Generator brushes Replacement - Logbook Chevrolet Niva LAIKOVOZ of the year on DRIVE2

Reasons for replacing a generator One of the reasons when replacing a generator on a Chevrolet Niva is simply necessary is damage to the windings.

no charging Niva Chevrolet. generator repair

Using a jack installed on the side where the generator is located, raise the car by engaging first gear.

#9 Chevrolet Niva - Simply about the complex. replacing the BOSCH generator armature commutator - Duration: Ramanych...

Full size This 80A generator is installed on my car from the factory. Last week, with a mileage of just a few thousand kopecks, I wanted to see the condition of the brushes - in the end they turned out to be almost completely worn out, and, as it turned out, the brushes on my generator were not more than a dozen or so “ chocolate”, and some brushes of their own with two wires and a square “chocolate”, which were bought for rubles in the nearest spare parts store for almost twice the price of tens and were waiting in the wings. First you need to remove the terminal from the battery. From their tips with a positive terminal, it is necessary to remove the rubber cap, which performs protective functions.

To install a new one, you need to go through the entire process in reverse order. If the result is poor, the ring is ground on a lathe to remove a small layer of metal. In this case, the negative terminal of the battery is removed and the wires that come from the generator casing are disconnected.

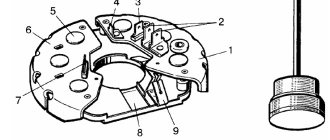

Check the ease of movement of the brushes in the holder. Remove the connector with wires from the generator. Unscrew the back cover of the generator. Disconnect the wires from the regulator, unscrew the connecting plate, the regulator mounting screw and remove the regulator 1 - screw, 2 - plastic gasket, 3 - connecting plate, 4 - regulator.

REPLACEMENT OF GENERATOR BRUSHES. GENERATOR VOLTAGE REGULATOR RELAY. VAZ, LADA.

Unscrew the screws indicated by the arrow that secure the graphite brushes and remove the brushes from the holder. Check the length of the graphite brushes, which should be at least 5 mm. Unscrew regulator A and disconnect the 2 wires indicated by arrows. Unscrew the screw securing the brush holder. Unscrew the brush holder and, carefully turning it outward, remove 1 - graphite brush, 2 - contact from the generator.

Check the length of the graphite brushes, which should be at least 4 mm. From their tips with a positive terminal, it is necessary to remove the rubber cap, which performs protective functions. Then from these wires you need to unscrew the nut with which they were attached to the generator block and remove them. After disconnecting the spring clamps of the generator, you should remove its black casing, made of plastic. Using a Phillips screwdriver, unscrew the voltage regulator fasteners.

Get it complete with brushes. Then disconnect the wire block from it. Replace the generator brushes and install them back, following the reverse order. If the length of the brush rods is less than 0.5 mm, they must be replaced. But if the brushes are in working condition, and the Niva Chevrolet generator does not supply a charge, it is necessary to check the operation of the voltage regulator and the circuit from the regulator to the brushes. Reasons for replacing a generator One of the reasons when replacing a generator on a Chevrolet Niva is simply necessary is damage to the windings.

If this happens, then either a rewind is needed, or you will have to purchase a new generator. Maybe the repair will cost a little less, but no one will give you guarantees about the quality of rewinding and the uninterrupted supply of current to the battery. Removing the generator For this process you need to take a Phillips screwdriver. In addition, you need to use a car tester or ohmmeter, a 10mm wrench and a test lamp. To change the generator, it must be removed from the engine compartment.

First, disconnect the wire and terminal of the battery with a negative charge. Next, disconnect the block with wires and the generator output, and take out the protective cover from there.

Then, unscrewing the nut, disconnect the wires on the generator contact bolt.

Replacement methods

- Replace the brush assembly with the voltage regulator relay (chocolate). As is known, maintaining charging at the same level is carried out by adjusting the voltage supplied to the generator armature winding. For reliable contact, the brush leads are attached to the contacts of the voltage regulator relay by soldering. To simplify car repairs, brushes, brush holder and relay regulator are most often sold assembled. The advantage of the complete replacement method is its simplicity. For example, the low cost of the assembly for many VAZ cars makes separate replacement of brushes very impractical.

