The fuel pump on VAZ 2110 cars is an important element of the car’s fuel system. It is responsible for pumping gasoline from the tank to the engine under pressure. Due to the poor quality of gasoline, this element very often fails, which in turn significantly affects the unstable operation of the vehicle’s internal combustion engine.

In today’s article I will tell you about the main reasons for the fuel pump malfunction, how to understand that it is the one that has failed, and I will give step-by-step instructions for dismantling and installing this element of the car.

Design of the VAZ 2110 fuel pump for injection and carburetor car models

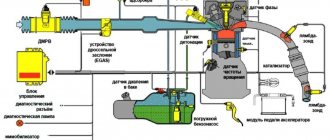

Two types of fuel pumps are installed on VAZ 2110 cars, depending on the type of car engine. The first type, mechanical, is installed mainly on carburetor models, the second type is electrical, which are installed on inverter tens.

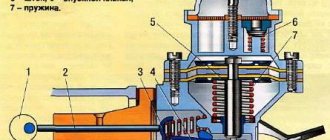

Mechanical fuel pumps, which were installed on the first modifications of the VAZ 2110/2112, have a simple design. It is based on a set of membranes made of special rubberized fabric that is resistant to the chemical action of gasoline. The pump body has two valves: inlet and outlet. The membranes are driven by a rod (pusher). It is driven by a cam mechanism rotated by a camshaft.

Such a mechanical fuel pump can serve for decades until the drive rod wears out or one of the membranes breaks. And even then, if this happens, you can replace these elements in half an hour.

With an electric fuel pump, things are much more complicated. Its design is based on a small electric motor. It is no different from a regular one, although it works completely immersed in gasoline. The pressure in the system here is created not by a membrane (although there are such pumps), but by a specially shaped impeller mounted on the electric motor shaft.

The VAZ 2110 fuel pump is located directly in the car’s tank.

The service life of the electric fuel pump is 150–200 thousand km. But it can fail much earlier. The main cause of breakdowns when the resource is not used up is additives added to gasoline, as well as various kinds of mechanical impurities. The former destroy the brushes and commutator, while the latter clog the valve mechanisms.

VAZ 2110 does not pump the fuel pump, reasons

First, let's look at breakdowns of mechanical refueling. All parts of a car engine are subject to aging and wear, and the life of a mechanical fuel pump also ages over time.

The main malfunctions in the operation of a mechanical device include:

- Valve fault.

- Diaphragm rupture.

- Shell deformation.

If the diaphragm is leaking air, the fuel pump may stop delivering fuel to the carburetor, or gasoline may pass through the ruptured diaphragm into the crankcase, where it mixes with the engine oil. When fuel gets into the oil, fuel consumption increases sharply and the engine begins to have difficulty starting, especially when warm. Checking the presence of fuel in the crankcase is quite simple - if you light the oil dipstick with a lighter, a fire will start. In addition, the sump will smell like fuel.

A common malfunction of mechanical fuel pumps is deformation of the mounting surface of the oil cylinder to the auxiliary housing. If the surface is deformed, engine oil begins to flow out at the meeting point of the planes.

Now about the electric fuel pump.

If it stops working, there may be several reasons for the failure:

- The fuel pump motor burned out.

- The relay has stopped working.

- The fuse has blown.

- Faulty electrical wiring.

- Engine control unit malfunction.

Causes of malfunction

During operation, VAZ 2110 car owners may encounter some difficulties associated with this element. Malfunctions of the VAZ 2110 injector fuel pump can be as follows:

- element failure due to breakdown;

- a dirty tank or low-quality gasoline with foreign inclusions that contaminate the pump filter.

The very first sure indication that the VAZ 2110’s fuel pump is faulty is the following symptom: the engine “jerks” during operation , especially at medium and high speeds . This indicates that the fuel pressure is insufficient. But this is precisely what the fuel pump is responsible for. But sometimes the reason should be sought in the injectors , as well as the RTD.

Fuel pump VAZ 2110 disassembled (in the photo you can see the dirt in the glass)

There are main signs of a malfunction of the VAZ 2110 injector fuel pump, in which you should definitely take action to check this component:

- A loud noise that the element has not previously made.

- The vehicle refuses to gain speed and also does not move when engaging first or second gear.

- The car moves jerkily and behaves strangely on the road.

- The engine suddenly stopped running.

Each of the VAZ 2110 fuel pump malfunctions must be carefully considered in order to understand what to do if you encounter them.

