Diagnostics of silent blocks in the front control arms.

Why do silent blocks need to be changed over time? There are several reasons for this:

- Over time, rubber loses its elastic properties and begins to crack.

- During use of the machine or during its maintenance, oil got onto the silent block.

- Incorrect installation of the part.

- Driving on very bad roads, of which there are a great many in Russia.

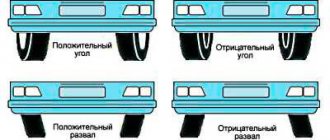

Everything is diagnosed quite simply. The first thing that should alert you is the deterioration in the responsiveness of the steering wheel. But this may not be the case only, let’s look further. The second sign of dead silents, the wheels are standing like a house. On the pit or on the lift, check the integrity of the rubber bands (they should not have cracks and they should not be squeezed out). You can take a crowbar or a pry bar and try to move the levers. They should not have free movement (should not dangle).

Replacing silent blocks in the upper control arm of a classic with your own hands.

So, let's begin! In rear-wheel drive VAZs, the silent blocks in the upper arm can be changed without even driving into a hole and without removing the arm from the ball (provided that you have a remover for silent blocks). But first you need to determine whether the bushings of the silent blocks are stuck to the bolt securing the lever to the body. To do this, jack up the car and remove the wheel.

Arrows point to bolt and nut

We loosen the nut securing the upper arm with a 22mm wrench and try to turn the bolt. If it spins and the bushings stay in place, then you're in luck! But if this bolt rotates with great force and the bushings rotate with them, then as they say: “Houston, we have problems!” Next we will consider both cases.

If the silent blocks are not stuck.

Further actions depend on whether you have a puller for silent blocks. If there is one, then you don’t have to remove the lever completely, but just unscrew the nut 22 to the end, take out the bolt and turn the lever towards yourself (for the convenience of further repairs).

We turn the lever for convenience.

Next, take a puller and press out the silent blocks.

Removing the silent block using a puller

And with his help we press in new silent blocks. Before pressing, the mounting hole must be cleaned and preferably lubricated with lithol. In the upper arms, silent blocks are pressed into place up to the ribs, as shown in the photo below.

The new silent should be pressed in exactly like this.

But what to do if you don’t have a silent block remover ? Then you will have to completely remove the lever. We take out not only the bolt securing the upper arm to the body, but also take out the ball from the hub (this is faster than unscrewing 3 bolts securing the ball to the arm). Detailed removal of the ball joint is written here.

We removed the lever, put the lever ear on a pipe or on a yew tree (as in the photo), the main thing is that the silent block does not rest against anything, and knock it out with a hammer.

To press in new ones, we need a mandrel (old bearing, piece of pipe, nut head). The inner diameter of the mandrel must be equal to the diameter of the skirt of the new silent block. And we begin pressing in new parts using this mandrel, having previously lubricated the seat with lithol. Reassemble in reverse order.

Important: we pull the bolt securing the lever to the body only under the load on this wheel! Those. The car should not be on a jack, but on all wheels!

If the silent blocks are stuck to the bolt.

This is a very difficult case, since you will have to spend a long time trying to get the bolt that secures the front upper arm to the body.

For those who want to save themselves a lot of time and are ready to fork out a little, I advise you to buy a new bolt, this lever from disassembly and just cut off the old bolt with a grinder.

Well, if you have time and nerves, then we take a gas burner in our hands and burn out the silent block. Follow fire safety precautions! After all the rubber has burned out, you can begin to knock out the bolt. Get ready to do this for a very long time. After you remove the bolt, knock out the remaining clip of the burnt silent tape from the lever and follow the instructions written above.

Replacing silent blocks in the lower arm of a VAZ 2107, classic.

Here, when replacing, we can no longer do without an inspection hole or a lift.

To begin, use a 24mm wrench to unscrew the nuts securing the lever. Next, if you have a puller, then use it to press out the silent blocks. If there is no special puller, then we simply take a mandrel with a diameter larger than the diameter of the silent block. We set the mandrel as shown in the photo and hit it with a hammer. At the same time, we rest the lever using a mounting tool or a crowbar, as in the photo. Thus, we remove the silent blocks in the lower arms.

Remove silent blocks without a puller

How to remove stuck silent blocks in the lower front control arm.