- Replace brushes separately. To do this, you will have to remove the old brushes and solder new copper-graphite products in their place (of course, for DIY repairs you will need a soldering iron, flux, solder and basic soldering skills). As in the case of complete replacement, the feasibility of the method largely depends on the cost of new rods. The point is not only the high price of parts for generators of many foreign cars, but also the fact that for some models (especially for old low-volume cars) it is simply impossible to buy a relay-regulator with brushes assembled. It is proposed to eliminate charging problems by purchasing a new generator. In this case, replacing worn-out elements is the only way to save a considerable amount. If you want to change the generator brushes yourself, you may encounter a lack of new parts for sale for your generator model. In this case, you should select suitable copper-graphite brushes from another car. For proper operation, the length of the rods is important (should not be less than that of new or slightly worn original rods) and the length of the copper flexible contact. New brushes should move freely in the brush holder. In fact, the shape of the new rods does not really matter, since they can be processed perfectly with a needle file.

Malfunctions that occur in the operation of the generator

Then unscrew the bolt that secures the generator to the tension bar and pull it out. It is also necessary to unscrew the bolt-shaped fastening at the bottom of the generator. Then you should remove the belt. After removing all the bolts, the generator must be removed from the bracket using a mounting spudger.

To install a new one, you need to go through the entire process in reverse order. After replacing the described electromechanical device, you need to inspect its drive belt and adjust its tension.

But before you replace the old Niva Chevrolet generator with a new one, you need to make sure that the replacement is really necessary.

Chevrolet Niva 2011, 80 l. With. — self-repair

There are times when you can do repairs yourself, without the help of specialists. In order to avoid confusion, you need to note how the generator covers are correctly positioned.

Next, you need to remove the plastic protective casing by unfastening the three latches on it. The voltage regulator and brush holder are removed together.

In order to release the rectifier unit and capacitor, it is necessary to disconnect the wires from the regulator terminal. The stator winding has three terminals. And in order to carry out the operation to remove the rectifier unit and capacitor, you need to bend these leads a little.

Use a flat-head screwdriver to pry off the side where the slip rings are located and remove the cover from the generator. Holding the generator rotor in a vice, unscrew the fastening from the pulley. Then remove the spring washer, pulley and thrust washer. Then the rotor and spacer ring are carefully pulled out and their condition is checked.

If the ring shows signs of damage, scratches and is noticeably worn out, it needs to be sanded with regular sandpaper. If the result is poor, the ring is ground on a lathe to remove a small layer of metal. Having connected the rotor to the slip rings, check the resistance of its winding with a tester.

If the wiring is broken, the meter will show an infinite reading. For this reason, the rotor must be replaced.

To check whether the rotor winding closes or not, you need to connect the test lamp to the network through which alternating current B flows.

Source: iaarus.ru

Replacement instructions

- Remove the negative terminal of the battery.

- Disconnect the main positive terminal of the generator, the voltage regulator connector and the negative terminal, if necessary. In some car models, engine speed is read from terminal W on the generator; otherwise, the contact may not be connected or may be absent altogether.

- If the replacement is carried out by removing the generator, loosen the service belt and unscrew the fastening bolts (you can read more about replacing, installing and tensioning the belt in the articles: “What to do if the generator belt whistles” and “Tensioning the generator belt”).

- Unscrew the rear cover mounting bolts.

- Unscrew the voltage regulator relay. If you chose the complete replacement method, all you have to do is install the new part and assemble all the elements in the reverse order. In any case, we recommend that you at least check the generator bearings and the condition of the collector plates. If the wear of the plates is within normal limits, before installing new brushes, clean the surface to a shine with fine-grained sandpaper.

Generator Chevrolet Niva

A generator is an important part of any car, which is responsible for its power supply. With the help of this unit, it is possible to provide a continuous supply of electricity to all components, various systems and sensors, making its operation possible.

On the car, a unit with article number 9412.3701 is used as a standard generator. Such a generator can also be found on the injector of the VAZ-21214, VAZ-2131, VAZ-2123.

If the generator on a Chevrolet Niva fails, you can replace it with analogues, the most popular of which are presented in the table.

| Generator | vendor code | Cost, in rubles |

| VAZ-2123 (produced after 2003) | 5112.3771-30 T | 5370 |

| VAZ-2123 (produced after 2003) injector 14V 80A PRAMO | 5112.3771 | 4460 |

| VAZ-2123 (produced after 2003) | 9402.3701-04 | 4380 |

A generator for a Chevrolet Niva costs between 5,000 and 7,000 rubles. The price of the original unit depends on the region of purchase. Many owners prefer to use Start Volt at 120 amperes when the factory generator fails.

What is a generator

A generator is an alternating current device that produces electromagnetic excitation during operation.

