Replacement of front supports and support bearings.

Good day, Friends!

Last trip to the village (665km from KZN)

, unfortunately, did not go unnoticed either for me or the car. On the way back, when the car “swallowed deep bumps in the road” at speed, the left front wheel rubbed against the edge of the wing locker, as a result, the rubber “eaten up” a little.

At the next maintenance

We inspected the chassis, but didn’t find anything critical until we paid attention to the amorik rod - there were pieces of debris hanging on it, reminiscent of a shock absorber bump stop.

My front amorics are still factory and have not yet asked for replacement, so I decided not to touch them! Sachs front bump stops.

—

Cat.No. 900187

.

Well, since I’m going to climb there, I took INA

—

cat. No. 713001100

, they are the ones that come originally from the factory, and

PH

—

cat. No. 96549921

or

1011BAFAA0

When replacing the supports, I noticed the “reinforced” MEYLE HD

, which I installed together with

the steering rack

- the racks covered a little more than 39,000 km.

And in defense of MEYLE HD

I will say that the same stand, whose boot was accidentally torn during installation, survived two winters and, surprisingly, is still alive, despite its appearance!

But let's return to the main topic of the post:

We started on the right side, replaced the bearing and support, and also installed a new bump stop, although the original one was still in good condition.

But the left Amorik’s bump stop was, to put it mildly, “tired.” The supports were also already sagging, the supports were rusty, but relatively alive, although they crunched a little...

Source

Chevrolet Cruze

The balance between handling and comfort in the Cruze is shifted towards the latter. Its chassis has no more sportiness in its genome than vitamin C in chicken soup. The suspension is rather tuned for comfortable and leisurely movement in space. But the Cruze's handling is immeasurably better than its predecessor.

The Cruze is moderately rolly, but steers accurately. In the zero zone there is plenty of information on the rim. But, unfortunately, that’s all it is. As soon as you turn the steering wheel a little, not a trace remains of this information, first there is a noticeable step in the force, then the hydraulic booster is abruptly engaged and the steering wheel falls in the direction of rotation. The steering turns out to be discrete; in order to change the trajectory smoothly, you need to get used to it.

Replacement of the ENTIRE Lacetti SW suspension with part numbers + useful information on parameters and replacements

Already at the time of purchasing the car on 07.2016 with a mileage of 75tkm on foreign Krasnodar roads there were big complaints about the suspension. Now, after a year, it has become impossible to ride comfortably. From the arch to the wheel axle in the front it was 355mm, in the rear it was 362mm, the car was lying almost helplessly on its belly, the front right shock absorber had completely leaked.

1. THEORY

1.1 SELECTION OF COMPONENTS

It all started with selecting the correct part numbers for your car according to your VIN, I once again used

the CHEVROLET EUROPE EPC 2012/06 catalog

.

I would like to draw your attention to the fact that NOT ALL PARTS FOR SEDANS/HATCHES FIT THE ARTICLE NUMBERS FOR STATION ESTATES!

For some reason, many people install struts and springs from sedans/hatches and then are “surprised” by the result... Very few manufacturers make suspension parts specifically for cars; the choice of these manufacturers is extremely small.

And one more thing - the given part numbers are suitable for all station wagons, regardless of the year of manufacture, that is, for the entire production period of 2005-2012, GM did not make any changes to the suspension parts, but only changed the part numbers.

Original part numbers for the front suspension of Chevrolet Lacetti SW 2005-2012

(the main parts subject to wear, aging and failure are listed)