Stuck silent blocks cause a lot of trouble when removing them. In order to get rid of them you need a gas torch and a hammer with a core. We burn out the rubber and tap the iron bushings on all sides. After that we try to knock them out using a core and a hammer.

If the nuts securing the lever shaft are not stuck, then it is better to completely remove the lever (this will make it easier to knock the bushings out of the shaft). To do this, you will also need to remove the ball from the hub. Above in the article there is a link on how to remove the ball joints.

Pressing silent blocks into the lower arm.

New silent blocks are pressed into the lever until it stops. This can be done using a puller or a mandrel of a suitable diameter; you can use a head as a mandrel.

After installing the new levers, tighten the nuts and release the car onto the wheels. Only after this do we fully tighten the nuts.

Of course, it will be clearer to see how everything is done once than to read it a hundred times. Especially for you, I am attaching a video about replacing silent blocks in the front arms of a rear-wheel drive VAZ.

Replacing the upper silent blocks

First of all, you should unscrew the vertical bolt securing the bumper, as it will interfere with removing the axle. Next, unscrew the nut securing the ball joint and, using a special puller, press the ball pin out of the bipod.

After that, using two 22mm wrenches, twist the nut and remove the bolt securing the upper arm to the body. Now we will need a puller. Having clamped the removed part in a vice, use a puller to press out the old parts, and press new ones, polyurethane or rubber, in their place.

After the replacement is made, assembly is carried out in the reverse order:

- The lever fastening bolt is inserted and the nut is screwed on. You shouldn’t tighten it completely, we’ll do it at the very end;

- The ball joint is installed in place, the nut is tightened until it stops;

- The wheel is screwed on, the car is lowered and removed from the jack;

- Having turned the steering wheel, tighten the upper arm securing nut until it stops.

How to adjust the front bearings?

Very often the front bearings on the front suspension of a car break. It is advisable to inspect them every 10,000 km. Diagnostics and configuration are as follows:

- Use a jack to hang the wheel.

- Remove the dust cap.

- Unlock the nut on the hub.

- Using a 27 wrench, you need to tighten or unscrew the nut.

Please note that you should not use too much force when tightening. Once you have tightened the hub nut all the way, you need to turn it back 60 degrees and fix it by knocking off the edge of the nut with a hammer

The bearings have a cone shape, so if the permissible tightening torque is exceeded, they are destroyed. But they can easily withstand heavy loads, since the rollers and the holder have a very large contact area.

Replacing the lower silent blocks

Changing silent blocks on the lower arm of a VAZ 2107 is somewhat more difficult. All work is carried out directly on the car.

- Unscrew both nuts securing the lever;

- We screw the puller onto one side and squeeze out the silent block;

- We perform a similar operation on the opposite side;

- We install new polyurethane silent blocks one by one and press them into the lower arm using a puller;

- Install the thrust washers and screw on the self-locking nuts, not completely;

- We fasten the wheel and remove the car from the jack;

- Tighten the lower arm mounting nuts until they stop.

In this work, the puller plays an important role, since without it it is practically impossible to complete the work without removing the lower arm.

Since your safety directly depends on the serviceability of the VAZ 2107 chassis, periodic diagnostics and replacement of failed elements are necessary. To do this, it is advisable to purchase the most popular pullers, namely:

- Ball joints;

- Silent blocks;

- Tie rod ends.

Thanks to them, repairing the chassis of your VAZ 2107 will not cause any difficulties. And the use of high-quality components will ensure your safety for a long time. It is for these reasons that polyurethane silent blocks are recommended for installation.

How to replace silent blocks on a VAZ 2107

Replacing the silent blocks of the front levers on VAZ 2101 - 2107 cars is not an easy task. However, they still need to be changed from time to time, and most car enthusiasts have learned to do this without much difficulty. A special universal puller will help to significantly simplify this work. It is with its help that both the upper and lower silent blocks are replaced.

So, you have come to the conclusion that it is time to replace the silent blocks. You should start by purchasing them. Today there are many domestic and imported products on the auto parts market. They differ from each other in price, quality, and service life. Experts recommend installing polyurethane ones as the most reliable and durable, however, due to the fairly high price, they are not affordable for everyone.

For the replacement process itself, it does not matter at all whether the silent blocks are polyurethane or rubber; they are changed on the VAZ 2107 in exactly the same way. From the tool you will need:

- Silent block remover;

- Ball joint remover;

- Keys for 13, 22, 24;

- Hammer;

- Chisel;

- Mount;

- Penetrating lubricant (eg WD-40).

