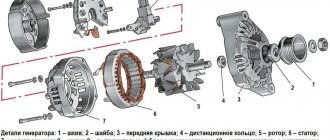

A car generator is designed to convert the mechanical energy of rotation of the engine crankshaft into electrical energy. It performs two main functions: recharging the battery and powering the vehicle's power supply systems with generated electricity. Along with the rotor and stator, the housing of the alternator also contains a brush assembly, a voltage regulator and a rectifier unit.

Brushes are the most vulnerable element of the generator. At the moment of their contact with the slip rings, the rotation speed of the generator shaft reaches 12-14 thousand rpm, which causes accelerated wear of the contacting surfaces. Timely replacement of generator brushes helps prevent damage to the brush assembly and ensure uninterrupted power supply to the vehicle while driving.

Generator brushes: what function do they perform?

When in contact with the slip rings located on the rotating rotor shaft, the generator brushes transmit current from the battery to the rotor field windings. This is how an electromagnetic field is created.

Under the influence of the alternating magnetic field of the rotating rotor, an electromotive force is induced in the coils of the stator windings and an alternating electric current is created. The current passing through the diode bridge (rectifier block of the generator) is converted into direct current. This is exactly what is needed to recharge the battery and ensure the functionality of the car’s electrical equipment.

When to change brushes: main signs

It is recommended to replace them as they wear out, but at least once every 4 years (or upon reaching a mileage of 50 thousand km). However, under difficult operating conditions, critical wear of brush rods made of graphite or its compounds with copper (bronze, aluminum) may occur earlier than the specified period. The brushes should protrude by at least 5 mm (the norm is 8-10 mm). This indicator is the most important - by measuring the length, you can understand whether there is a problem.

Several symptoms may indicate that your brushes need replacing, including:

- lack of starter response when turning the ignition key to the ON position - this can happen if the rods are skewed and there is no sufficient contact with the surface of the slip rings;

- slow rotation of the engine flywheel by the starter;

- reduced power of interior lighting, weak or flashing headlights, side lights;

- sudden shutdown of electrical appliances;

- rapid discharge of the battery, after which it becomes almost impossible to charge it.

To determine the cause of disturbances in the operation of the generator, it is necessary to accurately diagnose the malfunctions of the generator and, in particular, the brush assembly.

How to check generator brushes?

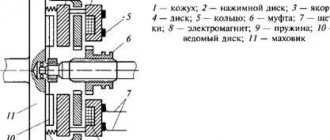

The brush assembly is usually combined with a voltage regulator. Contact with the rotor slip rings is carried out due to the force of the springs. A malfunction of the generator brushes can be easily determined by visual inspection (sign: the length of the protruding ends is less than 5 mm). You also need to check the diameter of the slip rings (the norm is 14.2-14.4 mm, the minimum is 12.8 mm). The presence of workings on contact surfaces is not allowed. Worn slip rings need to be replaced.

Problems with the generator can also arise due to increased brush resistance, which should be no more than 0.5 ohms. You will have to replace the brushes if, when checking, the multimeter shows increased resistance.

However, given that in most modern cars the brush assembly is combined with a voltage regulator, generator problems can be associated with a malfunction of the relay regulator, designed for a voltage of 15 V and a current of up to 5 A. For diagnostics, measurements with a multimeter are used. When the engine is running, the voltage at the battery terminals or at the generator outputs should be within 14-14.2 V. The voltage change is allowed by no more than 0.5 V. If the fluctuations are more significant, this is a sign that the relay-regulator is faulty and must be replaced.

It is also useful to check the voltage regulator.

To do this, assemble a circuit that combines, using wires, an adjustable power supply, a light bulb, a voltage regulator with a brush assembly, and a multimeter (voltmeter). The power supply and multimeter are connected with correct polarity to the contacts of the voltage regulator. The light bulb wires are attached to the brushes. By turning on the power supply, voltage is applied (from 3 V), the light comes on. With a gradual increase in voltage and upon reaching 14 V, the light should go out - this indicates normal operation of the regulator.

Why do you need a generator in a car, and why can’t even a working one always charge the battery?

photo: nairaland.com

Modern cars are usually equipped with a three-phase alternating current electric generator.