The generator design has a built-in rectifier unit, equipped with diodes made of silicon, as well as an electronic voltage regulator. Thus, the unit creates electrical energy from mechanical energy and energizes the car’s battery, and also provides energy to its devices and systems. The connection diagram for the generator on Niva-2121, 21213, 21214 is shown in the figure.

How to find out if the generator is faulty

When operating a Niva Chevrolet, certain difficulties and malfunctions sometimes arise. During a trip or long-term use of a car, various problems arise, and one of them is the failure of the generator.

Diagnosing a breakdown is quite simple. There are several manipulations that can be used to determine the need for repairs:

- The corresponding light on the dashboard lights up, indicating that the battery is constantly discharged.

- The battery drains quickly when the engine is running.

- The brightness of the light decreases as the engine speed increases. In this case, it is necessary to replace the generator brushes.

All of the above signs indicate that the generator urgently needs to be replaced or repaired.

Generator brushes

Worn brushes on the Chevrolet Niva generator can lead to a voltage drop in the vehicle's electrical system. This is considered one of the main and common causes of this type of malfunction. But since the generator has a simple design and is easy to access, even an inexperienced car enthusiast can replace its brushes.

The main signs of brush failure are:

- voltage drops occur;

- the battery does not hold a charge;

- weak headlights at night, blinking;

- The radio turns off, etc.

Usually, when passing a technical inspection, small elements of the generator are rarely checked. Therefore, worn brushes can make themselves known unexpectedly. But before you decide that replacing the Niva Chevrolet generator brushes is necessary, you need to find out if there are other faults that can cause similar symptoms. And only after making sure, you can disassemble the generator housing.

Replacement procedure

To change the generator on a Chevrolet Niva, you will need to follow a few fairly simple steps.

- First of all, you should take care of the safety of the work being carried out. To do this, you need to put the car in a repair place, turn off the engine and remove the terminals from the battery.

- The next step is to remove the wire from the contact bolt, which is located on the rear panel of the generator. You will also need to remove the block from the assembly that secures the brushes.

- After this, you should begin dismantling the alternator belt. The belt is tensioned using a special plate called a tensioner. You can adjust the tension using the fastening bolts; they need to be loosened. The plate is located in the area of the tension roller and is attached to the structure with three bolts. To unscrew them, you need to take an open-end wrench for two bolts, and use a wrench to loosen the third.

- Next, all that remains is to remove the belt and unscrew the generator mounting bolts. There are only two bolts - top and bottom, but they are massive, and you will need a wrench for a large diameter. If the bolts will not turn, you will need to hold them from behind.

When the bolts are unscrewed, all that remains is to dismantle the generator and begin installing a new one.

How to change the alternator belt on a Chevy Niva?

Look at the photo:

Procedure:

- Loosens bolt (1).

- Loosen the nuts (2), (3) and (4).

- We move the tension bar with the roller so that you can remove the old belt.

- We change the belt, tighten the nuts.

- By tightening the adjusting bolt, adjust the belt tension.

Attention! With normal belt tension, the deflection “h” under the influence of a load of 7.6 kgf should be equal to (12±1) mm.

That's all! As you can see, there is nothing complicated. Everyone has wrenches in the garage.

Photos taken from the Internet!

Installing a new generator

The algorithm for installing a new generator is practically no different from dismantling the old one, only all steps are performed in reverse order. So, the car owner will need:

- Screw the assembly to the engine by turning and fixing two bolts - upper and lower. At the same time, there is no need to tighten them too much, since then the belt still needs to be tensioned.

- Install a new V-ribbed repair on the pulleys. You need to put it on with a little effort and go around the pulleys in the following sequence: hydraulic pump pulley, roller, crankshaft pulley, power steering pulley, roller, generator pulley.

- Tension the belt by tightening the adjustment bolt and the special plate. It is important that the belt deflection in the upper free part does not exceed or be less than 15-16 mm.

Then all that remains is to tighten the three bolts of the bottom plate and check that the power source is secure.

Nuances of moving a generator

The disadvantage of domestic Niva SUVs is the location of the generator unit - at the bottom of the engine compartment. It constantly gets contaminated when driving off-road, and coolant constantly drips. The problem is solved by moving the generator upstairs (the author of the video is SARTANETS).

To transfer, you will need a set of keys, a bracket, mounting bolts, and a V-belt. You can make a generator transfer bracket with your own hands according to the drawing below.

Drawing of a homemade bracket

Sequence of actions during transfer:

- We dismantle the propeller, pump and remove the belt.

