The VAZ 2101 fuel pump rod is the main part of the membrane drive.

Now we will talk about what the VAZ 2101 fuel pump rod is, and what problems it can cause for the driver of the car. If you have not yet come across such a detail, then be sure to read it, a lot of interesting things will be told. Moreover, this is worth reading not only for owners of kopecks, but also for nines and tens, with carburetor engines.

The principle of driving the fuel pump is the same for all. And all the breakdowns, accordingly, are also the same, despite the obvious differences between the cars. Of course, the reliability of engines of eights, nines and tens is higher, but the rod still tends to wear out. Let's start with what a fuel pump on a VAZ 2101 is, and how it pumps fuel through itself.

Springs on the field, theory

There is a complete mess going on on forums and in people’s heads regarding the selection of springs. I won't dwell on factory springs for a long time, I'll just say one thing. My friend bought himself a Niva Urban Crocodile in 2022. The lower coils of the front springs closed at 20 thousand and the standard wheels began to bite the locker. Now one rhetorical question for fans of factory springs: it is known all over the world that the best quality goes to the assembly line, and everything else goes to the spare parts market. If conveyor springs are of such quality, then what do they offer you with all sorts of different stripes? Among the branded springs, another manufacturer has appeared on the market - Kayaba. All their adult lives, the guys made shock absorbers, and then they took up springs... and failed. They decided not to increase their production, but placed orders from a third-party manufacturer. Quality floats like a violet in an ice hole. At one of the technical seminars held in St. Petersburg, Kayaba representatives avoided questions about springs as best they could and emphasized in every possible way that these are different units and there is no need to equate them.

Now for the “Swedes”. There is complete obscurantism going on on the forums and the drive of numbers and articles. They say there are springs for M-ki, there are already 006 springs for urban and other fabrications. Meanwhile, just look at the official Kilen-Lesjofors catalog for everything to fall into place. The manufacturer offers springs for the field in four articles. 4047001 – front springs for a short wheelbase (three-door), 4047006 – front springs for a long wheelbase, 4247002 – conventional rear springs, 4247010 – reinforced rear springs. All! There are no other options. I do not take into account the Kilen numbers, since the essence and springs will be the same.

Springs on the field, practice

Let's divide the problem into two small tasks. Let them be called shorty and crocodile. And it doesn’t matter whether it’s Niva Classic, Niva-M or Niva-U. Before turning to the Swedes, a little more history. When in 2008, the classic Niva was replaced by the Niva-M, and in 2016 by the Niva-U, the plant proudly announced that they were aware of the problem of the front springs and that they would install a new type of spring, with a thicker coil and 20 mm longer. The result is written at the beginning of the second paragraph.

Shorty option. The front of the car is very overloaded. And if a winch or air conditioner (Niva Urban) is also hung on the front end, then it becomes completely sad. Therefore, according to our many years of experience, in all cases we install springs from a long-wheelbase Niva, that is, a crocodile. The rear springs for the shorty and crocodile are the same. I can recommend springs 4047001 (short wheelbase) only if you constantly drive alone and without a load, so we actually don’t keep them in stock. For the sake of fairness, I note that my family field rode on these springs for more than 7 years, until the first signs of spring sagging.

Signs of breakdown

Among the obvious breakdowns, the presence of which may require replacing the VAZ-2106 fuel pump, one can highlight one - a leak. If the housing is constantly wet, covered with gasoline that drips onto the engine block, it is necessary to carefully inspect the unit and make repairs. It is quite possible that the seal was lost due to loose tightening of the fastening screws. In this case, you don’t even have to disassemble the entire assembly, but wipe it dry and tighten the bolts with a screwdriver. If desired, you can change the engraving washers. If a leak appears from cracks in the housing, then it is better to completely replace the VAZ-2106 fuel pump. The price of a new one is not very high, but the resource is quite decent.

