Wheel bearings cannot be called consumables in a car. The service life of this unit is quite high, and with the advent of HUB-type bearings on the market, which do not require lubrication, preload and other adjustments, the mileage of these parts has become even higher. Unfortunately, domestic factories producing passenger cars and light commercial vehicles still use old types of bearings - single-row roller bearings. The only exception is AvtoVAZ, which long ago switched to double-row roller bearings for hubs of the HUB-1 type, a closed type. The Transservice.Avtobusiness magazine conducted a study of the retail market for wheel bearings for Russian-made cars and found out how successfully domestic manufacturers of auto components maintain their positions in their traditional segment.

The objects of our research are the front wheel bearings of VAZ 2110, UAZ Hunter, GAZelle cars. I don’t think there’s any need to explain the choice of cars. At the moment, these are the most common original Russian-made cars on the market. The study was conducted in 4 cities of Siberia: Novosibirsk, Kemerovo, Barnaul, Omsk. Specialists from the analytical department of the Transservice.Avtobusiness magazine collected information from 200 retail outlets using a telephone survey. The survey participants were asked questions about what brands of wheel bearings for each car are represented in the retail network at the time of the study and what are the retail prices for these products? Here are the results we got.

Wheel bearings VAZ 2110

Currently, three standard sizes of wheel bearings are produced for the modern line of VAZ cars (if you do not take into account the Chevy Niva and Niva 4x4 cars). On front-wheel drive cars VAZ 2108, 2109, 2110, 2111, 2112, bearing 256907 is used (on Kalina and Granta a smaller size 256707 is installed). The rear axle uses a 256706 hub bearing. All three models are HUB-1 type. These are double-row closed ball angular contact bearings of the closed type. The front bearings on Lada Granta and Lada Kalina are only slightly different in height. Type HUB-1 means that the bearing housing does not have flanges for attaching this part to the brake disc or hub. The demand for these bearings on the market is quite high, since the fleet of cars that use bearings of this type is quite wide. That is why competition in this market segment is much higher than in the other two. This competition is partly due to the fact that VAZs are equipped with HUB-type wheel bearings, which are quite widespread in the automotive industry today, in contrast to single-row tapered roller bearings. It is the generally accepted design of the wheel bearing for VAZ that allows foreign suppliers to easily offer their product to Russian consumers.

In this segment, more than 12 brands are competing for the attention of buyers. These are, first of all, five domestic enterprises:

• CJSC "LADA Image", supplier of original Lada wheel bearings to the secondary market,

• Saratov Bearing Plant, presenting products under the SPZ brand,

• Volzhsky,

• Vologda Bearing Plant, VBF brand.

• Samara SPZ-9 plant.

These five enterprises are traditional suppliers of wheel bearings for cars from Tolyatti. Until recently, there was another market participant, the Kursk Gas Processing Plant, but currently the company does not produce these products. But many more modern and stronger competitors have appeared, represented by both domestic brands, which offer under their brand quite high-quality bearings produced abroad in modern factories, and foreign manufacturers, whose products are, of course, more expensive, but also in terms of resource promises to be much more profitable.

However, for now Russian manufacturers have nothing to fear. Among Lada car owners, conservatism in the choice of auto components is quite strong. They rarely change their habits and attachments to a brand unless they feel that they are being outright cheated on quality. And since the price-quality ratio of Russian manufacturers of wheel bearings for Lada has not yet caused criticism, retailers are not going to refuse the products of these enterprises. The representation of Russian brands in this segment is quite high. Every second retail store offers customers at least one Russian brand. Of the imported brands, “packaging” (or, as they are also called, “engineering”) companies, such as HOLA, KRAFT, Autotechnik and others, are well represented on the market. At the same time, it cannot be said that products of foreign brands are more expensive on the market than domestic ones. On average, retail prices for wheel bearings in this segment are almost the same. If we traditionally divide the entire market into three segments: economy, middle class and premium, then we will see the following. In the lowest price segment we have only one brand - the Samara bearing plant SPZ-9. This is the only company whose products retail for less than 200 rubles. In the premium price segment there are wheel bearings from four companies: KRAFT, LGR, SCT and Trialli. Bearings from these companies cost more than 300 rubles apiece. The most popular segment is the middle one. Products from eight manufacturers are presented here. The average cost of bearings from this category ranges from 230 to 275 rubles.

