Your car has two power sources, a battery and a generator. The first of them fed the electrical circuit when the engine was not running. Second source during engine operation. In this case, the battery switches to receive electricity and supplements the energy consumed to start the engine.

In practice, failures of one or a second power supply are quite common. They often open up in the same way. The starter does not want to turn the engine and as a result, the engine does not start. When the engine is running, the battery indicator light illuminates on the switch. This means that an error has occurred and the battery is not loaded.

Generator VAZ 2106: purpose and functions

A car generator is a small electrical device whose main task is to convert mechanical energy into electrical current. In the design of any car, a generator is needed to charge the battery and feed all electronic devices while the engine is running.

Thus, the battery receives the necessary energy for engine operation from the generator, so we can say that the generator is an indispensable attribute in the design of any car.

The generator's task is to ensure uninterrupted operation of all electrical systems of the machine and the battery.

How exactly does the generator work on a VAZ 2106? All processes of energy conversion from mechanical to electrical are carried out according to a strict scheme:

- The driver turns the key in the ignition.

- Immediately, the current from the battery through the brushes and other contacts enters the excitation winding.

- It is in the winding that the magnetic field appears.

- The crankshaft begins to rotate, from which the generator rotor is also driven (the generator is connected to the crankshaft by a belt drive).

- As soon as the generator rotor reaches a certain rotation speed, the generator enters the self-excitation stage, that is, in the future, all electronic systems are powered only from it.

- The generator performance indicator on the VAZ 2106 is displayed in the form of a control lamp on the dashboard, so the driver can always see whether the device has enough charge for full operation of the car.

Read about the design of the VAZ 2106 instrument panel: https://bumper.guru/klassicheskie-modeli-vaz/elektrooborudovanie/panel-priborov/panel-priborov-vaz-2106.html

Standard device for the "six"

Design of the G-221 generator

Before talking about the design features of the VAZ 2106 generator, it should be clarified that it has unique clamps for mounting on the engine. On the body of the device there are special “ears” into which studs are inserted and tightened with nuts. And so that the “ears” do not wear out during operation, their internal parts are equipped with a high-strength rubber gasket.

The generator itself consists of several elements, each of which we will now consider separately. All these devices are built into a light-alloy cast housing. To prevent the device from overheating during long-term operation, the case has many small holes for ventilation.

The device is securely fixed in the engine and connects to various car systems

Winding

Due to the fact that the generator has three phases, windings are installed in it immediately. The purpose of the windings is to generate a magnetic field. Of course, only special copper wire is used for their manufacture. However, to protect against overheating, the winding wires are covered with two layers of heat-insulating material or varnish.

Thick copper wire rarely breaks or burns out, so this part of the generator is considered the most durable

Relay regulator

This is the name of the electronic circuit that controls the voltage at the output of the generator. The relay is necessary to ensure that a strictly limited amount of voltage reaches the battery and other devices. That is, the main function of the relay regulator is to control overloads and maintain an optimal voltage in the network of about 13.5 V.

A small plate with built-in circuitry to monitor the output voltage

Rotor

The rotor is the main electric magnet of the generator. It has only one winding and is located on the crankshaft. It is the rotor that begins to rotate after the crankshaft starts and gives movement to all other parts of the device.

The rotor is the main rotating element of the generator

Generator brushes

The generator brushes are located in brush holders and are needed to generate current. In the entire structure, it is the brushes that wear out the fastest, since the main work of generating energy falls on them.

The outer side of the brushes can quickly wear out, which is why there are interruptions in the operation of the VAZ 2106 generator

Diode bridge

A diode bridge is most often called a rectifier. It consists of 6 diodes that are placed on a printed circuit board. The main job of a rectifier is to convert alternating current into direct current to maintain stable operation of all electronic devices in the car.

Due to its specific shape, drivers often call the diode bridge a “horseshoe”

Pulley

The pulley is the driving element of the generator. The belt is tensioned simultaneously on two pulleys: the crankshaft and the generator, so the operation of the two mechanisms is continuously interconnected.

One of the generator elements

Checking with a light bulb

To implement this method, you need a 12-volt low-power light bulb and three wires 1 meter long. Two of them are used to form the indicator cord. To do this, they are first connected to the contacts of the light bulb, which as a result ends up in their gap. The third wire connects one of the battery contacts to the bridge.

To check the circuit, the bridge body is connected to the battery negative with a third wire. Then one end of the indicator cord is connected to the negative terminal of the bridge, and the other end is connected to pin 30 of the bridge. The light coming on is a sign of a breakdown of the bridge, and its absence indicates a break.

To check the negative diodes, the minus voltage of the battery is applied to the bridge body. The plus of the battery is connected with an indicator cord to the fixing screw of the bridge. If the lamp lights up, it indicates a breakdown; its absence indicates a break. Testing positive diodes begins by applying the battery positive to terminal 30, and the negative is connected through the indicator cord to the bridge mounting screw. If the diodes are working properly, the lamp does not light up.

