Imagine this situation: there are no auxiliary parts between the engine and gearbox. They are connected directly. Do you think the car will be able to drive? Hardly. The only thing you will achieve is strange intermittent movements of the car, as well as a further complete stop of the engine. If this ever happens, your box won’t last long, and within three days it will simply break. Moreover, problems with the engines themselves will overtake you as suddenly as replacing the gearbox. The prospect is not very good, you will agree. But, fortunately, in order to avoid such embarrassment, engineers came up with a clutch.

The main purpose of this device is to smoothly connect the engine and gearbox for their further functioning. If we omit all the terminology, then the clutch is necessary in order to turn off the torque. One of the biggest advantages when using this device is that if you have it, you don’t have to worry about the transmission deforming when braking at high speed. The use of such a device allows you to avoid expensive repairs that might be necessary in its absence.

Clutch operating principle

The clutch is responsible for transmitting torque from the engine to the gearbox. Its main task is to disconnect the units at the moment of switching speed. It is worth noting that this mechanism is different on cars with automatic and manual transmissions. On engines with a robotic transmission, the interaction with the engine is slightly different, and its functions are controlled electronically.

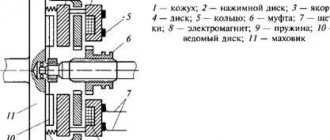

If we omit all the nuances, the clutch consists of the following components:

- The drive connects the pedal and the clutch itself (there are several options: mechanical, with a cable and hydraulic). On a robotic transmission, the drive is activated by an actuator, which receives commands from the ECU.

- Basket. Consists of a release bearing and a pressure plate.

- Driven disk.

- Fork.

- Damper springs.

- Control pedals.

When you press the pedal, force is transmitted to the clutch fork via a cable or hydraulic cylinder. The fork, through the release bearing, mechanically acts on the petals of the pressure plate, which, under the influence of this force, bends towards the flywheel. This causes the driven and driven discs to lose traction and the engine to idle without any load on the wheels.

Let's not forget about the dual-mass flywheel

Until recently, buying a car with a manual transmission had a strong argument in the form of the low cost of servicing and repairing the transmission. But the advent of dual-mass flywheels (primarily on diesel or simply powerful versions) reduced this factor to nothing, because sometimes they last less than the clutch and cost several times more. Like many other problems, they are trying to solve this one in a cheap way. In this case, by switching to a single-mass flywheel, especially since some component manufacturers have mastered such kits.

Of course, this raises a number of questions. At one time, they switched to dual-mass flywheels for a reason. A special feature of this unit is its powerful damping system. If you switch to a regular kit, the clutch will take on all the load. And this is a question of both resource and efficiency of damping vibrations and shocks.

Some craftsmen and spare parts sellers adhere to the following point of view on this issue. The further behavior of the car depends on the quality of the clutch disc. If you do not save on this, then the ordinary consumer will not even feel the differences when replacing. As for resource issues, the single-mass flywheel itself, as we have already noted, turns out to be “eternal”, and a good clutch still lasts a long time. Even if we assume that it will last less, in any case, replacing it will cost several times less than replacing a dual-mass flywheel.

Clutch kits in the Automotive Business ad database

Signs of clutch problems

Often drivers, especially new car owners, when problems arise with the clutch, realize that the car has begun to behave differently, but continue to drive without making any attempts to find out what the reason is. As a result, this leads to serious damage and the car completely fails. Knowing the main symptoms of a clutch malfunction, you can take timely measures - carry out repairs yourself or contact service center technicians or service stations.

Below are the main symptoms of clutch malfunctions and which unit is responsible for this or that atypical behavior.

Incomplete clutch release

Among motorists - “the car is driving.” In other words, when the clutch lever is pressed, the driven disc is partially disconnected from the motor wire shaft. This leads to the fact that the car begins to twitch at the beginning of the movement at the moment of changing gear, even though the pedal is depressed smoothly, as usual.

What causes this problem to occur:

- Small pedal free play. It may be different for each car; you should look for information in the technical data sheet.

- The drive is poorly adjusted. On mechanical and hydraulic drives, the defect is eliminated in different ways.

- Clutch disc deformation. This happens more often when the axial runout value is greater than 0.5 mm. Under such circumstances, the friction lining of the disk bends and presses it against the flywheel of the internal combustion engine.

- Clutch disc wedge in shaft grooves. A common reason is parking the car for long periods of time, especially outdoors.

That is, it is not so easy to determine exactly what led to the clutch failure, because one defect may be the result of damage to one or more elements.

If after adjustment the defect has not been eliminated, the only option is to replace the clutch with a kit. Always change the clutch as a set (disc, basket, release) since saving on spare parts usually leads to repeated disassembly, loss of time and money.

