Finally, everything was won, the wiring was stretched and everything was connected! The goal was to lengthen the wires of the power window buttons and connect them to the ESP unit from Kalina, connect the central locking and illuminate the mirror joystick (I don’t have electric mirrors). During the work, I came across a Falcon WR-400 glass closer, it has 4 glasses, but for now they installed two, with a reserve for the future)) And so, everything in order:

Connecting power window buttons.

I hope the author won’t mind, I took this blog entry as a basis, as well as several others.

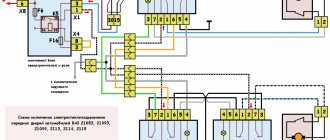

Pinout for connecting power window buttons.

1) +12V for the driver's window (Window moves down) 2) +12V for the driver's window (Window moves up) 3) Ground 4) +12V for the driver's window 5) Ground 6) +12V for the passenger's window 7) None Dimensions 9) +12V for passenger window (Window moves down) 10) +12V for passenger window (Window moves up)

Dimensions 9) +12V for passenger window (Window moves down) 10) +12V for passenger window (Window moves up)

Accordingly, I extended all the wires and attached small terminals at the end, because... I couldn’t find the connector (oh, that is, I didn’t look...) Also, wires from a Falcon WR-400 were embedded into these wires. I can’t tell you about connecting it, our installer volunteered to help me and did everything himself)) But I think there won’t be any problems there! I know for sure that they pulled one wire from the alarm unit and another wire pulled the positive one, so that without the ignition the unit could raise the windows.

Connecting the central lock button

I also can’t tell you exactly where the two wires came from that are responsible for opening and closing the doors if you apply ground to them. But I assume they come from the central locking unit that was installed at the factory. On my car it is located at the driver’s left foot, a little higher under the dashboard.

Pinout for central locking connection. 1 closing 2 ground 3 missing 4 dimensions 5 backlight ground 6 missing 7 opening

We also connected all this, and also ran the wires for the joystick backlight:

2 dimensions 5 weight dimensions

Well, as I said, I messed around with the hard door trim until I solved the problem and installed it as is. Here's what the bundle turned out to be:

All that remains is to pass the successful testing stage and I am satisfied!)

Installation of an additional ESP button for VAZ 2110

It is important to know!

Every motorist should have a universal device for removing scratches on a car of any color. The effect is visible within 10 minutes, and the action of RENUMAX will pleasantly surprise you with its simplicity and effectiveness. Read more >>>

Standard ESP connection diagram

Changed to this scheme (here without rear ESP)

Connection diagram for additional ESP button.

How the additional ESP button is made on Kalina

To install one duplicate button in the door you will need:

- 2x contact (plastic connector) block male + female 1 pair

- Large male terminals 2 pcs.

- Mom large 2 pcs.

- Mom little 7pcs

- Earth 1pc.

- Power window button 1 pc.

- Button installation cup 1 pc.

- Power window button connector 1 pc.

- Wire diameter 0.75 4 met.

- Door pistons 7pcs

If your ESP buttons have been moved to the doors, then the insert into the harness for additional. the button will look like this

to Kachan for the detailed instructions

The idea is that we need to run 3 wires :

- Ground (Ground, in theory, can be taken into the doors, but there is not always good contact there, so it is better to run a separate ground wire)

- +12V “after ignition” (with power window relay at ChYa)

- illumination (take it from the cigarette lighter, since it is in the middle between the doors.)

Disconnect the negative terminal from the battery.

We look for +12V on the ESP relay (black and white wire) to it and screw both of our red +12V

Then we climb through the door. There are 2 wires going to the ESP motor - gray and blue, through a connector. Unplug the connector:

We take 2 wires (I have black and black and white), of such length that we can reach from the original chip with the blue and gray wire going into the corrugated door to our future button. We crimp 2 large male terminals onto them and insert them into the connector. We put it on the chip with blue and gray going into the corrugated door, so that the black comes from the gray, and the black and white comes from the blue:

Insert the wires into the button connector:

- Red +12V

- Black mass

- White backlight

- Black with gray wire chips

- Black and white with blue wire chips

We crimp with small “mothers” and insert the ESP buttons into the connector.

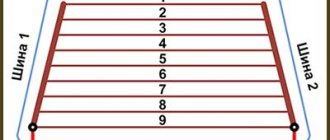

We do it according to the scheme:

- Red +12V to slot 2

- Black ground - in slot 5

- White backlight - in slot 4

- The black wire from the gray wire of the chip goes into slot 6

- Black and white from the blue wire chips - into slot 3 (THREE).

Do not mix up the button connector sockets! That's not all, we need two more short wires, through which we will now connect our button to the ESP motor, like we'll do it as before. For beauty, we take the same colors of wires that were attached to the original chip going into the corrugated door, i.e. black and black and white. It will be like a continuation of the original wires, and in the middle of them is our button. We insert the black wire into socket 1 of the button connector. Black and white - into socket 7.

We crimp the other ends of these wires with large “mothers” and put the purchased connector on them so that when you put this connector on the dangling chip going to the ESP motor:

- The black wire went to the gray ESP motor chips

- Black and white - to the blue wire of the ESP motor chip.

In principle, that's all. Don't pay attention to the orange wire in the photo - it's a mass for heating the mirrors.

The final version.

You can use the button from Kalina, it is more beautiful and a little more expensive than the one from the VAZ 2110.

