The crankcase ventilation valve (CVG) or PCV (Positive Crankcase Ventilation) is used to effectively use the gas mixture formed in the crankcase . The part is installed on most modern models with a fuel injection system and is directly involved in regulating the composition of the air-fuel mixture. Incorrect operation of the VKG valve leads to excessive fuel consumption and unstable operation of the internal combustion engine .

We will describe in detail below the device, operating principle, malfunction and methods of checking the PCV valve.

Where is the PCV valve located and what is it for?

The location of the PCV valve directly depends on the vehicle modification. Usually the part is built into the valve cover of the internal combustion engine, but can also be placed in a separate housing, combined with an oil separator, close to it. The latter option is actively used in the latest generations and models of BMW and Volkswagen.

You can find the crankcase ventilation valve by the thin flexible pipe extending from it, connected to the air duct in the area between the intake manifold and the throttle.

You can see what the crankcase gas valve looks like in the photo with a clear example.

Where is the crankcase ventilation valve on a VW Golf 4, click to enlarge

Where is the pcv valve located in the Audi A4 2.0, click to enlarge

Location of KVKG on Toyota Avensis 2.0, click to enlarge

What does the crankcase ventilation valve do?

The main purpose of the PCV valve is to regulate the volume of crankcase gases supplied to the throttle body in various operating modes of the internal combustion engine. This achieves more precise air dosing to create an optimal air-fuel mixture ratio. Additionally, the KVKG prevents the ignition of crankcase gases during a backfire in the intake.

Replacing KVKG

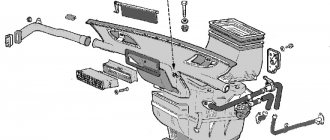

Replacing a valve is easy on almost any passenger car, but each SVKG engine model has its own design features. Let us consider, as an example, how the KVKG changes on the M54 B22 engine, the make of the car is a BMW fifth series in the back of an E39. The KVKG valve is located under the intake manifold at the front of the internal combustion engine, and to get to it you need to remove:

For convenience, you can remove the intake manifold itself, but then the work turns out to be quite labor-intensive, and you will also have to purchase manifold gaskets. After access to the valve is ensured, disconnect the hoses from the KVKG and dismantle the device itself. We are installing a new mechanism, putting all the parts in their places.

Design and how the crankcase ventilation valve works

VKG valve design: video

Structurally, this part in the ventilation of crankcase gases is a bypass valve, consisting of a housing with two pipes and a movable working element.

In built-in PCV valves, the inlet and outlet openings are blocked by a plunger, and in those located in a separate housing with an oil separator - by membranes. Free movement of the locking element without external influence is prevented by springs.

How does the VKV valve work?

The operating principle of the PCV valve is based on changes in inlet pressure. Conventionally, we can distinguish 4 main states of the crankcase gas valve according to the degree of opening and the amount of passing crankcase gases.

The degree of opening of the PCV valve depending on the operating mode of the internal combustion engine

| Modes | Engine not started | Idling/deceleration | Uniform movement, medium speed | Acceleration, high speed |

| Vacuum in the intake manifold | 0 | High | Average | Low |

| PCV Valve Condition | Closed | Ajar | Normally open | Fully open |

| The amount of passing crankcase gases | 0 | Small | Average | Big |

From the inlet side, the valve is exposed to pressure created by crankcase gases. When it exceeds the spring force, the element blocking the hole (membrane or plunger) moves inward, allowing the gas mixture to enter the filter housing.

VKV valve design in VW Polo

KVKG filling in the Chevrolet Lacetti

At the same time, from the outlet side, the valve is affected by a vacuum (pressure below atmospheric) created in the intake manifold. Limiting the valve flow area allows you to redirect some of the gases from the crankcase that have collected under the valve cover into the space between the air filter and the throttle valve. In the event of a backfire and a sharp drop in vacuum in the intake manifold, the outlet of the CVCG is completely blocked, thereby preventing ignition of the flammable gas mixture.

What does the PCV valve do?

PCV Valve Operating Modes

The PCV valve directly affects engine operation, optimizing the mixture formation process. By changing the flow area of the channel, it adjusts the flow of crankcase gases containing fuel particles into the air channel in front of and behind the throttle. This allows you to use the crankcase ventilation system as efficiently as possible and at the same time prevent the entry of unaccounted fuel-air mixture into the intake manifold.

When the crankcase ventilation valve fails, they are supplied to the intake in excess quantities or not at all. Moreover, in the first case this is usually not detected by any sensors, and in the second it leads to attempts at unjustified correction of the air-fuel mixture.

