In a modern gasoline engine, the combustible mixture is injected into the cylinders by injector nozzles at the command of the electronic control unit. Typically, diagnostics of the engine fuel supply circuit is carried out in a car service center, although the car enthusiast can determine obvious problems on his own. To find the cause of the malfunction, you need to check the pressure in the fuel rail and other points in the system.

What pressure should the fuel injector pump produce?

Pressure characteristics in an automobile fuel system are one of the most important parameters used during diagnostics. The behavior of the vehicle in various operating modes directly depends on this indicator. Using pressure data, the condition of various elements of the fuel system, for example, the pump, is studied.

Instructions for diagnosing pressure and repairing a fuel pump

- If the fuel supply is insufficient, this can lead to a decrease in engine power. This is also manifested by the fact that during active acceleration, characteristic jerks may appear. The same applies to driving at higher speeds. So, we remove the rear seat, which is located on the right side of the car. There we find a special metal plate that will need to be unscrewed.

- Now turn on the ignition. You should hear the characteristic sounds of a pump that pumps fuel. If this sound is heard very faintly, you can remove another seat to hear it clearly. But it also happens that there is no sound in this case. As a result, we will need to check the relay, as well as the fuses that control the operation of the fuel pump.

- The next step will be to loosen the fastening clamp, followed by disconnecting the fuel hose from the suction pipe of the fuel pump. The indicated hose is located slightly lower than the current fuel mark in the tank. And, so that gasoline does not start leaking, you need to close its hole with any suitable object that is at hand. Most often, we are talking about a bolt of the appropriate diameter.

Check the fuel hose for damage- Now we disconnect the fuel hose, and then lower it, simply pointing it down, finding the most convenient position. Next, you can tightly close the hole in the hose with your finger, and use the manual fuel pumping lever to pump the liquid several times. You should feel a characteristic force, which is provoked by the presence of resistance from a tense spring that is compressed. We are talking about a spring related to the diaphragm on the lever. If such an effect is not observed, then it is necessary to slightly turn the engine crankshaft, using a special fastening bolt that holds the pulley, to the desired mark.

- With each finger press, you should feel that the pressure in the hose is increasing, and the fuel pump begins to make a characteristic sound, more like a “squelching” sound. But, if there is no pressure, then this may indicate an insufficient level of tightness of the suction-type valve, or damage to the diaphragm.

- Close the suction pipe tightly with your finger and repeat the pumping cycle again.

In this situation, the absence of a vacuum effect in the pipe will indicate that the diaphragm or discharge valve has been damaged.

And, if there is no vacuum or discharge pressure, then in addition to the indicated possible breakdowns, it may turn out that a foreign object is stuck in the fuel pump filter.

Don't forget to wash the filter

To eliminate it, it will be enough to rinse the filter with regular gasoline, and then blow it with compressed air or a compressor.

If the filter is excessively deformed or cannot be cleaned to the required level, it must be replaced with a new one.

Rail pressure indicator

It is extremely important to check the indicator in the fuel rail at the same time.

On the other hand, there is no specific value for the pressure in the ramp. The norm for the performance of all elements of the fuel system is considered to be higher than 2.8 bar. As for the top point, there are no restrictions.

Here, for example, is what data should be there if there are no difficulties in the functioning of the vehicle and its elements.

If the indicator does not correspond to the factory values, we can conclude that the filters, pump or RTD (sensor) are faulty.

The pressure indicator on systems without return is slightly different. Here it can vary between 3.6 - 4 atm.

How to check fuel pump pressure? Using an air pressure gauge

Are you a novice car enthusiast and don’t know how to check the fuel pump pressure? Then this article is for you. The pressure in the fuel system of a car is an important parameter that needs to be measured periodically. When diagnosing an engine, auto repair shops first measure the gasoline pressure, and only then carry out all other related work. This parameter determines the quality of engine operation in various modes. How to check the fuel pump pressure with your own hands? You can do it yourself in several ways. On the open market, you can find a special device that includes a pressure gauge and other components. A similar measuring device in a car dealership will cost you 1,500 rubles (+/-). By the way, when you stop at a service station, they will carry out the procedure for measuring the pressure of the fuel pump for 200-300 rubles. If you are not eager to shell out money for a measuring device or visit a service station, then there is a way to measure pressure using an air pressure gauge designed to determine the pressure in car tires.