You should start by hanging the front end on a jack and removing the front wheel. Next, we proceed directly to the replacement procedure. For the upper and lower front arms of the VAZ 2107, the order of work is different, so we will consider both options. To simplify the work, it is recommended to pre-treat all threaded connections of the levers with penetrating lubricant.

- Replacing the upper silent blocks

- Replacing the lower silent blocks

- Security measures

Auto repair school - Do-it-yourself car repair

Aug 2, 2016 VAZ 2101, VAZ 2102, VAZ 2105, VAZ 2106, VAZ 2107, Zhiguli, Classic by admin

If on your kopeck, six or seven , when starting from a stop or driving on an uneven road, a knocking sound appeared in the area of the rear axle and along with it the rear axle of the car lost stability, then it’s time to check the condition and, if necessary, replace the bushings of the rear rods (reactive rods ) . Of course, you can take an easier route. And replace jet thrust . But this path, although easy, is not cheap. You can compare the price of a repair kit (metal and rubber bushings) for reaction rods and the price for a complete set of reaction rods. I think you will notice the difference. And why pay more if it's not necessary? If the reaction rods are normal (not broken, not bent, the lugs are not broken), then you can simply replace the rubber bushings. Yes, and if you figure it out, it won’t be difficult for you to do this. All that is required from you is the desire to do the work yourself and prepare the tools and accessories that are necessary for the work.

First of all, about spare parts. You can immediately buy a set of rubber and metal bushings . A standard set of rubber bushings for cars VAZ-2101, VAZ-21011, VAZ-2102, VAZ-2103, VAZ-2104, VAZ-2105, VAZ-2106, VAZ-2107 consists of 10 pieces, four large and six small. But I can advise you to buy a set of rubber bushings for the VAZ-2121 (Niva) , in this set all the bushings are equally large. Pressing them in is not much more difficult, but they can withstand the load better than standard ones. We also make sure to buy a set (10 pieces) of metal bushings (the old ones are often very worn out) - four large and six small. What do the rubber and metal bushings look like (pay attention to the color of the metal bushings, that’s the color we buy) look at photos No. 2. Of course, it’s better to buy new fasteners (bolts and nuts) too (especially if no one has worked on jet rods for a long time ), but here at your discretion or at the discretion of your wallet. Plus, you should buy a set of rubber bushings for the rear shock absorbers .

As for the tool... Here you will need to have, at a minimum: two 19mm spanners, a hammer, a metal rod (useful for knocking out bolts when removing rods). But you will have to think about the devices for pressing out and pressing in the bushings in advance (since work without them will be much more complicated). You can either make them yourself (take a bolt of the appropriate diameter, screw on the nut and grind it to the size of the outer diameter of the metal sleeve) or buy (or order a turner) a ready-made tool (see photo No. 3 for what it looks like). Also, having a vice will make the work much easier.

Further point by point (for example, we are considering the removal and repair of a short jet rod . To remove a long rod , you will also have to unscrew the lower fastener of the rear shock absorber):

1. Unscrew the nuts and remove (or knock out) the mounting bolts (photo No. 1). Let's relieve the traction.

2. If at one end of the rod the metal bushing can fall out on its own (photo No. 4), then at the other end the bushing will have to be knocked out using our pre-prepared device. (Photo No. 5). And, for example, we use a screwdriver to pry out the rubber bushing (photo No. 6).

3. Use a knife to clean the inside of the traction eye (photo No. 7).

4. Using a vice, press the rubber bushing into the rod , having first lubricated it and the rod eye with soapy water (photo No. 8). Precisely with a soap solution and in no case using oil, since the bushings are NOT made from oil-gasoline resistant rubber. And by lubricating them with oil, you will shorten their service life.

5. After this, using a “special tool” we press in the metal sleeve , also lubricating it with soapy water, see photos No. 9 and No. 10. In the absence of a “special tool”, a metal bushing, just like a rubber bushing , can be pressed into a vice.

That's all! We carry out the same procedure with other rear links . When installing jet rods on a car , it is better to lubricate the mounting bolts, for example, with nigrol. Otherwise, the next repair of jet rods will turn into an exam in the skill of using an angle grinder!))