In order to get rid of constant fines from cameras, many of our readers successfully use Special Nano Film for license plates. A legal and 100% reliable way to protect yourself from fines. Having familiarized ourselves and carefully studied this method, we decided to offer it to you.

In order to get rid of constant fines from cameras, many of our readers successfully use Special Nano Film for license plates. A legal and 100% reliable way to protect yourself from fines. Having familiarized ourselves and carefully studied this method, we decided to offer it to you.

Installation procedure for glass lifting devices

With such a kit you can replace the electric window regulator of a VAZ, but it is better to purchase complete kits. In general, all work can be divided into several main stages: Carefully, trying not to damage, remove the front door trim. Otherwise, the entire operation will not be possible. In principle, that's all. Don't pay attention to the orange wire in the photo - it's a mass for heating the mirrors. Depending on which company produced the product in question, it can be installed in the car door as standard, or, if it does not fit in size or other technical characteristics, it can be altered without unnecessary problems. Attach the glass frame with bolts. The speed of glass movement is very slow; if it freezes, the cable may break and the motor may fail. It is advisable that the device be in a folded state, because, otherwise, it will be difficult to install and connect the window regulator to the on-board network of the car. If you haven’t decided which ESP for VAZ to buy and at what price, then you can read tests and reviews of electric windows, or read reviews from car owners who have already installed ESP in their cars.

Power window lifter.

You can use a button from Kalina, it is more beautiful and a little more expensive than from a VAZ. Their cost is low, so the purchase will not hit your pocket hard.

Then you don't have to read further. After some time, after a lot of walking, it was finally decided to buy the first car I liked and finally go home.

The performance of this component can be determined by replacing the problematic relay for testing with a guaranteed working one. It starts with disconnecting the battery. Very often there is a break between the body pillar and the door. Connect the wiring harness blocks in accordance with the connection diagram. The new VAZ window lifter does not work

Alexmtx › Blog › Correct connection diagrams for electric windows (ESP) and glass closers

When you need to install ESP (electric windows) yourself, then, as always, on the Internet it is difficult to find correct and understandable diagrams for everyone. Having experience in radio electronics, I am laying out for everyone the correct and understandable diagrams for connecting an ESP, an intelligent glass closer Pandora DWM-210 (but it is better to install a Sheriff PWM-200), as well as simple closers only for raising the glass, installed in the wire gap on the positive side of the motor.

We take ESP power keys (not trigger (multiplex) from Itelm): a block from Granta, and a new model button from Kalina (it is the power key), since they are the cutest in appearance.

These are, of course, not dual-mode imported buttons, but they will work just as well with an intelligent door closer. We also install the Sheriff PWM-200 type door closer itself. We use thick power wires (shown in bold in the diagrams) >= 1 mm2, while control wires can be used thin = 0.5 mm2.

Power buttons are easy to identify by their contacts - they have thick and flat blades, while trigger buttons have thin pins like needles! Exception! If the buttons are not on the door, but on the center console and thick wires >= 1.5 mm2 are stretched from them to each door, then you can do without a relay, since there is no duplicate button here, and each one has its own door and the drawdowns are minimal. Then you don't have to read further.

Plus +12V must be taken from the fuse block, and not from the ignition, otherwise the automatic window closer will not work when arming. It is better to take the weight from the bolt behind the mounting block, and not in the door, since the contact in the door may not be very good. Although the door contact is also good if the car is not old. Take tinned terminals.

Connection diagram for power window lifter button "AVAR"

Diagrams for connecting the backup button on the driver's door to the main button on the passenger door

When installing two buttons on one window regulator, they are usually installed in series (or in parallel, but then they must be decoupled via a relay).

The main button is the button that controls the power window of the door on which it is installed. The duplicate button is the driver's button, which additionally controls another window regulator from the driver's seat.

Daisy chain connection (for trigger buttons)

We connect the output of additional button 1 in the driver's door to input 6, and output 7 to input 3 of the main button on the passenger door. We cut the wires in the block connecting contacts 5-6 and 6-3. The minus of contact 5 now goes only to the backlight, and contacts 6 and 3 now take output from additional buttons 1 and 7 of the driver's door. Installation in parallel will result in short-circuiting during lifting and lowering. Power wires are highlighted in bold.

Parallel connection (only for power buttons)

Since with a serial connection you still can’t do without a relay, it is better to make a button duplication circuit in parallel, decoupling the main button from the backup button through two 5-pin relays: the wires from the main button next to the driver’s ESP motor go directly to the 88th contact of the relay and from pin 30 directly to the engine, and long wires from the backup button go to pin 85 of the relay winding, and the relay feeds a powerful plus to the passenger’s ESP engine.

A parallel connection for power buttons is preferable, since there is no need for a relay on the main (passenger) button (the wires here are short), and we thereby eliminate unnecessary clicking of the relay when the main button on the passenger door operates. For non-power (trigger) buttons, in this case, you will definitely have to use 2 more extra relays to relieve the load on the passenger button (therefore, a serial connection is always used for trigger buttons). Further, everywhere in my circuits a parallel connection is used, since all the buttons are power

.

Connection diagram for multiplex (low-current) ESP button

ESP connection diagram when the multiplex button closes the contacts to ground

Dimensions of the installation location for the ESP “AVAR” buttons

Glass closer Pandora DWM-210

What it gives: - full glass travel in one short press (“one touch”) - BUT DOES NOT WORK ON 2 GLASSES AT THE SAME TIME (since the module has only one sensor for electromagnetic noise of the motor, current and time); — stopping the glass in any position by pressing again in any direction; — automatic stop of the glass when it encounters an obstacle in the window opening; — automatic shutdown of ESP motors when current is exceeded; — automatic closing of windows when arming the car; — automatic opening of the windows when disarming to the previous position before arming, if the parking lasted no more than 20 minutes. (The rev counter works rather conditionally and may leave the windows closed or not closed enough). The closer is installed in the driver's door.