Where is the fuel pump located?

The fuel pump is one of the most important devices in a car, performing the functions of pumping fuel. It takes gasoline from the tank, then sends it through a pipeline to the filtration system and then to the combustion chambers.

Often, the car owner needs to replace or temporarily remove this device; its location depends on the car model and the type of fuel system. In the VAZ 2110 it is located under the hood, directly next to the engine, so detecting it does not cause any difficulties.

How to check the fuel pump on a VAZ 2110

If the gas tank is full, the battery is in normal condition, the spark plugs are dry and give a spark, and the starter turns the engine, then the reason is the fuel pump. A more common reason is that after turning on the ignition, power does not flow to the fuel pump.

Assembling the fuel pump VAZ 2110 (installing the insert)

In the same way, it manifests itself when the car is moving, when power is lost and the engine begins to stall. Another important aspect is the supply of the required amount of fuel.

How to check the operation of the fuel pump?

VAZ 2110: fuel pump problems and all about it

First, you should check the fuse. To do this, check the instructions for its location. Next, you should check the voltage at the pump. Before doing this, be sure to check if everything is in order with the battery. The voltage at the fuel pump terminal must be checked using a multimeter or tester. The instruction manual always indicates the required voltage.

Using a tester, check the voltage supply to the fuse. Often this is where the electrical circuit breaks.

If the search does not yield results, then the voltage should be checked on the contacts themselves. All contacts must be in place and connected to ground. A broken contact or its oxidation leads to failure of the fuel pump system. If no broken contacts are detected, but the voltage drops by more than 1 volt, then the problem is in the wiring or oxidation of the contacts. There should be no short circuit in the wiring.

If, after checking the voltage, contacts and fuse, you do not find any problems, then the problem lies in the fuel pump itself. In this case, the fuel pump will most likely require replacement. In practice, it most often turns out that replacement is a last resort. First, you should try to restore and test the fuel pump again.

Before you check the fuel pump, you need to remember that, as mentioned above, pressure is the most important characteristic of the fuel pump, so it is worth measuring its level

How to check the pressure in the fuel rail?

You will need a pressure gauge that measures pressure in the range from 7 to 10 atmospheres. If you choose a pressure gauge with a large margin, you risk getting less accurate measurement results. Specialized stores sell a kit for measuring pressure, but you can also design your own device.

If you want to assemble the device yourself, you will also need a hose with an internal diameter of 9 millimeters. You will also need plumbing tow, with which you can seal the connection between the pressure gauge and the tube. All parts are connected and tightened using a clamp. You will also need a car spool. Next you need to perform a series of actions:

- Place the car on a level surface that is prevented from rolling, turn off the ignition and open the hood.

- Check that the injection nozzles have access to the fuel rail.

- Find the fuel pressure plug and remove it. Then you should unscrew the nipple using the spool.

- Prepare an empty container (a regular bucket will do) and a clean rag. This is necessary to collect residual fuel, which under pressure can splash out in different directions. Therefore, take care of the safety of your skin (especially your face and eyes).

- Connect the device to the fitting and begin checking the mechanism.

We recommend: Polishing car headlights with toothpaste – is it worth it or not?

Checking the pressure in the fuel rail should occur in four operating modes of the power unit:

- when the ignition is on;

- at idle engine speed;

- code the fuel pressure regulator tube is reset;

- when the drain tube is compressed.

Fuel rail pressure measurement results

The results may vary slightly for different car models, but in general they should be as follows:

- when the ignition is turned on, the pressure must be at least 3 atmospheres,

- at idle engine speed - at least 2.5 atmospheres,

- when the pressure regulator tube is reset - at least 3.3 atmospheres,

- when squeezing the drain tube - at least 7 atmospheres.

Fuel rail pressure fluctuates slightly during preparation. When you press the pedal, it suddenly takes on a value of 3 atmospheres; when you release the pedal, it drops to 2.5 atmospheres. When fuel enters the fuel system, turn off the ignition and begin observing the pressure gauge. The pressure in this case should drop to 0.7 bar and remain unchanged.

If the pressure drops to zero, there may be a problem with the fuel pressure regulator. In this case, the regulator must be replaced immediately. The cause could also be the fuel pump check valve.