UPD 01/05/2016

Please love and favor - SEVI-Extreme torque rod bushings for VAZ-2101, VAZ-2102, VAZ-2104, VAZ-2105, VAZ-2106, VAZ-2107 cars manufactured by SEVI . I won’t be afraid to speak loudly and say that these bushings are the best of all possible options for jet rod bushings for the Classic . I can say this with confidence, because as soon as these bushings appeared on the car market, I bought them and immediately installed them on my own dime. You can call this a pioneer experiment. In the photos below you can see in what packaging they were sold at first (initially the bushings were called SEVI-Spike ) and in what box these bushings can be found today. Plus, a photo of the kit. And to say that I was surprised by the result of the experiment would not be correct. That's right - I was shocked! Yes, I had to tinker with pressing the bushings, but the result was simply amazing. The comfort that appeared in the rear axle of the car is difficult to describe in words. The rear of the car has become more solid and stable. The amount of noise transmitted from the car suspension to the body has been significantly reduced. Plus, you can add to this the high wear resistance of these bushings - for example, on my car they worked steadily for almost 30,000 km . And none of the bushings failed. I can’t say exactly how long they lasted, since the car was sold.

After the tests, in my own car, it was the clients’ turn. Not everyone, however, agreed to install rubber-metal bushings for SEVI-Extreme jet rods. Since the price of a set of these bushings upset even the most fanatical car enthusiast, who doted on his iron friend and never spared money on its maintenance and repair. To make it clearer: the price of a set of these super bushings was (and is) equal to the price of a complete set of Chinese-made reaction rods. Or -60% of the cost of factory jet rods (rods) produced in Balakovo . Something to think about...

But, despite the price issue, I have already managed to install these bushings on about a dozen cars. All car owners are happy and do not regret the money they spent.

That's why I recommend it to you! nothing complicated about installing SEVI-Extreme jet rod bushings . Everything is the same as when working with standard bushings. But, there are some small features: the tie rod eyes of your car must be in good condition - not broken or destroyed by rust. Before pressing in the bushings, the eyes of the rods (rods) should be thoroughly cleaned. And only after that you can begin the installation. A bench vise is a must! We treat the eyelet and bushing with a soapy solution. And slowly we begin to press it in.

This is how it was:

Here it is:

There is nothing complicated, as I said. The main thing is that the eyes are cleaned and do not fall apart from rust in your hands. And the result should please you. I would be glad if you share your impressions or your opinion about SEVI-Extreme bushings in the comments .

When using an article or photographs, an active direct hyperlink to the website www.avtorem.info is required!

Did you like the article? Share it on your page!

Preparing instruments for the replacement procedure

Replacing VAZ 2106 silent blocks begins with the acquisition and preparation of tools. The main thing is that the tool fits in size and is comfortable to use. So, in order to replace the silent block, you will need:

- Device for changing rubber-metal hinge.

- Ball joint remover (for removing the upper arm).

- Tool for dismantling the steering wheel end (an irreplaceable thing when unpressing the distant steering wheel ends).

- Jack.

- Twenty-two and twenty-four millimeter wrenches (open-end, socket).

- Thirteen millimeter wrench (cross-cut, socket).

- Set of mounts.

- Hammer.

- A thin chisel (it must be very sharp, since the lower silent blocks are often glued to the lower arm under pressure, and to avoid removing the arm, you can use a chisel).

Since silent blocks play a very important role in the life of a car, and changing them is a rather complex and time-consuming process, there is no need to try to save money - you need to buy high-quality branded hinges. Don't know which one to take, rubber or polyurethane? Preferably polyurethane ones, but it should be noted that they are not cheap.

Replacing the rubber-metal joint of the lower arm without disassembling the suspension

The sequence of replacing the rubber-metal hinge

lower arm:

- Using a twenty-two millimeter wrench, we unscrew the fastening nut of the lower arm.

- We use a special puller and press the hinge out of the seat. This is where it came in handy that the steering tip had been removed in advance, since otherwise it would not have been possible to bring the puller to the silent block.

- After removing the damaged silent block, you need to clean and lubricate the axle and threads with oil. The seat is also checked for damage. You need to be prepared for the fact that the silent block will be very difficult to insert back. In this case, it may be necessary to center the lower arm axle and lug using a jack and pry bar.

- Using the prepared device, we press the silent block back into the seat. We fix the movable joints, and we can consider that the work is done.

- We reinstall the previously removed steering tips. At the same time, do not forget to pin them.

