VAZ 2106 owners know firsthand how many problems this car can cause. At the same time, a particularly large number of troubles are associated with the fuel pump: it either pumps, or does not pump, or becomes clogged with debris, or refuses to work for unknown reasons. Therefore, it is necessary to learn in advance about all the intricacies of the operation of the gasoline pump and be able to eliminate any malfunctions that may arise.

- Operating principle

Video: design and operation diagram of a gasoline pump

- Signs of a malfunctioning gasoline pump

What to do if the fuel pump does not pump

- The pump does not pump when hot

- Why does the pump hum but not pump?

- For what reasons can the fuel pump on the “six” fail?

- Drive faults

- How to remove a pump from a car

Video: dismantling procedure

- Video: fuel pump repair

- Video: how to quickly and correctly replace the pump

- Installation of an electric fuel pump

Video: electric pump for the “classic”

Fuel pump VAZ 2106

A car fuel pump is considered the most important element of the entire gasoline supply system. Actually, the pump is necessary in order to pump fuel from the gas tank to the carburetor. After all, it is in the carburetor unit that the air-fuel mixture is formed, which is then supplied to the engine.

The fuel pump supplies fuel from the tank to the engine through special hoses.

Principle of operation

The main task of the fuel pump is to generate excess pressure in the fuel system under any engine operating mode. It is necessary to ensure that there is always a sufficient amount of gasoline in the carburetor float chamber.

Video: design and operation diagram of a gasoline pump

Which fuel pump is better for the “six”

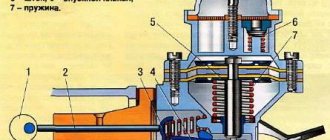

The standard equipment of the “six” is a gasoline pump produced by DAAZ (Dimitrovgrad Automobile Unit Plant). In terms of its structure, it is a mechanical unit, which is equipped with a diaphragm drive. Three diaphragms are built into the design of the DAAZ fuel pump to ensure uninterrupted operation of the device.

Find out what to do if the salon smells of gasoline: https://bumper.guru/klassicheskie-modeli-vaz/poleznoe/zapah-benzina-v-salone.html

The performance of a fuel pump of this brand is 60 liters per hour (on free drain). This volume is quite enough for optimal operation of the entire fuel distribution system on the VAZ 2106.

Initially, the “six” was equipped with DAAZ brand fuel pumps

A modern analogue of DAAZ is considered to be a petrol pump of the Pekar brand produced by the fuel equipment plant in Saratov. This pump has the same performance (60 l/h), but is considered more reliable due to its high tightness and resistance of the membrane elements to oil.

“Pekar” can be installed on a VAZ 2106 of any year of manufacture, but it became standard after 1990.

The Pekar fuel pump has the same performance as the DAAZ, but it is more modern and reliable

Thus, DAAZ and Pekar are the optimal equipment for the VAZ 2106 system, which allows the car to function without interruptions and breakdowns.

The gasoline pump on the VAZ 2106 is located under the hood. The device is fixed on the left side to the engine cylinder block. Fastening is carried out with studs with the obligatory use of a thermal spacer and an adjusting shim. This arrangement is very convenient, since if necessary, you can quickly find, remove and repair or replace the faulty part.

The fuel pump is located on the cylinder block on the left side

Start with the relay and fuse

Considering that the fuel supply module is located in the car tank, and it is not so easy to get to it, it is better to start diagnostics with the relay and fuse:

- Unscrew the screws securing the cover of the mounting block located to the left of the steering column.

- Underneath it, find fuse F3 (15 A) and relay R2. These are the elements that we need to check.

- As for the fuse, it needs to be “ringed” with a tester. If unusable, replace it.

Checking the relay in a garage is quite difficult. But you can take a similar one (from an adjacent socket), a known good relay, and install it instead of the one being diagnosed. Now turn on the ignition. Is the fuel pump pumping? The reason has been found! Well, if nothing has changed, move on.

Signs of a malfunctioning gasoline pump

Interruptions in the fuel supply to the engine or engine failure to start are not always associated with malfunctions of the fuel pump itself. Of course, these signs are a clear fact that there is a failure in the fuel system, but in order to find out their cause, it is necessary to carry out diagnostics. However, according to statistics, most often problems arise precisely because of the fuel pump.

The following signs can be identified that indicate a possible pump malfunction:

- the engine does not start or does not start the first time;

- the engine “troubles” at high speeds and runs jerkily;

- humming sound when driving;

- noticeable loss of vehicle dynamics.