Clutch slipping

The main signs indicating a malfunction of the clutch are the following: pressing the gas pedal almost all the way with the clutch released, the engine “growls”, but the car does not react or the reaction is very weak. In addition, you can hear a characteristic burning smell from the engine compartment, this is due to the clutch disc slipping and, as a result, its heating.

Causes of malfunction:

- The free play of the clutch pedal is out of adjustment (a very rare reason).

- Oil contamination of the friction lining of the driven disc. More common in cars with high mileage. Possible wear of the oil seal or gasket, insufficient joint tightness, etc. can lead to lubricant splashing and getting onto the friction linings (which leads to the smell of burning oil).

- The friction lining is worn.

- Drive faults. Help will be needed to determine this. Looking under the bottom of the car, ask an assistant to depress the clutch pedal. The rod of a working cylinder moves, pushing the fork. Otherwise the drive is damaged.

On a hydraulic drive, the problem may be caused by a clogged compensation hole in the main cylinder.

Almost always eliminated by replacing the clutch with a kit.

The occurrence of atypical noise when depressing the clutch pedal

When the pedal is released there is no extraneous sound. When pressed, a characteristic rustling sound appears, intermittent grinding of different levels and similar noises.

Causes of malfunction:

- The appearance of a gap or insufficient amount of lubrication led to the release bearing crumbling.

- Damper springs or basket petals have failed.

- The driven shaft bearing in the transmission is worn out.

If the release bearing wears out, you can only replace it, BUT only if you are sure that all other clutch elements are in excellent condition. Agree, it will be a shame to remove the box again in a month to replace the disk or basket.

The clutch pedal makes a squeaking sound and does not move back

In this case, you should try to move it to its original position with the toe of your shoe. If this does not help and the squeak remains, most likely the drive is jammed. A loose release bearing may also be the cause. Less commonly, the consequence of such a defect is the jamming of the clutch lever spring (for example, after a long period of inactivity) or the master cylinder rod.

In addition, the bushing on the rod at the place where the pedal is fixed can produce a squeak. In this case, it is enough to lubricate it.

The clutch disengages when the pedal is pressed hard

And when you press or release smoothly, the clutch does not engage. This is a symptom of a faulty hydraulic drive. There are several reasons for its failure:

- depressurization of the transmission system line;

- low fluid level in the system;

- Excessive wear of the master cylinder cuffs.

Car jerks when using the clutch pedal

If the drive is working properly, the reason may be caused by loosening of the friction linings or their wear. In this case, they will need to be replaced.

Insufficient effort when pressing the clutch pedal

More often, low pedal resistance is caused by air in the clutch hydraulic system. You can fix it by removing air - bleeding the system.

Basket installation

To repair or replace the clutch basket, you need to unscrew the bolts holding it. If you can see that the basket petals are very worn, it is best to replace the entire part.

To install a new basket, it is necessary to straighten or center the gearbox input shaft, since otherwise the displacement of the disk will not allow the box to be put on. Therefore, the operation of inserting the disk with the mandrel into the flywheel must be performed very carefully.

After putting the basket in place, you need to tighten the clutch bolts. In this case, the bolts are tightened gradually, over 3 or 4 turns of the flywheel.

The final step in replacing the basket is to install the release bearing on a well-lubricated shaft.

The specific technology for removing the clutch basket and replacing it depends on the type of engine and type of clutch mechanism, but for most cars it is similar to that described above.

Installation of all dismantled parts and their adjustment is carried out in the reverse order.

Provided that all operations are carried out in a strictly specified sequence and in compliance with technical regulations, repair and replacement of the basket or other parts of the clutch mechanism is possible with your own hands in your own garage.

In mechanics, a clutch is a mechanism whose operating principle is based on the action of sliding friction. Often the term "clutch" is used to refer to one of the components of a vehicle's transmission that is used to connect the engine flywheel to the transmission. Depressing the clutch pedal temporarily disconnects the power transmission from the engine.

The clutch mechanism is necessary so that you can start smoothly from a standstill, without jerking. The speed of the car begins to increase only at a certain minimum number of engine revolutions. The clutch is also used when it is necessary to match the vehicle speed and the engine crankshaft speed, that is, it ensures smooth transmission of torque from the engine to the gearbox and, if necessary, at some point completely disconnects the manual transmission gears from the engine transmission mechanism.

Diagnosis of clutch faults

You can check the performance of the coupling using simple and reliable folk methods. Naturally, we are not talking about disassembling the entire mechanism, but about how to independently check the clutch and, based on the data, make a decision about the need for in-depth diagnostics followed by dismantling.

"Drives" the clutch

In the case when the discs do not completely separate when pressing the clutch pedal, the clutch is said to have “engaged”. This means that they have some kind of contact, so the clutch is not completely turned off. Experienced car owners know how to check the mechanism for complete shutdown.