Technical characteristics of the VAZ 2106 generator

The “six” comes from the factory with a G-221 generator, which is classified as a synchronous alternating current device. The device is fixed to the engine on the right side, but it can only be adjusted or changed from under the body, since it is difficult to get to the generator from above due to the presence of many hoses, devices and instruments.

The nominal voltage of the G-221 corresponds to the voltage of a typical VAZ battery - 12 volts. The generator rotor rotates to the right (when viewed from the drive side), since this feature is due to the position of the generator relative to the crankshaft.

The maximum current that the VAZ 2106 generator is capable of delivering at a rotor speed of 5000 rpm is 42 amperes. Power indicator - at least 300 watts.

The device weighs 4.3 kilograms and has the following dimensions:

- width - 15 cm;

- height - 15 cm;

- length - 22 cm.

Standard device for equipping all VAZ 2106

What generators can be installed on the “six”

Structurally, the VAZ 2106 is ready to install a generator not provided by the manufacturer. The question arises: why change the “native” G-221 at all? In fact, for its time, this generator was the optimal device, since Soviet Zhiguli cars used a small number of electrical appliances.

However, over time, the VAZ 2106 began to be equipped with more modern devices, each of which requires “its share” of energy . In addition, drivers connect navigators, cameras, pumps, powerful audio systems and other devices to the battery, which makes it difficult for the generator to generate the required amount of current.

Therefore, car owners began to look for equipment options that, on the one hand, would allow all the equipment in the car to operate in normal mode and, on the other hand, would have an optimal effect on the battery life.

Today the following types of generators can be installed on the VAZ 2106:

- G-222 is a generator from the Lada Niva, which is designed for higher loads and produces 50 amperes of current. The G-222 design already has its own regulator relay, so when installing it on a VAZ 2106, the relay will need to be removed.

- G-2108 can be installed on both “six” and “seven” and “eight”. The device in normal operation produces 55 amperes of current, which even by modern standards is quite enough for the functioning of all electronic devices in the car. The shape and fasteners of the G-2108 are identical to the standard G-221, so there will be no problems with replacement.

- G-2107–3701010 produces 80 amperes and is intended for lovers of high-quality acoustics and additional electronic devices in the car. The only caveat: the generator for the VAZ 2106 will have to be slightly modified, since the regulator relay is not suitable for this model.

Photo gallery: generators that can be installed on the VAZ 2106

The device from Niva has good traction

The generator from the G8 is considered a more modern unit

The most productive device in VAZ equipment

Find out about the repair of VAZ 2106 units: https://bumper.guru/klassicheskie-modeli-vaz/poleznoe/remont-vaz-2106.html

Thus, the driver of the “six” can decide for himself which generator can be installed on the car. The choice ultimately depends only on the power consumption of the car.

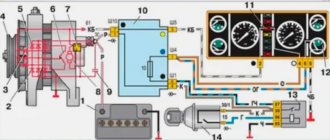

Generator connection diagram

Being an electronic device, the generator needs to be connected correctly. Therefore, the connection diagram should not cause double interpretation.

A schematic diagram of exactly how the G-221 is connected to a VAZ 2106 can be viewed here.

All components of the circuit are as clear as possible, so no separate explanation is required

Many car owners wonder when replacing a generator where which wire should be connected. The fact is that the device has several connectors and wires, and when replacing, you can easily forget which wire goes where:

- orange is not useful for connection, it can be left as is, or connected to gray directly to autostart the car;

- a gray thick wire goes to the brushes from the regulator relay;

- a gray thin wire connects to the relay;

- yellow - coordinator of the control light on the control panel.

Thus, when working independently with the G-221, it is better to sign the meanings of the wires so as not to connect them by mistake later.

The most difficult thing about working with a generator is connecting it correctly

Principle and features of determining the health of a diode bridge

Methods for targeted monitoring of bridge health, used in practice by car enthusiasts, are based on the fact that current flows through a working semiconductor diode in only one direction. When the test voltage is reversed, a working diode exhibits a large difference in resistance. Therefore, a failed element is easily detected by testing, which is carried out with a multimeter or a light bulb. The good thing about testing is that it detects both a broken (short circuit) and a burnt out (open) diode.

Certain subtleties of the dialing procedure make it possible to take into account the fact that the bridge is assembled from several diodes. The most accurate testing of the bridge's serviceability is done on a table, i.e. in case of its removal from the generator housing. In situations where it is possible to completely disconnect this unit from the rest of the circuit components by disconnecting the wires and the regulator, measurements can be taken directly on the generator, but they are not so convenient.