The next two malfunctions, typical of mechanical pumps, are diaphragm rupture and valve failure. If the membrane is torn, gasoline will begin to flow into the lower chamber of the fuel pump. And the unit will stop creating pressure in the system. There are two valves in the top cover - inlet and outlet. If one of them stops working normally, the necessary pressure will also not be created in the system. Very often the valves stick when exposed to high heat. In this case, you can moisten a rag with water and place it on the pump body - this is the only effective way out of this situation.

When to change?

Let me refer to quotes from the forums: look at how your lower control arm is relative to the ground, measure the distance from the edge of the wheel to the arch, and the like. Of course, there is some truth in all this, BUT these are all consequences. We need to look at the reason, that is, at the spring itself. The next legitimate question is: where to look? The photo shows springs from the same car, one side before replacing the springs, the other after.

when to change springs?

For some reason I remembered the magazine “Murzilka” with pictures on the topic, find 10 differences)). Red circles indicate where to look. Why do springs in this condition need to be changed and why is this criminal? Different alloys have different physical characteristics. In particular, spring steels do not withstand shock loads at all. When the coils of the springs close to full contact, an impact occurs. Stress tends to accumulate, and at some point the spring bursts. If this happens at low speed, the face of the car will simply fall down. The fuse will be the shock absorber, which will bend, and if the swing was stronger, then the body will lie on the wheel. It is much worse if this happens at speed or somewhere on the descent from a hill. I saw a short video from the Ladoga Trophy, when a short Niva drives down a hill, bounces a little and turns over. What can be seen in the slow motion replay: when flying up, the suspension dissolves. Then, the face of the car goes down, the spring bursts, the body falls on the wheel... and the car does a somersault through this wheel, since the kinetic energy has not gone away.

Disassembly and repair of the fuel pump

Before disassembling, it is necessary to thoroughly rinse the fuel pump, for which you can use the gasoline in its cavity. It is best to start disassembly with the top cover 4, screwed with a bolt 5 with an 8 mm socket head. Under the lid there is a nylon mesh filter.

Let us remind you that the deformed cover and the broken filter must be replaced with new ones. Under the strainer in the fuel pump housing you will see a pressed and rolled suction valve 6. There are cases when, due to valve failure, you have to replace the entire fuel pump housing since the valves are not supplied separately as spare parts, and replacing them at home is quite difficult .

To remove the fuel pump housing, you need to unscrew six screws 7 with a screwdriver. Before separating the housing from the bottom cover, try to replace their relative positions. This will come in handy during assembly.

The discharge valve is pressed and rolled on the inside of the removed housing. Wash the housing thoroughly in clean unleaded gasoline.

Remember that even the smallest grains of sand trapped between the valve and the seat disrupt the tightness of the valves, which leads to failure of the fuel pump.

Using a thin screwdriver or a match, you can check the mobility of the valves and the tightness of their fit to the seat under the action of the springs. If you can check the operation of the suction valve again on the assembled fuel pump, then the operation of the discharge valve can only be checked now, with the pump disassembled. When blowing air into the discharge pipe, monitor the behavior of the valve, which should sit in the seat and not allow air to pass through.

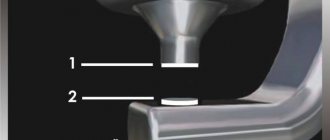

To inspect the diaphragm assembly, it is advisable to remove it from the bottom cover of the fuel pump; to do this, simply turn the rod 90°. Together with the diaphragm assembly, the outer and inner spacers 1, as well as the diaphragm spring 9, are removed.

Carefully inspect the working and auxiliary diaphragms. Remember that they should not have scratches, cracks, tears, or local hardening. The presence of one of the listed defects requires replacing the defective part with a new one. It should be remembered that the diaphragm assembly is collapsible. The diaphragms and internal spacer sit on the stem and are tightened with a nut. If the fuel pump suddenly fails along the way and you determine that the cause is a deformed diaphragm, plastic film can be used as a temporary measure.

Make a homemade diaphragm from a piece of film. At the same time, do not throw away damaged diaphragms, but place homemade ones between them. This recommendation should only be used as a last resort, but if you have a spare diaphragm assembly, play it safe and replace the entire assembly.

