiness is found in a heap in the throttle area.

This is why dirty chokes show a slimy mass, which in severe cases can resemble mush.

The deposits themselves directly on the plate are not at all dangerous. Deposits on the ends of the plate and on the inside of the throttle are terrible.

As I wrote above, oil and dust form a paste. This mush, figuratively speaking, formed. This very image grinds down the material at the points of contact. Where the plate comes into contact with the throttle channel. In the most advanced cases, the shape of the throttle and/or plate changes. It is for this reason that there are many reports on the network that throttles do not adapt without shamanic spells, and in severe cases, a sealant sticker and an imitation of a “step” on the inside of the throttle are required. But this is a case of extreme neglect, typical of old “unwashed” engines.

In most common cases, the oil-dust film in the area where the throttle and plate meet is compressed into a “step”. In the area of this step, an “incorrect” fit of moving parts occurs. Accordingly, the passage of air does not occur as it should. When closed, the plate is not in the correct position. All this leads to an incorrect response to the gas pedal and “miracles” at idle.

I hope everything is clear with the first two points. 3) Now we can discuss why adaptation is necessary.

As everyone knows, the throttles on our cars are electronic. That is, they are controlled by an electric motor, and the position of the damper is transmitted to the brains via a throttle position sensor.

It would seem that everything is simple.

So, the dirt described above accumulates in the throttle gradually. And the throttle (and, accordingly, the brains) seem to adapt to new conditions. That is, over time, the closed position of the throttle (according to the brain) may not correspond to the physical position of the elements of the mechanism.

It’s worth adding one more fact here. On our cars, the idle speed is set precisely by the throttle valve (for example, on Zhiguli cars there is a separate idle speed valve).

But now we are getting closer to the solution.

When we wash the throttle, we “physically” bring it to its initial position, but our brains “don’t know” about this. Therefore, after washing, you need to re-teach the machine the closed position and pedal strokes.

Finally, regarding common myths.

1) I washed the throttle and, lo and behold, no adaptation was needed.

This is not because you have a unique car, but because the throttle did not have time to clog up too much and, accordingly, “self-adapt” to the layer of dirt.

2) To remove or not to remove the terminal?

There's no point.

When the ignition is turned off, power is also removed from the throttles. Accordingly, do what you want, but the main thing is to return them to the closed position before turning on the ignition. When the ignition is turned on, the throttles are set to their initial position. It's easy to check: Open the hood and turn on the ignition. It's hard to hear them. 3) Should I remove the connector from the throttle?

Actually, everything is the same as in the paragraph before this.

4) Is it possible to move the plate/flap by hand?

I would say it is not only possible, but also necessary. Otherwise, there is a chance of not being washed. Naturally, all this must be done carefully and without fanaticism.

Well, that's probably all.

You can read how to carry out adaptation on your own here.

Everything described here applies to a greater or lesser extent not only to dates, but to all cars with electronic throttles.

Source

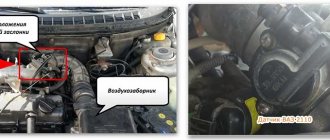

Algorithm for self-testing of the throttle sensor

Now let's look at the practical use of the information described above to inspect the sensor on our own. Before purchasing a part, you need to determine exactly what malfunctions of the throttle position sensor occur in your case. Only after identifying the causes of the problem can you decide whether to change the TPS.

How to determine a faulty throttle sensor? The procedure is as follows:

- Determine the location of the part you are looking for and make sure there is voltage on it.

- Connect one output of the multimeter to the TPS connector, and the other to the damper axis to measure the voltage in different positions of the DPS. If the voltmeter readings change, then the device is normal. If the voltage indicator remains unchanged, then there is a malfunction of the TPS.

- At the same time, the condition of the tracks should be checked. If there are any defects in the coating, the part must be replaced.

- Check and clean parts, devices - contacts, wires and connections. Broken pins must be soldered and treated with varnish.

Separately, it is worth emphasizing that the throttle sensor is a significant part in the car’s main computer system. The sensor transmits to the on-board electronic system the indicators of the opening/closing angle of the damper at a specific moment.

