What pressure should be in the VAZ 2110 fuel system?

On a VAZ 2110 with 1.6 liter engines, the pressure in the ramp is constant and amounts to 3.6-4.0 atm. Otherwise, the measurement technique is similar. Alternative ways:

- It is measured at the outlet fitting of the fuel pump module - this is the one with one tube. You will need a flexible gas-resistant hose with an internal diameter of about 8 mm and a pressure gauge (you need to remove the tube and put on a hose with a pressure gauge instead). The pressure should be 5-7 atm.

- Close the return line, as is done on an internal combustion engine with a drain ramp, but you must turn it off again at the fuel pump itself. We pull off the second hose (double) and insert a plug into the removed hose, made, for example, from an old fuel filter (saw off the nipple from it and plug it). A single hose must be put on the pump fitting, and now the measurement must be made at the fuel rail. According to the power system diagram, everything will be clear.

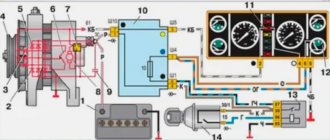

1 – fitting for checking the pressure in the power system; 2 – fuel rail; 3 – nozzles; 4 – fuel line; 5 – fuel tank; 6 – fuel pump module (in the fuel tank); 7 – fuel filter; 8 – tee.

[custom_ads_shortcode1]

Different measuring methods

In addition to measuring against the wall, there are many other ways to measure yourself. One of the options for checking the fuel supercharger is the “plug” diagnosis. In this case, the return line is clamped for two seconds, the engine starts, and the pressure reading is taken.

Another testing option. The speed of the power plant increases to three thousand revolutions per minute. At the same time, you need to monitor the instrument readings. If the pressure drops to 0, this is a sign of a “dead” pump.

The pressure on the ramp is measured as follows:

- fum tape is wound around the pipe;

- the device hose is reinforced with a clamp (if homemade);

- a rag is placed on nearby parts to prevent fuel from spilling (especially carefully you need to close the generating device in order to avoid a fire hazard in the engine space);

- there is a cap on the fuel rail that needs to be unscrewed;

- access to the hole with the nipple is opened - the latter is unscrewed with a cap from the car wheel;

- To prevent gasoline from splashing too much, it is necessary to release the pressure in the vehicle in advance;

- the end of the meter hose is threaded into the ramp hole and is also secured with a clamp;

- The rag is removed, the engine starts, and readings are taken.

On a vehicle without return.

- It is necessary to measure the pressure at the outlet of the fuel pump module (located on the fuel tank). For measurements, a hose with a diameter of eight millimeters is suitable, which must be resistant to gasoline. An ordinary pressure gauge is suitable as a meter.

- The original hose is removed from the pressure gauge and an 8 mm one is inserted. Pressure readings are taken, which should be within 5-7 atm.

Measurements are made in different ways:

- with the ignition on, watch how much the scale needle jumps;

- measurements are carried out with the RTD (fuel sensor) hose removed;

- separate idle pressure test;

- check with a pinched return hose.

Problems with the car's fuel system

are expressed by failures at high speeds, jerking of the car, or the car does not move when you need to accelerate sharply, and sometimes it simply stalls. Now knowing how to check the pressure in the fuel system of a car, we can diagnose the car ourselves. We can determine which component of the fuel system has failed (gasoline pump, fuel pressure regulator (FPR), injectors, filters, etc.), but first we need to understand how the fuel system works: The gas pump continuously pumps fuel while the engine is running. Excess gasoline is stupidly dumped through the RTD into the return line.

The pressure in the ramp changes (increases) not so much with the speed, but at the moment of accelerating (this is clearly visible in the video), because at this moment the vacuum (vacuum) in the receiver drops and the RTD adds pressure in the ramp.

If you turn off the engine, the pressure in the ramp will slowly begin to decrease exponentially. The rate of decline (from several minutes to several hours) depends on the quality of the check valve, which is located on the back of the fuel pump motor. When diagnosing, pressure measurements in the system are made in different ways:

- Measuring how much the needle jumps when the ignition is on

- Measured at XX

- Measurement with the tube dropped from the RTD

- Metering with pinched return

How to measure

All you need is a pressure gauge, which is designed to measure tires. It just needs to be modified a little by changing the scale. It is better to measure the pressure in the injection system with a device scale showing a variation within 6-7 atm.

There are other, more advanced measuring instruments. A special tool kit with a pressure gauge, adapter and drain hose is sold at an auto parts store. Costs about 1.5 thousand rubles.

Pressure can be measured at any car service center. They will charge nothing for the service - 500-600 rubles.

