Hi all. The thought came to me that before winter, it wouldn’t hurt to sort out the brakes. Lately, there has been a grinding noise when braking. An inspection of the brake system showed that the discs and pads were in good condition.

One of the reasons for grinding and rattling of calipers may be worn guides. Also, worn guides can lead to uneven wear of the pads (when one of the pads wears out faster than the other). This is exactly the wear that was on the old pads when they were last replaced.

Inspection of the guides showed that they are not jammed, but the lubricant has coked and thickened, and there is also noticeable play.

4 guides were purchased along with anthers, the price was 40 rubles per piece. And also a special lubricant for brake systems BOSCH SUPEFIT (5000000151) for 50 rubles. One bag is just enough for four guides.

It is important to know that not any high temperature grease will work for caliper guides. Do not use ceramic grease or copper-based grease. These lubricants coke and cause the guides to jam. They can also be aggressive towards anthers. As it turned out later, BOSCH lubricant is not suitable for guides; the temperature range is only -25°C +130°C, which is naturally not enough for this unit. Although the manufacturer claims that this lubricant is universal and is exactly suitable for guides. I found supporting information in the official brochure about the use of lubricant.

We'll ride it for now, and we'll see.

Before replacing the guides, remove the old grease and thoroughly wash the bracket. To remove the old grease I used 646 solvent.

Its disadvantage is that it is aggressive to the rubber from which the anthers are made, so after the solvent, I washed the staples with a degreaser. New lubricant should be applied in a thin layer.

DIY caliper repair

With the end of the cold weather, patience also ended. I couldn’t stand the smell of burnt dust, the whistle and stench of overheated pads from jammed caliper cylinders and the “nodding” when stopping, so we bought everything we needed and went to my father-in-law’s garage (I did the front and back with a break of a week). Unfortunately, there are no photographs, because I was very passionate about the process. What you need: 1. Rem. sets of calipers 2. Brake fluid Castrol DOT-4 1 3. Construction gloves 2 pairs 50 rubles, rubber gloves 4. GOI paste 5. A lot of unnecessary lint-free rags. 6. Plumbing thread. 7. Half a 5 liter bottle 8. Rust converter 9. Medical dropper 10. Medical syringe 20 cc