We measure with available means: Most likely, every car owner has a pressure gauge that allows you to measure tire pressure. Therefore, this method is perfect for novice car mechanics. I would like to immediately say a small note about this method. Air pressure gauges, as a rule, are designed to measure high pressure, about 16 atmospheres. Fuel pressure gauges have limits around 6 atm. The first type of pressure gauges have small errors at the initial scale values.

Different measuring methods

In addition to measuring against the wall, there are many other ways to measure yourself. One of the options for checking the fuel supercharger is the “plug” diagnosis. In this case, the return line is clamped for two seconds, the engine starts, and the pressure reading is taken.

Another testing option. The speed of the power plant increases to three thousand revolutions per minute. At the same time, you need to monitor the instrument readings. If the pressure drops to 0, this is a sign of a “dead” pump.

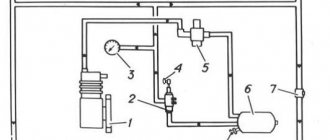

The pressure on the ramp is measured as follows:

Measurements are made in different ways:

We take a measurement in the fuel rail.

To work we need a “pressure gauge”. But not every pressure gauge is suitable, it all depends on the pressure limit that it can measure. In our case, we need a pressure gauge with a measurement limit of up to 7 atmospheres. If you have a pressure gauge measuring up to 17 atmospheres, then such a device will show incorrect data, because it has too much error at low pressure.

In addition to the pressure gauge itself, we will need “plumbing flax”. We wind flax under the pressure gauge nozzle and put a hose with an internal diameter of 9 mm on it. Next, we tighten the whole thing with a clamp. Our device is ready for use.

In a store, such a device with a hose and drain will cost you about 1200 rubles. Measuring the fuel system at a service center will cost you about 200-300 rubles.

- Open the hood, turn off the ignition, find the fuel injector rail.

- We unscrew the plug of the fitting for fuel pressure, then use a spool to unscrew the nipple that appears, carefully placing a container or rag, because gasoline will spray due to remaining fuel pressure.

- Place the pressure gauge hose over the fitting and secure it with a clamp.

You need to check the pressure in 4 operating modes:

- measure the pressure when the ignition is turned on;

- measure the pressure at idle;

- measure the pressure with the tube removed from the fuel pressure regulator;

- measure the pressure with the return pipe pinched.

Injection pump pressure on a Mercedes

This is a high pressure pump installed on diesel cars and some gasoline cars.

This is how pressure is measured.

The normal value should vary within 3 volts. If it is less, you need to raise the speed of the power plant and keep it within 2000 rpm. Adjust the pressure bolt in this mode by rotating clockwise. At the same time, you need to look at the device to stop rotation as soon as the pressure reaches the standard value of 3 volts.

If the pressure does not want to return to place, you can draw conclusions about a fuel leak or a malfunction of the fuel system elements, including the pump.

Video: how to measure the pressure of injection pump 4g94

Source

What devices are used

ATTENTION! A completely simple way to reduce fuel consumption has been found! Don't believe me? An auto mechanic with 15 years of experience also didn’t believe it until he tried it. And now he saves 35,000 rubles a year on gasoline! Read more"

Several instruments can serve as devices for taking pressure readings.

- A special device purchased from an auto parts store. It comes complete with an adapter, drain hose and pressure gauge. Costs about 1.5 thousand rubles.

- Converted tire pressure gauge. The instrument scale and tube are subject to modification. As you know, the air pressure gauge shows a value of up to 20 atm, and the fuel measurement limit is around 5-7 atm. For this reason, reading errors may occur, and the device is modified to take this into account. Regarding the tube: you need to change it to a gas-resistant version.