Whatever signs of malfunction of the throttle position sensor you find when analyzing the operation of the engine and other units, they cannot be left without any attention. Identifying problematic issues in the operation of the unit in question will allow you to avoid more expensive repairs.

Regular diagnostic measures and prevention of breakdowns of the throttle sensor are an important condition for comfortable driving and safe vehicle operation.

How to fix a problem by cleaning the throttle body

Let's look at how to properly clean the damper step by step:

- First of all, you need to get to the throttle valve. The design of different modifications of the internal combustion engine is different, but, as a rule, it is first necessary to dismantle the air duct running from the damper to the air filter.

- Then you need to remove the throttle valve. You should unscrew the fastening bolts (from 2 to 4 pieces), and then disconnect all the connectors, including the one that goes to the absorber purge valve.

- You can clean the throttle body using carburetor cleaner. Specialized auto chemical stores offer a wide selection of different formulations, so you can always choose the best option in terms of cost.

- Thoroughly wipe the throttle body inside and out using your chosen product and a rag.

- If the car is designed with a protective grille, it also needs to be cleaned.

- Reassemble the assembly in reverse order.

Cleaning the throttle valve is carried out in such a way that its metal surface becomes completely light. Such cleaning will help improve the dynamic characteristics of the engine.

- How to clean the throttle body without removing it

Many car enthusiasts are interested in how to clean the throttle valve without removing it. Some service stations actually offer this service, but it should be borne in mind that effective cleaning of this part can only be done after dismantling the damper.

To clean the throttle valve without removing it, use a special intake tract cleaner. In addition, this procedure can be performed using EGR valve cleaning fluid, as well as WD-40 or solvents.

We recommend

“Checking high-voltage ignition wires: subtleties of the process” More details

Algorithm for cleaning the throttle valve without removing it:

- Remove the air duct to provide access to the throttle valve.

- Spray the surface of the damper, which is in the closed position, with cleaning agent and wipe with a rag.

- Open the damper and clean the dirt from the side surface.

- It is necessary to ensure that the cleaning agent reaches all channels (rags are also used for cleaning).

Let us note once again that high-quality cleaning of the throttle valve can only be performed after its dismantling. When installing the part after cleaning, we recommend using a new damper gasket (its cost is quite affordable).

Manufacturers of cleaning products note that the procedure for servicing throttle valves without removal should be carried out every 7,000 - 10,000 km. Cleaning the damper with removal should be carried out at intervals of 30,000 - 50,000 km.

It is important to note that in most situations, after cleaning the damper, it is necessary to adapt it. For this, a special computer is used that connects to the machine's ECU. In addition, “learning” of the throttle valve can be carried out by performing certain manipulations with the ignition and accelerator pedal. In the latter case, it is impossible to give universal instructions, since the procedure will differ for cars of different brands. You need to keep this in mind when adapting the throttle valve.

How do you know when it’s time to clean the throttle?

You can visually assess the condition of the throttle yourself by moving the throttle to a vertical position by pressing the accelerator pedal, and you will need the help of a friend. Or remove the throttle and examine its condition, but we will talk about this in a few paragraphs. Many car enthusiasts rely on indirect signs - the engine does not start as quickly as before, the idle speed fluctuates or the dynamics disappear altogether and the speed “hangs” at the same level. If you have collected at least two points, it is better to address this issue. Otherwise it may come back to haunt you in the future.

Damper cost, service life and measures to maintain it in good condition

Prices for throttle valves vary depending on the car model and the manufacturer of the spare part. On average, their cost ranges from 3,000 to 10,000 rubles. The resource of this part is designed for the entire service life of the vehicle. The need to replace the throttle valve may arise due to breakdowns of the motor and its systems, as well as due to a faulty sensor.

Most often, improper operation of the throttle valve is caused by carbon deposits on its elements. Contamination of the remote control leads to accelerated wear of its axis and loose fit of the part in the channel. As a result, control of the volume of air entering the engine is lost. To maintain the throttle valve in working condition, it is necessary to observe the frequency of cleaning it, as well as monitor the condition of the engine and its systems.