- Next, tighten the nuts of both the upper and lower suspension arms of the VAZ 2106. If you follow the technology, then you need to perform this process with four passengers and an additional load of forty kilograms, which is placed in the trunk.

- In the absence of the specified number of assistants, you can get by with one (its weight must be at least eighty kilograms). It will alternately occupy seats in the cabin corresponding to the axles of the VAZ 2106, on which the nuts are tightened.

Replacing brushes on a VAZ 2106 generator without removing it.

Replacement is performed in exactly the same way

rubber-metal hinge of the lower and upper arm on other wheels of the VAZ

2106

. Do not forget that the final fixation of the axle nuts is carried out when all silent blocks have been replaced.

Removing the upper arm of the VAZ front suspension is necessary in three cases:

- Replacing the lever.

- Replacing silent blocks.

- Replacing the lever axis.

The procedure for removing the lever is as follows:

- Place the car on a lift or inspection hole.

- Remove the wheel using a wheel wrench and a jack (the latter is only needed in a pit).

- Remove the bolt securing the front bumper bracket.

- Disconnect the upper ball joint by unscrewing the self-locking nut and mounting bolts.

- Unscrew the self-locking nut of the lever axle, holding the axle with a wrench.

- Remove the axle.

- Remove the upper arm.

Lower arm repair

If the lower arm is slightly bent and no other damage is detected, then you can continue to operate the car, you just need to check the wheel alignment. Repair or replacement of this element of the front suspension is carried out in the following cases:

- severe damage to the lower arm;

- appearance of cracks.

To complete the work you will need the following tools:

- set of open-end wrenches;

- set of heads;

- metal brush;

- jack;

- puller for pressing out silent blocks;

Removing the lever

The need to dismantle the lower arm arises when the specified element fails to replace the axle or silent blocks.

Work order:

- Raise the front of the car. To do this, use a jack, but you can also use a lift.

Video: sequence of dismantling the lower arm

Replacing the ball joint

You can replace the ball joint on the lower arm without removing it. Since we have already removed the lower arm, it will be much easier to change the ball joint on it:

- Clean the ball joint mounting nuts. This is done using a metal brush; you can also lubricate the threads with WD-40.

- Remove the support. To do this, unscrew the three fastening nuts and remove the indicated element. Carefully inspect the lever to detect possible damage and cracks.

The new ball joint already comes with lubricant, so there is no need to lubricate it additionally. Some supports have an oil nipple in the lower part, through which you can additionally fill it with lubricant over time.

Video: replacing the ball joint

Replacing silent blocks

The sequence of work to replace silent blocks on the removed lower arm:

- The lever is securely fixed in a vice.

- Using a puller, the old hinges are pressed out.

Video: replacing silent blocks

Experts recommend that after replacing the ball joint and silent blocks, use only new nuts.

Lever Installation

After repairing the lever body, replacing silent blocks or a ball joint, installation of the lower lever is performed in the reverse order:

- The axle and the lever are secured using bolts.

At this point, the replacement of the lower arm is considered complete, and you can continue to operate the car safely and comfortably.

Video: installing the lower arm

By regularly inspecting the condition of the front suspension on the VAZ 2107, you can notice and eliminate any malfunctions in time. Even a novice car enthusiast can replace the lever, ball joint or silent blocks on his own. Keeping the suspension in good condition ensures not only comfortable, but also safe operation of the vehicle. The use of high-quality parts from trusted manufacturers will significantly increase their service life and repairs will need to be performed much less frequently.

Replacing silent blocks VAZ 2106

The silent block is installed on the car's suspension arms; it is one of the important elements of the suspension. The silent block consists of two metal bushings and rubber inserts.

Photo of the car's lower suspension arm. Number 1 shows the ball joint, 2 - the lever, 3 - the axis of the lever (square in cross section), 4 - silent block.

Where is the silent block located?

The silent block connects the torque rod mounting elements, shock absorber mountings, anti-roll bar mountings, gearbox mountings, beam supports, and rear suspension rods.

Why do you need a silent block?

The silent block exists in order to perceive and dampen vibrations transmitted from other elements of the vehicle’s suspension. The silent block design allows it to perceive and absorb vibrations in all planes simultaneously; the silent block can withstand radial, axial and angular loads.