- By unscrewing the standard bracket, you can remove the generator.

- We cut off the bead around the side of the cylinder head and on the cylinder block.

- Then you should unscrew the two bolts and two studs.

- Next, the assembly is installed on a new bracket and final assembly is performed.

Thus, moving the generator unit upstairs is not difficult.

Generator connection

Replacing the generator is only half the battle. It is also important to connect it correctly to the circuit source. Before connecting, you need to complete the work on the front and rear panels of the unit, only after that you can connect the terminals to the battery.

The contacts must be clean during connection. If contamination is detected, it can be removed using special cleaners. Also, the terminals on the battery must be tightened, otherwise the oxidation process will begin on their surface.

If everything was done correctly, then when you start the engine, the light on the dashboard indicating a low battery charge should go out. However, experts recommend, just in case, checking the operation of the generator using a multimeter by measuring the voltage at the terminals.

Thus, in order to avoid any serious problems with the generator during the operation of the Chevrolet Niva, it is important to undergo a technical inspection on time and repair the components of this unit.

Source: zapchasti.expert

Nature of the malfunction

In the design of the generator, copper or copper-graphite brushes are used to supply voltage to the collector plates. Accordingly, the force of electromagnetic induction that occurs when current flows through the armature winding depends on the quality of the contact between the brushes and the commutator plates.

Since the armature constantly rotates during operation, abrasion occurs and the length of the brushes decreases (the plates themselves wear out to a much lesser extent). To compensate for wear, the brush holder has springs that press the brushes against the commutator plates. But when wear becomes critical, the spring force is not enough to make good contact, which leads to a drop in the current flowing in the circuit.

The main characteristics of the generator installed by the manufacturer in Niva 21214, 21213, 2121 will be considered using the example of generator type 9412.3701:

- current – 80A;

- voltage – 13.2 V,

- rotation is right.

The cost of standard models of electric generators is 5-7 thousand rubles. If the unit breaks down, it is possible to replace its components or completely replace it with the original or analogues. The prices of the most common ones are presented in the table.

labavto.com

Everyone knows that in terms of build quality, domestic cars are in many ways inferior to foreign cars. Especially when it comes to electrical devices and components of the Niva car. One of the devices that car owners encounter is the generator of the Niva Chevrolet car. In this article we will talk about malfunctions and talk about repairing the device.

Replacing the VAZ 2121 Niva generator Photo instructions on how to change the generator on a Niva

The real favorite among SUVs in the modern automobile market of the country is the Chevrolet Niva.

It combines the excellent qualities of both a touring SUV and a car for family trips. Thanks to its light weight and short overhangs, the Chevrolet Niva can drive off-road and ford. It can handle steep climbs with ease. But the electronics system is one of the most vulnerable parts of a car. With regular inspection of electrical elements and timely removal of dirt and moisture from them, repairs will not be required even throughout the entire operation of the vehicle.

Features of the generator

The generator device on the Niva Chevrolet is designed to ensure the functionality of the electronics system. Since optics are an integral part of this system, if malfunctions are detected, the car owner should identify the breakdown as quickly as possible and fix it. Otherwise, operating a car without working headlights can lead to dire consequences.

The situation is similar with the battery - its recharging while driving is provided by a generator unit, which is characterized by fairly high durability. If the generator unit fails, recharging the battery will be impossible. Moreover, if the car owner does not know about this, he will use all electronic devices as usual. And this, in turn, will lead to a complete discharge of the battery and, accordingly, the inability to operate the vehicle.

Design of the Niva generator unit

Possible faults

All breakdowns associated with the operation of the Niva generator can be identified through detailed diagnostics.

In accordance with the operating diagram, the cause of a unit malfunction can be:

- Wear or damage to the pulley structure.

- Wear of current collecting brushes.

- Failure of the rectifier element.

- Failure of the voltage regulator. The voltage regulator in this case plays a very important role in the operation of the system - it is thanks to it that the incoming charge is regulated.

- Collector failure is most likely due to wear.

- Bearing failure is also usually caused by either wear or destruction of the device.

- Damage to the wiring in the charging circuit.

The car owner must know about all the causes of possible breakdowns in order to know what actions to take to eliminate them. To accurately understand that a generator device needs diagnostics and repair, we recommend that you familiarize yourself with the main signs of its breakdown.

Signs of failure

- The indicator on the instrument panel is constantly on or intermittently lights up, indicating that the battery is low. In this case, checking the battery shows that the battery is fully charged and holds a charge normally.