Due to the excess air entering the combustion chamber, the engine starts worse, failures are possible during acceleration or in other cases when it is necessary to increase thrust. Valve jamming can lead to increased fuel consumption and over-enrichment of the fuel assembly, resulting in unstable operation and vibration of the engine at idle speed.

Valve in the crankcase ventilation system

Alternative options

The next version of the improvement involves installing a hose with a small diameter into the crankcase ventilation circuit of the EPK valve of the “Cascade” model. In idle mode, the valve for standard exhaust gas outlet should be opened. Considering the fact that when installing the system in question, the supply of harmful impurities through the throttle valve stops due to the circuit opening. This is very important in the case of a transition of the engine operating mode from idle to light loads, when a lean air-fuel mixture is categorically unacceptable. Ventilation is carried out through the entire line, including the carburetor unit.

After further replacing the durite with a hose from the vacuum ignition advance device, it is reasonable to increase the diameter of the main jet of the first combustion chamber or simply reduce the input fuel flow to 4.5 mm. The scheme under consideration was tested on a model of the domestic VAZ 2101. At the same time, the following positive aspects became noticeable:

- The pedal drop during acceleration has disappeared;

- The engine's operation became smooth;

- There are no intermittent oscillations at idle.

Using the recommendations of specialists and folk craftsmen, it is possible to independently correct a number of malfunctions and shortcomings of a personal vehicle. Modification of the crankcase ventilation is appropriate for some vehicle equipment, regardless of the year of manufacture and country of manufacture. This problem is most pressing for domestic cars with carburetor engines.

Signs and Causes of a Malfunctioning PCV Valve

Stuck engine speed due to PCV valve and fixing the problem: video

Although the crankcase ventilation valve has a simple device, from time to time it still fails or does not work correctly. What may be signs of a faulty VCG valve? Most often this is:

- engine vibration other than vibration;

- hissing in the intake manifold after gas release;

- dip in traction from 3000 to 5000 rpm;

- XX rpm fluctuation.

If there are accompanying problems in crankcase ventilation, it is possible that oil consumption may increase and the throttle valve and ventilation hoses leading from the crankcase may become oily.

What malfunctions of the crankcase gas valve can occur?

Usually there is a violation of the seal of the housing due to mechanical damage (for example, during installation after cleaning) or untimely operation, incomplete opening and closing of the dampers due to their jamming.

Thus, the main causes of PCV valve malfunction are destruction or jamming of the locking elements or external influences.

Malfunctions of the crankcase gas valve and their symptoms are indicated in the table.

| Malfunction | Why does it occur | Symptoms | Why is this happening? |

| Depressurization/air leaks |

|

| Air that is not accounted for by the mass air flow sensor is sucked into the manifold, and crankcase gases come out completely or partially. |

| Stick Open/Increased Performance |

|

| Excess crankcase gases with fuel particles enter the intake. When warming up and under load, this mode is optimal; in other internal combustion engines it does not work correctly. |

| Stuck closed/reduced performance |

| The calculated flow of air into the intake is disrupted. The entire flow of crankcase gases is supplied in front of the throttle valve. |

The KVKG may not work correctly due to problems in the crankcase ventilation system or problems with the CPG. In this case, passing through the valve increases Therefore, before checking the PCV valve, you should make sure that there are no problems that lead to oil being released through the breather or being squeezed out through gaskets and seals.

In what cases is the presence of oil in the breather not related to the crankcase?

Before diagnosis, it is recommended to make sure that the unpleasant symptoms are actually associated with gases. Oil ingress is also possible in other cases, for example, if more fluid is poured than required according to the standards. It is possible that the breather is not installed correctly and moving it will correct the problem.

Sometimes oil penetrates from the internal elements of the power unit, including injectors. Driving style, as well as the condition of the roadway, also influences. Oil particles may remain when the motor actively moves in the transverse direction.

PCV Valve Check

Diagnostic auto scanner Rokodil ScanX

You can check PCV valves using physical and software methods . In the second case, you will need an assistant, a diagnostic scanner or OBD II adapter, and a special application for a PC or mobile device. One of the best options is the Rokodil ScanX , since it is compatible with all brands of cars, view the performance of all sensors and systems, and provides error tips.

For physical diagnostics, carried out by checking the response of the KVKG to external influences from instruments, you only need an open-end wrench to remove the valve.

A preliminary check of the PCV valve is possible by blowing with your mouth. When air passes freely from the outlet side, the part is definitely not working. If the KVKG is purged only from the entrance side, this indirectly indicates that it is in order. You can definitely verify that the part is working properly using one of the following methods.