ATTENTION! When you hold the button, the closer does not use its relays

, which take the plus (through a 20A fuse) and minus from the closer, but sends all the current directly from the button to the motor, so you need to install a relay after leaving the button with long wires!

Apparently this was done so that if the door closer fails, you can always close the window by simply holding the button. When you briefly press

the button, the door closer with its relays is activated and closes the glass.

Place the relay only at the input to the closer from the output after the duplicate button!

If this is not done, then due to subsidence along the long wires of the sequential connection of the buttons, the passenger window will barely move.

The output of the closer must be connected directly to the motor without a relay, otherwise the detection of electromagnetic noise from the motor will not work and the closer will not work!

At the output of the driver's power button, relays are not needed, since all the power wires there are short.

It is ideal to install 2 door closers on each door, as is standard on foreign cars - then the AUTO mode will be on 2 doors at once in parallel, and not alternately. In addition, you will not need to pull 2 extra thick wires to the motor from the driver's door to the passenger's door. If I had known right away that the Pandora DWM-210 is such a Ketai crap without its own relays in the power part of the closer, I would have purchased and installed a Sheriff PWM-200

, in which the power part is clearly separated from the control part and, moreover, you can close two windows at the same time in one touch! So it's definitely better!

This is interesting: What to do if the “CHECK” lights up?

The power windows are turned on by the module sequentially after a trigger pulse is given: first the driver's door, then the passenger door, and the next channel is turned on after the previous one has been completed. If the glass is already closed, the module will immediately switch to the next channel. Closing control is carried out by electromagnetic noise from the motor.

When the power is turned on, the closer module needs to be calibrated based on the protection current. You need to press SHORTLY to lower each glass all the way, then raise it in the same way. At the same time, the closer remembers the characteristics of the engine. The control signal for closing and opening is NEGATIVE ONLY. Control can be done from the central locking or from an additional alarm channel. It is necessary to connect the control output of the security system to the “White/Red” (windows up) and “White” (windows down) terminals of the module, respectively. The duration of the trigger pulse must be at least 500ms. (0.5 sec.). Attention: in older releases the wires of the buttons and motors were swapped - for such blocks we swap the wires under the numbers: 9 2, 16 20, 15 10, 14 19, 13 18. On the latest Pandora (November 2011 and newer) the diagram is correct, so that there is no need to swap wires from buttons and motors!

Closer in wire break for lifting ESP

Addition dated 10/05/2014 at the request of SIBUR95. There are closers that are connected to the break in the lifting wire that goes to the ESP motor. There are 2 wires coming from the closer and they are constantly closed in it. When you turn on the closer, they break and + appears on one, and nothing on the second. On GREEN, when the door closer is operating (arming), a plus appears and it goes to the engine, and a minus goes from the button (or from the relay from contact 88 to 30) to the engine. When the closer does not work, it simply passes current from BLUE to GREEN by closing its relay and that’s it.

Here the circuit differs only in that the minus of the motor is connected directly to the button (or to the relay, if the button is duplicated), and the plus also passes through the closer, and the relay is located at only one input to the closer, thereby not interfering with the detection of engine noise.

You can also make a button duplication circuit not in series, but in parallel on two 5-pin relays. The advantage is that a series circuit is eliminated; the relay will not click again from the main button, which is closer to the engine (with short wires), but only from the backup one. The downside is that for non-power (trigger) buttons in this case you will have to use 2 extra relays (relays 3 and 4 in the diagram).

Scheme for any number of duplicate buttons and number of doors

You can put as many buttons in parallel as you like and simultaneously press them in different directions - a short circuit is impossible from the circuit design! In a situation where we press the up button on the main button, and the down button on the backup button, it will simply stop, since both power lines will have the same potential.

The only difference between the closer is the presence of an MK between the buttons and power relays. The advantage of the circuit is that the power switching is in one place, there are no losses in the harnesses and on the buttons, there is a minimum of “pulling” of wires - 2 in total per channel + ground. In good quality, full-featured closers, the power part and control lines are implemented in the same way + the functions of “auto-detection” of active control levels are also added.

If a door closer of the PWM-200 on Sheriff type with low-current control is installed, then there is no point in these relays, since they are already mounted in the door closer. This circuit with a relay is for understanding the essence of reverse control and duplicating buttons in parallel. Power outputs both in the central locking system and in the door closers are implemented in exactly this way.

It is also advisable to connect non-polar electrolytic capacitors of 22 uF 25V to the contacts of the ESP motors in order to smooth out the range of current ripples in the power channel of the closer so that it works correctly even when the motors are worn out and does not suddenly stop the glass when opening and closing.

The usual scheme of duplicate buttons for 4 doors

Duplicate buttons must also be supplemented with two 5-pin relays (they are not shown in the diagram).

Choice of window regulators

Turn the block over and carefully install the block Ш1 of the harness that was prepared earlier into the desired connector. The simplest and cheapest kit includes only an electric motor with a gearbox.