Other causes of fuel pump breakdowns, defects, malfunctions

There are cases when, in cars with high mileage, the fuel pump does not ensure engine operation at maximum crankshaft speed. The cause in most cases is a weakened diaphragm spring. The normal free length of the spring should be 47 ± 0.5 mm. If the spring is truly weakened, it must be replaced with a new one. A temporary option to eliminate the defect is to stretch the spring by hand and install it in place.

Sometimes the cause of a malfunction of the fuel pump is a violation of the length of the pusher outlet. The fact is that during operation, hardening is formed on the pusher, which naturally changes the length of its exit. This pusher needs to be replaced. If a defect is discovered on the way and there is no new pusher at hand, you can, as a temporary option, remove the hardening and try to adjust the length of the pusher using a set of shims.

At the end of the description of the repair operations performed with the gas pump, car enthusiasts should be reminded of one more type of defect, which occurs quite often. Some fuel pumps work well only before the first disassembly, and after secondary reassembly, despite the absence of visible defects, they stop working altogether or work at half capacity.

If you are unlucky and your car has just such a stubborn fuel pump, connect the body of such a fuel pump to the mating surface of the bottom cover without a diaphragm assembly and you will see the cause of the defect: there will be a gap between the mating surfaces.

Such deformed surfaces must be ground in. The zinc alloy from which the body is made is easy to abrade and the grinding process does not take much time.

Springs Kilen-Lesjofors, coating

I cannot help but note the issue of spring coating. The most important difference from other manufacturers is not the paint. Primary coating is made with zinc phosphate, secondary with epoxy powder. Let me note an important thing. Spring coating isn't just about "beauty" - it's about long-lasting performance. Metal whose structure has been penetrated by rust is, in most cases, scrap metal. In St. Petersburg conditions, the coating lasted more than 7 years before the first chips appeared on the springs.

Suspension springs have a direct impact on the smoothness of the car and driving safety. Being in constant operation, these suspension elements wear out, and therefore they should be regularly inspected for mechanical damage. It is also necessary to constantly “listen” to the behavior of the car when hitting bumps.

The main signs that it is time to change the front springs on a Chevrolet Niva are:

- Reduced ride smoothness, suspension breakdowns;

- Creaking, grinding and a characteristic metallic knock when hitting an uneven surface;

- Distortion of the front of the car;

- Noticeable “sag” of the front suspension;

- Body sway when driving, etc.

Symptoms that clearly indicate a faulty pump and rod

Ford Focus 2 fuel pump replacement

The main sign of a faulty fuel pump is that at high temperatures the engine begins to stall, and after stopping it does not start. It sits for a while, cools down, and only then is it possible to start the engine. Of course, another breakdown has a similar symptom - a violation of valve adjustment. Only in this case does it feel as if the engine is trying with all its might to pull the car, but cannot, it is beyond its capabilities. And when the fuel pump starts to malfunction, the engine simply stalls.

The reason for this is excessive heating. As we said, the VAZ 2101 fuel pump consists of two valves. Well, one or both became warped due to heating and stopped opening. Cool them slightly and you can continue moving. Remember how often you saw a wet rag thrown over a gas pump? Now you know what purpose this is for.

But there is also a VAZ 2101 fuel pump rod, a truly wonderful contraption. It is made of steel. And if in the Soviet years it was hardened, now no one needs it. The price of the stock is at least 25 rubles. Well, who will spend kilowatts of energy on a part whose final cost is 25 rubles? Nobody! What happens then? But an unpleasant picture emerges - the fuel pump lever simply erases the rod, reducing its length.

And if you have gaskets under the fuel pump housing, then you are just lucky! When you pull one out, the rod will protrude from the insert more. And that’s it, the pump will continue to pump gasoline normally. But what if there are no gaskets? Who knows what could happen, for example, they forgot to put them on? And that’s why the rod was worn out. What to do then? Try taking it out and inserting it the other way. You know, this action helped several times.