Generator malfunctions on VAZ 2106

Like any other mechanism in a vehicle, the “six” generator can work incorrectly, break down and fail. However, cases of unexpected breakdowns are extremely rare, since the driver can always track the occurrence of a “disease” by noticing its first signs.

The charging indicator light came on

There is a lamp on the instrument panel that indicates the functionality of the generator. It can blink or stay on continuously. In any case, the activation of this indicator is considered the first signal of a malfunction in the generator.

| Cause of malfunction | Remedies |

| Slipping of the generator drive belt Break in the connection between plug “85” of the charge warning lamp relay and the generator The battery charge warning lamp relay is misregulated or damaged Break in the power supply circuit of the excitation winding The voltage regulator is misaligned or damaged Wear or freezing of the generator brushes; oxidation of slip rings Open circuit or short circuit to ground of the excitation winding of the generator Short circuit of one or more positive diodes of the generator Open circuit in one or more diodes of the generator Open circuit in the connection between plugs “86” and “87” of the charge control lamp relay Open circuit or interturn short circuit in stator winding | Adjust the tension of the generator belt Check and restore the connection Check the relay, adjust or replace it Restore the connection Clean the contacts, adjust or replace the voltage regulator Replace the brush holder with brushes; wipe the rings with a rag soaked in gasoline Attach the winding leads to the slip rings or replace the rotor Replace the radiator with positive diodes Replace the generator rectifier unit Restore the connection Replace the generator stator |

Battery won't charge

The generator can work, but the battery is not charging. This is the main problem of the G-221.

| Cause of malfunction | Remedies |

| Weak tension of the generator belt: slipping at high speeds and when the generator is running under load. The fastening of the wire lugs on the generator and battery is loose; battery terminals are oxidized; Wires are damaged Battery is faulty Voltage regulator is misaligned or damaged | Adjust the tension of the generator belt Clean the battery terminals from oxides, tighten the clamps, replace damaged wires Replace the battery Clean the contacts, adjust or replace the regulator |

Find out how to start a car with a dead battery: https://bumper.guru/klassicheskie-modeli-vaz/poleznoe/kak-zavesti-mashinu-esli-sel-akkumulyator.html

The battery is boiling over

If the generator connection is poor, there may be a problem with the battery.

| Cause of malfunction | Remedies |

| Poor contact between ground and voltage regulator housing Voltage regulator is misaligned or damaged Battery is faulty | Restore contact Adjust or replace voltage regulator Replace battery |

The generator is very noisy

The device itself should make sounds during operation, since the rotor is constantly rotating. However, if the operation sound is extremely loud, you need to stop and find out what's wrong.

| Cause of malfunction | Remedies |

| The generator pulley nut is loose The generator bearings are damaged Inter-turn short circuit of the stator winding (generator whine) Brush creaking | Tighten the nut Replace the bearings Replace the stator Wipe the brushes and slip rings with a cotton cloth soaked in gasoline |

How to check the generator

Checking the functionality of the device will give the driver confidence that it is working properly and there is no cause for concern.

It is prohibited to check the generator on a VAZ 2106 when it is disconnected from the battery while the engine is running, as a voltage surge is possible. In turn, instability of operation can damage the diode bridge.

Checking the functionality of the generator can be done in various ways. The most common are:

- checking with a multimeter;

- at the stand;

- when using an oscilloscope.

Self-check with a multimeter

This technique is the simplest and does not require special devices or extensive knowledge of how the car works. However, it is necessary to purchase a digital or indicator multimeter, and also enlist the help of a friend, since the test involves the work of two people at once:

- Set the multimeter to DC measurement mode.

- Connect the device to each battery terminal in turn. The voltage should be between 11.9 and 12.6 V.

- The assistant should start the engine and leave it idling.

- At this time, the measurer must carefully monitor the multimeter readings. If the voltage in the network drops sharply, it means that the generator is not working fully, or its resource is not enough to charge.

- If the indicator is more than 14.5 V, the driver needs to know that such operation of the device will in the near future lead to the boiling of the battery.

The fastest way to find out what condition the generator is in

Testing at the stand

The check is carried out on a computer stand by service station specialists. In this case, the generator will not need to be removed from the car, since the computer is connected to the device through special probes.

The stand allows you to simultaneously check a working generator in all respects with high accuracy. Current performance indicators will be displayed on the computer screen, so the car owner can determine the “weak” points of his generator in real time.

The computer immediately determines all the operating parameters of the device

Checking with an oscilloscope

An oscilloscope is a device that reads basic voltage readings and converts them into waveforms. The device screen displays curved lines, from which a specialist can immediately identify defects in the operation of the generator.

The device can be used to check the functionality of any device

Video “Do-it-yourself mechanism repair”

For more information on how to repair a “six” generator device at home, see the video below (the author of the video is Nikolai Purtov).