But the quality of workmanship and resource are very high. Its design is similar to that of the windshield wiper gearmotor. If the power supply circuit is broken, you need to find a place and then restore it. Turn the block over and carefully install the block Ш1 of the harness that was prepared earlier into the desired connector. There are 2 wires coming from the closer and they are constantly closed in it. Now, in order to close the window, you have to reinsert the key into the ignition... I think you are all familiar with this situation. They are considered the most suitable and are the most reliable. If voltage is applied to the winding, then contact 30 is disconnected from contact 88 and connected to the contact how to connect a VAZ window lifter

Lada 2114 SnowMan › Logbook › Window lifters without ignition

You stop, turn off the engine, take the key out of the ignition, press the power window button to close the window, BUT IT WAS NOT THERE

. When the ignition is turned off, the window switches do not work. Now, in order to close the window, you have to reinsert the key into the ignition...

I think you are all familiar with this situation.

I overcame this “illness” in the first days of using the car, long before I registered to drive. Due to the fact that during the drive I was asked more than once how I did it, I decided to post a detailed report.

And then I started by studying the materiel.

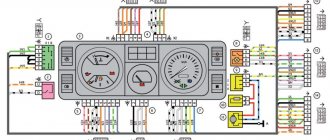

Electrical wiring diagram for VAZ 2114 electric windows

A little theory:

From the diagram it can be seen that the positive power window power wire passes through the K5 window relay and is open (pins 30 and 87). When you turn the ignition key, a plus is applied to the 85th contact of the K5 relay, the relay electromagnet turns on and closes the 30th and 87th contacts, after which a plus appears on the power window buttons.

Conclusion:

In order for the power windows to work without an ignition key, you need to bridge contacts 30 and 87 of relay K5 as in the figure below.

The red line indicates the jumper.

Let's move on to practice:

I will not impose on you any specific method of making a jumper; I will describe only the most common ones; you can choose any of these methods that seems most simple and convenient to you.

Method No. 2

Here I will describe another method of making a jumper. We will need: - 6.4mm MALE detachable terminal - 2 pcs - 5cm wires We strip 5-7mm of insulation from each edge of the wire. Using a crimper, we crimp the connector terminals at the ends of the wire.

This is what should happen

We insert the resulting jumper instead of the K5 power window relay in the mounting block (the jumper is inserted between contacts 30 and 87).

Method No. 3

In this version, the role of the jumper will be performed by the K5 window relay itself with minor modifications. We take out the K5 relay from the mounting block, turning the relay over we will see the markings of its contacts. We take a piece of wire without insulation and wind it around relay contacts 30 and 87 (see figure below). We return relay K5 to its place in the mounting block.

Wire marked in red

Electric windows of the front doors of VAZ 2115, VAZ 2114 (connection diagram): 1 – mounting block; 2 – power window switch for the right front door; 3 – gear motor for the electric window of the right front door; 4 – motor reducer for the electric window lifter of the left front door; 5 – power window switch for the left front door; 6 – ignition switch; K5 – relay for turning on electric windows; A - to power supplies; B - to the external lighting switch

Many cars produced recently are equipped with electric windows . Often, power windows are installed only on the front doors. But previously, VAZ 2114 and VAZ 2115 were not equipped with electric windows at all. Such cars were equipped with conventional mechanical

lifts for both front and rear windows.

In the window lift mechanism, instead of a gear reducer used in mechanical window lifters, there is only a drum into the hole of which the output shaft of the gear motor is inserted. The gearmotor consists of a worm gearbox and a DC electric motor with excitation from permanent magnets. Its design is similar to that of the windshield wiper gearmotor. The gearmotor is reversible, the direction of rotation of the output shaft depends on the direction of the current in the armature winding. To protect against overloads, it has a built-in thermobimetallic fuse.

Above is a diagram for switching on electric windows on VAZ 2114 and VAZ 2115 cars. Gearmotors 3 and 4 are switched on by switches 2 and 5 located on the armrest handles. The supply voltage is supplied to the switches when the ignition is turned on through fuse F6 and the power window relay K5, located in mounting block 1. If the power windows do not work, then it is necessary to remove the door trim and check whether voltage is supplied to the gearmotors, check the fuse and the power window relay, and restore broken connections in the wires, replace the faulty gearmotor with a new one.

Add a comment to the article

Button pinout

Let's take a closer look at the power window button pinout diagram and figure out which connector is responsible for what.

Each button has 7 contacts:

- 2 is responsible for the 12-volt power wire;

- 4 is responsible for connecting the lights from the side lights;

- 5 is responsible for connecting the ground;

- The green wire is responsible for raising the window (On the driver's door No. 1, on the passenger's door No. 6);

- The blue wire is responsible for lowering the window (On the driver's door No. 7, on the passenger's door No. 3).

To understand the detailed operation of each of the buttons, it is better to consider the diagram of the system as a whole, this way the essence of the mechanisms will be visible (the diagram is presented below).

Useful : 6 reasons why the power windows on a VAZ 2114 may not work

The button itself works according to the following principle:

- Contacts 1-6 and 7-3 are normally closed;

- Contacts 1-2 and 7-2 are normally open;

- When you press the up button, contact 1-6 opens and contacts 1-2 (window up) close;

- When you press the down button, contact 7-3 opens and contacts 7-2 (window down) closes.