The first step was to disassemble the problematic right rear caliper. 1. Jack up and remove the wheel. 2. Remove the handbrake mechanism. To do this, we bend and pull out the spring (although I am not small in caliber, I am also not a master of sports in arm wrestling, I was able to do this with my fingers to my surprise), then unscrew the bolt securing the swing and disconnect the cable (I immediately discovered the reason for the handbrake freezing in winter - a torn boot on a cable, this still needs to be sorted out, not sold separately, only assembled with a cable, will have to be farmed). 3. Next, loosen the bolt securing the hose to the caliper body (after removing the caliper, this will be more difficult to do). 4. Next, we unscrew the bolt that secures the caliper and fold it back, helping ourselves with a screwdriver and swear words, because the pads are jammed by the cylinder. We remove it from the guide and see the reason - a torn boot on the cylinder. 6. Place a 5-liter bottle sawn in half under the scene of action to avoid clogging everything with brake fluid. 5. Next, you can try to unscrew the brake cylinder with pliers, inserting it into the groove for the special device counterclockwise (or with a mythical special device that could not be found in the city), but I did it easier - I drove my father-in-law into the car, he started it and, progressively, without quickly pressing the brake pedal has been pressed out by a cylinder from the caliper body, but it is still under the boot. 6. Next, unscrew the bolt securing the hose and try not to lose the two copper sealing washers. We wrap the bolt with plumbing thread and insert it into the coupling with a hose to prevent brake fluid leakage. PS It is better to remove the pads with the springs and put them in a secluded place so as not to lose the latter, it will be very difficult to then look for steel wire to make the springs. 7. Now we have the caliper with the almost disconnected cylinder at our disposal, we can work on it. We take a screwdriver with a small, non-sharp tip and look for a locking open ring above the boot, pry up the end and carefully remove it. Then we remove the stuck boot and cylinder. Next, the cause of the jamming was visible - the internal cradle where the edges of the boot are inserted, as well as the edges of the hole for the piston, as well as part of the piston, are covered with corrosion. There is nothing to do, we begin a long, stubborn and inconvenient cleaning of corrosion using rags, rubber gloves, a rust converter and in non-working places (not the cylinder and not the hole under its walls) - with a screwdriver to remove the converted corrosion. Next, we thoroughly rinse everything with the old drained brake fluid and wipe it off. It's time for the top hat. We rub the rags with GOI paste, firmly clamp the cylinder in a vice and begin polishing the surface free of corrosion. After some time, the cylinder shone like a cat's bells and became much smoother. We change the sealing collar in the caliper body (the old one seemed to be good, well, since we took it apart...), lubricating it on all sides with red grease from the repair kit (the Chinese Germans are great - they put enough grease and 2 types, red and yellow, red as times for internal parts). We lubricate the cylinder itself and the boot with it on all sides. We put the boot on the cylinder (just throw it on), insert the cylinder into the caliper, take the pliers and begin to twist the cylinder into the body clockwise with moderate dosing of pressure and rotation. We are approaching the end of the year - carefully use a screwdriver to tuck the edge of the boot into the groove, take the open ring and no less carefully place it in the groove where the edges of the boot have just been pushed. Apply yellow grease to the caliper fixing bolts and reassemble in reverse order. 8. Afterwards, repeat the operation on the left caliper. 9. After completing the repair of the calipers, it is necessary to bleed the brake system to remove all the air. With the help of my father-in-law, we pump all the wheels one by one (even the front ones, which I only got to in a week). To do this, remove the cap from the bleeder fitting, place the key on the 8th ring side, and put a hose on top with a rubber band from the dropper (fits perfectly). On command, the Father-in-law pumps up the pressure with the brake pedal until it becomes stiff, and holds his foot in this position. At this moment I open the fitting with a key, bleed air and liquid and control the air outlet through the transparent dropper hose. As soon as the brake pedal goes to the floor, he commands, I close the fitting, after which he releases the pedal. Next, we repeat the operation, and every 2 such times we run to add brake fluid to the reservoir so that more than a quarter does not go away, as recommended. We repeat until liquid comes out without air, make another control pass, and tighten the fitting. We carry out the operation on all 4 wheels in turn from the closest to the farthest wheel from the place where the hose is disconnected. After the operation was completed, it was already evening. But you need to check it. I sit down, drive out onto the alley of the garage cooperative, accelerate to 20, press the pedal, it’s soft (It brakes well, but there is a treacherous idle to the point where it starts to grip confidently. The cylinder doesn’t jam, there’s no stink, it doesn’t bite. A profit is made, but and I got an inconvenience in the form of a soft pedal (I thought about the air in the system, but after the second pumping after repairing the front calipers, which I will write about later, the situation remained the same).

This concluded the first day of the struggle. Since I did everything carefully and slowly, and for the first time, it took about 6 hours. To be continued.

Continuation. I drove for a week with the “new brakes”, gradually got used to it, but still anticipating the return of the old harsh, upsetting ones, I planned Sunday to work on the front pair of calipers. Started. 1. Jacked it up and removed the wheel

front caliper, top view

2. Loosen bolt 1 in the assembled state with a 10mm head 3. Remove the cap, then use a 8mm L-shaped hexagon (the set was purchased a long time ago, because it’s unlikely to be unscrewed with an ordinary bit from a screwdriver), feel for the groove of the sleeve and unscrew it (it was unscrewed without problems because earlier after replacing the pads, everything was lubricated with lithol - of course it’s not high-temperature shit, but it did its job). 4. Next you will have to unscrew bolt 2 completely. Do not lose the 2 copper washers of the gasket. 5. We plug the hose coupling with a bolt wrapped in plumbing thread, tilt the caliper and remove it from the lower guide. It will not work without disconnecting the hose, because it is short. 6. Return the hose to its place, tighten the bolt, and hold the caliper in your hand. 7. The father-in-law starts the car, carefully progressively presses the brake so that the cylinder comes out of the caliper body. 8. The cylinder comes out, unscrew bolt 2, equip it with plumbing thread, and lock the hose coupling. 9. Now you can work. Unlike the rear caliper, the front caliper does not have a ring that pushes the boot apart; it can be removed without effort. The cylinder itself does not have grooves for screwing in/unscrewing; it moves on its own without threads. As a result, we see the following: On the caliper

Inside the caliper

Corrosion in the groove for the boot 1 (the boot was torn), corrosion on the walls of the hole along which the cylinder 2 moves, and a worn cuff 3.