While driving, it generates energy for all electricity consumers in the car (the voltage corresponds to plus or minus 14 volts and is maintained by the regulator). The more sophisticated the car, the more consumers it has and the more current it requires. Air conditioning, heated mirrors, rear/front windows, heated seats, cruise control and so on and so forth, from the latest electronic assistants to the fuel pump and engine control unit. see also

The use of a 48-volt on-board electrical network

In addition, as many people know, even those who are not very familiar with the structure of cars, the generator is responsible for charging the battery and ensuring that it always remains fully charged while driving. This is very important, since the battery, in turn, is an energy storage device in the car and, so to speak, a conditional backup generator that supplies current, which is sometimes even required while driving.

IMPORTANT! Do not forget to turn off energy consumers when the engine is off. If you turn off the engine, turn off all energy consumers: headlights, radio (if you use the radio for a long time on an old battery, the car may not start after parking - there is not enough current), even the interior lighting.

Use a fresh battery of normal capacity. Moreover, if the car is used for short trips, especially in winter, when it is necessary to turn on voracious consumers of electricity such as glass/mirror heaters, heated seats, then even a working generator will not have time to saturate the battery with energy, which will ultimately lead not only to the inability to start the car, but also to battery degradation.

How to change brushes on a generator?

You can replace it without removing the generator - just remove the voltage regulator along with the brush assembly. Before this, you should disconnect the generator from the power supply (disconnect the negative terminal from the battery). After this, unscrew the clamping nut and remove the voltage regulator with the brush holder. If the wear is critical (the offset is less than 5 mm), the brushes (graphite rods) will need to be replaced. Here's how they do it:

- disconnect the contacts (unsolder the wires) and remove the old brushes, clean the soldering area, check the elasticity of the springs;

- install a new set into the brush holder, solder the contacts;

- check the free movement of the brushes in the brush holder;

- install the brush assembly in place and secure it with a nut.

Sometimes the solution may be simpler: perhaps the contact between the brushes and the rotor rings was broken due to the former sticking. The reason may be mud or graphite deposits, which can be easily removed by blowing contaminated areas with compressed air.

Important: before installing a new part, you should carefully check them for manufacturing defects.

Causes of generator failure

There are many reasons for generator failure - wear of brushes, damage to bearings, breakdown of windings, etc. As a result of some damage, the device will still work for some time, although it will no longer be able to generate a sufficient amount of energy, and after others, it will fail altogether. In this case, the generator will need to be repaired.

Wear of the brushes is the malfunction after which the generator becomes completely inoperative. But the car is designed in such a way that there is easy access to this device, so there are no problems with replacing the brushes.

On most modern cars, the brushes are made in the same housing with the voltage regulator. This means that if the brushes are worn out greatly or the voltage regulator relay has become unusable, then the entire assembly will have to be replaced. Replacing brushes is necessary in cases where their length is less than five millimeters. If you have at least a little experience in car repairs, then you can replace the brushes yourself. Otherwise, it is recommended to contact a generator and starter service workshop.

Replacing brushes on most generators in modern cars is possible even without removing it from the engine. But, if the device is removed, it will be much more convenient to work; moreover, it is even possible to remove and replace the brushes and regulator separately. When starting work, you should remember that it is better not to unscrew the plastic cover - the visible screws have a completely different function, and if you unscrew them, small washers will get inside the generator, which will cause a lot of unnecessary problems. That is why it is recommended to to replace the generator brushes - specialists know all the intricacies and will do the job quickly and efficiently.

Is it possible to restore brushes?

In emergency situations, when you can’t count on help, you can use the advice of experts on emergency restoration of the brush assembly. However, reliable operation of the brush assembly can only be fully ensured by using high-quality spare parts recommended by manufacturers. Recovery is always a temporary solution; As soon as the opportunity arises, you need to go to the service center.

The procedure for replacing brushes, despite its apparent simplicity, requires certain skills and special knowledge. Therefore, it is better to go to a car service center, where diagnostics and maintenance of your car’s electrical equipment will be performed quickly and with a quality guarantee.

Signs of brush wear

You can tell if the brushes are very worn out by the following signs:

- in the dark, the headlights burn dimly and blink frequently;

- interruptions in the voltage supply are felt;

- poor battery charging;

- The radio turns off spontaneously.

It often happens that when carrying out maintenance, in particular when inspecting a car generator, little attention is paid to small details, which is why many car owners are caught by surprise when brushes fail. But even if during operation of the car there are disturbances in the operation of the generator, you should not immediately resort to replacing the brushes - it is first recommended to make sure that they are the cause of the malfunction, and only then get to work.