Which element of the car's suspension bears the heaviest load? The answer is silent block. That is why silent blocks wear out quite quickly. If the silent blocks are heavily worn, the car's wheels become uneven or come together. Wheel alignment in this case is a useless exercise, and besides, the money is simply wasted. Replacing silent blocks is quite difficult, especially if you are doing this car repair process for the first time.

Replace silent blocks

This can be done both in a car service center and at home. Now technologies have emerged for restoring worn silent blocks; restoration takes place using special equipment - vulcanizers. Restoring old silent blocks is cheaper than buying new ones.

How much does it cost to restore a worn silent block? In Russia, in car services where there are special vulcanizers, they restore worn silent blocks at a cost of 700 to 1800 rubles.

How to replace silent blocks on a VAZ 2106? To replace silent blocks on a VAZ 2106, you will need the following tools: 13 keys (two pieces), a 22 key, special devices for removing and installing silent blocks on the lower arm of a VAZ 2106. Instead of special tools for removing and installing silent blocks on the lever, you can use bushings with an internal diameter larger than the diameter of the silent block and such a length that you can install a washer on the lever axis and screw on the nut. These are tools if the levers have already been removed. And in order to remove the suspension arms of a car, you need to put the car on a jack, remove the wheels, free the fork from the ball joints, and free the lever from the beam.

How to change front shock absorbers on a VAZ 2106

1200 rub. for the photo report

We pay for photo reports on car repairs. Earnings from 10,000 rubles/month.

Write:

Before changing the shock absorbers on a car, in particular the classic VAZ 2106, you need to treat the fastening bolts and nuts with a product like WD-40 so that they become acidic and can be unscrewed. So in this case, when replacing the front shock absorbers on a VAZ 2106, we perform the same procedure.

Take the key and unscrew the shock absorber mounting bracket (bottom). The upper shock absorber mounting bolt will be somewhat more difficult to unscrew since the manifold is in the way. Then simply pull out the shock absorber along with the bracket from underneath the car. To replace the shock absorber on a VAZ Classic, you need an inspection hole or overpass. Next, unscrew the bolt securing the bracket and screw it onto the new shock absorber. We perform the installation in reverse order. In order not to confuse anything, watch the video instructions.

Replacing the front shock absorbers of a VAZ 2106 is required if the car’s suspension does not absorb road unevenness well, the car sways strongly, and the wheel rubs against the locker when going over bumps. The fact is that, working in tandem with springs, the front shock absorbers do not allow the car to sway when driving (on bumps and when cornering), and in this situation they do not cope with their functions. Another reason why they need to be replaced is excessive oil leaks. In these cases, installation of new parts is necessary.

Before purchasing new shock absorbers, you should know why the car nods when braking sharply. This occurs due to poor performance of the front suspension. Moreover, such a “disease” is inherent in the entire classical family. The fact is that VAZ oil shock absorbers cannot cope with such a load. Therefore, having given preference to gas-oil ones, the owner will feel the difference on the very first day.

Healthy!

You can check their performance yourself. To do this, you need to press hard on the front fender of the car. After the force is removed, the shock absorber should smoothly lift the body and lock it in its previous position. If this does not happen, and the car rocks up and down, this suspension element requires replacement. The procedure must be performed for each side of the machine.

The whole process can be formally divided into 2 stages: removal and installation. Since right and left change in the same way, the manual will be based on an example of one element. It is more practical to carry out the work on a pit or a lift. Actions related to steering or suspension components on a jacked-up vehicle are strictly prohibited by safety regulations.

Healthy!

Replacing the front shock absorbers of a VAZ 2106 is exactly the same as on all cars of the “classic” family, so the manual can be used for other AvtoVAZ models.

Installation of a new shock absorber to replace the old one is carried out in the reverse order of removal. But during the work, several more very important features should be taken into account:

We can definitely say the following: replacing the front shock absorbers of a VAZ 2106 yourself is not a complicated procedure, and its implementation does not require special skills. The only difficulties that an inexperienced car owner may encounter is the sticking of some suspension elements to each other. Therefore, you should stock up on a full can of Vedashka.

The suspension shock absorbers of the VAZ 2106, as in any other car, are an integral part on which not only comfortable movement depends, but also the safety of driving the vehicle. The condition of these elements must be periodically monitored and their performance checked.

What is a silent block

A silent block, or hinge, is a special part of a car’s suspension. Its design consists of two steel bushings, which are connected to each other by a special insert made of soft material. The most commonly used are rubber or polyurethane.