A sign that the fuel pump rod has worn out is that the car accelerates to a certain speed. I had such a thing that I drove around the city normally, but as soon as I got on the highway, my maximum speed was 90 km/h, and that’s all. You step on the gas, but the engine stalls, it doesn’t have enough gasoline. I released the pedal a little - it drives calmly and shows no signs of breakdown. Moreover, a pump rod malfunction cannot always be detected when driving around the city or at idle speed. A short-term increase in engine speed will not give the same effect as long-term driving at high speed.

Purpose

Chevrolet Niva comes from the factory with springs, both front and rear. The main purpose of these devices is to absorb all the shocks of the suspension that occur when the wheels hit potholes and bumps. They are located in the gap between the wheel and the frame of the car, due to which shocks from the road are smoothed out.

For their manufacture, special high-strength steel is used. The number of turns of the device affects not only the quality of shock absorption, but also the distance of the body from the suspension.

Many Chevrolet Niva owners upgrade the rear springs by installing spacers or reinforced parts.

Adjusting the fuel pump drive for VAZ 2108, 2109, 21099 cars

As you know, on VAZ 2108, 2109, 21099 cars the fuel pump is mechanical, driven from the camshaft through a pusher.

The performance of the fuel pump, and therefore the normal operation of the engine, directly depends on how correctly the fuel pump drive is adjusted.

If there are dips, jerks, twitches in the engine operation, throttle response has decreased at medium and maximum loads, or no fuel is supplied to the engine at all, it makes sense to adjust the fuel pump drive.

Classification

The suspension elements under consideration are divided into two types according to their rigidity:

- Standard hard ones are designated by the letter “A”. They have high stability and load capacity.

- Soft “B” is their main advantage in providing increased comfort, but at the same time they quickly become unusable - they “sag”.

Reference! From the factory, Shniva is equipped with class “A” parts, that is, rigid ones.

Lada 2107 777 number › Logbook › =>24

Good afternoon everyone! I decided to raise my car for the winter and delved into numerous articles on this matter, and then I realized that there are a million opinions, and perhaps this entry is being read by someone who has encountered the same problem - what to install?

I wanted to raise it to stock or to Niva, I hesitated, delved into Drive2 and the entire Internet. There are many options and conflicting opinions, I want to write my opinion, maybe it will help someone.

After a week of searching for information and tips, I settled on this option:

Front struts - Niva Rear struts - Ordinary classic (in my case Hola oil) Springs all around Niva. (Class A or B, I don’t know, it wasn’t written).

Compatibility of springs from Niva and Shniva

The springs on the Chevrolet Niva from the regular Niva VAZ-2123 are not suitable. The reason for this is the differences in length. Let's consider the main technical parameters of these elements.

| Parameter name | VAZ-2121 Niva | VAZ-2123 Chevrolet Niva |

| Front | ||

| Bar diameter | 15.2 mm | 15.7 mm |

| Length | 278 mm | 313 mm |

| Rigidity | 74.42 kg/cm | 75 kg/cm |

| Load | 815 kg | 815 kg |

| Rear | ||

| Bar diameter | 13 mm | 13.9 mm |

| Length | 434 mm | 410 mm |

| Rigidity | 22.44 kg/cm | 30 kg/cm |

| Load | 483 kg | 483 kg |

From the comparison table it is clear that the free length of the parts in question does not correspond, which is the reason for the impossibility of installation, since the springs from the Niva are shorter.

DIY replacement

Replacement of rear and front springs is carried out not only when they sag, but also when chips, cracks, and other defects are detected. At the initial stage of work, the necessary tools and materials are prepared.

Tools and materials

To carry out the replacement work, you will need the following tools and materials:

- Set of wrenches.

- Jacks and stops.

- New set of springs.

Important! It is recommended to replace them as a set or in pairs for the front and rear wheels. You cannot install parts from different manufacturers or different stiffness classes on the machine.