Gasoline pump for carburetor VAZ 2107

One of the mechanisms of the power supply system of any engine is the fuel pump. The startup and operation of the power unit directly depends on its performance. Mechanical fuel pumps of the diaphragm type DAAZ 2101 were installed on carburetor “sevens”. Thanks to the simple design, the mechanism is repairable. However, it often causes problems for Zhiguli owners. Therefore, it is worth dwelling on the operation and malfunctions of this unit in more detail.

Main functions

The job of the fuel pump is to move fuel from the tank to the carburetor.

The design of the unit is not ideal, so it is one of the weak points in the car. This is explained by the fact that the impact of constant loads and low quality gasoline lead to natural wear and tear of the elements. This is what causes the device to fail. If a problem occurs with the pump, the engine begins to work intermittently or stops functioning altogether.

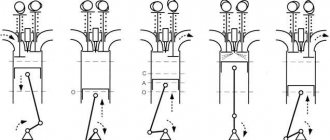

Design and operating principle

The mechanism is made of several parts connected to each other by fastening elements. There are two fittings in the upper part of the body through which fuel is supplied and pumped into the carburetor. The design includes a lever that allows you to manually pump gasoline from the tank into the fuel system, which is important after the car has been parked for a long time. The main elements of the node are:

The principle of operation of a classic fuel pump is based on creating the pressure necessary to maintain the required fuel level in the carburetor chamber. Thanks to the diaphragm, the flow of gasoline stops or decreases when a maximum pressure value is established in the fuel line. On carburetor “sevens” the fuel pump is located under the hood on the left side of the cylinder block. It is secured to two studs through a thermal spacer and gaskets, which are also used for adjustment. The spacer is also a guiding part for the pump rod.

The device operates in the following order:

Which fuel pump is better

When there are problems with the fuel pump, the question of choosing a new device often arises. Owners of Zhiguli cars mainly prefer products of two. If problems arise with the factory mechanism, for example, when it overheats, many change it to the second option, explaining that Pekar pumps do not have a tendency to form a vapor lock, which causes defects in the operation of the device in hot weather. In fact, this opinion is wrong, since they also have this problem, as evidenced by numerous reviews from car owners. It is also worth considering that Pekar costs 1.5–2 more than DAAZ. Therefore, a standard fuel pump is the best choice based on criteria such as reliability, price and quality. The cost of a factory pump is 500–600 rubles.

Table: parameters of different fuel pumps

| Test results | "Baker" | DAAZ | QH | OTA |

| Zero supply pressure (at a crankshaft speed of 2 thousand rpm), kgf/cm² | 0,26 | 0,28 | 0,3 | 0,36 |

| Capacity for free drainage (at a crankshaft speed of 2 thousand rpm), l/h | 80 | 76 | 92 | 74 |

| Suction period at a crankshaft speed of 2 thousand rpm, s | 4 | 13 | 9 | 6 |

| Valve tightness at a pressure of 0.3 kgf/cm² (fuel leakage within 10 minutes), cm³ | 8 | 12 | 8 | 8 |

| Place | 3 | 4 | 1–2 | 1–2 |

QH petrol pumps are manufactured in the UK, while OTA petrol pumps are manufactured in Italy. However, these devices have some features: the QH pump does not have a lever for manual pumping of fuel, and the housing is non-separable. The Italian mechanism has excellent parameters compared to others, but its price is almost 3 times higher than Russian products.

Checking fuel pressure and fuel pump

Next we will talk about self-diagnosis of electric fuel pumps that are installed on modern cars. There are several available methods that allow you to check the fuel pump yourself.

Before starting work, the possibility of fuel leakage and a decrease in throughput in certain sections of the fuel system should be eliminated. Conduct a detailed inspection of fuel lines and connections for kinks, cracks, other deformations or damage. It may also be necessary to replace the fuel filter, various gaskets, etc.

If everything is in order with the lines and filters, but the engine does not start, you need to turn on the ignition and listen carefully. On most cars (but not all models), a working fuel pump hums or makes a slight buzzing sound in the first seconds after turning on the ignition, pumping fuel into the system. The absence of such a sign of a working pump will indicate its malfunction or electrical problems.