The cylinder itself is in good condition, slight corrosion in the groove for the boot 1 and on the body itself 2

front brake cylinder

I treat corrosion with a rust converter. I clean the groove for the boot (non-working surface) with a screwdriver suitable for the width of the tip, and wash it with old brake fluid. I polish the cylinder body with a rag coated with GOI paste until the corrosion spots are reduced to a minimum. I am changing the guide boots from the repair belt. kit, lubricating them with yellow grease (the Chinese Germans squeezed a second bag of yellow grease into the front repair kit, unlike the rear one there is only one). I clean and treat the corrosion in places 1 and 2 in the caliper body, wash it with the old brake fluid, change the sealing collar 3, having previously lubricated it with red grease from the belt. set. Lubricate the cylinder boot and the cylinder itself with red grease. Next we assemble: In order not to repeat my mistake (I wanted to insert the cylinder as in the back, first - then put on the boot - it didn’t work - in the end I ran to squeeze it out again through the hose) put the boot on the end of the cylinder (number 2 in the photo), tuck the boot into the groove carefully so as not to jump off the cylinder and slowly move the cylinder inside. Next, without much effort, resting your fingers on the edge of the cylinder, we gently press it into the caliper body without distortion. Profit. PS. Don't forget that the brake hose is still short, so we lubricate the guide and bushing with yellow grease from the belt. kit and install the caliper in place, tighten the bushing, then connect hose 2 from the first photo into place (do not forget about the copper washers). Then we do the same on the left side. Upon completion, we bleed the brake system through fitting 3 in the first photo (all the same with spare parts from the dropper, as in the first part of the post). PPS Unfortunately, it won’t be possible to bleed the rear wheels from the pit, well, this is the design, everything is closed with levers, so you still have to remove the wheels one by one. The procedure, like the back part, took a leisurely 6 hours. After bleeding the system, I go for a check. The whistle disappeared, but the brake was still soft. Air? who knows, they are not professionals, of course, but they have pumped up more than one car, this has never happened. The soured cylinder is no longer soured and has a greater stroke than before, which is responsible for the greater useless stroke of the brake pedal? Logical, but idk. In general, now this is mystery No. 1.

Detailed instructions for repairing calipers

The most common cause of brake caliper failure is its souring and subsequent jamming.

If the caliper is regularly maintained and lubricated, it can last for decades without any repairs. But the main thing is to choose the right lubricants!

If interested, read about choosing lubricants. In this article we will work with them, but I will not spend letters in this article describing these lubricants.

Caliper repairs can be divided into three categories:

- Mandatory caliper lubrication when replacing pads

- Reanimation of the caliper if the wheel is already heating up

- Complete disassembly of the caliper and replacement of worn elements

The first two categories can be viewed via the links. And in this article we will look at the third category, when it is too late to drink Borjomi and surgical intervention is necessary.

Most often, the reasons for complete caliper failure are two things:

- The caliper has never been lubricated or serviced. As a result, the piston and guides were severely corroded.

- The caliper was not lubricated with what was needed. As a result, the lubricant turned into plasticine or powder, and the anthers and cuff mercilessly swollen.

In these two cases, you can no longer get by with half measures and you will have to do the job thoroughly.

Diagnostics

The following signs will tell the motorist that repair of the brake wheel cylinder is approaching:

- Uneven operation of the wheels when braking, which can result in the car skidding. This is a sign of a stuck piston, which can cause the use of low-quality fluid or air entering the system.

- The indicator light is triggered when the fluid in the tank is critically low, or this is detected during a visual inspection, which indicates a possible leak of hydraulic fluid from worn cuffs or leaky pipes.

- The pedal is pressed with great effort, this can happen for all the reasons described above.

A stuck piston and a stiff pedal are not yet indicators for repairing and replacing working cylinders. You should pay attention to the thickness of the pads; if their wear has reached its maximum, this can cause the pistons to jam, since they practically do not work.

Initially, completely replacing the hydraulic fluid or bleeding the brake system may also help correct these problems. If these actions do not lead to a positive result, it is necessary to repair the working brake cylinder; fortunately, there is a repair kit for the working brake cylinder on sale, the set of which, depending on the make of the car, includes: cuffs, piston, boot and other components.

Signs of caliper malfunctions

The breakdown of the caliper components and their impending repair can be understood by some signs that occur during braking:

- The car pulls and pulls to the side when braking.