Diagnosis is quite simple. To do this, at low speeds with the pedal fully depressed, first gear is engaged. If such an action was carried out easily and was not accompanied by extraneous noise, the shutdown occurred completely. In case of difficulty in switching, which additionally caused gear noise, it means “drives”.

To eliminate the causes you will need:

- adjust the drive;

- clean and lubricate the splines;

- repair or replace the driven disk;

- replacing friction linings.

Any mechanism has to be changed sooner or later. In a hydraulically driven system, you will need to pump it to remove any accidentally trapped air, check the tightness of the connections and the integrity of the pipes. If necessary, replace parts that have failed (for example, the main or working cylinder in case of a fluid leak).

Clutch “slips”

If while driving you heard the smell of burnt oil, and on uphill slopes the car began to noticeably lose speed, and in general the dynamics deteriorated significantly, then no diagnostics are needed. Verdict - the clutch is slipping.

This indicates that the drive and driven disks do not mesh tightly enough when turned on. There is one very simple and accessible way to check the operation of the mechanism. To do this you will need:

- put the car on the handbrake and start the engine;

- Depress the clutch pedal and engage gear;

- smoothly press the gas pedal and then also smoothly release the clutch.

The engine should stall. Otherwise, the clutch slips. Defects can be eliminated by adjusting the drive and replacing the linings. Rubbing parts that have been exposed to oil should be thoroughly cleaned with a solvent (for example, white spirit). Then determine the reason for the lubricant getting into the mechanism and eliminate it.

Checking clutch wear

Checking the degree of wear of the driven disc is also a fairly simple task, which will tell you whether it is time to change the clutch or not. To do this, you need to start the engine and engage first gear. Then try to move away without accelerating. This will help you understand the condition of the clutch disc:

- the clutch “grabs” at the very beginning - the disc is in excellent condition, the mechanism is fully operational;

- The clutch “suffices” approximately in the middle - the disc is worn out by half or needs adjustment;

- The clutch “grabs” only at the end of the pedal stroke - the disc must be replaced.

In some cases, the disc is not yet completely worn out, and normal clutch operation is restored by simply adjusting the appropriate nuts.

Procedure for removing the mechanism

It is easiest to repair or replace the clutch basket when the entire engine is overhauled. If the power unit is removed, then you can inspect, repair or replace worn parts of this part of the car without much effort. In this case, dismantling the unit does not present any difficulties.

Let's take a closer look at how to disassemble the clutch and how to remove the failed part. The operation scheme is simple. The main thing is to comply with the technological regulations given below:

- First you need to remove the gearbox (gearbox). If the gearbox does not need to be repaired, then there is no need to disconnect the drives before removing the battery and mass flow sensor and draining the oil.

- Unscrew the drive (cable) that activates the mechanism and remove it.

- Unscrew and remove the starter.

- Unscrew the top bolts securing the box.

- Unscrew all electrical wiring harnesses and the speed sensor chip.

- Loosen the drive nut on the right side and completely unscrew the nut on the left side.

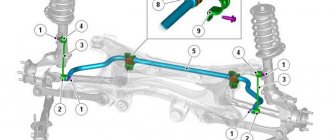

- Unscrew the suspension arm.

- Unscrew the ball joint.

- Remove engine protection.

- Remove the reverse signal switch chip.

- Unscrew the torque rod from the gearbox and remove the lower cover of the clutch housing.

- Loosen the nut of the gearbox control drive clamp and remove the rocker.

- Unscrew the lower bolts and gearbox mounting nut.

- Jack up the engine.

- Unscrew the gearbox from the pillow.

- Remove the box and gain access to the necessary component of the car.

Other signs of clutch failure

When the friction linings wear critically, the behavior of the car changes significantly. The following are signs of a burnt coupling:

- It is difficult to start moving. The car can remain stationary even when the clutch pedal is fully released. This means that the disc is not pressed enough to transmit torque to the transmission. Here you can judge the critical wear of the driven disk.

- Car jerking while driving. In this case, you can still start moving, but the start will create discomfort - the car jerks strongly. When the speed increases, the jerking disappears. However, the next time you try to drive from first gear, the jerking and vibration will appear again. In addition, the car may accelerate atypically when switching to higher speeds. Since the disk is not pressed tightly enough to the flywheel, the torque is transmitted intermittently. The car loses acceleration dynamics. If you disassemble the coupling, you can see the play of the diaphragm springs. They are responsible for compensating and smoothing the loads coming from the flywheel to the transmission. If such play is detected, the mechanism must be replaced.

- Free play of the clutch pedal.

Based on these signs, you can judge whether the clutch is faulty without additional diagnostics. However, to get the full picture, it is better to contact specialists.