It is necessary to observe the behavior of the pressure gauge even at 3,000 engine speeds. A drop in pressure will indicate a faulty fuel pump. Sometimes the fuel pump cannot reach the required pressure for a long time. In this case, the problem lies in a clogged fuel filter, which needs to be replaced, or in a dirty fuel pump mesh (read more about where the fuel filter is located).

If the above methods do not reveal a malfunction of the fuel pump, you will have to diagnose other units (DPZD, IAC, mass air flow sensor, compression in the engine and some other indicators and parts).

Step-by-step instructions for checking a mechanical fuel pump

First of all, let’s check whether the supply system of your VAZ 2110 is working at all. To do this, you need to take the following steps:

- Remove the pump fuel hose from the source or discharge fitting;

- Manually press the fuel pump lever several times;

- If the pump is operational, a strong stream of fuel will immediately flow through the fitting;

- If there is no jet or it is very weak, it will be necessary to carry out other checks.

Next, check the operating condition of the intake valve:

- Disconnect the hose from the suction fitting so that both hoses are eventually removed, each from its own fitting.

- Simply plug the suction fitting with your finger, then pull the lever several times to manually pump fuel. If everything works fine, your finger will begin to be sucked into the fitting. This effect indicates that the pump is working properly. Therefore, we look for the problem in the tank or lines.

- If there is no suction, you will have to disassemble the device to replace the inlet valve. Its tightness is most likely broken.

The next step is to check the VAZ 2110 fuel pump for leaks for this:

- Place your finger on the hole from the injection fitting and pump up the fuel several times using manual pumping;

- In this case, a stream of air should come out of the hole, significantly repelling the pressed finger;

- If the stream turns out to be weak or does not exist, the fuel pump simply does not pump.

In this situation, there are two options - look for the problem inside the fuel pump device, disassembling the pump, or change the entire unit.

Tips and tricks

If it is necessary to replace the VAZ 2110 pump or after removing the pump for preventative replacement/cleaning of the mesh, after completing the reassembly and installation of the pump, do not immediately install the rear sofa and the pump cover.

Additional verification will be required before doing this. To do this, you need to turn on the ignition and determine whether gasoline is leaking from the fuel pipes. Also, the smell of gasoline in the car interior, etc. is not allowed. If this is the case, then you need to determine the cause of the leak and replace the problematic elements, tighten the tube nuts, etc.

As for the fuel pump itself, the VAZ pump does not have to be replaced as a whole module. You can replace only the pump part, which will be cheaper. In this case, you only need to install the pump that came from the factory. You can also try to choose an analogue that matches the characteristics, but in the case of a VAZ, it is often optimal to use original parts.

To make the selection accurate, the existing module must be removed from the car and purchased a similar one. Also, when choosing, you need to take into account the type of engine, since the pumps are different. Before purchasing, the fuel pump itself should also be inspected, its housing should be checked (cracks, dents, and defects are not allowed).

Step-by-step instructions for checking the electric fuel pump VAZ 2110

To check the electric fuel pump on a VAZ 2110, you will need an indicator sold in any car store. The installation of the indicator, in each specific case, should be done in accordance with the instructions that come with it. Then the engine is started and, after a few minutes, it is turned off. After this, the indicator readings are studied: normally, the pressure should not drop below 1.6 atm. – otherwise, you will have to replace either the injector or the regulator.

You can also check the fuel pump using a pressure gauge. It is connected directly to the fuel rail, and the device itself is connected to the windshield of the car (this is done under the edge of the hood).

The process of checking the pressure in the fuel pump VAZ 2110

As soon as the ignition is turned on, it is necessary to take the pressure gauge readings (they should not exceed 380 kPa and be less than 300 kPa). After accelerating the car (it would be optimal to do this up to 3rd gear), you again need to take the pressure gauge readings, which, if the fuel pump is working, should not vary much and go beyond the specified range.

If the car stalls while driving, first of all, check the relay on the fuel pump. This procedure consists of connecting a special light bulb to the fuel pump connector. After this, turn on the ignition. If the light stays on for a few seconds, then the fuel pump relay is working properly.

If fuel starts to leak, you just need to change the filters or gaskets. It may also be necessary to replace the diaphragm, or, in rare cases, valves.

Remember that extreme care must be taken when working with the fuel system. It is best to immediately go to specialists who know exactly how to check the fuel pump quickly and efficiently.