- When you turn on the optics, you begin to notice that the headlights work dimmer. At the same time, pressing the gas, the headlights become brighter.

- The battery begins to quickly lose charge.

- Electronic devices began to work less stably than before (video author - Avto-Blogger channel).

Generator "Niva Chevrolet"

Depending on the type of current, generators can be either direct or alternating current. Owners of the named car sometimes do not know what generators are used for this model? The Chevrolet Niva was provided with an electromechanical alternating current device. There is a built-in diode bridge - rectifier. To provide work to electrical consumers, it converts alternating current into direct current. The diode bridge with the generator is one mechanism; they can be located both in the housing and in the cover of the generator.

The operation of the latter is affected by the speed of the vehicle and its engine speed, since the generator is connected by a belt to its crankshaft. To regulate the output current, a voltage regulator relay is installed. In addition, modern generators have built-in integrated voltage regulators.

The Niva Chevrolet generator may be subject to the following malfunctions:

- electrical;

- mechanical.

If the malfunction is of a mechanical type, then it includes a breakdown of the fastening, housing, faulty condition of the pressure springs, bearings, belt drive or other breakdowns that are not related to the electrical system.

With the first type of malfunction, the winding may break, the brush may burn out or wear out, the rotor may break through, and a short circuit may occur between the turns. The diode bridge and the relay regulator may be faulty.

Sometimes signs appear indicating that the Chevrolet Niva generator is faulty, but this problem can be caused by completely different breakdowns.

Do-it-yourself device repair

Now let's talk about how a generator is repaired. The repair procedure can be performed at a service station or in a garage, of course, if you have an idea of what needs to be done.

Replacing the alternator belt

- First of all, the connector with the DPKV is dismantled, after which the screw that secures this regulator is unscrewed and removed.

- The nut that secures the device should be loosened slightly, but not completely unscrewed. The generator assembly can be moved towards the block, after which the strap on the displaced device can be removed without problems, since it will be loosened.

- Using a jack, which must be installed in advance on the side where the unit is located, you need to slightly raise the car by turning on first gear.

- Next, pull the strap itself so that it can move away from the pump shaft. Then spin the wheel until the tension point reaches the pulley.

- The next step in replacing the alternator belt will be to remove the belt from the other shafts.

- As for installing a new one, it should first be put on the shaft of the unit and the crankshaft, only after these steps can it be installed on the pump shaft.

- The wheel turns until the strap hits the pulley. Then the device is put in place, the strap is tightened, after which the assembly is fixed to the bracket using a nut. The final stage will be the installation of the DPKV in place (author - Ig K channel).

Replacing the tension roller

Repair of the Niva Chevrolet generator may involve replacing the tension roller. The main part of this element is the bearing, so if the strap is loose, then first of all it is necessary to check it. If the roller is in good condition, then the bearing will rotate quietly and there should be no jerking.

To replace an element, follow these steps:

- First, install a crowbar or other tool so that the clutch shaft is blocked. This will prevent the crankshaft from moving.

- Then the screw that secures the roller itself is loosened, and the tension on the strap is relieved.

- The axial screw is unscrewed, after which the roller can be removed.

- A working roller is installed and the strap tension is adjusted. After replacement, make sure the device is working properly.

Replacing the brush

Worn and new voltage regulators

- To replace these components, the regulator must be completely removed. Also, the “-” terminal is disconnected from the battery and the wiring coming from the generator unit is disconnected.

- Next, the block of wires is dismantled, from the tips of which the rubberized cap is removed - this component is intended for protection. After this, you need to unscrew the nut from the wires that secured them to the mechanism block.

- Then you need to disconnect the spring fasteners and remove the plastic casing, using a Phillips-head screwdriver to unscrew the regulator clamps.

- The regulator is dismantled along with the brushes, after which the wires need to be disconnected from this element.

- The brushes are changed, and further assembly of the structure is carried out in the reverse order. Brushes should be replaced if their length is less than 0.5 cm. If the length of the brushes is normal, and the generator device is not working correctly, it is necessary to diagnose the regulatory element, as well as the electrical circuit in the area from it to the brushes.

Dismantling the generator

- Replacing the generator begins with removing the device from the engine compartment. All wiring going to it is disconnected, and we must also not forget about disconnecting the battery. The protective plastic casing is removed.

- The nut securing the wires and the screw securing the assembly are unscrewed. The fastening in the form of a bolt is detached; it is located at the bottom of the structure, after which the strap is removed.

- When all the bolts are unscrewed, the mechanism can be removed from the bracket; a mounting spade may be needed for this.