In some cars, particularly new BMW models, the PCV valve is non-removable and non-removable. to check it physically without destroying the case . In this case, you can check either using computer diagnostics or replacing it with a known-good unit.

To check the operation of the crankcase gas valve, follow this procedure:

Do-it-yourself check of the VKG valve Toyota Vitz: video

- Remove the valve from the hole in the valve cover, first removing the hose from the outlet pipe.

- Inspect the inlet for contamination and remove it if necessary.

- Blow out the valve with your mouth from the outlet side: no air should pass through a working CVCG.

- Reattach the ventilation hose to the outlet.

- Start and warm up the engine.

- Close the valve inlet tightly with your finger. In a working part, this action is accompanied by a click and a vacuum is felt - the finger will “stick” to the hole.

The crankcase ventilation valve is checked programmatically using the throttle position at idle.

Checking the PCV valve using computer diagnostics using the example of a Chevrolet Lacetti:

Professional check of the PCV valve on a Chevrolet Lacetti with computer diagnostics: video

- Unscrew the valve with a 24-mm open-end wrench, having first removed the hose from the outlet pipe.

- Place the hose onto the outlet fitting.

- Connect the scanner or OBD II adapter to the diagnostic connector in the passenger compartment.

- Run the diagnostic program and display the throttle position readings (actual throttle position).

- Start and warm up the engine. In this case, the value of the actual position of the remote sensing should be within 35–40 steps.

- Plug the valve inlet with tape or have a helper plug it with your finger. The parameter should increase by approximately five 5 steps.

- Remove the vent hose from the PCV valve outlet. If the KVKG is working properly, the reading of the actual throttle position will drop to 5 steps. This indicates that the valve was restricting the passage of gases into the intake at idle.

Servicing the crankcase ventilation valve

One of the main reasons for the incorrect operation of the KVKG is contamination of the working surfaces. This can be avoided by cleaning the crankcase ventilation valve every 20,000–30,000 km .

Slight oiling of the surface of the KVKG is a natural process. However, if it becomes oily faster than 10,000 km, this is a reason to diagnose the crankcase ventilation system. It is possible that the oil separator or ventilation hose is clogged.

How and how to clean the PCV valve

Cleaning the PCV Valve with WD-40 Aerosol

The following products are best suited for cleaning the PCV valve:

- carburetor or injector cleaner;

- brake cleaner;

- WD-40;

- kerosene or diesel fuel.

When using the product in the form of an aerosol with a tube, it should be pumped through the inlet pipe into the KVKG. Kerosene and diesel fuel can be injected using a syringe or syringe. The washing procedure must be repeated until all deposits are removed.

After cleaning, it is necessary to check the functionality of the PCV valve using one of the methods described above. If washing does not help, the part must be replaced .

In addition to the valve itself, the oil separator and hoses of the crankcase ventilation system also require periodic flushing with the same means. If they are clogged with oil deposits, the system will not be able to relieve pressure in the crankcase even with a working CVCG.

Frequently asked questions about the crankcase valve

What is a crankcase ventilation valve?

KVKG is an element of the crankcase ventilation system, which is structurally a membrane or plunger bypass valve.

Where is the crankcase ventilation valve located?

In most models, the KVKG is located in the valve cover of the internal combustion engine (rear or top) or in close proximity to it in a separate housing together with the oil separator.

What is a PCV valve for?

The PCV valve controls the flow of crankcase gases into the intake manifold, directing them ahead of the throttle valve. It allows you to optimize the composition of the air-fuel mixture under various operating modes of the internal combustion engine.

How to check the operation of the PCV valve?

A working KVKG is not blown through from the outlet side, but allows air to pass through from the inlet side. When closing the inlet hole of the removed valve with the engine running and warm, you hear a click and feel how the blocking object (finger) is attracted. If the valve does not pass any of these tests, we can conclude that the VKG valve is inoperable.

First option

Modification of crankcase ventilation can be done in several ways. For example, on the M50 you can install an oil separator unit from the M52 model. However. This manipulation does not solve the problem of having a container for draining liquid, external aesthetics and the need to place a water seal.

One of the current solutions to the problem under consideration would be the installation of a HEPA filter, which contains wire and filament components that make it possible to adjust as accurately as possible the amount of gases released. The inside of the oil separator is filled with copper wire wool. In the standard version, the packing should protrude slightly beyond the base of the lid. The corrugated inlet and throttle assembly are thoroughly wiped. After performing the manipulations, the element is checked by mechanical purging for changes in air flow.