VAZ 2109 fuel pump injector how it works. Replacement and inspection

You will need to consider the features that the VAZ 2109 fuel pump has. If the injector is in the fuel injection system, then the pump is of an electric type. Its use is due to the need to control the fuel supply to the combustion chambers. But, as you know, gasoline first enters a special ramp, in which it is mixed with air in a certain proportion (14 to 1). It maintains constant pressure, with the help of which the mixture is supplied to the combustion chamber through holes in the electromagnetic injectors. These are devices that transform the air-fuel mixture into very small droplets. Essentially, the mist in which the gasoline is suspended in the combustion chamber is ignited.

How does a fuel pump work?

There is nothing complicated about the fuel supply system. A conventional pump, which is driven by the rotor of an electric motor. To protect the entire fuel system from small particles, a filter is used. But this is not the end of the features, because it is worth noting that it is necessary to maintain the pressure in the ramp at the same level. And the VAZ 2109 fuel pump (the injector simply cannot work without it), provided that it constantly pumps gasoline, will begin to pump up the pressure higher and higher. And this will disrupt the operation of the system.

Therefore, it is necessary to adjust the pressure. For this, a special device is used, which is called a pressure regulator. It is installed in the fuel rail and connected to a pipeline that serves to dump excess gasoline into the tank. When the ignition is turned on, the rail pressure sensor is polled, after which the fuel pump drive is turned on. After the pressure in the rail has increased to the required value, the fuel pump is turned off. Therefore, it does not work all the time.

How to remove the fuel pump

The VAZ 2109 fuel pump is located under the rear seat. The injector implies its installation directly in the tank. The thing is that the pump is a submersible type. In the same unit there is a float-type fuel level sensor. It works due to the fact that the float moves the slider using variable resistance. At the same time, the current in the power circuit changes. The amount of gasoline remaining in the tank is determined by the magnitude of the change. To remove the pump you will need to use pliers, screwdrivers and an 8mm wrench.

It is quite possible that the reason that fuel is not supplied is a non-working VAZ 2109 fuel pump relay. The injector contains it, as well as a fuse, which could easily burn out. Before starting work, thoroughly clean the entire cover so that after removal no dust gets inside the tank. Then, using a screwdriver, loosen the clamps that secure the hoses. Remove them; if you can’t do it with your hands, try gently squeezing them with pliers and twisting them. After this, use a size 8 wrench to unscrew all the nuts that secure the lid to the tank body

Please note that there are washers there. Don't lose them. That's all, now the pump can be easily removed for replacement or repair

That's all, now the pump can be easily removed for replacement or repair.

Checking the pump's functionality

It is easy to check the VAZ 2109 fuel pump even without special instruments. The injector will not be able to operate without pressure in the fuel rail. Therefore, you need to keep the pump motor spinning. It’s easy to check; just connect its terminals to the battery. If you are afraid, then turn on an incandescent lamp in the gap of one wire. It will help determine the health of the motor winding

Please note that the filter must be as clean as possible. If it is clogged, be sure to change it. Otherwise, the pump will not be able to create the required pressure.

Otherwise, the pump will not be able to create the required pressure.

Pump installation

Pay attention to the condition of the wires when replacing the VAZ 2109 fuel pump. The injector involves powering the engine from the on-board network, so there should be no breaks or destruction of the insulation. Installation of the fuel pump is carried out in the reverse order of removal

First, place the body in the tank, landing on the studs. Then you need to tighten all the nuts, then put the hoses in place and connect the plug with wires

Installation of the fuel pump is carried out in the reverse order of removal. First, place the body in the tank, landing on the studs. Then you need to tighten all the nuts, then put the hoses in place and connect the plug with the wires.

Choosing a fuel pump for the top ten - what to look for

When choosing a fuel pump for a VAZ 2110, confusion often occurs between the concepts: the fuel pump module and the fuel pump itself. In the first case we are talking about the assembly structure, which we remove from the tank, in the second case we are talking about the fuel pump motor .

The choice of a fuel pump is carried out according to the following criteria: reliability and quiet operation, because the quieter the pump operates, the more comfortable it is to use.

When choosing a fuel pump, you must purchase the same product with the same part number. Often, among many analogues, car enthusiasts highlight the Bosch fuel pump, which is used on 1.6-liter cars and is equipped with a fuel level pressure regulator.

conclusions

Replacing a gasoline pump on a VAZ-2112 with your own hands is not difficult. The total time of the operation is about 1.5 hours, unless force majeure occurs in the form of a break in the power contact group or a breakdown of the pipeline connector.

