The last few days I have been busy fixing engine problems that arose after a long-distance trip of about 1200 km to Moscow.

The symptoms of the malfunction were as follows:

— The malfunction clearly manifested itself while stopping at a traffic light. — The car began to jerk while driving, very strong jerks. — The Check Engine light came on and while driving it began to flash. — The engine idle speed floated between 700 and 500. — The car body began to vibrate very strongly at idle and at low speeds during acceleration. — The traction disappeared and the car began to pick up speed very slowly when accelerating. — When you press the gas pedal, the engine speed quickly rises, but there is no acceleration. — At high speeds and speeds above 80 km/h, the malfunction ceased to manifest itself clearly, but there could be a powerful short-term unexpected jerk. — When reverse gear is engaged, there are significant jerks when driving. — Engine troubles during operation. — There was additional noise from the exhaust pipe (a loud clicking sound). — Gasoline consumption has increased from 8.3 to 11 liters according to the on-board computer.

What's the first thing that comes to mind?

— Problems with oil. — Problems with candles. — Clogged injectors.

What did you do right away?

— Checked the oil. The oil was at a minimum, but not critical. Topped up in the wind and frost. — I ordered spark plugs via Wi-Fi and replaced them immediately. It got better, but the problems did not disappear. — I thought about cleaning the injectors, but decided to replace them.

I ordered a new set of injectors, but I was not sure that replacing the injectors would go away the problems. While the injectors come with Exists, I need to somehow drive, and I began to study further on the Internet.

Symptoms on all forums indicate a malfunction of the following components: - Spark plugs. - Coils. - Injectors. - High voltage wires. — Engine mountings (vibration). - Catalyst.

I was ready to replace everything except the catalyst, because a new one costs about 68,000 rubles, and they usually don’t change it, but install a flame arrester for significantly less money, something like 12,000 rubles.

What interested me most about my malfunction was the drop in engine power with jerks and the vibration in the body, which was a consequence of these jerks.

It turned out that the blinking Check Engine and the “triple” of the engine indicate that one of the engine cylinders is not working due to a “misfire”. I don’t have an ODB II cord, and therefore there is no way to read the error code, and engine diagnostics with this cord from the officials costs the same as the ODB II cord itself with software for connecting to a computer (1200 rubles).

It seemed to me that the engine might be “troubling” because the injector for injecting air mixtures is not working or the coil with the spark plug simply does not ignite it. When I saw on numerous forums a description of the obvious symptoms of “Loss of engine thrust” with a faulty coil “Dielectric breakdown”, it immediately became clear that most likely life was being poisoned by a broken coil. Plus, I looked again at the photo of my old spark plugs from the article about replacing engine spark plugs. It turned out that three spark plugs are dry, and one has a slightly damp inner insulator, and there are many oil spots on the outer ceramic insulator. Oil spots on the outer insulator of the spark plug indicate that the spark is hitting anywhere, and the efficiency of igniting the fuel mixture in a given cylinder is reduced. I am attaching a photo of the old candles again.

As a result, it turns out that on some cylinder the spark plug simply does not work correctly and because of this there are misfires and all other symptoms.

In the morning I pulled out all the coils and examined them again. It turned out that the second coil was very badly punctured and charred in the area of the rubber tip. As a temporary solution, you could wrap the breakdown with fum tape or heat shrink to fix the problem in order to get there normally or wait until a new coil arrives. A solution with fum tape and heat shrink will not be enough for a long time, and it is better not to do it yourself, but to replace the coil with a new one, because this element is considered not suitable for repair.

CHECK ENGINE

—

Check Engine Check - There's nothing fun or enjoyable about those two words. There is also not much logic that can be derived from this phrase, at least not logic that we understand. What does “Check Engine” mean? Is it something more or less specific? No is not. That's because the Check Engine Light means there's something wrong with our engine, and we can't know 100% what it is under the hood that caused that proverbial light to come on. In general and most common cases, Check Engine means that you will have to communicate with car service workers; in the worst case, if your car is far from young, Check Engine may even mean an upcoming major repair.

Replace the oxygen sensor (lambda probe)

The oxygen sensor in your car is part of the exhaust system that monitors how much oxygen is not burned in the engine combustion chamber. This sensor helps control the vehicle's fuel consumption. A malfunction of the oxygen sensor (lambda probe) means that the car computer does not receive the correct data and can significantly increase fuel consumption, and at the same time reduce engine power.

For what reason does the oxygen sensor in a car become unusable: - Over time, the sensor becomes covered with a layer of used and regular motor oil (oil soot), which reduces the accuracy of reading sensor readings for regulating the gasoline mixture and distributing optimal fuel consumption.

What needs to be done: -If you do not change a faulty car oxygen sensor, this may lead to failure of the car catalyst (it may burst), which will result in expensive repairs for you. The cost of new catalysts is very high due to the precious alloys they contain.

Some cars have several of these catalysts at once and their cost can reach up to 90 thousand rubles. So gentlemen, don’t delay replacing the oxygen sensor. Although replacing the sensor itself and its cost are decent, it is still not commensurate with the cost of the exhaust gas catalyst system itself.