Replacing the lower arm on a VAZ-2107

The hinge connects several components of the chassis, and with the help of a soft insert, it has the ability to dampen various vibrations and thus prevent their transfer to another element. That is, almost all the impacts received by the chassis go directly to the presented components.

The silent blocks take the bulk of the shock from the suspension, which is why they wear out the fastest.

Silent blocks are installed in the car suspension. Available in both the front and rear parts.

The chassis of the car is responsible for handling, dynamics and smoothness. In order for all these indicators to correspond to the factory settings, you need to carefully monitor the condition of the suspension and promptly change the silent blocks, as one of the main components of this part of the machine.

On the front suspension, the arms are attached using silent blocks, and on the rear suspension, the levers are attached to the reaction rods that connect the body and the axle.

Appearance of parts

Types

When a car owner is faced with the question of replacing silent blocks, he needs to carefully select consumables. When visiting a specialized store, the buyer will face a difficult choice between two materials:

- Rubber. Made from ordinary rubber. About 70% of all such products are created using this method. These hinges are considered noisier, less reliable and durable, but have an undoubted advantage - low price.

- Polyurethane. Products made from this material have a longer service life and high reliability. In addition, experienced car enthusiasts have noticed that their use improves the performance of the car’s chassis. As for the minuses, it is definitely a high price. On average, such silent blocks cost four or five times more than standard ones.

Using polyurethane products on any vehicle will directly improve performance such as ride and handling. In addition, the level of wear of suspension parts will be significantly reduced, since shocks and deformations will be less transmitted and felt by other components.

When replacing the silent blocks of the front control arms on a VAZ-2107, installing polyurethane products will allow you to radically change the behavior of the car on the road and make fewer visits to the service station.

How to change the outer CV joint boot yourself!

Rear suspension

The rear suspension of the VAZ 2106 is of a dependent type. The basis of the suspension is an axle, at both ends of which there are mounting knuckles. The beam itself, in addition to holding the wheels, has in its design a driveshaft that transmits torque from the driveshaft to the drive wheels. That is why the rear suspension design provides a dependent type.

The rear beam itself is supported on four supports: 2 lower support rods, and 2 upper ones. Both rods are attached to the body, and fix the rear suspension so that it can only move at a certain angle, without exceeding it.

An additional fastening of the rear beam is a transverse rod. It is located from one edge of the rear axle to the other, while being at an angle. Two shock absorbers are attached to it, on both sides, also at an angle.

In addition to shock absorbers that ensure smooth passage of road irregularities, the rear suspension also has two springs. They are located near the inside of the rear wheel. Inside each spring, there is a special stabilizer that controls the maximum permissible compression of the spring.

Instead of a steering knuckle, as on the front suspension, brake drums are installed at the rear, to which the wheels are attached. The mounting principle is the same as on the front suspension: using four nuts and threaded screws.

Why do they fail

Cheap hinges have a short service life. The fact is that rubber has low quality characteristics when used for a long time. It begins to deteriorate, dry out and tear, which leads to the consumable being unusable. In addition, there are other reasons why hinges may wear out and require replacement:

- increased vehicle mileage affects the performance properties of rubber in blocks, which leads to damage and deformation of the material;

- various reagents and chemical elements that get on the hinge during operation of the machine harm the material. This could be engine oil, substances from the road surface, such as salt or sand, which are sprinkled on roads in winter;

- incorrect installation. The arms should only be secured when the vehicle is on the ground and not on a lift or jack. If the fasteners are not tightened correctly, the hinge material will become twisted. This may change its properties and reduce its service life.

How to change silent blocks on a VAZ-2107

Method for replacing products on the upper arm

It is noteworthy that the hinges are those elements that cannot be repaired. Therefore, it is clear that when they fail, old products need to be removed and thrown away, and new ones installed in their place. Before performing any actions to change the hinge block, you should prepare the following devices and tools:

- special pullers for hinges and ball joints;

- set of wrenches. Typically needed for 22, 24 and 13 mm;

- chisel and hammer;

- mount;

- lubricant, “VD-40” is suitable.

A set of tools for removing and installing silent blocks.

There is no need to select special tools to replace silent blocks. Those listed in the list above will suffice.

Having picked up everything you need, you need to lift the car and remove the required wheel. Next you need:

- Unscrew the front bumper bracket fasteners.