- To install a new unit, all steps should be repeated in the reverse order. After the new generator is installed, it is necessary to diagnose the condition of the drive belt and also adjust the tension.

Sorry, there are no surveys available at this time.

How to change brushes on a generator with your own hands

Alternator brushes are very important for supplying the car with a sufficient amount of electricity, as well as removing its excess. If they are faulty, the car will not be able to function normally due to interruptions in the power supply system.

General information about generator brushes

Alternator brushes are sometimes called carbon brushes. This is due to the fact that they are made from graphite. It is worth noting that the use of generator brushes is quite wide and is not limited only to cars. They are installed on any type of equipment that has an electric motor in its design. The most common model of brushes in the modern machine industry is EG-4.

Note that the brushes of the EG-4 generator are suitable for cars of various years of manufacture. The second most popular are EG-61, which are characterized by a greater degree of reliability. Collectively, these brushes are found on 80 percent of cars.

If we talk about domestically produced cars, then the generator brushes are located just below the right headlight. To get to them, just open the hood and look into the generator.

Video. Replacing brushes on a VAZ 2109 generator

Let us remind you that in the previous article we told you how to clean your car’s air conditioner with your own hands. Cleaning can be done in a garage, you just need to purchase the necessary tools.

In what cases should generator brushes be replaced?

To avoid problems with your vehicle's alternator, you should check the alternator brushes every 50 thousand kilometers. However, you must understand that this is a separate procedure that is not included in standard maintenance. It is the lack of knowledge of the list of works that are included in maintenance that most often leads to unexpected breakdown of the generator brushes.

It is worth noting that both to check the generator brushes and to replace them, you do not need to remove the generator, which is very convenient. some typical symptoms may tell you that it is time to change the carbon brushes

1. Abrupt and causeless shutdown of various electronic devices of the vehicle. 2. Reducing the glow intensity of interior lamps and headlights. 3. General decrease in voltage in the electrical circuit of the vehicle. 4. Very fast discharge of the vehicle battery.

Chevrolet car repair manuals and tips

Do-it-yourself repair of generator breakdowns

A car generator is a device consisting of three main parts:

1. Stator. 2. Rotor. 3. Brushes.

The stator is characterized by a stationary winding, which receives direct current when the engine starts. It creates a magnetic field in the stator, which in turn acts on the rotor (the moving part of the winding). When the engine is running, the rotor is driven by the crankshaft. The rotational force is transmitted via a belt drive. Thus, during the rotation of the rotor, a current arises in it, which is transmitted to the stator through brushes. The current in the stator winding induces an electromotive force, which is converted into alternating voltage. To convert the alternating components of the generator power, a diode bridge rectifier is used.

The generator is designed to charge the battery. If it is faulty, then it is possible to drive the car, but the battery will be drained by all the electronics, which will ultimately lead to the battery becoming unusable. The result of a generator failure will be disastrous, since you will have to shell out a considerable amount of money to buy a battery.

How to detect a generator failure on a Chevrolet Niva

The exact cause of the malfunction can only be determined using special equipment. Determining this at home is more difficult. But you can find out the malfunction by the following signs:

1. On the instrument panel, after starting the engine, the warning light in the form of a red battery should go out. If the lamp does not go out, this indicates that the battery is not receiving a charge. 2. With the engine running, the headlights became less bright. This is evidence that the headlights are draining the battery, which is not being recharged. 3. Noises in the motor. When, with all of the above, you still hear extraneous noise in the form of a clattering or whistling sound, then you should obviously remove and check the device.

The Chevrolet Niva is equipped with electronics that consume a lot of power. In addition, to start such a powerful engine, it is necessary to use a battery with a capacity of at least 60Ah. Which puts a lot of stress on the battery. Therefore, it is important to control its charging from the generator. What are the causes of Chevrolet Niva generator breakdowns?

The most common cause of failure is a broken belt. The belt has the shortest service life compared to other structural elements. You can detect a broken belt visually by opening the hood and looking at the belt pulley. If the belt is intact, but you hear extraneous noise in the form of a metallic ringing, then most likely the bearings need to be replaced. It can only be detected after removing the device.