About other causes of engine failure: https://bumper.guru/klassicheskie-modeli-vaz/poleznoe/ne-zavoditsya-vaz-2106.html

What to do if the fuel pump does not pump

The most common sign of a pump failure is a lack of pressure in the fuel system, that is, the fuel pump simply does not pump fuel. The cause of such a breakdown may be:

- natural wear and tear of pump elements;

- cracks and ruptures in diaphragms;

- diaphragm spring extension;

- clogged valves;

- severe contamination of filter elements;

- cracks in the pipes and hoses of the fuel system.

It is quite easy to see damage to hoses during a normal visual inspection. In all other cases, you will need to remove the pump from the machine and disassemble it in order to identify the faulty element and replace it.

In many cases, it is more advisable not to repair the old fuel pump, but to replace it

The pump does not pump when hot

In some cases, the pump on a VAZ 2106 may malfunction only in specific cases - for example, it works properly when starting the engine, but stops supplying fuel when it’s hot.

This is due to the fact that the gasoline in the tank and throughout the fuel system does not have time to cool. As a rule, the problem lies not in the pump itself, but in the drain pipe or fuel receiver. It will be necessary to check these elements so that the pump can operate smoothly.

remove the gas tank, check the blue drain tube for constriction, remove the fuel receiver, and also check if it is clogged

Artificial intelligence

https://otvet.mail.ru/question/60646959

Why does the pump hum but not pump?

VAZ 2106 owners may encounter a different kind of problem: the fuel pump turns on and hums, but does not supply fuel to the engine.

The pressure in the VAZ 2106 fuel system should be equal to 3 atmospheres. You will need a pressure gauge to check this indicator. If the pressure is significantly lower, the fuel pump requires replacement.

Gasoline may not flow into the engine even if the fuel pump is working. The reason in this case lies in the lack of tension. If you do not hear a characteristic buzzing sound when you turn the key in the ignition switch, then the problem lies in the relay, wires or connectors.

A working fuel pump should create a pressure of 3 atmospheres in the fuel line.

For what reasons can the fuel pump on the “six” fail?

As practice shows, the DAAZ fuel pump is more susceptible to wear and tear, and therefore fails much faster than the Pekar brand pump. However, for both models, the following reasons are equally sources of breakdowns:

- Gasoline pump rod. During vehicle operation, the pump rod inevitably shortens (natural wear). In this regard, the device stops supplying the required amount of gasoline to the engine. Only VAZ 2106 carburetor models are equipped with rod fuel pumps.

- Valve mechanisms. The valve is one of the fastest-wearing components in a pump. In this case, most often the sealing ring on the valve fails, which leads to incorrect operation of the opening mechanism.

- Low quality fuel. Gasoline used to power the engine of questionable quality can quickly damage the electric fuel pump. Electric pumps are installed only on injection models of the VAZ 2106.

To extend the life of the pump, you must:

- refuel only at proven gas stations;

- periodically clean the gas tank from dirt and impurities;

- monitor wear of pump parts;

- listen to the operation of the pump and carefully monitor the dynamic characteristics of the machine.

Performance diagnostics

The main reasons for checking the performance of the pump are as follows:

- significant reduction in fuel supply to the carburetor;

- reduction in engine performance;

- car jerking while driving.

Before diagnosing pump malfunctions, you need to make sure that other elements of the fuel system are working - carburetor, fuel hoses, filters, etc.

For diagnostic work you will need:

- open-end wrench 10;

- flat screwdriver.

The work is performed in the following sequence.

- On a car with a cold engine, the hood opens.

- Use a screwdriver to loosen the clamp securing the pump inlet pipe.

Use a screwdriver to loosen the clamp securing the inlet pipe. - The pipe is removed and a plug (bolt of a suitable size) is installed in its hole to prevent fuel leakage.

- The fuel supply hose is disconnected from the carburetor fitting and lowered, and a plug is placed in the hole.

- By pressing the manual pump lever, the resistance of the diaphragm spring is checked - the pump should make retracting sounds. If there is no resistance and no characteristic sounds, then the pump is faulty.

Fuel pump drive

The fuel pump drive for the “six” is a rod. Due to its translational movement of the pusher, gasoline is sucked in.

This movement is provided by the actuator cam and diaphragm return spring. When the membrane moves, pressure is created in the system. Immediately after the diaphragm stops, the exhaust valve closes, so the fuel flows into the opening inlet valve. Through it, with a new forward movement of the rod and membranes, the fuel is transferred to the carburetor.