It's good that I found this article with photos. I changed the fuel pump myself and didn’t have to go to the service station.

It took me a long time to get used to the fact that the fuel pump was in the tank. On the classic it was more convenient to remove and repair it. But, in principle, there is nothing complicated here, it just takes longer.

I also had no problems replacing the fuel pump. There are no rusty nuts here. Everything is easy to unscrew and replace.

I couldn’t remove the last eighth nut, it turns (I tried it with pliers and didn’t use any current, but nothing worked. Please advise something useful

Bosh fuel pump for VAZ 2110 – pros and cons performance and characteristics

The manufacturer Bosch produces its own fuel pump for each type of fuel system. Why, after the original fuel pump fails, do people install a Bosch fuel pump from a VAZ 2110? How does the pressure and performance of the fuel pump compare with the original one? If you put it with high pressure, will the flow rate increase?

Consumption does not increase due to the performance of the fuel pump, since on cars the return line is activated and excess fuel is returned to the tank, there is also a fuel pressure regulator, from the name it is clear, I think what function it performs.

Consequently, there was a 2.8 bar pump, they installed a Bosch VAZ 2110 fuel pump with 3.8 bar and it will only get better. Fuel consumption may increase if the fuel pump does not create sufficient pressure in the rail and the injectors begin to pour gasoline, which does not burn, rather than spray.

Photo: Bosh fuel pump is recommended for installation on domestic car models, including the VAZ 2110

Most often, the characteristics of gasoline pumps (not only Bosch, but also from other manufacturers) may differ in length, pressure, location of terminal chips, and that’s it. The fuel pump mesh does not differ in seating, but it may differ in shape.

The chip for the terminal can be remade or supplied from the same VAZ. The length of the fuel pump is important, since its operation depends on this when the fuel level in the tank is low, and if it is in the module, then you need a match to install it.

Replacement

It is necessary that the gasoline level is no more than half the volume of the tank. Next we proceed like this:

- Disconnect the negative battery;

- Removing the back seat;

- Remove the cover from the hatch;

- Disconnect the electrical connector;

- We remove the fuel supply pipe by unscrewing the fitting;

- We do the same with the drain pipe;

- Remove the clamping ring (it is secured with nuts 7);

- Carefully remove the float from the hole in the tank, remove the electric fuel pump along with the fuel level sensor;

- Using a screwdriver, disconnect the fuel level sensor;

- We remove the clamps and remove the fuel pump itself from the guides;

- Reinstalling a new Bosch pump is simple and straightforward.

You just need to consider a few points:

- If you installed not a new, but a refurbished pump on a VAZ injector, lubricate the centering bushings (WD-40 grease is usually used);

- The fuel pump with a fuel sensor is installed in the tank so that the arrow on the flange faces the rear of the car;

- Be sure to check that all o-rings are intact, but it is best to replace them with new ones.

After replacement, start the engine and check what pressure the fuel supply system produces and whether there are any leaks.

How to replace the fuel pump on a VAZ 2110 with your own hands - step-by-step instructions

In order to replace the fuel pump on a VAZ 2110, you must perform the following procedure:

- Disconnect the negative battery terminal;

- Relieve the residual pressure in the fuel rail using a special fitting;

- The “tens” fuel pump is located under the rear seat of the car. We recline the seat and unscrew the protective cover;

- Disconnect the electrical terminal block of the pump, unscrew the fuel supply and drain lines.

- The rubber gaskets for the tips of the lines should be replaced;

- On a VAZ 2112, the fuel pump is held in place by eight bolts on an O-ring with a lining

- All you have to do is remove the old fuel pump and install a new one according to the indicating arrow on the body of the product.

As you can see, removing and installing a fuel pump on a VAZ 2110 is a simple procedure that does not require any special skills from you.

Cleaning the gas tank of VAZ 2110 2112

Solid fractions are constantly deposited in the gas tank of a car. Some of them simply sink to the bottom, others settle and form a kind of hard crust. Both of them clog first the fuel pump filter, and subsequently the fuel filter, which can adversely affect the operation of the carburetor or injector. Accordingly, the car will not only begin to become “dull,” but parts will also wear out much faster. There are a large number of ways in which you can determine the level of contamination of a gas tank, but any specialist will tell you that it needs to be cleaned periodically. At the same time, no liquid will help fully, while removing and cleaning the gas tank will help get rid of deposits and the entry of its fractions into the fuel system. Ideally, this entire procedure for cleaning the VAZ 2110-2112 gas tank should be performed with an assistant, but if he is not there, you will have to “tighten up” a little.