You can save money on replacing this sensor by doing it yourself. Many car manuals have detailed instructions on how to replace the oxygen sensor yourself. If you know where the oxygen sensor is located, then it will not be difficult for you to disconnect the faulty lambda probe and replace it with a new one. Remember that you cannot delay replacing this important element!

The engine stalls, the check light flashes or lights up: the main reasons

Let's start with the fact that injection engines are equipped with special catalyst devices for cleaning the exhaust. At the same time, the catalytic converter is a rather vulnerable and at the same time expensive element, and all sorts of malfunctions in the engine create a risk of damage.

As a rule, the check flashes when there is a risk of damage to the catalyst. In this case, the simultaneous tripping of the engine means that one or more cylinders are not working or are not working correctly. In practice, this means that the fuel in the problem cylinder does not burn completely, after which it enters the exhaust system.

As a result, the remaining unburnt fuel burns out in the area where the catalyst is located, since the temperatures there are very high. Fuel also gets on the catalyst itself, causing it to fail.

It becomes clear that the check often lights up when problems arise with the combustion of the mixture in the cylinders. It is not difficult to guess that such combustion can be disrupted for a number of reasons, ranging from problems with the ignition or fuel supply system to lack of air in the intake, air leaks, reduced compression in the engine cylinder, etc.

It should be added that the check also often lights up in the event of failure of any ECM sensors. One way or another, it is quite obvious that the “check” in the vast majority of cases indicates either problems with the electronic engine control system itself, or the risk of damage to the catalyst due to malfunctions of the internal combustion engine.

It is important to understand that the engine tripping indicates a non-functioning cylinder. In this case, the check is flashing not due to the failure of any ECM sensor, malfunction of the exhaust gas recirculation system or poor fuel in the tank, but rather signals to the driver about a direct threat to the catalyst.

In a nutshell, fuel that is not burned and gets into the outlet causes a special sensor (lambda probe, oxygen sensor) to send readings to the ECU indicating deviations from the norm. The control unit begins to try to correct the situation, but taking into account the tripping, it is simply not able to adjust the operation of the motor so that everything returns to normal. As a result, fuel consumption increases, while the engine operates unstably, idle speed fluctuates, etc. In some cases, the motor “falls” into emergency mode.

This mode is necessary in order to minimize damage to the catalyst and the internal combustion engine itself. In practice, this is expressed in such a way that although the driver presses on the gas, the car in emergency mode with the “check” on still does not accelerate above 30-40 km/h, the crankshaft does not spin up, engine traction disappears, etc.

This feature of engine operation is primarily aimed at preventing burnout or melting of the catalyst. The catalyst itself consists of small honeycomb cells. If unburned fuel intensively enters the exhaust and burns out in the catalyst, the element will simply melt.

This melting will lead to the fact that exhaust gases will not be able to pass normally through the catalyst, that is, a plug appears in the exhaust pipe. Naturally, the engine will “suffocate”, power will drop, the engine may not start at all, etc.

Also, the catalyst will no longer be able to clean the exhaust, and toxicity will increase. There is only one way out in this situation - repairing the engine to eliminate the main cause of the engine tripping, and only then replacing the expensive catalyst with a new one. To minimize risks, a special program is programmed into the ECU, which involves operating the engine in emergency mode.

Causes of engine error

The fact that the check is flashing indicates a danger to the catalyst is understandable. The question “why?” Most likely, when you connect the scanner, you will receive the error p0300 multiple misfires. There may be several reasons for such omissions.

The most undesirable thing, in my opinion, is a burnt valve. When a valve burns out, the engine starts to rough up. Such tripling is usually permanent, since the cause is mechanical. Of course, such a motor pulls very poorly. It is highly not recommended to drive such a car, unless of course you want to change the oxygen sensor and catalytic converter in addition to the valve.

Well, the simplest reason for tripping is the candles. Always carry a spare set of candles with you. Don’t think that a modern car doesn’t need repairs and can’t break down on the road.

In addition to valves and spark plugs, there may be the following reasons:

Individual ignition coils may have a breakdown or an interturn short circuit. This can be determined using a non-contact probe and an oscilloscope program on a laptop. If you have an ignition module, you can check its operation by carefully removing the caps from the spark plugs.

If clicks are heard, then there is a spark; if there are no clicks, the module does not work for this spark plug. Be careful with this check, if the secondary circuit of the module is left without load (move the cap too far from the spark plug) and there is nowhere for the spark to break through, then the switch in the engine control unit can easily burn out.

Carefully inspect the spark plug wells. The presence of water or oil in them is unacceptable. The motor may stall precisely for this reason.

If one or more injectors do not work, the engine will, of course, stall and the check mark will start flashing.

Well, if the timing marks are suddenly knocked down or incorrectly installed, the engine will operate in a mode similar to tripling. But at the same time, there is a spark in all cylinders, fuel also flows through the injectors normally and the check lamp is blinking.