Work progress

Replacement of the front elements should be carried out in this order:

1. Jack up the SUV and remove the wheel. Set the stop. 2. Unscrew the nut securing the lower arm axle using an open-end wrench. 3. Unscrew the shock absorber mounting bolt, having first unscrewed the nut. 4. The stabilizer cushion bracket is dismantled after unscrewing the two fastening nuts. 5. Place the jack under the suspension and lift until the compression limiter moves freely. 6. Unscrew the three nuts securing the ball joint. The bolts securing the support are removed. 7. Slowly unloading the suspension, remove the springs. 8. The spacers are also dismantled, and then new parts are installed in the reverse order of removal.

The process for replacing rear springs is as follows:

1. You need to disconnect the lower shock absorber hinge from the rear axle and move it to the side. 2. Raise the car to unload the spring. 3. Remove the springs with spacers.

4. Install new springs in reverse order.

The entire replacement process takes no more than an hour for one wheel.

Article: 2101-1106166, additional articles: 21010110616600

Order code: 003329

- Buy with this product

- show more

- Passenger cars / IZH / IZH 27171 drawing

- » href=»/catalog/ij-7/legkovye_avtomobili-30/ij_2717-607/ustanovka_toplivnogo_nasosa-40/#part1693778″>Pump pusherPower system / Fuel pump installation

- Passenger cars / VAZ / VAZ-21021 drawing

- » href=»/catalog/vaz-3/legkovye_avtomobili-30/vaz_2102-4/nasos_toplivnyiy_i_truboprovod-91/#part6652″>Pump pusherPower system / Fuel pump and pipeline

- Passenger cars / VAZ / VAZ-21041 drawing

- » href=»/catalog/vaz-3/legkovye_avtomobili-30/vaz_2104-5/nasos_toplivnyiy_i_truboprovod-70/#part13877″>Pump pusherPower system / Fuel pump and pipeline

- Passenger cars / VAZ / VAZ-21061 drawing

- » href=»/catalog/vaz-3/legkovye_avtomobili-30/vaz_2106-7/ustanovka_toplivnogo_nasosa-71/#part20014″>Pump pusherPower system / Fuel pump installation

- Passenger cars / VAZ / VAZ-21081 drawing

- » href=»/catalog/vaz-3/legkovye_avtomobili-30/vaz_2108-18/nasos_toplivnyiy-84/#part28131″>Pump pusherPower system / Fuel pump

- Passenger cars / VAZ / VAZ-210991 drawing

- » href=»/catalog/vaz-3/legkovye_avtomobili-30/vaz_21099-79/nasos_toplivnyiy-92/#part36349″>Pump pusherPower system / Fuel pump

- Passenger cars / VAZ / VAZ-21111 drawing

- » href=»/catalog/vaz-3/legkovye_avtomobili-30/vaz_2111-11/nasos_toplivnyiy-119/#part45057″>Pump pusherPower system / Fuel pump

- Passenger cars / VAZ / VAZ-21151 drawing

- » href=»/catalog/vaz-3/legkovye_avtomobili-30/vaz_2115-65/nasos_toplivnyiy-83/#part53174″>Pump pusherPower system / Fuel pump

- Passenger cars / VAZ / VAZ-1111 “OKA”1 drawing

- » href=»/catalog/vaz-3/legkovye_avtomobili-30/vaz_1111__oka_-16/nasos_toplivnyiy-59/#part66894″>Pump pusherPower system / Fuel pump

- Passenger cars / VAZ / VAZ-21141 drawing

- » href=»/catalog/vaz-3/legkovye_avtomobili-30/vaz_2114-647/nasos_toplivnyiy-20/#part1669229″>Pump pusherPower system / Fuel pump

- Passenger cars / VAZ / VAZ-212131 drawing

- » href=»/catalog/vaz-3/legkovye_avtomobili-30/vaz_21213-731/ustanovka_toplivnogo_nasosa-69/#part2009289″>Pump pusherPower system / Fuel pump installation

- Passenger cars / AZLK / Moskvich-21411 drawing

- » href=»/catalog/azlk-9/legkovye_avtomobili-30/moskvich_2141-53/smazochnaya_sistema_dvigatelya-67/#part148805″>Pump pusherEngine mod. 2106 / Engine lubrication system