The generator is the source that is responsible for recharging the battery while driving. If the generator does not work properly or is unstable, the battery discharges too quickly and requires constant recharging from the electrical network. Since you can check the generator at home, if you have a problem with the battery quickly discharging, it is not necessary to go to a service station for diagnostics.

If a generator is suspected of malfunctioning, the car owner first tries to identify the breakdown himself. There are several verification methods that involve measuring both a removed and an undismantled device. The verification in both cases will be reliable. In addition to knowing how to check the generator, you need to find out the reasons why it may fail. Although the generator is a fairly reliable device, incorrect or careless operation of the car can cause it to fail prematurely.

How to remove, disassemble and repair a generator on a VAZ 2106

The G-221 generator on the “six” cannot be called a simple device. Therefore, in order to carry out certain repair work, careful preparation will be required, since you will have to first remove the device from the car and then disassemble it.

Removing the generator from the car

To quickly and safely remove the G-221 from the machine, it is recommended to prepare the tools in advance:

- open-end wrench 10;

- open-end wrench 17;

- open-end wrench 19;

- mounting blade.

Of course, it is easiest to work with a cooled engine, so you need to let the car sit for a while after the trip.

The generator is held on by two long pins

The process of removing the generator is carried out according to this scheme:

- Loosen the lower generator fixing nut. Then loosen the nut on the other stud.

- Remove the nuts along with washers.

- Move the generator slightly forward (relative to the engine).

- This movement will allow you to easily remove the belt (first from the generator pulley, then from the crankshaft pulley).

- Remove the wires from the terminal.

- Disconnect the wire from the winding plug.

- Remove the wire from the brush holder.

- It is immediately recommended to label the wires by color and connection location, since problems may arise when reinstalling the generator.

- Next, unscrew the nut from the stud of the lower mounting of the generator.

- Remove the generator from the studs.

Video: dismantling instructions

Disassembling the generator

After the device has been dismantled, it must be disassembled for subsequent repairs. To do this, let's change the set of tools:

- open-end wrench 19;

- socket wrench 19;

- ratchet (you can add an extension);

- head at 8;

- head at 10;

- small hammer.

It is recommended to put small parts in separate containers so as not to lose them.

Next, if necessary, you can lightly clean the device body from dirt and begin disassembling:

- Unscrew the four fastening nuts on the back cover.

- Using a 19mm wrench, unscrew the pulley mounting nut (to do this, you will need to carefully fix the generator in a vice).

- After this, you can separate the device into two parts. If the halves are jammed, you can lightly tap them with a hammer. As a result, two equivalent parts should remain in your hands: a rotor with a pulley and a stator with a winding.

- Remove the pulley from the rotor.

- Pull the key and key out of the housing cavity.

- Next, pull the rotor itself along with the bearing towards you.

- The other part of the generator (stator with winding) is also disassembled into parts; you just need to pull the winding towards you.

Video: disassembly instructions

After disassembly, it is necessary to clarify which element of the generator needs to be replaced. Further repairs are not particularly difficult, since all components of the generator are interchangeable and can be easily removed/put on.

What you need to know about diode bridges

First, we will look at what they are and what is inside a diode bridge. These circuit elements are available in two versions:

- From discrete (separate) diodes. Usually soldered on the board and connected by tracks in the correct circuit.

- Diode assemblies. The assemblies can be either single-phase bridges for rectifying both half-cycles of alternating voltage, or assemblies of two diodes connected in a circuit by a common cathode or anode, and other connection options.

In any case, the rectifier single-phase diode bridge consists of four semiconductor diodes connected to each other in a series-parallel manner. Alternating voltage is supplied to two points at which the anode and cathode are connected (opposite poles of the diodes). Constant voltage is removed from the connection points of like poles: plus from the cathodes, minus from the anodes.

In the diagram, the location of the AC voltage connection is indicated by the symbols AC or “

", and the outputs with constant voltage are "+" and "-". Draw this diagram for yourself, it will be useful to us when checking.

If you imagine a real diode bridge and combine it with this circuit, you get something like:

Video: operating principle of a diode bridge

Generator belt

Of course, the G-221 will not work without a drive belt. The belt for the VAZ 2106 generator is 10 mm wide and 940 mm long. It is wedge-shaped and toothed in appearance, which allows it to easily cling to the teeth of pulleys.

The belt resource is designed for 80 thousand kilometers.

The belt is made of high-strength rubber and is designed for a long period of operation.

How to tighten a belt

Tensioning the alternator belt after installing it is considered the final stage of work. For fast and high-quality work, you will need to comply with the factory tension regulations:

- Loosen the self-locking nut (on the top of the generator).

- Loosen the lower generator fixing nut.

- The body of the device should move slightly.

- Insert a pry bar between the generator housing and the pump housing.

- Move the pry bar to tighten the belt.

- Without releasing the mount, tighten the self-locking nut.

- Then check the belt tension.

- Tighten the bottom nut.