First of all, you need to dismantle the tank itself. To do this, you need to remove the rear seat, unscrew the screws securing the fuel pump cover and remove it. After this, we start the engine so that it selects the remaining gasoline from the fuel system (before this, we turn off the contact group that powers the gas pump itself so that fuel from the tank does not enter the fuel system). Then disconnect the fuel hoses. Unscrew the bolts securing the pressure ring of the VAZ fuel pump and remove it. Now the fuel pump can be removed and set aside. Further work takes place from the bottom of the car. Near the fuel filter, you need to remove the air hose clamp and remove the hose. In the same way, disconnect the hose coming from the filler neck and the pipe that collects fuel vapors. On the side of the fuel supply pipe, on which the fine filter is installed, you need to loosen the bolts of the tight-fitting clamps, and then release the clamps themselves. It is now that an assistant will come in handy - he will help support the tank during the following steps.

After the clamps are released, make sure that the gas tank is not connected to any fitting or hose. Now it can be removed. To do this, you need to move the tank towards the pipe that connects the resonator and the muffler, tilt it and bring it under the brake hoses. Then remove the gas tank from behind the exhaust system pipes and remove it.

First of all, you should remove the remaining gasoline and particles that did not have time to settle at the bottom. To do this, you can simply rinse the tank with any detergent, even dishwashing detergent. After this, it is best to plug all the holes with available materials (rubber plugs, rags, improvised plugs) and pour one of the special tank cleaning products inside (the gas tank should be in the same position as it is on the car). The liquid needs some time to “acidify,” but you can speed up the process in an old-fashioned way: you can pour a large number of foreign metal objects, such as nuts, bolts, washers, small pieces of fittings, etc. into the tank. After this, shake the gas tank well for at least half an hour. This way, most of the plaque will simply be erased. Then drain the “spent” suspension, shake out the remaining “working material” and rinse the tank. It is better to wash with gasoline.

After the gas tank is washed, it is best to blow it out with a compressor - a powerful air flow will remove all settled microparticles. If this is not possible, then you can wash it several times, letting it dry completely. Of course, this process may take 2-3 days, but the result will be obvious - the service life of the fine fuel filter will increase significantly, and the car will respond better to pressing the gas pedal. After the gas tank is cleaned, it must be installed in the reverse order of dismantling. It is advisable to replace the hose and pipe clamps with new ones so as not to look under the bottom again

You should pay attention to the fact that the fitting clamps of the gas tank itself are not the same, so they must be installed in strict accordance with the seats

Flushing a VAZ gas tank yourself, of course, is a labor-intensive process. But this procedure will help you not only save on the services of specialists and spare parts, such as fuel filters, fuel pump mesh, fuel system hoses, but also significantly improve ride quality.

Prevention and useful tips

For trouble-free operation and increasing the life of the fuel pump, professionals recommend:

- refuel only with high-quality fuel;

- maintain the maximum fuel level in the tank;

- do not use a car with a discharged battery;

- promptly replace the fuel filter;

- use sport driving mode less often.

Self-diagnosis and replacement of the fuel pump is quite simple. To do this, you just need to carefully follow the recommendations of professionals. The same applies to preventive measures. Refuel with high-quality gasoline and do not forget to replace the fuel filter on time. Then you will have problems with the fuel pump much less often.

When to replace

Fuel pump in the VAZ 2110/2112: self-diagnosis and replacement

Such minor repairs are made as the grid becomes dirty, which happens quite quickly, given the quality of domestic fuel. The correct approach is to change all consumables at the same time, guided by the frequency of pouring new oil into the engine.

During this procedure, you can replace the air and oil filters, as well as the fuel pump mesh. If you make it a habit to change this mesh only after it is completely clogged, the pump will constantly work with increased load, as a result of which repair or even replacement of the VAZ 2110 fuel pump will quickly be required.

The first sign of a faulty fuel pump is the engine refuses to start. After turning on the ignition, you can hear a slight buzzing sound of the operating gasoline supply device, which stops after it creates the necessary fuel pressure in the system.

If after this the car engine does not start or even the sound of the VAZ 2110 pump cannot be heard, then you need to check the presence of gasoline pressure in the line. This is done using the bleed valve on the ramp. The verification procedure will be discussed below. If there is no fuel, it becomes clear that the fuel pump is not working or its screen is clogged.