UAZ wheel bearings

All UAZ hubs, both passenger and cargo, use bearing 127509. This is a roller, angular contact, conical (or this type is also called “with tapered rollers”), single-row bearing. On the right there is an additional designation A (reinforced) or AK (K - minor design changes). The bearing can withstand significant axial loads, which is very important for cars that operate in such difficult road conditions. The main manufacturers of bearings for the Ulyanovsk plant in Russia are the Samara and Saratov bearing plants already known to us. Moreover, if in the Lada segment the products of the Saratov plant are presented on the market much better than bearings from Saratov, then in this segment the opposite is true. In addition to these two companies, bearings in original packaging are well represented on the market. It is worth noting that the supplier of wheel bearings to the UAZ conveyor is the Volzhsky Bearing Plant; therefore, the original UAZ packages most likely contain products from this particular manufacturer. This partly explains the absence of the Volzhsky Standard brand in our diagram. Bearings from the Lutsk plant (LPZ) and the Moscow plant GPZ-2 are also well distributed on the market. Of the foreign brands in this segment, only KRAFT brand products are represented. There is a simple explanation for such little interest in this segment. A bearing of this standard size has only one currently widespread application - the hubs of UAZ vehicles. And despite the fact that it is installed on almost all models of minibuses and cars of this brand, foreign companies apparently did not consider this market segment interesting for themselves.

Stories from our readers

“Fucking basin. "

Hi all! My name is Mikhail, now I’ll tell you a story about how I managed to exchange my two-wheeler for a 2010 Camry. It all started with the fact that I began to be wildly irritated by the breakdowns of the two-wheeler, it seemed like nothing serious was broken, but damn it, there were so many little things that really started to irritate me. This is where the idea arose that it was time to change the car to a foreign car. The choice fell on the melting Camry of the tenth years.

Yes, I had matured morally, but financially I just couldn’t handle it. I’ll say right away that I am against loans and taking a car, especially not a new one, on credit is unreasonable. My salary is 24k a month, so collecting 600-700 thousand is almost impossible for me. I started looking for different ways to make money on the Internet. You can’t imagine how many scams there are, what I haven’t tried: sports betting, network marketing, and even the volcano casino, where I successfully lost about 10 thousand ((The only direction in which it seemed to me that I could make money was currency trading on the stock exchange, they call it Forex. But when I started delving into it, I realized that it was very difficult for me. I continued to dig further and came across binary options. The essence is the same as in Forex, but it’s much easier to understand. I started reading forums, studying trading strategies. I tried it on a demo account, then opened a real account. To be honest, I didn’t manage to start earning money right away, until I understood all the mechanics of options, I lost about 3,000 rubles, but as it turned out, it was a precious experience. Now I earn 5-7 thousand rubles a day. I managed to get the car buy after half a year, but in my opinion this is a good result, and it’s not about the car, my life has changed, I naturally quit my job, I have more free time for myself and my family. You’ll laugh, but I work directly on the phone)) If If you want to change your life like me, then here’s what I advise you to do right now: 1. Register on the site 2. Practice on a Demo account (it’s free). 3. As soon as you get something on the Demo account, top up your REAL ACCOUNT and go to REAL MONEY! I also advise you to download the application to your phone, it’s much more convenient to work from your phone. Download here.

Checking the wheel bearing. There is something humming in the cabin and the hum intensifies as the speed increases. Instructions for checking bearings.

Removing the VAZ 2110 wheel bearing. It is worth noting that replacing a wheel bearing on an old car is quite difficult.

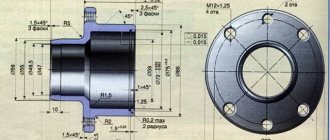

The VAZ 2110 front wheel bearing has the catalog number:

- 2108-3103020-01

- 2108-3103020-02

The rear wheel bearing of the VAZ 2110 has the article number:

- 2108-3104020

- 2108-3104020-01

- 2108-3104020-02

About the price of a wheel bearing. For a VAZ 2110, the approximate cost of bearings is 350-650 rubles.

Where to buy a wheel bearing for a VAZ 2110. In online stores.

So, let's vote and leave reviews about wheel bearings :

- What was the service life of the old bearing?

- Which wheel bearing manufacturer is the best?

ps All off-topic comments will be deleted.

Which brand of wheel bearing is better to choose?

After how many km? mileage Did you have to change the wheel bearings?

- ✅ Contents of the article:

- 1. Diagnosis of the malfunction and causes of bearing failure

- 2. How to choose a new wheel bearing for a VAZ 2110

- 3. Step-by-step instructions for removing the wheel bearing

- 4. Instructions for installing and replacing the wheel bearing

- 5. Video of the replacement process and tips for repairing the VAZ 2110

Lada VAZ 2110, 2111, 2112 and in 2016 remain popular cars, for example, among novice motorists and lovers of the Russian automobile industry. Strong suspension and chassis Ladas are adapted for poor road conditions, but suspension elements wear out over time and need to be replaced.

The VAZ 2110 rear wheel bearing (rear bearing) is replaced on average after 60,000 km , but failure will occur earlier if you have an aggressive driving style and the road surface is not smooth. Replacing the rear wheel bearing of a VAZ 2110 is carried out independently; you need a minimum set of tools, not a lot of time, and you will save money on service stations.