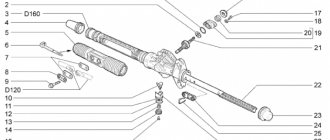

04 — 96549921 — SUPPORT 05 — 94535236 — SUPPORT BEARING (the same INA F-225479 are inside) 06 — 96498780 — SHOCK ABSORBER STRUT CASE ASSEMBLY 07 — 96498781 — SUPPORT PLATFORM 08 — 9630 0082 — SHOCK ABSORBER STRUT CASE 09 — 94580660 — UPPER SUPPORT GASKET 10 — 96549925 — BAMPLER 11 — 96561767 — FRONT SPRING for manual transmission (for sedan/hatch — 96407751) 11 — 96561768 — FRONT SPRING for automatic transmission (for sedan/hatch — 96407752, 964157 32, 96415733) 12 — 96549919 — LOWER SUPPORT PAD 13 — 96561721 — FRONT LEFT SHOCK ABSORBER STRUT (for sedan/hatch — 96407819) 13 — 96561722 — FRONT RIGHT SHOCK ABSORBER STRUT (for sedan/hatch — 96407820) ————————————————————— ————— 02 — 96490218 — BALL SUPPORT FOR FRONT ARM 05 — 96399710 — FRONT STABILIZER 09 — 96839849 — STABILIZER BUSHING 13 — 96378346 — FRONT BUSHING BLOCK 18 — 964 03099 — FRONT LEFT STABILIZER STRUCTURE 18 — 96403100 — FRONT RIGHT STABILIZER STRUCTURE 31 — 96391856 — REAR SILENT BLOCK

Original part numbers for the rear suspension of Chevrolet Lacetti SW 2005-2012

(the main parts subject to wear, aging and failure are listed)

03 - 94515455 - NUT (disposable!) 04 - 96407217 - STRUT MOUNTING 05 - 96457423 - UPPER GASKET 06 - 96407219 - REAR SPRING (for sedan/hatch - 96415734 96417016) 0 7 - 96408290 - LOWER GASKET 09 - 96549918 - CHAMPLER 10 - 96408640 — REAR LEFT SHOCK ABSORBER STRUT (for sedan/hatch — 96407821) 10 — 96408641 — REAR RIGHT SHOCK ABSORBER STRUCTURE (for sedan/hatch — 96407822) ————————————————————— ————— 06 — 96412670 — REAR STABILIZER 07 — 96933804 — STABILIZER BUSHING 11 — 96561754 — REAR STABILIZER STRUCTURE

When I started counting how much all these original parts cost and on half of the parts I saw the amount was more than 30,000 rubles - I didn’t even count further (fainting didn’t do me any good). Therefore, we delve deeper into the search for crosses from normal, high-quality manufacturers. The choice of one manufacturer or another is a matter of taste, worldview and habit.

As a result, my list began to look like this:

04 - SACHS 803000 - 2 pieces for 455 rubles (made in China) 05 - SACHS 801015 - 2 pieces for 200 rubles (made in Germany, inside are the same INA F-225479 that come from the factory) 10 - ROSTECO 20479 - 2 pieces for 200 rubles 11 - FENOX 15039 - 2 pieces for 1150 rubles 13 - FENOX A61200 - 1 piece for 1755 rubles 13 - FENOX A61201 - 1 piece for 1755 rubles 09 - GM 96839849 - 2 pieces for 130 rubles 18 - JustDrive JSL0002L and JSL0002R - 2 pieces for 186 rubles ( made in China) ————— ————————————— 03 — KIA 1339608007K — 6 pieces for 9 rubles 06 — FENOX SPR15040 — 2 pieces for 967 rubles 07 — GM 96408290 — 2 pieces for 148 rubles 09 — ROSTECO 20491 — 2 pieces for 187 rubles 10 — FENOX A62120 — 1 piece for 1623 rubles 10 - FENOX A62121 - 1 piece for 1623 rubles 07 - GM 96933804 - 2 pieces for 126 rubles 11 - GMB 10120095 - 2 pieces for 275 rubles (made in Japan)

TOTAL - 14860 rubles

Source

Symptoms and troubleshooting of the shock absorber strut

Faulty suspension parts produce squeaks and dull knocks when driving on uneven roads. To determine the health of the node, you need to:

- Drive 10–15 kilometers.

- Stop on level ground.

- Rock the front and rear of the car, pressing hard on the hood and trunk lid. If the body swings more than 1 time up and 1 time down after the swing stops, then the racks are faulty.

- Rock the car, pressing hard on the fender or rear roof support from each side of the fender to determine which part has failed.

Replacement of front supports! Gap correction!

I came across a post about replacing the front supports, and what a gap there should be between the buffer and the glass! I looked at mine and was horrified.

New supports (PH) and bearings (INA) were immediately purchased, as well as a pair of new original bolts and all the nuts.