Professional pressure gauge for measuring fuel

But whatever one may say, an experienced motorist should have his own pressure gauge among his tools. If it is purchased, then with it the driver receives all kinds of adapters that allow pressure measurements on a wide variety of car brands. In addition, commercial pressure gauges are equipped with a better scale that allows you to measure pressure more accurately. And a professional pressure gauge is generally a godsend, since it makes it possible, among other things, to relieve residual pressure in the system, which increases the accuracy of the readings.

If you decide, nevertheless, to use a homemade pressure gauge, then remember!

It is better to use a regular air pressure gauge from VAZ, since it can also measure oil pressure (you just need to unscrew the fitting). Instead of an adapter, you can use a regular threaded fitting. It is important to use high-quality clamps so that there are no gaps.

How to take measurements.

- Most often they are carried out with the ignition on. It is necessary to check whether the arrow has jumped in comparison with the standard value.

- Measurements are also carried out in XX mode.

- Measurements are carried out with the “return” compressed and with the RTD reset.

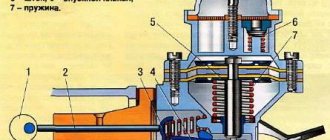

How to determine the status of the fuel pressure regulator (FPR)?

There are two ways to determine if an RTD is faulty:

- If the pressure with the engine not running with the fuel pump turned on is below 2.8 atm. To turn on the fuel pump directly without starting the engine, then on the diagnostic block we close the closest contacts to the gear shift lever.

- Turn off the fuel pump. The pressure in the ramp should drop by about 0.7 atm and remain at this level. If the pressure in the fuel system does not hold and immediately drops to zero, then the RTD or the pump check valve is faulty (located on the back side of the fuel pump motor; it is not advisable to change the pump because of it). Do not rule out cracks in the fuel line or poor condition of the injectors (gasoline flows in)

Injection pump pressure on a Mercedes

This is a high pressure pump installed on diesel cars and some gasoline cars.

This is how pressure is measured.

- Motor 4g93 starts.

- Take a multimeter, which is connected with one probe to the middle connector of the RTD chip. The second probe must be connected to the negative terminal of the battery.

- Indicators are taken.

The normal value should vary within 3 volts. If it is less, you need to raise the speed of the power plant and keep it within 2000 rpm. Adjust the pressure bolt in this mode by rotating clockwise. At the same time, you need to look at the device to stop rotation as soon as the pressure reaches the standard value of 3 volts.

If the pressure does not want to return to place, you can draw conclusions about a fuel leak or a malfunction of the fuel system elements, including the pump.

Video: how to measure the pressure of injection pump 4g94

How to determine the condition of the fuel pump?

In order to determine a fuel pump malfunction, you need to check the fuel pump “at the wall” (zero supply pressure or “at the plug”). In simple terms, this is the pressure that the fuel pump develops.

It is by this parameter that the service life of the fuel pump can be determined. As the pump wears out, this parameter gradually decreases. When the pressure is “into the wall”:

- about 3 atm - the car stalls

- 4 atm - the pump will still serve

- 5-7 atm – the state of the new pump (the Czech gas pump produces 7 atm)

Checking the fuel pump “for a plug” is quite simple; you need to pinch the return line with pliers (for 2-3 seconds) with the car running and watch the pressure gauge readings. Another way to check the fuel pump: smoothly raise the engine speed to 3000 rpm. If the pressure gradually drops, then this is a sign of a “dead” pump.

How to check the condition of the fuel system without a pressure gauge?

Unscrew the fuel supply line and apply power to the fuel pump. If everything is in order, then about 1.5 liters should flow in a minute. By the way, if the pressure in the fuel rail is only 1 atm and the sound of the pump is uneven. The reason is there is no gasoline in the tank! Now, if you stalled far from the city, then diagnosing the car yourself in the field is not a problem for you! Intense acceleration of the car without dips and jerks is the first sign of a serviceable fuel system of the car! If after such a diagnosis the problems remain, then pay attention to other points (compression in the cylinders, ignition module, etc.).

Causes of malfunction

The main causes of malfunctions of the VAZ 2110 fuel pump are the low quality of the fuel being filled, low fuel supply pressure, the regular presence of a small amount of gasoline (less than 5 liters) in the fuel tank and improper operation when starting the engine - before starting the engine, you must wait after turning on the ignition 2-4 seconds to pump fuel into the engine power system.

It is also possible that the fuel pump as a part will naturally fail, depending on the mileage of 150 - 200 thousand km. or for a period of 4-5 years, but again this malfunction depends on the operating conditions of the car itself. Usually the factory fuel pump is replaced with a BOSCH one.

There are secondary malfunctions of the VAZ 2110 fuel pump failure - failure of the relay, blown power fuse, they are located in the fuse mounting block either under the hood or in the lower left part of the dashboard, front console, depending on the engine modification, and contamination of the fine filter mesh fuel cleaning (located directly on the fuel pump).