The electrical system of any car is designed in such a way that various faults are indicated. For example, if there is a malfunction of the generator, the red indicator light on the dashboard immediately lights up. Well, quite often the cause of the problem is wear or sticking of the brushes. In the first case, the situation can be corrected only by replacing them, and in the second, if the brushes are still functional, they can be slightly ground so that they move freely in the seat.

Replacing generator brushes , as a rule, does not cause any difficulties, so any auto repair shop can handle this very quickly.

- Signs of a generator malfunction

- 1. What is a generator?

- 2. What are the generator malfunctions and how can they be eliminated?

- 3. Self-diagnosis, or how to figure out generator problems

A car's generator is a very significant element of its design, which, together with the car's battery, provides many important components of the vehicle with the necessary electricity. Thus, thanks to the energy received from the generator, the ignition system, lighting devices and various electronic devices, of which there are quite a lot in a modern car, operate. Of course, even the slightest malfunction of the generator will affect the operating efficiency of any electrical appliances on the machine, up to the point of completely blocking their activity.

Therefore, it is advisable for the car owner to have at least a general understanding of the main causes of generator problems, their characteristic symptoms, diagnostic and elimination methods.

What is a generator?

A car generator is a device responsible for converting mechanical energy received from the engine crankshaft into its electrical version.

The first generator “saw” the world in 1832, and its “parents” were the Parisian technical scientists - the Pixie brothers.

Of course, at that time such a design was far from perfect, and it was difficult to use. To operate such a machine, people were forced to rotate a heavy permanent magnet, which created an alternating electric current on two wire coils fixed near its poles. This generator had a device for equalizing the current, and to increase the power of electrical machines, scientists of those times began to increase the number of magnets and coils.

Check Features

You need to know how to check the operation of the generator on a car correctly, otherwise you may encounter the fact that a working part will be completely damaged. By following just a few simple rules, you can avoid unexpected breakdowns.

- Checking should be done using a multimeter.

- When diagnosing the condition of the valves, the current should have a voltage of no higher than 12 V.

- If it is necessary to replace the wiring, you need to select wires with an identical cross-section to the original ones.

- Before you start checking the generator, you need to make sure that all fasteners are connected correctly and that the belt tension is correct (read more about the generator belt tension roller). If necessary, the connections are brought to a working condition, and the belt is tightened or loosened.

The main condition under which it is possible to check a generator at home is to maintain its working condition. If the device is disassembled or has received damage that prevents it from functioning, then diagnostics will not allow us to determine the suitability of the device for further operation.

We also recommend reading our expert’s article, which talks about how to remove the generator on a Priora.

You may also be interested in our specialist’s article on how to remove a generator on a VAZ-2114.

We recommend that you additionally read our expert’s article, in which he talks about how to repair a VAZ-2106 generator.

There is a list of actions that absolutely cannot be performed during verification:

- performance testing should not be performed using a short circuit or in other words “spark”;

- connect terminals of different configurations to each other, as well as connect terminal 30 or B+ to ground;

- diagnostics and operation of the generator should not begin without connecting consumers. It is especially important to observe this point when the battery is disconnected;

How to test a generator for performance at home

There are two main verification methods. One of them, although very old, allows us to reliably understand the performance of the device. The second works more subtly and is able to respond to minor system flaws. Using the second method, you can identify the slightest deviations in the operation of each element.

How to check a generator on a car without removing it and without having the necessary tools

There is an ancient way to identify a generator malfunction. It is very simple, but the result can only consist of two points:

- works properly;

- there are malfunctions.

Since anyone can check a car generator at home using this method, its popularity is fully justified. You need to start the engine and turn on the low beam. You need to remove the negative terminal from the working engine. If the headlights are on evenly and the engine is not out of sync, then the generator is working properly. If the internal combustion engine operates uncertainly or the brightness of the headlights changes, it is necessary to perform a more in-depth diagnosis, since the device is in a faulty state.

How to test a generator with a multimeter

Measuring with a special device will reveal even a small failure. There are a number of indicators that are considered optimal for all types of machines. The battery without load has a voltage in the range of 12.5 - 12.7 V. Since a load is placed on the battery when the engine starts, the normal readings are 13.8 - 14.8 V. After receiving the maximum load, the voltage reading should drop to 13 ,8. If this does not happen or the voltage drops even lower, then the generator will need to be checked.