- Remove the upper ball joint fasteners.

- Unscrew the upper arm axle nut. At the same time, you must hold the axle, otherwise it will turn.

- Remove the axle from the mount.

- Remove the entire arm from the machine.

- Using a special puller, press out the old products and put new ones in their place.

Hinge removal process

Suspension faults

It cannot be said that the VAZ 2106 suspension is unreliable, but taking into account the quality of our roads, it is still necessary to carry out diagnostics and carry out repair work from time to time. The occurrence of a particular malfunction can be judged by characteristic symptoms, based on which it will be easier to determine the damaged part.

Knocks

Knocks may appear at different moments when the vehicle is moving, which indicates the following malfunctions:

- at the beginning of the movement. Indicates damage to the rear axle rods or the brackets to which they are attached. The silent blocks themselves may also wear out. First you need to inspect the attachment points of the rods and their integrity, check the rubber-metal elements. Replace faulty parts;

- while driving. With such a manifestation of a malfunction, the shock absorbers and their bushings may fail or the fasteners may loosen. If there is severe wear, ball joints can also knock;

- when the damping system is compressed. A malfunction can occur when the rebound buffer is damaged and can be eliminated by inspecting and replacing damaged elements.

Replacing lower products

To change the silent blocks on the lower arm, you should carry out the following steps:

- Raise the car. To do this, you can use a lift or a standard jack.

- Unscrew the wheel.

- Loosen the nuts on the lever axis at the bottom.

- Unscrew the fasteners from the anti-roll bar cushion.

- Return the vehicle to a level surface.

- Unscrew the fastening element for the pin on the lower support.

- Remove the stabilizer by knocking it out with a hammer or a special puller.

- Raise the car again on a lift or jack.

- Move the stabilizer through the mounting pin.

- Hook the required spring and remove it from the support cup.

- Unscrew the lower arm axle fasteners.

- Remove the lever itself after unscrewing the washers.

- If you need to completely replace the lower arm, then remove the ball joint at the bottom. It has three fasteners that must be unscrewed and removed. There is no need to do this to replace the hinges.

- Secure the lever using a vice. After this, you can remove the silent blocks using special pullers.

- Install new products and reassemble the entire assembly.

Removing the old lower hinge

Replacement with jet rods

Elements such as torque rods relate to the rear suspension. They are fastened with bolts and bushing-type adapters to absorb impacts, reduce wear and deformation when hitting bumps. Like any other rubber products, such bushings also fail quite often. It is noteworthy that it is recommended to change them all at once.

To disassemble the suspension and torque rods you need a special set of tools:

- keys, especially 19 mm;

- lubricating fluid;

- a set of new hinges;

- blade for installation;

- brush for working with metal.

The VAZ-2107 car has such an element as a long longitudinal rod. It also has bushings; the process of removal and replacement is also important, because the remaining consumables on other elements are dismantled in a similar way.

In this case you need:

- Clean the fasteners from dirt using a special metal brush.

- After this, the fasteners must be treated with a lubricating fluid.

- After a certain time, unscrew the fastening using a key and remove it.

- On the reverse side of the rod, unscrew the fastening of the lower side of the shock absorber.

- Remove all fasteners and spacer sleeve.

- Move the shock absorber.

- Having approached the jet thrust fasteners, lubricate them and unscrew them.

- Take a mounting spatula and use it to remove the jet thrust.

- The rubber bushings can only be removed if the cage is knocked out of the metal. In this case, you need to apply a special instruction.

- You can try to squeeze out or knock out the rubber elements that remain in the traction.

- Clean the cage thoroughly before installing new bushings.

- Lubricate the new product with liquid and drive or press in with a hammer.

- Take a special cone and install a metal sleeve. If it is not available, you can make it yourself by grinding off the head of the bolt.

- Press in the bushing with the cone.

- To completely remove the bolt, use a sleeve.

How to remove silent blocks without a puller

Without using a puller, most likely it will not be possible to remove the silent block. If you don’t have a ready-made tool, you can make it yourself. There is a sufficient amount of material for this on the Global Network.

Homemade puller diagram

Thus, you can replace the suspension joints in a VAZ-2107 car yourself. This will take quite a lot of time, but will save you on visiting the service. It is advisable to choose a set of new hinges made of polyurethane, as it is more reliable and durable.

vote

Article rating