If the car starts, but then stalls while driving, then you should start checking with the fuel pump relay. To check, you will need to connect a warning light to the fuel pump connector, after which you should turn on the ignition. If the warning light comes on for a few seconds, it will indicate that the fuel pump relay is working properly.

Fuel pump drive

The VAZ 2107 fuel pump operates from a pusher (rod) and an eccentric located on the shaft of auxiliary devices (“piglet”, intermediate shaft), which is driven by the timing mechanism through a gear. Auxiliary devices include distributor, oil and fuel pumps.

Operating principle

The drive works as follows:

Fuel pump drive malfunctions

As the fuel supply unit wears out, problems may occur that affect the performance of the latter.

Rod wear

The main sign of a worn-out rod is that the car does not reach the required speed. If the car accelerates, but, having gained speed to a certain value, does not develop it anymore, the reason is precisely the wear of the rod. Recently, the pusher has been made from such low-quality metal that it leads to wear out literally after 500–1000 km. The edge of the rod on the eccentric side is simply flattened, which indicates the need to replace the part.

The fuel pump rod should be 82.5 mm long.

Troubleshooting

The main symptoms of a malfunction of the VAZ 2110 fuel pump are engine interruptions in various operating modes, lack of pressure in the fuel system, loss of acceleration dynamics, increased fuel consumption, or complete failure when trying to start the engine.

The first step is to check the functionality of the pump. When you turn on the ignition, you should hear a slight whirring sound from the pump under the rear seat for a few seconds.

If the engine is running, it is necessary to check the fuel supply pressure using a pressure gauge; the fuel supply pressure to the injector should be 3.5 - 4 atmospheres. If the sound of the fuel pump is not heard, if you have an electrical tester, you can check whether power is being supplied to the pump.

To do this, you need to remove the back seat of the VAZ 2110, the decorative cover, and the terminal from the fuel pump housing, turn on the key to crank the starter, if the tester does not receive power, you need to check the relay, fuse or wiring trace for a break! If there is power, the fuel pump needs to be replaced.

The serviceability of the relay can be checked by replacing it with a working one from the fuse box, for example the high beam headlight relay. When replacing a new relay, you need to pay attention to the manufacturer and the recommendations of a spare parts specialist in the store; it is better not to save on the cost of the relay.

[custom_ads_shortcode2]

Electric fuel pump for VAZ 2107

Increasingly, owners of “classics”, including the VAZ 2107, are installing modern devices on their cars. So, the mechanical fuel pump is replaced with an electric one. The main goal of introducing an electric fuel pump is to get rid of the problems that arise with standard pumps. However, you need to understand that if on injection “sevens” such a mechanism is installed directly in the gas tank, then on carburetor cars it is placed under the hood.

Which one can be installed

As an electric fuel pump, you can install any device designed to work on fuel-injected cars on the “classic”. Based on reviews from Zhiguli car owners, Chinese-made pumps, as well as Magneti Marelli and Bosch, are often used. It is important to know that the product must provide low pressure . A standard mechanical pump produces about 0.05 atm. If the indicator is higher, then the needle valve in the carburetor will simply let fuel through, which will lead to it leaking out.

Installation of an electric fuel pump

To install an electric fuel supply pump on a carburetor “seven”, you will need a certain list of materials:

We carry out the work in the following sequence:

Checking the pressure in the fuel rail on VAZ and Lada cars with an injection engine

The article will describe a testing technique that does not require special devices.

From the tool you will need:

- Any mechanical pressure gauge with a maximum reading from 6 to 10 atmospheres (0.6-1.0 MPa)

- 8 or 9 mm fuel or oxygen hose

- Cap for unscrewing nipples on the wheel

- Two clamps

- Pliers

1. We took a regular gas pressure gauge with a scale of up to 1.0 MPa. It has a threaded connection and screws perfectly onto a 9 mm oxygen hose. You can use a mechanical one to check tire pressure. They are usually inserted into the fuel hoses by 8 mm.