Catalog numbers: Upper nut 94515070 Support nut 94515420 Front support 96549921 Bearing 94535236 Bolt 94500712

And the disassembly process began, I’ll immediately say the supports (SACHS), bearings (INA), bump stops, struts (SACHS), shock absorbers and springs (KYB) were changed a year ago (Mileage 14,800) And this is the first thing that was done after buying the car, so I immediately I didn’t pay attention to the gap between the buffer and the glass (I didn’t know what it should be)

I took out the supports and compared them with the new ones.

The supports sank by 1mm, which means it’s not them. And then the nut, or rather its height, catches your eye! Compare with the original

As it turned out, the nuts that came with the racks were screwed on!

Put everything back together and voila!

Everything is fixed! Maybe there was a rush, or maybe the lack of attention of the former owner (last year we collected everything the same way as it was), there’s no way to know!

Source

Chevrolet Lacetti rear suspension

Rear suspension elements: 1 — front wishbone; 2 — rubber cushion of anti-roll bar; 3 — anti-roll bar bracket; 4 — trailing arm bracket; 5 — trailing arm; 6 — stabilizer bar; 7 — hub assembly with bearing and wheel speed sensor; 8 - fist; 9 — shock absorber strut; 10 — rear wishbone; 11 — subframe; 12 — anti-roll bar.

Elements of the rear suspension on the car: 1 - subframe; 2 — rear wishbone; 3 — front wishbone; 4 — shock absorber strut spring; 5 — telescopic stand; 6 — stabilizer bar; 7 - fist; 8 — trailing arm; 9 — bracket; 10 - bracket; 11 — anti-roll bar

The rear suspension is independent, mounted on a subframe. Each wheel is suspended on a longitudinal and two wishbones, the shock absorber and spring are installed coaxially, forming a telescopic shock absorber strut that allows the rear wheel to move up and down when driving over uneven surfaces and at the same time dampen body vibrations. The anti-roll bar reduces vehicle roll. The shock absorber strut consists of a telescopic strut in which a double-acting hydraulic gas-filled shock absorber is installed, a cylindrical coil spring, a compression stroke buffer and an upper rubber-metal support. The spring rests on the spring cups through rubber gaskets. The shock absorber rod is connected to the upper support, which is attached to the rear wheel arch using three nuts. Due to its elasticity, the support allows the strut to swing during suspension movements and dampens vibrations when driving over small irregularities.

Elements of the shock absorber strut: 1 - telescopic strut; 2 — compression stroke buffer; 3 — protective cover; 4 - plug; 5 — rod fastening nut; 6 — upper support of the rack; 7 — upper spring cup; 8 — upper spring gasket; 9 - spring; 10 - lower spring gasket

A bracket is welded to the bottom of the strut housing for attachment to the forged rear suspension knuckle. The cylindrical collar of the hub fits into the knuckle socket, and its flange is bolted to the knuckle flange.

The hub is a one-piece unit with a bearing and a wheel speed sensor for the anti-lock brake system. Braking forces when the car is moving are perceived by the trailing arms, and forces in the direction perpendicular to the longitudinal axis of the car are perceived by the transverse arms of the suspension. To ensure the mobility of the levers in connections with the body and knuckles, silent blocks are pressed into the eyelets of the levers. The front end of the trailing arm is attached to a bracket fixed to the body, and the rear end is attached to the eye of the knuckle. Each wishbone is attached at one end to the knuckle eye, and at the other to a subframe mounted on the body. The bolt securing the front wishbone to the subframe has an eccentric collar and an eccentric washer, and the hole in the subframe for the bolt is oval. When the bolt is turned, the position of the lever relative to the subframe changes, thereby adjusting the wheel toe. To increase lateral stability and reduce vehicle roll angles, a stabilizer bar is installed. The stabilizer bar in its middle part is attached with brackets through rubber split pads to the body. The rods of the stabilizer struts are made of polymer material, and ball joints are made at the ends of the rods. Stabilizer struts connect the ends of the stabilizer bar to the bodies of the telescopic struts. Elements of the rear suspension on the car: 1 - subframe; 2 — rear wishbone; 3 — front wishbone; 4 — shock absorber strut spring; 5 — telescopic stand; 6 — stabilizer bar; 7 - fist; 8 — trailing arm; 9 — bracket; 10 - bracket; 11 — anti-roll bar. Elements of the shock absorber strut: 1 - telescopic strut; 2 — compression stroke buffer; 3 — protective cover; 4 - plug; 5 — rod fastening nut; 6 — upper support of the rack; 7 — upper spring cup; 8 — upper spring gasket; 9 - spring; 10 - lower spring gasket.