These faults can be fixed relatively quickly and without large financial investments. Fuel pump repairs are performed quite rarely, and the cost of repairs relative to the cost of the pump is insignificant.

[custom_ads_shortcode1]

Troubleshooting

The main symptoms of a malfunction of the VAZ 2110 fuel pump are engine interruptions in various operating modes, lack of pressure in the fuel system, loss of acceleration dynamics, increased fuel consumption, or complete failure when trying to start the engine.

The first step is to check the functionality of the pump. When you turn on the ignition, you should hear a slight whirring sound from the pump under the rear seat for a few seconds.

If the engine is running, it is necessary to check the fuel supply pressure using a pressure gauge; the fuel supply pressure to the injector should be 3.5 - 4 atmospheres. If the sound of the fuel pump is not heard, if you have an electrical tester, you can check whether power is being supplied to the pump.

To do this, you need to remove the back seat of the VAZ 2110, the decorative cover, and the terminal from the fuel pump housing, turn on the key to crank the starter, if the tester does not receive power, you need to check the relay, fuse or wiring trace for a break! If there is power, the fuel pump needs to be replaced.

The serviceability of the relay can be checked by replacing it with a working one from the fuse box, for example the high beam headlight relay. When replacing a new relay, you need to pay attention to the manufacturer and the recommendations of a spare parts specialist in the store; it is better not to save on the cost of the relay.

[custom_ads_shortcode2]

Checking the electrical circuit

Unlike a carburetor engine, where the fuel pump is mechanically driven, on the injection VAZ 2110/2112 a special relay and fuse are responsible for the operation of this device. Therefore, before moving on to diagnosing the pump itself, it is necessary to check the indicated elements. If any one of them is faulty, the pump will not work at all.

Turn on the ignition without starting the engine and listen. When the fuel pump is running, it emits a characteristic “whistle” when started. If it is not there, it means that either the pump itself has failed, or one of the elements of its power supply circuit has failed.

The pump relay and fuse are located in an additional mounting block located inside the vehicle's center console. It can be accessed by removing the plastic trim (near the front passenger's left foot). It is secured with several screws. Under the cover you will find three relays and three fuses. Typically, the fuel pump circuit protection elements are located centrally.

The relay and fuse are located in an additional mounting block under the cladding

To check the fuse, remove it from its socket and “ring” it with a tester. If necessary, replace it, observing the rating (15 A). It is unlikely that it will be possible to check the relay for functionality without special equipment. But you can take another relay, for example, the radiator fan (far left), and install it in place of the one being diagnosed. Turn on the ignition and listen to see if the fuel pump starts working. If yes, buy and install a new relay. If the problem persists, continue diagnostics.

To check the fuel pump relay, you can install the radiator cooling fan relay in its place.

Replacement

Replacing a fuel pump with a new one requires careful selection of the manufacturer; each pump has its own performance. The absolute leader in this area is BOSCH.

To replace or remove for repair the VAZ 2110 fuel pump we will need: a 17mm wrench, depending on the modification, a 10mm socket, pliers, a flat screwdriver. We remove the rear seat, it is advisable to unscrew the gas tank cap to relieve excess pressure in the system. Disconnect the plastic pump power terminal.

Depending on the modification, we remove the fuel supply and return hoses, or, by pressing the spring clip and pulling the hose, disconnect it from the fuel pump housing. In the second option, use a 17mm wrench to unscrew both fittings and disconnect the tubes.

In both cases, it is necessary to disconnect carefully, since the system is under pressure and when disconnected, the pressure will be released from the injector and a small amount of fuel will leak. If the performance of the old fuel pump is small, there will be no pressure in the system.

Unscrew the 8 nuts from the studs using a 10mm socket and remove the retaining ring with the seal. Carefully pull out the VAZ 2110 fuel pump housing at a slight angle so as not to damage the fuel level sensor; repairing it is unlikely. Using a screwdriver and pliers, remove the lower part of the fuel pump housing and remove the connectors and hoses from the pump. We dismantle the pump.

Assembly is carried out in reverse order. By the way, the original BOSCH fuel pump comes with a mesh. The new fuel pump has high performance, so after replacing it, when you turn on the ignition several times, there will be extraneous sounds when the system is pumped.

Bosch fuel pump performance - from 3 to 3.8 bar

The manufacturer Bosch produces its own fuel pump for each type of fuel system. Why, after the original fuel pump fails, do people install a Bosch fuel pump from a VAZ 2110? How does the pressure and performance of the fuel pump compare with the original one? If you put it with high pressure, will the flow rate increase?

Consumption does not increase due to the performance of the fuel pump, since on cars the return line is activated and excess fuel is returned to the tank, there is also a fuel pressure regulator, from the name it is clear, I think what function it performs.