Fuel pump fuse VAZ 2115

The fuel pump relay is located under the dashboard. On the passenger side, a side panel is opened that covers the beard on which the radio, on-board vehicle, and heater controls are mounted. We see a strip with three relays and fuses.

The pump relay is the lowest. Its fuse is also at the very bottom. When you turn the key, the relay turns on for 5 seconds in order to pump up pressure in the system and turns off. After the engine starts, control of the pump passes to the computer.

The mass of the pump (and fuel level sensor) is attached to the stud securing the handbrake to the body under the carpet. To get to it you need to remove the vestibule between the passenger and driver seats. There are 3 wires going to the fuel pump. first +, second minus, third fuel level sensor.

Where is

If we describe them from top to bottom, we get the following:

1. The fuse that controls the fuel pump. Its current strength is 15 amperes.

A fuse is a small element whose task in the design of electrical circuits is to melt in the event of an overload. The device melts and the current-carrying circuit opens.

Using the example of a solution from the popular VAZ Priora model, we can superficially examine the design and operating principle of the fuse. The device is small, the outer casing is made of plexiglass.

There is a conductive element inside. Such an element is based on several plates, which are made of different materials. Between these plates there is a special low-melting material. Electricity passes through this material, which allows the fuse to be an integral part of the electrical power circuit of the fuel pump. Fuses have a special marking in the form of the letter F. This designation indicates that the fuse element belongs to a circuit whose power is not large. To calculate the current that certain devices are designed for, you need to divide the power by 220. The result will be a figure in amperes.

If the fuse is blown, then such a malfunction is often caused by the following reasons:

— short circuit in the electrical circuit;

— failure of the fuel pump relay;

- low quality of the fuse itself;

In other words, more often the fuel pump fuse blows due to faults in the electrical circuits or as a result of failure of the components of the pump power circuit. Note that situations also arise when the fuel pump fuse burns on its own, but this phenomenon occurs much less frequently with high-quality elements.

How to identify a malfunction

The fuel pump relay turns on the fuel pump and delivers fuel to the injectors. The safety relay is activated when the engine is not running and the ignition is on (the control unit does not receive speed signals). This relay is switched off in the control unit via a safety switch and interrupts the power supply to the pump. For example, in the event of an accident, gasoline cannot flow into the engine. Checking the fuel pump is a job most likely reserved for service centers. In this regard, to find errors, we will limit ourselves to the following points:

— turn off the ignition;

— disconnect the fuel supply line at the distributor, while preparing a rag for spilled gasoline;

— even when the engine is turned off, a certain amount of gasoline may come out, since the system is under pressure;

— turn on the ignition for a short time without turning on the starter;

— if the pump does not start working, check the fuse or safety relay again;

— if fuel does not flow, check the pump relay;

— if the relays are working properly, the fuel pump should start working;

- otherwise, remove the cover under the rear seat and carefully tap the pump housing with a small hammer - sometimes it helps;

— check the correct connection of the wires to the fuel pump;

- if the pump does not work, check the voltage using a diode bridge (a conventional test lamp can damage the control unit). Don't forget to turn on the ignition first;

- if the voltage is normal, it means the pump is damaged or there is an open circuit. The pump should be replaced with a new one.

Signs of a clogged filter

By indirect signs you can determine whether it is dirty, but it is not always possible to reliably find out about its condition without visually assessing the mesh.

Signs of a dirty filter:

- The car accelerates poorly;

- There is no necessary dynamics;

- Unstable idle;

- The engine starts poorly and stalls;

- Increased engine vibrations;

Based on the signs already stated above, you should begin inspecting the fuel system and be sure to start with coarse and fine filters. You can read how to replace the fine filter here.

Also, if the mesh is very dirty, the fuel pump itself may fail. Therefore, it is not recommended to neglect its replacement.