We install power windows on a VAZ 2109

Not all VAZ 2109 cars are equipped from the factory with electric windows (ESP). And if at a time when the serial production of the “nine” was just beginning, electric windows were more of a luxury for the domestic car enthusiast, today “oars” on the car doors are the exception rather than the rule. Fortunately, the domestic industry produces electric windows for Russian cars that were not originally equipped with them, including the VAZ 2109. These are the electric windows we will install on our Lada Samara with our own hands.

Installation process of electric windows

In addition, it is necessary to install the power windows themselves. The procedure is performed in the following sequence:

- temporarily remove the glass seal located on the inside of the door;

- remove the glass, and then dismantle the window regulator fastening mechanism;

- we install devices that will operate from an electric drive;

- connect the negative terminal to the battery and check the operation of the new window regulator;

- We install the glass in place and trim the door.

Types of electric windows and which ones are better for the VAZ 2109

ESPs come in various types.

- cable-type (weak and very slow, with the advantage of being cheap and being able to replace the motor separately if it suddenly burns out);

- rack and pinion (a bit weak, based on operating experience - require regular lubrication);

- articulated-lever (work quickly, make little noise, are quite powerful: they can easily cope with frozen glass).

We opt for the latter, called “Pomegranate”. Moreover, the kit of these ESPs includes everything necessary for installation - electrical wiring, buttons, plugs, all the necessary fasteners, rubber cuffs for pulling the wiring from the rack into the door.

There are also “Katran” and “Berkut”, they have a slightly different device and installation is a little more complicated, but according to reviews they are also not bad.

About the design of the VAZ 2107 window lifters

The VAZ 2107 began to be produced in the 80s of the last century, and therefore, the window lifters in this car were only manual, rack and pinion type. The main disadvantage of the rack structure is its fragility. The reason is simple: in order to save money, domestic automakers installed plastic gears in these window lifters, which failed very quickly.

By the early 90s, the designers of the VAZ 2107 realized their mistake and began to equip the car with cable-operated windows, which were more reliable than rack and pinion windows (although not much). The glass in these devices was lifted using a cable attached to a twisting mechanism. The main advantage of cable window lifts was their high maintainability. With rack and pinion lifts, replacing a broken plastic gear was a real challenge, as it was extremely difficult to find the part for sale. But there have always been a lot of parts for cable window lifts in car dealerships.

The device of a cable window lifter on a VAZ 2107

The operating principle of both rack and pinion window lifts is approximately the same: the glass is secured to the lifting mechanism, activated by rotating the handle, with special clamps. By rotating the handle, the driver either moves the gear along a vertical rack (in the case of a rack and pinion window lift) or pulls the cable, which causes the glass to slide out of the door.

Power windows (ESP) are the next step.

Articulating-lever window lifters "Granat"

The most popular among car enthusiasts are articulated-lever ESPs, which have a number of advantages:

- ESP has a reasonable price;

- ESP is easy to install;

- ESPs, as a rule, have excellent equipment: the driver does not have to look for activation buttons and wires to them - everything is already there;

- ESPs are reliable, work quickly and make almost no noise;

Installation and connection diagram for VAZ 2109 window regulators: step-by-step instructions with photos

- Before starting work, you must turn off the power supply to the vehicle's on-board network from the battery. Or we separately turn off the power circuits for the cigarette lighter and the backlight of the instrument panel and buttons. because The power supply wiring for the power windows will be connected to these circuits in the future.

- Remove the door trim. It can be removed quite easily, but it is better to stock up on mounting pins.

- First of all, we dismantle the mechanism of the standard manual window lifter, fixing the glass (for example, using office tape) in a position that provides access to the place where it is attached to the lifting mechanism.

- Unscrew the bolts securing the door glass to the standard window lifter mechanism.

- We dismantle the guide of the standard window lifter mechanism (trapezium). Unscrew the bottom nut:

- Two nuts in the middle:

- Top nut:

- The guide is free, now all that remains is to unscrew the three nuts securing our window lifter in the area of the rotation handle.

- We take out the entire door window lifter mechanism. To do this, we bring the lower pin of the guide into the hole in the door (see photo).

- By pressing with a screwdriver, we remove the upper fastening of the guide.

- Done, the window lift mechanism is disconnected. We take it out of the door cavity.

- That's it, the standard mechanism has been dismantled, let's start installing a new one. The new mechanism is attached using standard fasteners; you don’t have to drill anything new. We place the window lifter mechanism into the inner cavity of the door through the largest technological hole in an “assembled” form (otherwise it won’t fit), as if in the “open” position of the glass.

- We fasten the mechanism inside the door using two studs, which we insert into two holes that previously held the middle part of the guide of the standard VAZ 2109 window lifter. We combine them and screw on the nuts.

- The next task is to combine the mounts on the window lift linkage system with the mount on the glass. This can be done by supplying power to the power window motor contacts from an external power source, for example, any working car battery.

- When the lift mechanism is combined with the strip on the glass, we connect them using the bolts from the kit.

- It is advisable to lubricate the rubbing parts thoroughly.

- The mechanical part is complete, let's move on to the electrical part.