How to properly remove a bearing

Assembly dismantling procedure:

- We put the vehicle on the hand parking brake, set the gearbox to first speed, and wedge the vehicle wheels using the shoes.

- Remove the cap from the hub.

- Using a 30mm wrench, unscrew the hub nut.

- Using a wheel wrench, remove the disc with the tire and the brake system caliper, without damaging the hose of the brake system itself.

- We press out the hub.

- Using an open-end wrench set to “19”, unscrew the fastening of the ball joint, dismantle the locking ring and remove the pin with a puller.

- We press out the front wheel bearing of the VAZ 2110.

- We clean the inner surface of the mechanism from the remains of the previous lubricant and metal shavings.

- We visually inspect the surface for possible damage.

- We replace the old VAZ 2110 wheel bearing with a new one, having previously lubricated it.

- Install the retaining ring.

- Next, the brake system caliper is assembled, the wheel is installed, and the hub nut is fixed.

At this stage, we examined the algorithm for dismantling and replacing the front wheel bearing on a VAZ 2110. The average cost of a part ranges from 700 to 850 rubles, depending on the country of manufacture.

Reasons for replacing and diagnosing wheel bearing failure

In addition to driving style and road quality, the reasons for wear are the following: – quality of products; - quality of service; – weather conditions (at high temperatures, overheating and expansion occur, and the bearing is also susceptible to drying out of the lubricant). – other minor factors: serviceability of the suspension, tire profile, play in the units, alignment.

Let's look at the signs of a breakdown, there are several of them: 1. Rumble from behind when driving; 2. Vibration in the cabin; 3. Over time, the noise will turn into periodic grinding; 4. The wheel is loose when raised;

Area of use

Roller bearings are present in the transmission of trucks and cars. Roller bearings 2110 are equipped with axle boxes on the shafts of railway platform bogies. The products are available for gearboxes and high-power motors. Bearings are used in rotating components of metalworking mechanisms.

Bearings with rollers with a spiral groove for lubrication are used in situations of heavy contamination and heavy loads. Service parameters for roller bearings depend on their type. Made from special steels and subjected to heat treatment.

Upon completion of installation of the roller bearing, checks are carried out. An explosive rise in temperature and a sharp sound indicate an incorrect clearance in the roller bearing. A weak, uniform noise indicates stable operation of the bearing. Initially, a small load is applied at a low rotation speed.

Rear wheel bearing VAZ 2110: price, dimensions, choice for replacement

After diagnostics, making sure that repairs cannot be avoided, the question of choosing a new spare part will arise. The hub is equipped with a double-row angular contact bearing, number 6-256706E1S17 (marked according to GOST). The price of the bearing varies from 600 to 900 rubles.

It is recommended to purchase bearings from the following manufacturers: – VPZ (see VBF marking) – Russian plant in Vologda; – SPZ – SPZ GROUP – Russian Samara; – GPP – produces high-quality bearing products in Vologda.

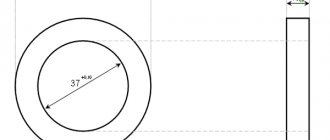

To avoid mistakes when purchasing, check the markings and dimensions: – External bore diameter – 60 mm; – Internal landing diameter – 30 mm; – Height – 37 mm.

Radial roller bearing 2110

To improve the properties of the lubricant, anti-slip additives are used. Liquid lubricants are recommended for rotation speeds above 10 meters per second. In general, mineral oils are most often used for liquid oils.

Roller bearing lubrication system

Correct selection of lubrication for radial roller bearings:

- increases service life, reliability

- reduces starting effort

- reduces heat generation, friction

A sign of significant wear is a dull raceway. The appearance of a pink or brown coating on a treadmill bearing is not alarming. Lack of the required amount of lubricant or its incorrect use leads to the formation of a shiny glassy mark on the raceway of the rollers of the rolling bearing.

The greases are suitable for peripheral speeds up to ten meters per second. With correct operation and effectively selected lubrication, the bearing bushing raceway is shiny and smooth. For radial roller bearings, soft greases are used compared to ball bearings.

How to change the rear wheel bearing on a VAZ? First, let's prepare for repairs

We will prepare the car, as well as the tools according to the list: – Jack; – A driver or pipe to increase the torsional moment; – Wrench 30, preferably with a head; – A set of other keys; – Wheel hub puller with claws (to remove the hub); – Vise; – Hammer and chisel; – Round nose pliers; – Torque wrench.

Now familiarize yourself with the design of the hub: 1 – rear axle; 2- hub body; 3- protective casing; 4 – lock pin. ; 5 – bearing; 6 – washer; 7 – nut; 8,9 – protective cap with gasket.