Auto Reviews - VAZ-2110-12 Diagnostics of fuel pump and injectors

Diagnosis of faults, repair and replacement of the oil pump VAZ 2110-12 with your own hands

The April issue of the magazine “Behind the Wheel” showed ways to check the electrical circuit of the fuel pump on a VAZ-2110...2112. We will assume that it is working properly: the pump hums as usual. But does this mean that gasoline flows normally to the injectors? No! This is where problems can occur.

fuel pump and injectors VAZ-2110-12″ w >

Let's start with the simplest. Remove the protective cap of the fitting (photo 1),

put a rag underneath so as not to spray the engine compartment with gasoline, and use the blade of a thin slotted screwdriver to press on the spool of the fitting. A thin, weak stream of gasoline indicates low pressure in the fuel rail - you will have to look for the reason. If gasoline sprays with good pressure, there is hope that the pressure is close to normal (2.8–3.2 bar), all that remains is to measure it with a pressure gauge. Service specialists do this using fuel pressure gauges with adapters. We will use a simple one, from a tire pump

It is only important that the measurement limit is at least four bar. You will also need a piece of gas-resistant hose 150 mm long with an internal diameter of 10–12 mm, and two clamps for it

Using the wheel valve cap, unscrew the spool valve from the fuel rail fitting (the pressure has already been released) (photo 2).

We put the pressure gauge hose on the fitting and tighten it with a clamp. We turn on the ignition without starting the engine: after two seconds, the fuel pressure in the ramp should rise to 2.8–3.2 bar and stabilize at this level (photo 3).

If it is significantly lower (about 1 bar) and remains this way for a long time, you need to check the supply line 4 (see figure) - most likely, it is clogged. There are two problem areas here: fuel filter 5 and fuel pump mesh 2.

Let's check the filter first. It is located under the underbody near the gas tank (photo 4).

If it's ok, let's look at the pump grid. We take out the fuel pump from the tank, remove the screen and wash it. Before installing the fuel pump, it is very useful to check the tightness and reliability of the connection of its tube (arrow in photo 5)

to the fuel line. You will, of course, ask what to do if the supply line is clean, the pump is humming, and the pressure is low. Change the pump! It's worn out. And it also happens that the pump is working, but there is no pressure at all! This happens in winter if there is a lot of water at the bottom of the gas tank. If it freezes on the pump grid, it will interrupt the flow of gasoline into it. What to do? Under no circumstances should you light a fire under the gas tank or heat it with a blowtorch or other source of fire. It is better to remove the fuel pump and clear it of ice. Another option is for those in no hurry: roll the car into a warm room and wait... By the way, in this case it makes sense to drain the water from the gas tank at the same time. It's a troublesome task, but rewarding.

But now we are convinced that the pressure in the ramp is normal. Does gasoline enter the engine cylinders? This is not a fact! The injectors may become clogged, the fuel supply will decrease, or even stop completely. But sometimes the injectors do not receive a control signal, although they themselves are working.

We begin the control by inspecting the spark plugs. Wet means fuel is flowing. Dry. Then we’ll check the signal at the injector harness connector with a probe (photo 6).

Yes, are the spark plugs dry? You will have to unscrew the screws securing the ramp and lift it under the intake manifold so that the injector nozzles become visible. Turn on the ignition and turn the engine crankshaft with the starter. Can't see the streams of gasoline? This means you will have to remove the injectors and, most likely, replace them with new ones. True, almost every serious service provider will offer to rinse them. Take an interest in the prices: if a new set of injectors is a little more expensive than washing, you should give preference to replacement. After all, old injectors also have age-related diseases.

Related news

Download VAZ-2110-12 Diagnostics of the fuel pump and injectors Mirror VAZ-2110-12 Diagnostics of the fuel pump and injectors Mirror VAZ-2110-12 Diagnostics of the fuel pump and injectors Mirror VAZ-2110-12 Diagnostics of the fuel pump and injectors Like the material, click on the button News Media2

Discuss on the forum

Master node of the system

The VAZ-2110 fuel pump is equipped with an electric drive. Its body is lowered into the fuel tank. Gasoline is both a pumpable fuel and a coolant. It should be remembered that traveling with an empty tank is fraught with overheating of the VAZ-2110 injector fuel pump.

This electrical device is an independent unit. Accordingly, its operation does not depend on the state of other mechanisms. A necessary condition for rotating the VAZ-2110 fuel pump rotor is maintaining normal voltage on the on-board network.

The voltage comes through the ignition switch. When the key is moved to position 1, the circuit is closed to turn on the drive. The VAZ fuel pump fills the fuel rail. The engine is ready to start.

If symptoms of poor fuel system performance occur, the pump should be checked. We list the signs that make it possible to replace the VAZ-2110 fuel pump:

First of all, a hearing test is performed. After turning the ignition key to position No. 1, there should be a noise under the rear seat. The sound lasts for a couple of seconds. This means that the pump has pumped up the required pressure.