The reason why it is easier to buy a new generator rather than repair an old one is because the windings are damaged. If this happens, you need to rewind it or buy a new one. It’s cheaper, of course, to have it repaired, but there is no guarantee that the rewinding will be of high quality and will deliver the “correct” current to the battery. Therefore, the decision which is better is up to you. Brushes periodically fail due to constant friction against the rotor. Brushes can be replaced at home. Replacing the belt on a Chevrolet Niva

Replacing a belt is carried out not only when it breaks. To prevent it from breaking along the way, it is necessary to carry out periodic inspections. If the following damage is detected, the belt must be replaced immediately:

1. When traces of cuts or wear and cracks are found; 2. If the belt begins to peel off and the threads are visible from it; 3. The presence of oil and ruffled appearance indicate its unsuitability.

To replace the belt, it is important to arm yourself with the following tools:

1. mount; 2. screwdriver; 3. jack; 4. a set of keys.

Having purchased a new belt, you can begin installing it:

1. Disconnect the car from the battery power supply. 2. Pull out the connector from the crankshaft sensor. To do this, unscrew the mounting bolt with a Phillips screwdriver. The sensor needs to be removed. 3. The nut that secures the device must be slightly unscrewed and the device moved towards the block. 4. The worn belt is removed. Since the device is weakened, this is not difficult to do. To do this you need to use a jack. 5. The right side is jacked up, having previously placed chocks under the wheels. The right wheel will need to be rotated, so you need to put the car in fourth gear. 6. Pulling the belt, remove it from the pump pulley. Next, the wheel spins, gradually pulling the belt off the pulley.

The removed belt cannot be repaired, so we immediately proceed to installing a new one:

1. First, the belt is thrown onto the crankshaft pulley, and then sequentially onto all the others. 2. It’s better to finish with a generator pulley. The wheel rotates until the belt is put on. 3. The device is placed on the seat and secured with a bolt. The sequence of throwing the belt onto the pulleys.

| 1 | Crankshaft pulley. |

| 2 | Tension roller. |

| 3 | Right lower pulley. |

| 4 | Roller under the generator. |

| 5 | Pump pulley. |

| 6 | Generator pulley. |

It is important to adjust the tension. Weak tension will not provide the necessary charge to the battery.

4. The sensor is installed in its place.

Belt selection. It is better to use a LUZAR brand belt. It is ideal for Chevrolet Niva pulleys.

Replacing the belt is the only “easy” alternator repair; all other problems need to be fixed only when it is removed. So, withdrawal is carried out in the following sequence:

1. Using a “10” wrench, loosen the nuts that hold the base with the tension roller. The nuts must be removed from their seats; 2. Find the adjusting screw and unscrew it. Having unscrewed it to the top of the platform, we make sure that it now moves freely. All these bolts are visible in the photo below, so they are not difficult to find;generator

3. Now you can remove the belt from the pulley; 4. Now the bolts holding the device are unscrewed. To do this, you need to unscrew the bolts with a key to “13” and on the other hand to “17”. There are two wires connected to the back of the generator, one is connected in a plug way, and the other is connected to the bolt head. They need to be disabled; 5. Now it can be removed from the seat.

Installation in place

After repair or a new generator is put in place in the following order. For ease of readability, the installation order is listed in the table:

| 1 | Installed directly into place. |

| 2 | The mounting bolts are tightened. Wires are connected. |

| 3 | Throwing the belt onto all rollers is carried out sequentially. The description can be found in the section “replacing the belt”. |

| 4 | The tension is set. |

| 5 | The adjusting screw is tightened. |

| 6 | All three nuts are tightened. |

| 7 | The tension is checked. |

Replacing the generator bearing

A worn bearing can be completely freely replaced at home. In addition, it is irrational to buy a new generator if you can get by with replacing the bearing. The bearing replacement process involves disassembling the structural elements of the generator. To do this, you need to remove the device and start disassembling:

1. Remove the pulley. The tightened nut is unscrewed and the drive element is removed. 2. Remove the cover from the back of the device. 3. Having removed the cover, unscrew the two screws from the voltage regulator. The bolts around the perimeter of the device that secure the back and front covers are also unscrewed. 4. Now the front side of the device is removed. To do this, you need to carefully knock it out with a hammer with a rubber tip. There is a bearing visible on the cover that needs to be replaced. 5. The most difficult part is removing it from the lid. To do this, you need to take a tube whose diameter will be equal to the bearing itself. If you can’t knock it out, you can buy a cover with a new bearing. 6. Removal of brushes must be done carefully. The brush antennas are soldered to the body, so they need to be separated and then soldered back. 7. Replacing the rear bearing also has some difficulties. First, the rotor and bearing are removed. 8. After which the bearing itself is removed. To remove it, it is better to use a special removal device.