The operation of the fuel pump is controlled by a pusher (2), which moves under the action of an eccentric located on the engine camshaft

On the VAZ 2106, to facilitate work with the fuel system, a lever is installed to increase the pressure in the system. With its help, the driver can artificially create pressure up to 30 kPa.

Drive faults

One of the most common causes of fuel pump failure is damage to the rod. Diagnosing this malfunction is very simple: its main symptom is the inability to accelerate the car even on a flat, straight road.

The rod is the steel rod at the base of the pump. During long-term use, it wears out, which leads to a malfunction in the drive part. As a rule, if the rod is worn out or bent, it is impossible to accelerate the car to a speed above 90 km/h.

The fuel pump rod is made of wear-resistant steel alloys, but during prolonged use it wears out and causes the part to malfunction

Replacing the rod mechanism involves simultaneously replacing two gaskets. When inserting a new rod into the pump body, you need to ensure that it protrudes beyond the spacer by a distance of no less than 0.8 mm and no more than 1.3 mm. That is, the optimal protrusion option is 1 mm.

In order to ensure this overhang, you will need to select gaskets of the required thickness. If the rod overhang is less than 0.8 mm, the engine will begin to experience difficulties when accelerating, and if it exceeds 1.3 mm, the diaphragms may break.

Read about the malfunctions of the VAZ-2106 GBZ: https://bumper.guru/klassicheskie-modeli-vaz/grm/poryadok-zatyazhki-golovki-bloka-cilindrov-vaz-2106.html

Reasons for lack of submission

After making sure that there is fuel, that the filters are clean and that the fuel line is clear, you can begin diagnosing the pump. The reasons for its failure can be caused by:

- natural wear and tear from long-term use;

- violation of the integrity of the diaphragm;

- stretching of the spring and loss of its elastic properties;

- accumulate dirt on the valves;

- loss of filter capacity due to clogging;

- violation of the tightness circuit, etc.

The owner of a VAZ 2106 is faced with a choice - which path to take in order to restore the functionality of the pump.

The first option is the simplest and most reliable

, but expensive in terms of cost. Any decent service station has equipment that, in a minimum amount of time, will not only measure the pressure at the inlet and the vacuum at the outlet of the fuel pump, but also identify the part causing defects in the operation of the equipment.

Second

The option is not the simplest, not so fast, but practically free, except for the time spent on it - do all the diagnostic and repair work yourself in the garage.

Electric drive and filter

The fuel pump in the injection VAZ 2114 is an element of the fuel module, which is located in the car’s tank. It also includes:

- coarse filter;

- fuel level sensor;

- pipes for connection to the fuel line.

To get to the module, you need to remove the lower part of the rear seat, disconnect the wiring harness and unscrew the 8 screws securing its cover. Remove the entire device assembly. First of all, inspect the coarse filter. If it is clogged, replace it.

To test the electric motor, you will need to connect it directly to the battery terminals. If it is operating normally, “ring” the wiring and check the contact of the ground wire on the module cover. If the electric motor shows no signs of life, the question “why the fuel pump doesn’t pump” has finally found its solution.

It is not advisable to try to repair it yourself. Just buy a new motor and install it in place of the old one. And yet, you shouldn’t spend money on buying the entire module, which now costs about 3 thousand rubles. Buy the electric motor and a new filter separately. All this will cost you three times less.

Replacement stages.

1. First of all, it is necessary to loosen the fastening of the fuel mixture supply and discharge hoses. To do this, use a Phillips screwdriver to unscrew the holders located on the clamps.

2. The next step is to remove the fuel conductors from the fitting. You should first prepare the bolts that will act as plugs. Of course, you don’t have to use bolts, but in this case most of the gasoline will spill out.

3. Next, unscrew the nuts that secure the pump. To do this, you will need a thirteen socket wrench.

4. After the fastening nuts have been loosened, it is necessary to remove the element from the racks and at the same time dismantle the sealing element.

5. The next step is to dismantle the heat insulation element along with the drive mechanism.

6. Now, let’s begin installing the new original VAZ 2106 fuel pump. A working pump is installed in the complete opposite order. To increase the service life of a new fuel system element, it is worth periodically checking the adjustment of the sealing gasket. Correct shim adjustment is determined as follows.

Once the new pump is in position, the pump wire should protrude approximately one millimeter (plus/minus 0.2 mm).