After we have decided on troubleshooting, it’s time to choose the best clutch kit for your car, our rating.

Release bearing wear

Release bearing wear manifests itself as follows.

When you press the clutch pedal, you hear a loud buzzing noise. The mechanism begins to function and puts a load on the deformed bearing, hence the sound.

In addition, another indicator is also the strange vibrations that appear the moment the car starts moving. The release valve is replaced as necessary.

Hydraulically operated release bearings have some other problems. The clutch pedal becomes very soft and it stops working, and brake fluid leaks out. And the clutch also stops working. A working clutch works as follows: torque is transmitted very smoothly. The car behaves smoothly on the road, without jerking or slipping. There are no unnecessary sounds when changing speeds. The pedal is easy to press and the car does not make any strange sounds.

The most common causes of clutch system failure

The human factor can lead to premature failure of a given unit. Here are several factors that affect clutch life reduction:

- Aggressive driving style. You should not constantly press and release the clutch pedal sharply - this will cause the friction linings to quickly fail.

- Driving under increased loads.

- Incorrect towing. Inexperienced car owners often keep the pedal half-pressed when towing. It is also not recommended to tow vehicles much heavier than your car.

- Driving with the clutch pedal half depressed.

- Sharp starts and too smooth at high speeds.

- Many beginners often keep the clutch depressed during short stops (for example, at a traffic light). This should not be done, since in this position the release bearing is under constant load, and this leads to its premature failure.

The working life of the coupling is quite long and ranges from 100 to 150 thousand km. When used correctly, the mechanism is quite reliable and reaching the top level is quite possible.

How to check pedal free play?

The clutch pedal has a certain free play value. After some time or due to the influence of certain factors, this value may increase. First, it is necessary to determine this value at the moment, and if it deviates from the permissible norm, it is necessary to carry out appropriate repairs. Many cars are equipped with an adjustable clutch system, and you can adjust it either yourself or with the help of a specialist. If the car has only had minor mileage on its basket, then this repair method can solve the problems, but if it is serious and the clutch has already been adjusted, then replacing the discs or basket is recommended. Repairs and adjustments should be made when the first signs of a problem are detected, as this will save money on expensive repairs.

Avto.tatar specialization includes “ clutch replacement ”

Mistake #3: Overloading and using a trailer

The clutch will also fail faster if the vehicle is loaded. In this case, the overload may not go beyond the passport data, but if you carry hundreds of kilograms in a passenger car over and over again for many years, know: the clutch on your car will last noticeably less than on those cars that did not carry heavy loads.

Every start from a traffic light, every switch under overload will force the disk to work at the limit, causing premature wear.

The clutch will suffer no less if you transport a loaded country trailer or tow other cars “on a tie”.

The advice suggests itself. If you want the clutch to last longer, do not overload the car. It is better to make more trips to the country than to try to remove the entire crop in one go.

Here are the basic tips for motorists who are accustomed to taking care of their car and avoiding premature breakdowns, the repair of which is expensive and quite problematic.

How much does a standard hour of labor and spare parts cost to replace a clutch?

To understand that clutch failure is not a very cheap “pleasure”, let’s give an example of several packages (basket, release bearing, disc) for popular brands and the cost of replacing them

Lada Vesta

Lux clutch kit: 4.5-5 thousand rubles

Lada Granta

SACHS clutch kit: 5-6 thousand rubles

Kia Rio

SACHS clutch kit: 5-7 thousand rubles

Hyundai Solaris

SACHS clutch kit: 7 thousand rubles

Which elements wear out?

All components of the unit have a different working life, but it is recommended to change the entire unit at once. Of course, you can save money and replace only the worn-out part, but it is unlikely that other elements will last twice as long, and repairing parts in total will cost you much more than replacing the entire unit.

This is where the friction linings become unusable. Under a powerful load of torque this is inevitable; the linings wear down and can no longer fully perform their function. The problem cannot be neglected, since if the linings are very worn, there is a high risk of damaging the engine flywheel.

Damper springs

They work in tandem with a disk and are designed to dampen vibrations. Since springs constantly operate at temperatures up to 200-300 degrees, steel eventually becomes deformable and bursts. The spring itself may lose elasticity and become shorter. Of course, all this affects its performance.

Release bearing

Its purpose is to move the disc away from the basket and flywheel. The wear of this element is indicated by the appearance of play in the bearing itself.

Basket

The most durable element of the unit in question is the basket itself. It can last 2 or 3 times longer than the parts described above, but, as already mentioned, if one of the elements is worn out, it is better to change the entire set at once.

The basket wears down during operation; when the thickness reaches critical values, there is a risk of the unit splitting into several parts. Also, overheating can cause the release disc blades to break, and their particles can damage other car mechanisms.