2. Screw it into the hose and tighten it with a clamp:

3. Unscrew the plastic cap from the fuel rail. It should unscrew by hand, but if it hasn’t been touched for a long time, you may need pliers:

4. If the car has just been turned off, then the gas in the ramp is under pressure. First, it is recommended to release the pressure by pressing on the spool and placing a rag or a plastic “bottle” with the neck cut off. It is more convenient to bleed using a wheel cap.

5. Unscrew the nipple with the cap. It is similar to a wheel nipple:

6. We put a hose with a pressure gauge on the threaded part and tighten the connection with a clamp:

7. Start the car and first of all make sure that there are no gasoline leaks from the connections. Then we look at the pressure gauge readings.

8. For fuel systems with “return” (a pressure regulator is installed on the fuel rail, from which a tube goes back to the tank), a pressure of 2.7 atm is considered normal (when re-gasping it should jump up to 3 atmospheres). However, a pressure of 2.5 atm is also acceptable. If the pressure is less, then the fuel system is faulty. Pressure pulsation (0.2 atm) indicates a clogged coarse mesh (located in the tank with the fuel pump).

9. Next, we check the pressure regulator. To check, disconnect the hose going from the regulator to the intake manifold. The fuel pressure should increase to 3.2 atm (at 2.7 initial). Up to 3.0 atm is also acceptable. If the pressure has not changed or changed only slightly (0.1-0.2 atm), then you need to check the fuel pump.

10. The maximum pressure developed by the pump is checked. To do this, use pliers to pinch the return fuel line (coming from the regulator). Different pumps show different pressures, but a new one should have at least 6 atm. A pressure of 5 atm indicates severe wear, but will still serve. If the pressure is less than 4.0 atm, the pump is faulty or the pipeline with the fine filter is clogged. If the fuel pump is working properly, and the pressure in the rail drops after the “return” is restored to less than 2.5 atm, and/or does not change when the regulator hose is disconnected, then the regulator is faulty. If, when the return line is pinched, the pressure rises slightly, and engine performance deteriorates significantly, then there is a high probability of injector leakage.

11. To eliminate the influence of the injectors, it is better to measure the pressure on the supply line itself by disconnecting it from the ramp and inserting it into a hose with a pressure gauge. If the pressure has risen to 5-6 atm, and with the “return” compressed it is significantly less, then the injectors are allowed to pass through. It is necessary to remove the ramp and check the condition of each individually.

12. You can check for clogging of the pipeline as follows. Remove the rear seat and unscrew the hatch. We see the fuel pump assembly underneath it. If the pipeline has quick-release connections, then we buy such a connection in the store (50 rubles).

13. If the pipeline is installed on threaded connections, you will have to buy the entire tube and cut off the tip:

14. Connect it to the pump outlet, and put a hose with a pressure gauge on the other end. Let's check the pressure again. If the pressure gauge readings increase to the normal 6 atm (after pumping gasoline several times by turning the key), then change the fine fuel filter and bleed (or flush the entire system).

15. Replacing the fuel filter is shown here: replacing the fuel filter on Lada Priora, Kalina and Granta cars. The only difference is that after removing the filter, we direct the fuel supply hose into a plastic bottle (preferably transparent) and turn on the ignition with the key (the fuel pump turns on and fuel spills into the bottle). We inspect the condition of the fuel in the bottle. Then we install a new filter, remove the hose from the ramp and direct it into the bottle. We turn on the ignition several times and spill gasoline. We inspect the fuel in the tank again. If dirt is found after the filter, then washing the injectors is also required. We assemble the entire system and measure the pressure readings again. If the readings have not changed, then check the correct clamping of the “return” (you can try connecting a pressure gauge to the output of the regulator). If this does not help, then perhaps the blockage is serious and requires blowing with air under high pressure. It would be a good idea to check the entire pipeline from the tank for mechanical damage (dents, kinks).

16. Fuel systems without a return line are diagnosed in almost the same way. The main difference is that here the fuel regulator is located on the pump body. The fuel goes from the pump to the fine filter, and then goes to the regulator. Near the body, the fuel pipe bifurcates. One tip goes to the regulator, and the second goes to the fuel rail.