Opel strut supports on Lacetti + Fenox condition after 25,000 km

In October 2022, I changed all the parts of the carriage suspension - Replacement of the ENTIRE Lacetti SW suspension with part numbers + useful information on parameters and substitutes

. Almost two years and 25,000 km have passed since then. Yesterday I had a reason to shake up the front suspension, and at the same time evaluate the condition of its parts.

And after such a period of time I can say: - Fenox A61200 / A61201 racks

— excellent, almost no complaints;

— Fenox 15039 springs

— any complaints;

— supports SACHS 803000

— I have some complaints (because of the supports I went into the front suspension).

— JustDrive JSL0002L / JSL0002R stabilizer bars

are just crap, I don’t even want to evaluate them, I replaced them exactly a year later (I installed reinforced

Meyle 29160600007HD / 29160600008HD

, which to this day work without complaints).

After less than two years, the supports sank a little. Unpleasant jolts/knocks appeared. So Niyaz received a legitimate opportunity to switch to Opel front shock absorber supports

))))) Now about everything in more detail.

A year ago, I started seeing records of the transition to miracle supports from Vectra B, Opel G, Zafira A and the like. The discoverer (at least on Drive before I recorded it) was Senya-pl - Front strut supports from OPEL

.

A few months later, interest was fueled by Pavka

pachyk -

Front strut supports from OPEL

.

Then Vinni303 - Opel + Lacheti.

Replacing front supports from Opel to Lacetti Indeed, Opel supports are made with a greater margin of safety and are free from the disadvantages of Lacetti supports: - a larger rubber section slows down or completely eliminates subsidence of the support; — the support bearing is pressed into the support body, which eliminates the mobility of the glass.

Anatoly for the visual photo of these spacer rings

tolik89rus

Niyaz grabbed his head and began to delve into the essence of the problem. But there were two problems: - there are soft and hard supports; - the guys were chasing savings (and took the “soft” LEMFORDER and similar slag).

Additional confirmation is provided by the records of Opelovodov (for example x16xel -

Shock absorber supports

).

So you shouldn’t say unequivocally that “Opel supports = feces” if you yourself installed the wrong parts.

SOFT AND HARD SUPPORTS OPEL

When I started digging into the topic, I found out that there are two types of supports - soft and hard.

I even wrote a post in the Opelovodov thread. Question about the soft and hard design of the Opel front strut support.

The difference is with a larger rubber collar (thickening of the section of the rubber casting). Hard ones were installed on diesel cars (they have more mass, soft supports would sag too quickly)

An attentive reader will probably see that only SWAG separates the article numbers for hard and soft supports; the rest of the manufacturers don’t care about the lantern. And indeed, until a certain year, SWAG packages contained exactly the original supports that were in Opel packages, but were much cheaper. But for about two years now, FEBI has been included in SWAG.

As a result, my list of parts turned out like this: - Opel 344525 / GM 90538936 - Opel 312510 / GM 90468618 - Teknorot ST20 - GM 94515420 and 94515070 2 pcs each

By the way, one of the suppliers still has an offer for two GM Opel supports 0344525 for 550 rubles. I ordered them, but instead of the original they brought out FEBI in a bag with an article number written in marker. Passed. Don't buy, don't waste your time. Current prices for original rigid supports Opel 344525 / GM 90538936 - 2000-2200 rubles. I have an extra pair of the original rigid supports. To anyone who wants to get rid of sagging supports forever, I’ll give them a pair for 2,800 rubles.

Source

Knock Lacetti

As it turned out, Lacetti knocking in the suspension is not a rare problem. But I found the cause of the knocking and got rid of it.

Sounding Knock Lacetti

The problem turned out to be, oddly enough, not in the suspension, but in the braking system. Or rather, in the brake pads of the rear left wheel. Moreover, the knocking was detected only when I hung the wheel. One block had very little play, but it was very loud. To test my guesses, I inserted an ordinary match into the gap and took it for a test ride.

The sound of Lacetti pads. Gap location

If your wheel gets hot or you have problems with your brakes, check out this useful article.