Good day to all! As you may have guessed, today I will talk about when to change the timing chain, what it even is and what are the signs of wear or malfunction of this unit.

Surely you know about such a device as the timing belt, that is, the gas distribution mechanism. Using the example of Renault Logan, there was already talk about replacing the timing belt. But in addition to the belt mechanism, chain drive types can also be used here.

As part of today's material, we will talk to you about what a drive chain is, how to determine the wear of this unit and in what situations replacement is required. Knowledge of the theory is of great importance in matters of self-diagnosis and maintenance. No one forces you to change the chain yourself, since you can always turn to specialists.

A little theory

Chain drives transmit rotational force from the crankshaft to the camshaft, which is located in the cylinder head of overhead valve engines.

Chains are divided into 2 categories. They can be toothed or roller. Roller mechanisms, unlike gear ones, are not so widespread. Therefore, it is gear systems that are most often found on cars with a timing belt, which include a chain drive. Gear units are distinguished by their high smoothness, they are quite reliable, and produce an insignificant level of noise during the operation of the internal combustion engine. In terms of their characteristics, the use of toothed chains brings them much closer to belt drives. One can argue endlessly about which one is better. But we won’t dwell on this today.

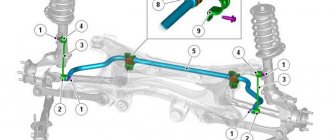

The chain is tensioned due to the operation of hydraulic tensioners, for which motor oil is used as a working fluid. The lubricant is supplied through the engine lubrication system.

Depending on the number of camshafts, that is, camshafts, the number of tensioners also differs. On cars there are from 1 to 3 units.

The service life of the chain directly depends on what the element is made of, how high quality it is and the degree of effectiveness of the heat treatment performed. Similar requirements are placed on timing sprockets, since they constantly operate together with the chain. Do not forget about the influence on the condition of the unit of the engine lubrication system, the quality of the oil itself and timely replacement of the fluid. In practice, when the part is made of high-quality materials, and the correct tension was carried out as part of the service, plus lubricant was introduced on time, then replacing the chain may be necessary at the same time as replacing the motor itself.

That is, you understand that a stretched chain cannot function for a long time and effectively. If you want to extend the life of this unit, initially take a high-quality chain, adjust its tension correctly and lubricate the drive generously with high-quality oil.

Replacing a component yourself

Want to save money? It is quite possible to replace the chain with your own hands. However, this task is not an easy one, so it is better not for a beginner to take on it. Expect to spend at least 3-4 hours. You also need to prepare a place and a set of tools in advance.

Let's look at the process of replacing a chain using the Nissan Almera N16 Classic as an example.

Platform and tools

It is advisable to carry out the work where there is a lift, overpass or pit. Prepare the following tools:

- hex key 6;

- socket heads sizes 12, 13 and 14;

- chisel and hammer;

- clean cloth for wiping;

- containers into which technical fluids will need to be drained;

- adjustable and torque wrenches;

- block of wood;

- sealant and “anti-silicone” (degreaser);

- and, of course, a new chain.

Workflow for dismantling and installation

- The first thing to remove is the cables connected to the ignition coil. After this, you can unscrew the coils and put them aside. Be sure to label these components with numbers in the order in which they were removed - this will help avoid confusion during assembly.

From here we begin work on preparing for the chain replacement

- Separate the air pipes from the valve cover. The cover itself is secured with bolts. They also need to be unscrewed - then it will be possible to remove the part.

- Remove the right engine mount, otherwise it will interfere with further work.

- Locate the engine oil drain hole. Place a container under it and unscrew the cap. Wait until the technical fluid flows into the container. Remove the oil filter.

- Take another container. Find the lower radiator hose clamp and remove it. The coolant should also flow into the container. After this, find the radiator cap and unscrew it to remove any remaining coolant.

- Afterwards you need to remove the radiator and remove the generator drive belt. Then remove the supply hose clamp (you may need to loosen it first).

- The next task is to dismantle the cylinder head. The cover of this component is secured with four bolts. They need to be unscrewed, after which it will be possible to remove both the cover itself and the fan and its components.

- You need to remove the engine sump. This can be done by first removing the muffler (it is installed on several bolts).

- Slightly loosen the bolts that secure the pump pulley. This will make it possible to remove the belts connecting to the control and climate control components.

- Locate the space between the side of the crankcase and the crankshaft. Place a block of wood there and carefully remove the crankshaft pulley. To unscrew its bolt, use a socket head of the appropriate size. If you cannot reach the bolt, use an extension.

- Find the water pump pulley and remove it too. Under this part there is a gasket, which should also be removed. We'll have to temporarily get rid of the oil pump.

- That's it, the preparatory work is completed. You can proceed directly to dismantling the old chain. The camshaft gears are secured with bolts that must be unscrewed. The camshaft itself will have to be fixed with an adjustable wrench.

Dismantling the chain is carried out in the following order.

- Remove the damper (bar at the top).

- We remove the hydraulic tensioner and the bar responsible for tensioning the damper. It may be worth replacing the tensioner - especially if your car has an older version where the valve is in the stem rather than the head.

- Take the bottom bar and put it on the hairpin.

- We remove the chain itself.

- We get rid of the gear located at the bottom using a flat-head screwdriver.

If the tensioner in your car looks like this, it is better to replace it

- Compare the old chain with the new one. Most likely, the used version will be slightly longer than the new one. The increase in size occurs due to stretching. Place the new version in place of the old one and lubricate it with machine oil.

- That's it, all that remains is to install the parts in place. Before doing this, clean the mechanism components. Degreasing and cleaning the side of the engine is carried out using “anti-silicone” and a clean cloth.