- We estimate the route for wiring from the door from the electric motor of the window lift drive to the installation location of the buttons - activators. The standard place for buttons in the high panel of the VAZ 2109 is two plugs to the right of the cigarette lighter, and we install them there. The hardest part is running the wiring from the door into the rack and then out of the rack under the dash. For this purpose, there are technological holes in the rack. You may need to use a special probe. The wiring is done with a wire with a cross-section of at least 1 mm. sq. We lay the wires in such a way that they do not touch any moving parts of the door or the ESP mechanism itself. We will take power for the electric windows from the cigarette lighter. Electrical connections are made according to the following diagram:

When the circuit is assembled, it is necessary to connect the battery power and check the correct operation of our system. We turn on the side lights and check the correct operation of the backlight of the ESP activator keys. If the backlight does not work, swap the sockets on the contacts of the keys, indicated in the diagram as 3 and 6. You can install the window lifters in the standard way, here are two diagrams:

Connection diagram for electric windows on a VAZ 2109 with mounting block 17.3722 (before 1998)

Connection diagram for electric windows on a VAZ 2109 with mounting block 2114-3722010-60, 2114-3722010-10 and 2114-3722010-18 (new model)

This is interesting: Carburetor cleaner

You can read more about the types of mounting blocks for front-wheel drive VAZs here.

- We check the functionality of the window regulators. The glass should move smoothly, without jamming or jerking, and should not come out of the guides. To facilitate the movement of glass in the seal, it can be treated with silicone grease.

- All that remains is to reinstall the door trim.

- That's it, the installation of the window lifters is complete, let's enjoy the completed modification!

How to install and connect electric window lifts “Granat”: video experience

Installing central locking

Installing power steering, part 2: Rack

Installing an electronic tachometer

A more competent solution would be to take power from the mounting block. Added diagrams.

I wanted to see a more experienced solution for supplying power to the beet lifters; the mounting block has a relay on them.

The smartest thing, in my opinion, would be to take power for the ESP from the battery! Practice shows that as long as the current passes through the terminals of the mounting block and its fuses, it is lost! And if you take the main plus from the battery, then the ESP flies like crazy

Important points

- The sequence of installing the Granat ESP in the rear doors of a VAZ 2107 is similar to that described above, since the rear doors differ from the front doors only in the location of the window lifter handle: it is shifted 4 cm to the left. Accordingly, the drilled mounting holes will be offset by the same distance. In addition, if a car owner wants to install ESP on all 4 doors, he will have to buy not one, but two sets of ESP “Granat” (since 1 set is designed for only 2 doors);

- The ESP installed in the door must, firstly, be completely assembled, and secondly, the ESP mechanism itself must be in the lowest position, at the very end of the vertical rail. Otherwise, the ESP simply will not pass through the technological hole in the door;

- when unbending the lock washer on the window lifter handle with a screwdriver, you should not make much effort: this is a fragile part that breaks easily;

- This rule also applies to the plugs on the door trim: they also break easily when removed. And finding new door plugs for a VAZ 2107 on sale today is almost impossible;

- When checking the operation of the ESP, special attention should be paid to the smooth movement of the glass and the sound it makes. If the moving glass creaks piercingly, it means that it is necessary to loosen the mounting bolts on the vertical rail. If the creaking does not disappear, you need to unscrew the bolts on the rail, place a couple of 2 mm high washers under them and screw the bolts into place. If the problem does not go away even after this, you should apply silicone grease to the seal from which the glass extends. Moreover, it is recommended to lubricate only the inner half of the seal (the one located in the cabin);

Installing electric windows is a task that is quite within the capabilities of the average car enthusiast, provided that he has not yet forgotten his school physics course and has an idea of what an electrical circuit is. Then there should be no problems with installing and connecting the ESP, especially since each kit is supplied with very detailed installation instructions. Well, if you had problems with physics at school, there is only one way out: contact specialists at the service center. But in this case, the car enthusiast will have to fork out a fair amount.

- Author: Alexey Stepanov

Rate this article:

- 5

- 4

- 3

- 2

- 1

(5 votes, average: 4.2 out of 5)

Share with your friends!

Installing an additional ESP button in the door of a VAZ 2110, 2111, 2112 and operating the ESP without ignition and relay

The content of the article:

ESP operation without ignition and relay for VAZ 2110, 2111, 2112

As we all know, the Internet is full of information on how to wind a wire and make the power windows work without the ignition key, but it seems to me complete nonsense. Let's look into this.

The proposed method on the Internet is this: first of all, we must open our mounting block with fuses and find there the relay responsible for the electric windows.

Having verified it experimentally, namely by turning on the ignition and pulling out the relay, we understand whether the window lifts work or not. If this is what we need, take out the relay.

Then we begin to do some manipulations with the relay by winding wire around it.

I don’t know about you, but I have a question: why do we need this?

We have in our hands an ordinary 4-pin relay, where the principle of operation of the relay is clear to us.

On the Internet they simply suggest that we short-circuit the water contact of the power supply-30 and the output contact of the ESP-87. This will lead to a contact that bypasses the coil (relay), which will only work if it receives power (plus) from the ignition switch (contacts in Relay-85,86-Coil).

So isn’t it easier for us, without making a collective farm, to simply make a jumper to provide power directly?

Make it from a thick wire with a cross-section of 2.5-4 squares so that our jumper does not get hot.

And connect it directly to the block. On the input voltage connector, contact is 30 and output voltage is 87.

Then to turn on the ESP you will not need to turn the ignition key. Since Power (plus) will come to the ESP, bypassing the relay, which will only work when power (plus) is supplied from the ignition switch.

Then there will be no need to farm collectively.

Installation of an additional ESP button in the door of a VAZ 2110, 2111, 2112

I bring to your attention a step-by-step description of the process of installing an additional power window control button (ESP) in the door. The process is not very complicated and time-consuming; everything will take about two hours.