The optimal thickness of the gasket between the cylinder block and the heat insulation element is 0.3 millimeters (an error of no more than 0.03 mm is also allowed. The seal located between the heat insulation attachment and the pump itself is selected individually. Most often, this element is made by the hands of a car enthusiast.

As it turned out, replacing an element of one of the most important vehicle systems turned out to be quite affordable

The fuel pump is an important part of the engine fuel supply system

Given the importance of this component of the vehicle system, it is worth paying due attention to its maintenance

In most cases, the cause of fuel compressor failure is the use of a low quality fuel mixture. The presence of abrasive particles in gasoline leads to premature wear of the pump and other elements of the fuel system. To increase the service life of the pump and other elements of the fuel system, it is worth regularly checking the condition of the fuel filter and replacing it in a timely manner.

The VAZ 2106 fuel pump is very picky about the quality of gasoline. Of course, the car will operate on low-quality fuel, but in order to avoid unexpected costs for car repairs and maintenance, we recommend filling up with gasoline at trusted gas stations.

COMPONENTS OF THE FUEL SYSTEM

The VAZ 2114 fuel system consists of the following main elements:

- Gas tank;

- Fuel pump;

- Gasoline filtration devices;

- Pipeline system;

- Fuel rail;

- Injectors;

- Waste disposal unit.

Fuel system diagram Let's analyze each component separately.

GAS TANK

The VAZ 2114 gas tank is a container made of two equal metal parts. A neck is removed from the tank into which gasoline is poured. The neck is connected to the tank via a rubber pipe and clamps.

FUEL PUMP

The fuel pump is located directly in the tank. It has a fuel level sensor, which transmits information about the current amount of gasoline to the ECU. The gasoline pump is connected to a line through which gasoline is transported to the fuel rail. The fuel pump itself consists of several parts - coarse filters, wiring and an electric motor, which pumps fuel. As evidenced by reviews from owners of fourteenth cars, fuel pumps from the German company BOSCH have proven themselves to be the best.

FILTRATION DEVICE

The VAZ 2114 fuel injection system very much depends on the quality of the filter devices used. A bad filter will significantly reduce both the efficiency and the longevity of the entire system.

On the fourteenth, non-separable filters with a working element made of paper are installed. Such filters clog quite quickly, and they need to be changed at least once every 10-15 thousand kilometers.

FUEL RAIL

The fuel rail is located on the intake manifold housing. Its design consists of two parts, separated by a spring-loaded diaphragm. The first is the fuel one, in which the required level of gasoline pressure is set, the second is the air one, air is pumped into it, due to which the diaphragm compresses the fuel chamber and changes the pressure level in it.

Ramp

PIPING AND HOSES SYSTEM

To circulate gasoline from the gas tank to the injectors, the fourteenth uses steel fuel lines located on the bottom of the car. The VAZ 2114 fuel supply system also provides for a return pipeline through which excess gasoline from the injectors is returned back to the gas tank.

VAZ 2114 owners are advised to carefully monitor the condition of the fuel line in order to avoid gasoline leaks. Pipes should be checked regularly for deformation and corrosion.

INJECTORS

Injectors are valves actuated by electromagnetic control. They have a sprayer, with the help of which fuel under pressure is supplied directly to the combustion chambers.

Injectors are one of the most problematic parts of the fuel supply system of the fourteenth (as well as VAZ 2115 and VAZ 2113), the service life of which directly depends on the quality of the gasoline used. If the fine filter does not fully perform its functions, the injectors will become clogged, and from time to time you will need to clean them at a service station (doing this at home is very problematic).

A critical failure of the injectors is a short circuit or break in the winding, after which it is necessary to replace the failed part.

WASTE DISPOSAL UNIT

The EURO-3 environmental safety standard, to which the VAZ 2114 complies, provides for the presence of a gasoline vapor recovery chamber, for which the fourteenth uses an adsorber with activated carbon. The adsorber is connected to a throttle assembly, from which all resulting vapors are sucked out.

Adsorber

Additional Information

The above instructions give a complete idea of what replacing a fuel pump is. Note that the need to replace the fuel pump occurs infrequently - everything is determined by the quality of the fuel used. Those who, in pursuit of penny savings, refuel at random gas stations using low-octane gasoline are doomed to repeat this procedure with a certain regularity.

It is much easier (and, ultimately, cheaper) to “feed” the car with high-quality gasoline that does not contain foreign impurities and other undesirable components - debris, rust, etc.

Timely replacement of coarse and fine filters also helps protect the fuel pump from premature failure.