- The new component must be installed so that the marks on it and on the pulleys match (this is important!). After this part of the work is completed, the side of the engine is lubricated with a new layer of sealant. Tighten the bolts that secure the cover and wait until the sealant sets. After this, you can perform the work in reverse order.

The same marks that must correspond to one another

Choosing a trailer and rating the best manufacturers

The operation of the timing belt directly depends on the condition, degree of wear and quality of the chain. When the motor is running, the mechanism also works actively, and under heavy loads. And in this mode, not a single element can serve forever. The process of gradual wear and tear begins. If even one tooth on the chain breaks, slippage will occur. Even this alone can lead to a series of malfunctions and complete failure of the unit. As practice shows, if the circuit breaks, problems appear with the engine valves, which must eventually be replaced. If it is a diesel engine, then there is a risk of camshaft failure. In this situation, it is necessary to change not only the chain, but also the camshaft, valves and head gasket.

If you change the chain untimely, the consequences can be extremely serious, and you will have to spend an impressive amount of money to eliminate them.

In this regard, it is recommended to carry out diagnostics in a timely manner. If you notice signs of wear, the chain must be replaced. By the way, if you buy a used car, be sure to examine the condition of the chain drive. The element is not the cheapest, and therefore the cost of putting the car in order will increase significantly.

Why change the timing chain

During engine operation, this part is subject to enormous loads, which after a certain mileage can even lead to a chain break. In this case, the damage can be partial, for example, when one of the links comes off. In this case, the mechanism continues to work, but slippage is observed and the engine begins to operate intermittently. Since the part is located inside the motor, even with the slightest errors, the consequences can be the most unpredictable. From this it follows that the timing chain must be changed in a timely manner. If you are a fan of long trips, then it would not be a bad idea to carry a spare part, especially since it will not take up much space.

Every car owner should know and take into account that the timing chain has a certain resource, after which the part needs to be replaced

How is wear determined?

Now let's talk directly about how to understand or how to find out that the timing chain assembly has worn out and needs to be replaced. Diagnosing and understanding the signs of wear and tear will save you from costly repairs.

Similar problems can happen on any machine, be it:

- Volkswagen Polo Sedan 1.6;

- Kia Sportage;

- Volkswagen Tiguan;

- Kia Rio;

- Skoda Yeti 1.2;

- Hyundai Solaris;

- Hyundai Elantra;

- Kia Spectra;

- Volkswagen Jetta, etc.

But if you look into the regulations for the maintenance and operation of some cars, you will, to your surprise, find that on many cars the plant does not provide for replacing the chain at all during the entire operating period.

That is, replacement is not carried out at a certain interval. But this is only possible under ideal operating conditions, which are almost impossible to achieve.

Experienced motorists advise changing the chain approximately every 100 thousand kilometers. This is a normal resource for a quality part.

But it’s best to start from the characteristic signs indicating wear. Namely:

- When starting the engine or idling, the engine runs rough and intermittent;

- There are strange sounds coming from the engine. Moreover, they are heard most clearly at idle with low oil pressure. The knock is characteristically metallic;

- During the diagnosis, a strong output of the chain tensioners is noted, as well as characteristic signs of wear on the sprocket teeth.

But that's not all you need to know.

Consequences of malfunctions

Problems in the timing chain drive lead to the following problems:

- A stretched and weakened chain jumps several teeth. As a rule, this happens when the engine starts.

- A chain operating with increased free play often breaks the guide and even “gnaws” a groove in the cylinder head made of aluminum alloy.

- In some brands of cars where a single-row chain is used in power units, it may break.

Note. Chain drives of the timing unit can be single- or double-row. The former are not as reliable and durable as the latter, and often break down after a run of 50-80 thousand km. Double-row drives break extremely rarely, even when the owner of the car does not pay due attention to it.

Double-row chains also break, but very rarely.

The consequences of the listed problems can be as follows:

- The most harmless option is a shift in valve timing due to the chain jumping 1-2 teeth. The engine does not start well and vibrates strongly during operation, and there is a clear loss of power while driving. When you press the accelerator pedal sharply, shots are heard in the intake manifold or exhaust pipe.

- When there is a 3 tooth offset, the engine will no longer start. Another thing is that in practice such situations are rare; a too loose chain skips much more. The result is a piston hitting a valve that opened at the wrong time.

- Due to severe wear or breakage of the damper, the chain drive is weakened even more, causing the consequences described above.

- The damage caused by a broken single-row chain depends on the type of engine and the moment when it happened. If all the valves were closed, then the pistons, which continued to move, would not reach their plates.

This is what the valves look like after meeting the pistons.

In power units with 8 valves, meeting a piston happens quite rarely due to the technological clearances provided for by the design (except for individual motors). But a 16V engine valve that is open when the chain breaks or jumps almost always receives a blow from the piston. As a result, its stem bends and the valve remains in the open position. In especially severe cases, the consequences are as follows:

- even the valve seat and guide bushing are damaged;

- a through hole appears in the upper part of the piston;

- A dent appears on the plane of the cylinder head near the combustion chamber, which makes it necessary to replace it entirely.

We recommend: Rear view camera for a car with a monitor on E-catalog

A chain that has jumped or broken while driving makes itself felt by a sharp loss of power or complete engine failure. If you were able to hear a metallic knock, indicating the meeting of the piston and valve, then you should prepare for serious repairs to the power unit.

And this is a piston pierced by a valve plate

Useful tips

It is recommended to regularly check the condition of the drive in accordance with the manufacturer's instructions, and also strictly adhere to timing chain replacement intervals.

Care must be taken when replacing the timing chain as this will also determine how the engine will perform. If the timing chain is not installed correctly, the engine will also not run properly. The repair must be done precisely.

Drive elements should always be replaced according to the recommendations for our vehicle. Buying quality parts will certainly extend the life of the timing chain.