Consequently, there was a 2.8 bar pump, they installed a Bosch VAZ 2110 fuel pump with 3.8 bar and it will only get better. Fuel consumption may increase if the fuel pump does not create sufficient pressure in the rail and the injectors begin to pour gasoline, which does not burn, rather than spray.

[custom_ads_shortcode1]

Pumps and injectors from Bosch: tables

The most famous manufacturer today. Pumps from Bosch are installed on many well-known car models.

The electric fuel pump from Bosch uses a high power rating, which allows it to push fuel directly onto the injectors and into the power plant. The operation of this fuel supercharger is controlled electronically. It calculates the state of the damper, exhaust and takes into account the amount of gasoline in the fuel assembly completely in AUTO mode.

It is noteworthy that Bosch develops unique pumps for this or that brand of car. For example, for our VAZs, units with a capacity of 3 or 3.8 bar are produced. These figures are higher than those provided for by the car, however, many owners install just this option. The Bosch pump in no way affects the increase in fuel consumption, as some believe. On the contrary, fuel consumption is caused by a situation when optimal pressure is not created in the ramp, and as a result, the injectors do not function correctly - they do not spray gasoline, but simply pour it.

Thus, Bosch pumps can have different performance data. It all depends on the specific analogue. Read more in the table, which shows the types of fuel pumps by model.

| Bosch fuel pump model | System pressure max, kPa | Capacity l/h |

| 0 580 254 005 | 500 | 168 |

| 0 580 254 040 | 650 | 102 |

| 0 580 254 044 | 700 | 172 |

| 580453978 | 300 | 95 |

| 580453979 | 300 | 103 |

| 580453980 | 400 | 103 |

| 580453981 | 300 | 85 |

| 580453982 | 400 | 103 |

| 580464008 | 300 | 130 |

| 580464031 | 300 | 140 |

| 580464061 | 310 | 180 |

Bosch pumps are also installed on the popular German BMW car in Russia. Performance also varies depending on the BMW model. Basically, it is customary to divide pumps from this manufacturer for BMW into two categories.

| Productivity at rated voltage 95-135 l/h | Productivity at rated voltage 130-195 l/h |

| BOSCH 0 580 254 945 | BOSCH 0 580 464 008 |

| BOSCH 0 580 254 946 | BOSCH 0 580 464 013 |

| BOSCH 0 580 254 950 | BOSCH 0 580 464 014 |

| BOSCH 0 580 254 951 | BOSCH 0 580 464 015 |

| BOSCH 0 580 464 030 | BOSCH 0 580 464 016 |

| BOSCH 0 580 464 034 | BOSCH 0 580 464 019 |

| BOSCH 0 580 464 040 | BOSCH 0 580 464 020 |

| BOSCH 0 580 464 041 | BOSCH 0 580 464 023 |

| BOSCH 0 580 464 032 | |

| BOSCH 0 580 464 033 | |

| BOSCH 0 580 464 038 | |

| BOSCH 0 580 464 048 | |

| BOSCH 0 580 464 050 | |

| BOSCH 0 580 464 051 | |

| BOSCH 0 580 464 056 | |

| BOSCH 0 580 810 046 |

Characteristics of the Bosch fuel pump 0580453453

Especially for my readers, I got confused and measured the fuel pump that is on my display case. In fact, the characteristics of Bosch gasoline pumps differ in the length and very rarely in the diameter of the body. Why? The diameter of the body can be adjusted using a gasket made of petrol-resistant rubber.

Most often, the characteristics of fuel pumps (not only Bosch, but also from other manufacturers) may differ in length, pressure, location of terminal chips and that’s it :). The fuel pump mesh does not differ in seating, but it may differ in shape. The chip for the terminal can be remade or supplied from the same VAZ. The length of the fuel pump is important, since its operation depends on this when the fuel level in the tank is low, and if it is in the module, then you need a match to install it.

Fuel pump length:

- Bosch fuel pump 0580453453 - 105 mm

- Bosch fuel pump 0580453449 - 65 mm

- Bosch fuel pump 0580453465 - 90 mm

[custom_ads_shortcode2]

Breakdowns

The following signs indicate that the sensor is broken and not working properly:

- a sharp increase in fuel consumption;

- unstable operation of the power unit, it stalls at idle, despite the serviceability of all systems and a sufficient fuel level;

- drop in engine power, feeling of lack of it;

- when driving, the speed disappears for a while;

- increased level of emissions from the exhaust system;

- high concentration of CO and CH in the exhaust;

- too high or, conversely, low crankshaft speeds;

- the engine starts with great difficulty, especially if the car has been standing for some time;

- poor response to the gas pedal.