Place the car on a level surface, provide light, and install wheel chocks. Next, we put the first gear, and if desired, the parking brake, now we proceed to operations.

Tools and spare parts

Before going down into the pit, you need to prepare all the tools and materials. It should also be noted that replacing the front wheel bearings is much more difficult than doing the same work on the rear components.

Therefore, you need to start work from the front node.

A list of required tools should be provided:

- A special puller to remove the bearing;

- The so-called mandrel, that is, a pipe cut of the required size. This device is used to knock out hubs;

- Head 30, equipped with a high-quality wrench;

- Socket wrenches 19 and 17 sizes.

In addition, you need to purchase new suitable bearings that will be needed for replacement. For a VAZ 2110 car, you should choose Russian-made bearing parts rather than giving preference to Chinese analogues. The difference in price for these products is small, so there is no need to experiment.

Replacing rear wheel wheel bearings on a VAZ yourself

The rear wheel bearing of the VAZ 2110 is changed according to the instructions, but first consider the following points:

- The bearing cannot be reinstalled.

- It is recommended to replace the second bearing immediately, on the other hand.

We disassemble the hub assembly and dismantle the product

- First, loosen the bolts securing the wheel and the hub nut.

- Next, we jack up the car.

- Now unscrew the bolts and nuts completely and remove the chassis.

- The decorative wheel cap (boot) also needs to be removed.

- Now use a hexagon to unscrew the pins that hold the drum; you don’t need to remove the pads.

- Unscrew the hub nut using the wrench extension and remove the washer. If you are performing such work for the first time, in this case it is advisable to unscrew it before jacking up the car.

- Dismantling the hub - we use a removable device.

- Using the puller, we install the device on the axle.

- We hook our paws onto the back surface of the hub part.

- We install and check the correct installation of the legs, now we tighten the threaded connection with a wrench.

- The hub can be easily removed, leaving the outer bearing ring with balls and a separator inside.

- The inner ring of the old wheel bearing will remain on the axle.

- We attach the puller, as shown in the photo, to the rear end. You may need sharper paws, or we can remove it with a different puller.

- Pull the inner ring off the axle shaft. It is recommended to perform this operation exclusively using a puller.

- Now we press the old parts out of the hub; first, use round pliers to remove the locking element.

- Next, we dismantle the protective casing (boot), clamp the hub in a vice and carefully knock off this cover with a chisel and hammer.

- All that remains is to press out the outer race. To do this, we select a head of the required outer diameter (slightly less than 60 mm), as well as special spacers that are needed so that the bearing comes out on the other side when pressed out.

- We clamp the structure and twist until the bearing comes out of the housing. This completes the dismantling, all that remains is to replace the old element.

Installing and replacing the wheel bearing

Before installing the ball bearings, clean the inner seating surface of the hub from dirt and rust. During the pressing process, it is important to maintain a smooth force and ensure that there are no distortions.

- We fit the new bearing into the hole, evenly and without distortions, then clamp it in a vice as in the second photo.

- We tighten it in a vice and press it to the end.

- When replacing, we will use the old race and press the bearing in completely.

1. It is not recommended to insert and remove the bearing using the impact method, since there are many non-impact, safe methods. 2. When pressing, the mandrel must rest strictly against the outer part of the holder.

- After pressing, install the locking ring.

- After we insert the ring, do not forget to put the casing on, this is done with a hammer through the spacer.

- The bearing has been replaced. We begin assembly, put the hub in place, tighten it to a torque of 19-23 kgf/m. Be sure to lock the shoulder of the locknut.

- Install the brake drum and then the wheel.

- Further assembly of the unit is performed using reverse technology. Replacement is complete.

Design features

Fundamental bearing tolerances are designated by the letters lb L. A small letter l is used for the outer race. The letter L is used to mark the small ring. The outer ring of a bearing of the sixth accuracy class is designated l6 (el 6).

The marking of 2110 roller bearings is described by GOST 3189. The marking contains letters and numbers. The designation encodes the basic characteristics of the product.

Failure to maintain alignment changes the motion of the rolling elements. The quality properties of roller bearings are reduced. The axes of the installation locations require mandatory adjustment.

Bearing 2110 is a support for the rotating mechanism. Rolling elements - short or long rollers. The rolling elements are screwed into the cages. The composition includes inner and outer rings.

The spherical roller 2110 improves the technical properties of the bearing. Roller bearings can be used in cases of significant and undistributed radial stresses. The geometry of the inner plane of the outer ring can compensate for the lack of alignment.

The outer plane of the small ring and the outer one from the inside also have running tracks. During activity, rollers move in the raceways. The work is accompanied by constant friction.

Additional design features are present in products with short rollers. They perform poorly at high speeds. Plus it has increased load capacity. Technical flaw - inability to perceive longitudinal load.