- Passenger cars / IZH / IZH 2126 with VAZ1 engine drawing

- » href=»/catalog/ij-7/legkovye_avtomobili-30/ij_2126_s_dvigatelem_vaz-307/ustanovka_toplivnogo_nasosa-18/#part946015″>Pump pusher Power system / Fuel pump installation

- Passenger cars / IZH / IZH 21261 drawing

- » href=»/catalog/ij-7/legkovye_avtomobili-30/ij_2126-606/ustanovka_toplivnogo_nasosa-42/#part1690680″>Pump pusherPower system / Fuel pump installation

- Passenger cars / VAZ / VAZ-21011 drawing

- » href=»/catalog/vaz-3/legkovye_avtomobili-30/vaz_2101-3/nasos_toplivnyiy_i_truboprovod-91/#part2168″>Pump pusherPower system / Fuel pump and pipeline

- Passenger cars / VAZ / VAZ-21031 drawing

- » href=»/catalog/vaz-3/legkovye_avtomobili-30/vaz_2103-106/nasos_toplivnyiy_i_truboprovod-63/#part10376″>Pump pusherPower system / Fuel pump and pipeline

- Passenger cars / VAZ / VAZ-21051 drawing

- » href=»/catalog/vaz-3/legkovye_avtomobili-30/vaz_2105-6/nasos_toplivnyiy_i_truboprovod-70/#part16983″>Pump pusherPower system / Fuel pump and pipeline

- Passenger cars / VAZ / VAZ-21071 drawing

- » href=»/catalog/vaz-3/legkovye_avtomobili-30/vaz_2107-8/ustanovka_toplivnogo_nasosa-86/#part23726″>Pump pusherPower system / Fuel pump installation

- Passenger cars / VAZ / VAZ-21091 drawing

- » href=»/catalog/vaz-3/legkovye_avtomobili-30/vaz_2109-9/nasos_toplivnyiy-92/#part32410″>Pump pusherPower system / Fuel pump

- Passenger cars / VAZ / VAZ-21101 drawing

- » href=»/catalog/vaz-3/legkovye_avtomobili-30/vaz_2110-10/nasos_toplivnyiy-119/#part40749″>Pump pusherPower system / Fuel pump

- Passenger cars / VAZ / VAZ-21121 drawing

- » href=»/catalog/vaz-3/legkovye_avtomobili-30/vaz_2112-12/nasos_toplivnyiy-119/#part49365″>Pump pusherPower system / Fuel pump

- Passenger cars / VAZ / VAZ-21311 drawing

- » href=»/catalog/vaz-3/legkovye_avtomobili-30/vaz_2131-73/ustanovka_toplivnogo_nasosa-104/#part62909″>Pump pusherPower system / Fuel pump installation

- Passenger cars / VAZ / VAZ-2110, 2111, 21121 drawing

- » href=»/catalog/vaz-3/legkovye_avtomobili-30/vaz_2110__2111__2112-415/nasos_toplivnyiy-129/#part1303155″>Pump pusherPower system / Fuel pump

- Passenger cars / VAZ / VAZ-21131 drawing

- » href=»/catalog/vaz-3/legkovye_avtomobili-30/vaz_2113-648/nasos_toplivnyiy-20/#part1669229″>Pump pusherPower system / Fuel pump

- Passenger cars / VAZ / VAZ-21213-214i1 drawing

- » href=»/catalog/vaz-3/legkovye_avtomobili-30/vaz_21213_214i-1240/ustanovka_toplivnogo_nasosa-105/#part2988287″>Pump pusher Power system / Fuel pump installation

- Passenger cars / AZLK / Moskvich-23351 drawing

- » href=»/catalog/azlk-9/legkovye_avtomobili-30/moskvich_2335-688/toplivnyiy_nasos-26/#part1903409″>Pump pusherPower system / Fuel pump

There are no reviews for this product yet.

In the series of articles “Crystal VAZs or typical breakdowns of domestic cars,” we will tell you about typical problems that occur when operating cars from the Volzhsky Automobile Plant. In this article we will talk about the VAZ-1111 (“Oka”) car.