Bearing puller 9. Installing a bearing into a seat is easier than removing it. 10. The generator is assembled in the reverse order of removal. 11. The generator is installed in place and its functionality is checked. You can contact an auto electrician to check the current output.

It is important not to let the generator get wet, otherwise it may short out.

The process of repairing and replacing a generator is simple, but quite intensive, especially if bearing replacement is necessary. Winding repairs are carried out by specialists, so rewinding the rotor is not easy and almost impossible at home. The winding often fails after long-term operation of the generator, when the car's speedometer has more than 100,000 km.

Source: chevymanual.ru

I installed a new Chinese generator on the Chevy

When replacing the timing belt on a Chevrolet Niva, follow these steps.

- Remove the air conditioning and cooling radiators completely. Before this, of course, you will have to drain the liquid from the cooling system and bleed off the freon. There is no need to remove the fans from them.

- Remove the air purification filter housing.

- Remove the A/C compressor and alternator drive belts. Be sure to remove the tension mechanisms as well.

- Remove the upper part of the timing housing.

- Place marks on the shaft gears. They must definitely match. There is a notch on the engine crankcase that should match the mark on the pulley.

The first step is to prepare the generator for the repair and replacement process. To do this, old parts are removed. To do this, you will need wrenches of diameter 10 and 17.

1. First of all, you need to loosen the belt and remove it, otherwise you will not have access to the bearings themselves. To do this, you need to loosen the roller, which is held by a platform with nuts. There are three nuts, they require a 10mm wrench. Once they are all unscrewed, you need to unscrew the adjusting screw so that it moves up from the platform.

- Place the car in first gear to prevent the crankshaft from turning;

- Unscrew the nut that secures the part

- Remove the spring washer and remove the part.

The process of removing generator rollers on a Niva Chevrolet is identical to any other car.

5. The new ring is installed in its place;6. A new roller is installed in place of the old bearing. Before doing this, you should check the diameters of both parts to avoid the mechanism not working;7. Next, the bearing is fixed using a washer with a spring mechanism and a nut;

And also interesting: ✅ What is the diameter of the Chevrolet Niva steering wheel - auto-parts.su/

8. After this, the belt is put on the new roller.

1. You can put the car in 4th gear, put the belt on the roller and push in the direction of rotation of the crankshaft. When it starts to turn, you need to pull the belt onto the generator pulley, and it will fall into place on its own.

2. In the same way, you can not push the car, but lift the wheel and spin it, or spin the generator itself.

This makes it easy and quick to replace the Chevrolet Niva generator belt rollers. You should regularly diagnose the moving parts of the car in order to prevent possible breakdowns in time and replace faulty parts.

We recommend replacing the bearings and belt every 40 thousand kilometers.

As it turned out, the generator jammed and because of it the belt broke. Why did this happen? Most likely (my version) - when replacing the pump, the service center tightened the belt too much, because we couldn’t tighten the same one at all. As a result, during the hellish “tightening”, the old gene grunted; the bearings could not withstand such abuse. Therefore, it is better to do everything yourself or in a trusted service. Well, tighten it correctly, you could press the samples with your finger by 1 cm.

How did they even manage to tighten the 1885 belt? I can't imagine))

First I'll tell you about the generator

I took the old one, they completely disassembled it, looked at it and said that it had come to an end. The bearings were torn, and the rotor was worn out to such an extent that repairs would cost 2,500 rubles. And a new one costs 3100. It’s Chinese, but the warranty is 3 months, we checked it at the stand - everything works.

Therefore, it is better to take a native gene with the same width of the roller and with the correct number of rivulets (grooves). That’s why the belt is called a ripple belt, because the grooves must match, it turns out something like rails.

I wanted to buy a 100 Amp Pramo, but I couldn’t find it anywhere in the city; the original genes cost 4,000 rubles. So I decided to try Chinese))

How to remove a generator from a Chevrolet Niva

First you need to loosen the belt, which if tense, cannot be easily reset. So, our task is to loosen the tension roller; it is held in place by a platform with three nuts. You will need a 10mm wrench, it is very advisable to have a ratchet with the same head, preferably an elongated one, because the third nut is located directly under the belt and it is better to approach it from the side.

The first 2 nuts are easy to get out with a regular open-end wrench. But the third one is much easier with a ratchet.

We've loosened it - now we turn the adjusting screw (key 10) so that it moves as far up the platform as possible, so the entire platform with the roller will move freely up and down.

We need to go up to throw off the belt.

We remove the generator itself (in my case, I already put it back)