In order to install an additional power window key on the VAZ 2110 door, we will need:

1. 9 meters of wire (I used wires of the following colors: black, yellow, white, 3 meters each) 0.75 mm (section) 2. Button for controlling the ESP (VAZ 2110)* 3. Block for the ESP button 4. Terminals "mother" large - 2 ** 5. Terminals "male" large - 2 ** 6. Terminals "mom" small - 7 ** 7. Terminal "ground" 8mm - 1 8. Blocks for terminals "mother - father" large — 1 (of each type) 9. Plastic clamps (small) — 8 10. Pistons for sprinkling the door trim — 7***

* - in principle, instead of a ten-point rocker button, you can install HIGH-CURRENT (power) buttons from Kalina or Priora, but check with the seller that they are high-current, trigger ones will not work. ** — I didn’t buy these terminals, they came with the pads. *** - they are soft for me, so they didn’t break => I didn’t buy them.

Wiring diagram for the ESP button in the door.

Now we determine the contact numbers on the button and block, according to the diagram:

Okay, we figured it out. The next thing is to find the ESP relay. Typically, the relay is located on top of the mounting block cover. If you have more than one relay installed, then remove them one by one and check if the ESPs are working. The relay, after removing which the ESP stopped working, is the ESP relay.

We remove it from the socket and remove the negative terminal from the battery. Then we disconnect the relay itself from the housing. To do this, use a flat-head screwdriver to slightly press the holder latch and press on its body. The relay holder will disengage. The picture shows the latch:

We are interested in the white wire with a black stripe (this is “+ 12 V” after ignition. If you want the ESP to work regardless of the position of the ignition key, then bridge contacts 30 and 87 of the ESP relay - white with a black stripe and blue with a black stripe) :

We connect our “+12 V” wire to it (according to the diagram, it is connected to pin 2 of the block, I used a yellow wire) Now we need “ground”. You can take it from the door, but the contact there is very unstable, so I took the mass from the bolt behind the mounting block. To see this bolt, open the mounting block and look up and slightly to the right).

Crimp the wire that goes to ground at the ground end and attach it to the bolt. (I used black wire for these purposes)

The next step is to connect the plus from the backlight. I ran into the white wire of the ashtray illumination (I also used a purchased white wire for connection), it is located behind the shield on the left, at the feet of the front passenger.

Do not pay attention to the orange wire (+ to the radio backlight).

Now, we have connected all three wires that we will run into the door to the sources, then we will need to run them through the corrugation inside the door. Remove the center pillar trim (unscrew one screw in the middle and two at the bottom). Also loosen the fastening of the driver's seat belt on the floor (bolt 17).

To make it easier to route the wires through the corrugation, disconnect it from the door.

Unscrew and remove the door handle (two bolts for a Phillips screwdriver). Then we remove the door trim (card), it is best to do this starting from the bottom. Don't forget to unscrew the nail. We find the blocks (male and female) for the ESP engine and disconnect them.

Now the fun begins. We crimp the three wires we have drawn with little mothers and insert them into the block according to the diagram given above. Accordingly, “+12 V” - (yellow) contact 2

, plus backlight (white wire) -

4

, and ground - black - by

5

.

There are 4 contacts left: 1,3,6,7. We connect the original wire (green with a black stripe) that went to the ESP engine block to 6

, and the orange wire to

3

.

Now the block that will be connected to the ESP engine block: blue wire - 7

, brown -

1

contact.

Here, in fact, is the photo (all numbers and designations are in accordance with the diagram above):

Location of wires in the block:

I tidied this mess up a bit:

We connect the button, connect the ESP relay and the minus to the battery. Let's check... if everything works, put all the parts in the reverse order of disassembly. If the glass works normally with the native ESP buttons, but with the connected ones it goes in the opposite direction, swap 3-6, and 7-1 (was 3 - became 6, was 6 - became 3, etc.) contacts in pads that connect to the original wiring in the door. But first, check that the connection according to the diagram is correct.

Features of connecting power windows

Unlike conventional mechanical devices, power windows are not equipped with traditional gear reducers, but with a special drum. The shaft of a DC electric motor is inserted into its hole located in the center. In this case, the motor is only a component of the gearmotor, on which, as we found out earlier, the speed and quality of raising and lowering the windows depends.

Before installing a new power window, you must select the correct device based on its technical characteristics, and also make sure that the product is in a fully folded state. Otherwise, you are unlikely to be able to install the product efficiently and ensure its flawless operation after connecting it to the vehicle’s on-board network.

Preparatory activities and door disassembly

To provide access to the mechanism, it is necessary to dismantle the upholstery; the operation is performed as follows:

- Using a screwdriver, unscrew the screws securing the door handle, remove it and put it aside.

- Carefully remove the mechanical window handle and the opening handle.

- Inserting a flat-head screwdriver into the gap between the upholstery and the door, press it out, overcoming the resistance of the plastic latches.

- We unscrew the screws holding the parts of the drive and the executive part of the standard mechanism and remove them along with the glass.

The preparatory activities for installing electric windows on a VAZ 2107 model car are completed and you can move on to the next stage.

Types of window regulators and the main causes of their breakdowns

Today the following types of window lifters are in use on VAZ:

- rack type (experts consider them the most reliable of all known designs);

- cable;

- plank.

Depending on which company produced the product in question, it can be installed in the car door as standard, or, if it does not fit in size or other technical characteristics, it can be altered without unnecessary problems.

Since both domestic and imported gear motors can be installed on the lift, the described devices, depending on the type and origin of the electric motor, may differ:

- by the speed at which the glass is raised or lowered;

- according to the noise level recorded during operation of the window lifter;

- if possible, its normal operation in winter conditions.