17. The main difference in the readings is the normal pressure at the ramp is 3.8 atm. When over-gassing it should jump up to 4 atmospheres. If the pressure is less, immediately check the pump. We connect a pressure gauge to the pump outlet and check the pressure. The pressure should also be at least 6 atm for a new one.

18. If the pressure is working, then check if the fuel filter is clogged. To do this, we restore the fuel line from the pump and connect to the tube suitable for the regulator. The easiest way to do this is to cut off the old tip from the fuel filter, install one end of it in a clip, and put a hose with a pressure gauge on the other. If the pressure is identical to the pump pressure, then the filter is clean. If a significant drop is visible, the filter must be replaced.

19. Next, we check the supply line to the ramp. Shut off the fuel supply to the regulator. It is easier to do this by inserting a soldered (twisted/crumpled) tip from the filter into the quick-release connection. If there is no difference here, then change the regulator. If losses are detected, then we check the entire pipeline - there may be leakage or crumpling of the pipeline, it is also possible that nozzles are leaking.

Signs of a fuel pump malfunction

An experienced car enthusiast can determine the malfunction of his car by its behavior or by extraneous sounds. This also applies to the fuel pump. If knowledge is not enough, it is worth considering the following characteristic signs indicating problems with the fuel pump:

- the engine does not start;

- the engine stalls almost all the time;

- the power and dynamics of the car decreases.

However, it is worth considering that power may decrease for a number of other reasons: problems with piston rings, valves, etc. If the fuel pump is completely faulty, the engine will not be able to start.

The fuel pump does not pump

There may be several reasons why the device does not supply fuel. Before you start troubleshooting, you need to make sure that there is gasoline in the tank. It happens that the level sensor shows incorrectly and the problem simply comes down to a lack of fuel. You also need to make sure that the filter elements are not clogged, but it is better to replace them, because they are inexpensive. After these steps, you can begin diagnostics.

The causes of problems may be:

- wear due to long mileage;

- diaphragm damage;

- insufficient spring stiffness as a result of stretching;

- valve contamination;

- violation of the tightness of the unit.

If the gas pump on the “seven” does not supply fuel, then there are two ways out of this situation: install a new device or disassemble the old one, carry out diagnostics and replace damaged parts.

On my car, a situation once arose that indicated a lack of fuel for the engine: there was no normal dynamics, the engine periodically stalled and would not start. There was enough gasoline in the tank, the filters were in good condition, but the car did not drive. After lengthy investigations and clarification of the reasons for this phenomenon, the problem was found: the fuel supply hose from the pump to the carburetor was swollen inside, which indicated the poor quality of the product. The internal cross-section has become very small and insufficient to pass the required amount of fuel. After replacing the hose the problem disappeared. In addition, I change fuel filters at least every 5 thousand km. mileage (preferably more often). I have them before and after the fuel pump. As practice shows, even with the installation of two filters, as well as with a mesh in the fuel pump itself and at the carburetor inlet, debris still penetrates into the float chamber. This results in the carburetor having to be cleaned periodically.

Video: VAZ fuel pump does not pump

Stops pumping when hot

One of the problems of classic Zhiguli cars is overheating of the fuel pump, which leads to a disruption in its performance - it simply stops pumping. The problem is caused by the formation of a vapor lock, which blocks the supply of gasoline. There are several ways to solve the problem: water the cooling pump with water or ride with a wet rag on it. These methods are applicable in a critical situation, but not for everyday use. The problem can be eliminated by adjusting the fuel pump using gaskets, replacing the rod, replacing the unit itself, or using higher quality fuel.

Checking the fuel pump

If there are suspicions or characteristic signs of fuel pump problems, the mechanism should be checked. To do this, perform the following steps:

- Loosen the clamp of the hose that supplies gasoline to the carburetor, and then pull the hose off the fitting. Gasoline will leak out of the pipe, so it is better to lower its edge into an empty container.