- It feels like when braking you have to put more force on the pedal or, conversely, less.

- The brakes rattle or knock when driving over bumps or when stopping.

- The brakes are jamming, which will be indicated by possible skidding.

- The appearance of brake fluid leaks on the wheel.

- Feedback in the pedal, expressed in a strong pulsation when pressing the brake.

If these symptoms appear, you should not delay repairing faulty caliper elements. You must first figure out why this happened and make repairs immediately.

Device

Modern cars use a disc brake system. However, on budget class cars, it is installed only at the front. The rear wheels are driven by drums. To actuate the pads, the rear brake cylinder is used. The VAZ-2110 is also equipped with it.

The brake system of this car itself includes the following elements:

- Front calipers.

- Hoses and tubes.

- Rear brake slave and master cylinder.

2110 and other VAZ models include a vacuum booster. It is controlled using the brake pedal. Pressure is created from the cylinder pistons, which acts on the pads.

If the brakes rattle

This type of brake has pressure springs or floating calipers.

They are responsible for securing the pads to the caliper body. The reason for their failure is metal fatigue or poor quality. As a result, they lose their elasticity and stop pressing the pads against the body. Because of this, the pads rattle at the slightest passage of irregularities and may come into uneven contact with the disc, which will lead to the appearance of a shoulder or grooves on it. Also in this case, the staples themselves may rattle.

What should you do when your brake calipers or pads rattle? If it is not possible to replace them, then you should try to loosen them with your own hands using pliers to make them more rigid. To do this, you need to pull them out of their seats, unclench them and insert them into place, after which they will stop rattling for a while.

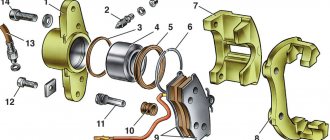

Caliper repair

- The housing in which the piston (cylinder) is mounted.

- Bypass valve.

- Sealing ring.

- Piston (cylinder).

- Cylinder boot.

- Retaining ring.

- Frame.

- Pressure bar.

- Pads.

- Guide boot.

- Guides.

- 14. Fastening bolt.

- Brake hose.

To repair calipers we will need the following materials:

- Caliper piston lubricant

- Caliper Guide Lubricant

- Guide block lubricant

- Brake cleaner or any cleaning agent

- Brake Caliper Repair Kit

- Copper brake hose O-rings. If new ones are not found, and the old ones are not very compressed, then you can go over them with a file and grind off the protrusions. But it’s better, of course, to have new ones in stock.

- If it turns out that the piston or guides of your caliper have large holes and pockets of corrosion, then you will need to purchase them as well.

- Possibly brake fluid for topping up

The kit includes two guide boots, a piston boot, a cuff and a cap for the bleeder fitting.

To repair the caliper with your own hands, we will need the following tools:

- metal brush

- medical syringe

- spanners. In my case, 10 and 12 mm

- clean rags

- a good screwdriver or a small tool

- two small packages

- soft wire

- preferably an assistant. We don’t need it for work, but cleaning the ram with clean hands and bringing beer at the right time will be just right. Also, at the very end, he will help you press the brake pedal a couple of times to bleed the brakes to make sure there is no air in the system.

Which lubricant to choose?

The question is quite sensitive for any motorist. In order for the caliper guides to work under normal conditions and ensure proper safety while driving, it is recommended to use high-temperature lubricant. This will almost completely eliminate the possibility of jamming or jamming of the brake pads while driving. When you carry out repairs, be sure to pay attention to the condition of the guide boot. The fact is that dirt and other foreign inclusions get underneath it. The lubricant is washed out and loses its original properties. If the front caliper guides are sticking, then with a 99% probability we can say that the problem is in the lubricant. Every brake pad replacement should include an inspection of the guide. Remove the boot, remove the layer of old grease and apply a new one to the grease-free surface. The staples, as well as the metal surfaces of the pads, must be processed. For this purpose, anti-charging paste is used. The lubricant can be containing copper or with the addition of ceramics (magnesium, disulfide).

Rear caliper repair

Actually, let's look at the process using the example of the rear caliper of a Chevrolet Lacetti

The first step is to open the brake reservoir cap, place a bag on the neck and screw the cap into place.

This is necessary in order to limit the access of air into the tank. This will prevent the brake fluid from quickly flowing out of the hose when we unscrew it.

Jack up the car and remove the wheel.