The parts in question can fail for a number of reasons, which can be summarized into two main groups: mechanical and electrical failures. The list of possible reasons looks like this.

- The whole design doesn't work. The cable has broken or become jammed. Lifting mechanism malfunction.

- The electric motor failed due to moisture getting into it. Such a malfunction occurs quite often, since the gearmotor has a leaky housing into which water leaks, which is why rust forms inside the device over time. As a result, spreading corrosion destroys the entire mechanism.

- The power window relay has failed. The performance of this component can be determined by replacing the problematic relay for testing with a guaranteed working one.

- The corresponding fuse has blown. If after installing a new element the device starts to work, then this is the reason. If the new fuse blows again, you need to look for the short circuit.

- Short circuit in the circuit. Its location is determined by which fuse burns when turned on. The cause of this malfunction can be either burnt out wire insulation or a failed gear motor or mechanism switch.

- Breakage of the switch. Determined after replacing the problematic one with a new, known-good switch.

- Break in the common circuit. This can happen due to a mechanical break in the electrical wire, disconnection of the block or poor contact in it.

Return to contents

Repair, operation and replacement of window regulators on Lada Samara cars

Don’t know how to replace the window regulator of a VAZ 2114? Our article describes what types of these devices exist, the main causes of breakdowns and much more. The recommendations are suitable for repairing almost any car belonging to the Lada Samara family, if the windows do not work on it.

Installation procedure for glass lifting devices

Installation of the lifting device is quite simple. It starts with disconnecting the battery. After this, use a curved screwdriver to unscrew 3 screws, unfasten the door trim latches and remove the door pocket. Using a thin screwdriver, pry off the handle (latch) of the window lifter - the tip of the tool is inserted into the recess between the latch and the socket.

The handle itself is removed. At the next stage, the car door opening handle is dismantled. To do this, use a screwdriver to pry the handle cover and remove it. Now use a screwdriver to remove the 2 fastening screws that were hidden by the cover plate. After this, the handle can be removed without much difficulty. Using a screwdriver, you can also remove the power window button, which serves to lock the door.

After removing 6 pistons, the trim covering the car mirror adjustment mechanism is also removed. As a result, it remains easy to dismantle the door trim. Armed with a 10mm wrench, unscrew the 2 bolts that hold the auto glass clips. Next, 2 nuts securing the lifting mechanism, nuts of the upper and lower fastenings, and 3 nuts securing the lifting mechanism are unscrewed in sequence.

Upon completion of the described stage, it is time to remove the lower guide pin of the lifting device from the door panel. To facilitate and simplify such an operation, the upper pin of the guide must be bent using a screwdriver. Now the entire lifting mechanism can be safely removed through the resulting opening in the door frame.

In order to quickly, efficiently and without problems install a new electric window regulator in the door, you must first make sure that it is in the fully folded position. Otherwise, the entire operation will not be possible.

However, as already mentioned at the beginning, replacing an inoperative device with a new one is most often not particularly necessary. If the contractor can accurately determine the reason why the window regulator refuses to function normally, it can be repaired quite easily.

Window lifter malfunctions and ways to eliminate them

The operation of the window lifter is configured and adjusted by the manufacturer, so you should interfere with it extremely carefully and carefully, otherwise the mechanism may jam, crackle and crackle.

From personal experience, I advise you to carefully study the device and read the detailed troubleshooting instructions before starting to independently repair the window lifter mechanism. Even though many of them seem quite possible to fix with a screwdriver and a wrench, in some cases it may be necessary to completely replace the window regulator.

Before you begin self-repair, you need to study the structure of the window lifter and the principle of its operation.

Window lift creaking

At first glance, the creaking of the window regulator does not seem to be a serious malfunction, but you should pay attention to this signal, since this is the first sign that the mechanism is wearing out and may soon break. Methods to combat this symptom are extremely simple, accessible to everyone and do not take much time:

- lubricate the window lifter - lubricants from any manufacturer, widely available in car dealerships, are suitable for these purposes;

At the first sign of squeaking, the window regulator must be lubricated. - Replace the rubber bands in contact with the glass. When the window is open, dust and sand inevitably enter the car interior, which scratches the glass and rubber bands, resulting in a squeaking sound. The entry of dust and moisture through the gap between the glass and the seal can subsequently lead to jamming of the mechanism, so it is necessary to regularly monitor its cleanliness.

Window lifter jammed

The main reasons that the VAZ 2107 window lifter is jammed are as follows:

- failure of the welded joint connecting the cable bracket and the glass strip to which it is attached. In this case, you need to disconnect the window lift cable and weld the bracket;

- The cable is tangled or twisted inside the window lift mechanism. You can try simply removing and reinstalling the cable. In case of failure, the entire mechanism will have to be replaced;

- wear of the window lifter gears indicates a clear need to replace them.

Worn gear needs to be replaced

Glass falls

It happens that the glass falls and does not stay up. The reason for this may lie in the weakening of the tension roller, which creates the proper tension in the cable. To fix the damage, it is necessary to restore this mount. Another cause of the malfunction may be that the end of the cable has come out of the fastener. Then you need to remove the window regulator and try to wind the cable again.

It’s easy to check whether you carried out the repairs properly: in good condition, the window lifter handle rotates freely and effortlessly, the glass rises easily, without getting stuck and without any extraneous sounds.