The service for replacing the emergency protection at a service station will cost from 900 to 1,500 rubles. In addition, for adaptation of the node you will need to pay from 500 to 700 rubles. Some car repair shops may offer restoration of your car's worn-out electronics or exchange for a refurbished spare part. The price of a restored part ranges from 5,000 to 6,000 rubles.

Recommendations for choosing TPS

Some automakers use inexpensive film-resistive throttle sensors to equip their models. The service life of such a part is not very long, so over time various symptoms of malfunctioning of the sensor will appear.

To replace a faulty part, experts recommend using more expensive non-contact sensors, which are characterized by increased reliability and long service life. The operating principle of such a device is based on the effect of magnetic resistivity.

Opinions of car enthusiasts about the malfunction of the damper sensor

1. PDZ sensor - works the same as the simplest volume controls in older TV models...

“This device is an analogue of the simplest volume control that is found in old televisions. The sensor has the following problems - “rustling” during operation. If in the case of a TV the regulator is not used so often, then in a car the throttle sensor works constantly. Its “rustling” is far from the speed that can be expected in accordance with the logic of movement. This is precisely what causes difficulties with engine speed freezing by 1.5-2 thousand revolutions or more. It is worth noting that the ECU will definitely detect a malfunction of the throttle sensor, as a result of which a “check” will light up on the dashboard. Usually the code for such an error is deciphered as “High level of TPS”.

2. Lean mixture is a consequence of problems with the throttle sensor

“If I understand correctly, when driving at a constant speed the car jerks, and when the accelerator is abruptly released, a dip is felt and the engine may stall. If the throttle is more than half open, does the car drive pretty well?

If all the symptoms converge, then:

- Was the mixture composition measured at a car service?

- the symptoms indicate a possible lean mixture, so I would first check the lambda probe and then the air flow sensor. Of course, you should also check all sorts of places where excess air is leaking, but not the throttle sensor.

- disconnect the lambda probe and drive without it; if the car drives normally at average values, then you need to change the lambda.

This is what my opinion looks like at this moment. If it’s wrong, we’ll think further.”

Prevention methods

Although a sensor failure is not a critical failure, symptoms of a malfunction in the throttle position must be identified and corrected as soon as possible. Otherwise, the motor will begin to experience significant loads, which will certainly shorten its service life.

Of course, one of the effective prevention methods is regular cleaning of the air supply channels. It helps improve vehicle dynamics and extend the life of the sensor.

This is done until the metal surface becomes completely light.

Craftsmen usually do this manually, in the following sequence:

At the end, the damper must be wiped dry. If the design of the car also provides a protective grille, then this too is cleaned. The assembly is then assembled in reverse order.

Another method is also used when the unit is not removed from the machine. Its advantage is the speed of execution, but it does not provide the effect that is achieved with manual processing. To clean the valve with this option, you need to use fluid for the intake tract or the EGR valve. WD-40 and good solvents are also suitable.

The cleaning procedure without removing the throttle looks like this:

Throttle valve before and after cleaning

It is recommended to service the throttle valve in this way every 10 thousand kilometers of the vehicle or earlier. Specifically, everything depends on the operating conditions (city, countryside), climate, driving style. If the damper is cleaned manually, with removal, then it will be enough to do such repairs once every 5 years.

The important point is that after cleaning it is necessary to adapt the damper. This procedure is carried out using a special computer program integrated with the computer. The throttle adapts anew to the sensor, gas pedal, and ignition.

The consequence of problems with TPS can be a lean fuel mixture. Therefore, from time to time it is also necessary to check the quality of its composition, analyzing signs of problems. First of all, you should inspect the lambda probe and air flow meter. For example, turn off the oxygen regulator, and then bring the engine speed to medium. If the performance of the unit improves, the lambda probe must be replaced. It is also necessary to exclude all possible areas for excess air suction, not counting the damper device itself.

Source