Use a metal brush to clean everything that can be cleaned.

After this, apply penetrating lubricant to the brake hose bolt.

We wait a little and try to unscrew the bolt with a 12 mm wrench.

If it's good, that's good. And if it doesn’t work out, then that’s bad and I don’t envy you.

We wrap the unscrewed hose into a “finger” from a rubber glove and wrap it with wire. During repairs, these measures will be enough to avoid brake fluid leakage.

There are craftsmen who clamp the brake hose for these purposes, but I don’t want to do that. Who knows what will happen to this hose later. It's better not to take risks.

We remove the unscrewed bolt to the side and at the same time try not to lose the copper sealing rings. There are two of them.

That's it, the caliper is disconnected from the system and we now need to remove the caliper cylinder itself. To do this, use the same 12 mm wrench to unscrew the lower bolt of its fastening.

After this, lift the cylinder up. If it is very jammed, then you can help yourself with a large screwdriver or a pry bar.

We take it out together with the upper guide. We look into the hole where the brake hose was previously screwed in and see the back of the piston.

Using something, we need to squeeze out this very piston through this hole.

If it’s really tight, then you can help a little with a hammer, or better yet, with a vice.

After the piston has come out, we assess the situation. If the piston is full of holes and pockets of corrosion, then it is better to replace it. If the corrosion is not significant, then you can polish it with felt and Goya paste. In my case, there were pockets of corrosion, but it was not possible to purchase a new piston. Therefore, after a little polishing, I left it to serve further.

We clean and wash all the grooves in the cylinder.

The far groove is the seat of the sealing collar, and the near one is the boot

After this, lubricate the cuff groove and the cuff itself with piston lubricant. The groove must be lubricated to avoid corrosion under the cuff. Install the cuff into the cylinder. This is done quickly and easily.

Now the most important thing. It is necessary to put on the piston boot and insert the piston itself. To do this, lubricate the piston with the same grease and put the boot on the piston from the back side.

I was filming a video and forgot to take a photo. That's why I inserted a still from the video. It looks bad, but the essence, I think, is clear. The part of the boot that is inserted into the cylinder groove hangs slightly from the piston.

Now, when installing the piston, the boot will fall into its groove in the cylinder. In this case, the piston can be rotated slightly so that the boot placed on it falls into its groove completely. If the boot is bitten a little, then you can help it get into the groove with a screwdriver. But be careful not to tear the boot.

There is nothing complicated. You can easily figure out the place.

Now you can push a little more grease under the boot. This can be done more conveniently using a syringe.

Squeeze the lubricant into the syringe.

We push the piston into the cylinder and excess lubricant will be squeezed out from under the boot.

The piston should move easily and move with bare hands. If it doesn’t move, it means something went wrong or you didn’t eat enough porridge as a child. If the problem is a mess, then you can use this device to recess the piston.

Now you need to wash the seats of the guide pins.

If there is severe contamination, then it will be more convenient to dismantle the whole thing and wash it on the table.

After that, apply a little grease for the guides there. You can insert the guide and use rotational movements to evenly distribute the lubricant.

We install the anthers so that they fit into their grooves. And insert the bottom guide

Clean the pad guides and lubricate them with a thin layer of high-temperature grease

We lubricate the ends of the pads with the same grease.

We do the same with the back side of the block.

It is better not to lubricate the second pad, which faces the piston, so that the lubricant does not get on the piston boot.

We install the pads in place, first making sure that the lubricant does not get on the working area of the pads.

Lubricate the second guide that remains on the cylinder

And install the cylinder in place.

Screw on the brake hose. We remove the bag from the brake reservoir, but do not screw the lid on yet.

We unscrew the bleeder fitting and wait for brake fluid to flow out of it.

It is located at the top of the cylinder and the liquid, filling the volume of the cylinder, will displace the air from it.

After the liquid begins to come out, you can tighten the fitting. To ensure that there is no air in the system, you can have an assistant press the brake pedal several times and bleed the system. If your assistant cleaned the ram properly, ask him not to touch the steering wheel with his hands while pumping the brakes.

That's all you need to do to repair the caliper yourself.

1306 words written... In general, restoring a caliper is much faster than writing about it.

What happens if you don’t service the caliper and don’t notice a worn boot in time.

Don't forget to check the brake fluid level and tighten the reservoir cap. Before leaving, press the brake pedal several times until the piston reaches its working position.