Conclusion

The main reasons for the VAZ 2110 8-valve engine tripping are identified, and methods for solving the problem are described. So, the main problems arise due to an incorrect air-fuel mixture, the formation of a spark or in the piston mechanism. There are different ways to solve the problem.

But, it is recommended to turn to professionals in solving such problems who can do everything quickly and efficiently. Because improper repairs can lead to even bigger problems, which will entail additional costs.

Why does the “check” light up: the most common and common malfunctions

So, we figured out the general scheme. Now let's look at what problems lead to the check light coming on and the engine stalling. Often a p0300 error occurs, which indicates that a misfire (misfire) is occurring. There are several reasons for these omissions, and to determine them it is necessary to carry out a step-by-step diagnosis, taking into account certain individual symptoms.

- You should start by checking the ignition system. The most common cause of tripping is the failure of spark plugs and armored wires. Candles can wear out their service life, break down, or become heavily contaminated. Armored wires suffer from insulation damage and breakdowns. One way or another, the result is either no spark at all, or there is a spark, but it’s weak.

If everything is in order with the spark plugs and wires, you should pay attention to the ignition module or ignition coils, which may be shorting. In this case, it is better to entrust the check to experienced specialists, since unprofessional actions lead to the fact that you can burn the switch or damage other important elements.

It should also be added that you need to carefully inspect the spark plug wells themselves. Quite often, the engine fails if water accumulates in the wells or engine oil gets there. In some cases, lubricant gets into the wells due to problems with the valve cover gasket.

- Having dealt with the ignition system, it is necessary to check the power system. As a rule, incorrect operation of injection nozzles or malfunctions in their operation lead to engine tripping. At the same time, the check will light up or flash.

The best option would be to check the injectors on a special stand. Such diagnostics allows you to determine the need to clean, repair or replace injectors. At the same time, specialists check the power supply to the injectors, the condition of the injector O-rings, etc.

- As for compression, a burnt-out valve often leads to an unexpected decrease in the indicator. If the valve burns out, the engine starts to run rough. In this case, tripling is constant and occurs in all modes of engine operation. Engine thrust drops significantly, and significant excess fuel consumption is observed.

Please note that in this case you cannot drive the car, as there is a high risk of damaging the catalyst and oxygen sensor (lybda probe). To confirm the diagnosis, you need to measure the compression, and to solve the problem itself, you need to remove the cylinder head, troubleshoot the head and change the valve.

It is worth noting that most causes of the malfunction can be diagnosed with a scanner. An inexpensive device will cost even less than a visit to a service station, without taking into account the time saved. For example, you can consider the multi-brand scanner Rokodil ScanX

With its help, you can easily determine the exact cause of the malfunction. For example, if we are talking about misfires in cylinders or a problem with injectors, the scanner will more accurately indicate the location of the faulty element (P0301-P0304 - misfires in cylinders 1-4 and similarly with injectors P0200). The serviceability of the catalyst can be checked down to the degree of its contamination, based on the readings of oxygen sensors, which can be checked in real time. Rokodil ScanX is compatible with most cars and can help out in difficult situations more than once.

How serious can the reasons be?

Each signal on the car panel is an indicator that the driver must be attentive. When the check engine light comes on, there are several reasons.

- A common cause is gasoline. Due to the additives that unscrupulous manufacturers use in gasoline, the engine does not work properly and becomes clogged. You should change the fuel or refuel at another gas station, and everything works correctly.

- Faulty spark plugs.

- Broken ignition coil.

- A faulty oxygen sensor (lambda probe).

- Broken exhaust catalyst.

- Incorrect operation of high-voltage conductors.

- Malfunction of injectors.

- Fuel pump or fuel filter.

The check should begin with the fuel tank filler cap. If it is not tightened completely or there are defects on it, then the light indicates that the engine is not operating properly.

Each of the reasons is not very scary, but requires immediate elimination. If you do not pay attention in time and do not diagnose the malfunction, you can lead to complete engine failure and incapacity of the machine.

The engine is serious business, but the job doesn't necessarily require a major overhaul or engine replacement. The work of the craftsmen is important in any matter of diagnosing and repairing the engine. But, if the reason is candles, then the replacement is carried out independently and quickly, without the involvement of specialists.

Long-term use of the vehicle

If the checkbox starts blinking on a VAZ car with high mileage, then the reasons for the power unit tripping are as follows:

If the above procedures have been completed, and the power unit is still running, then it is recommended:

- Diagnose the ECU. If necessary, it is replaced with a new block.

- Check the injectors and the entire gasoline supply system.

- Check the oxygen sensor for functionality. If the device is faulty or the performance is deteriorated, repair work is carried out.

- The crankshaft position sensor fails - in this case, the ECU generates an error indicating this failure.

What to do if the light comes on

If you see that the check engine light does not light up as it should (does not go out after starting the engine or lights up when driving), then you should stop to diagnose the car. This may not be done right away, but it is necessary. Remember, if it lights up, this is the reason, either go to a service station for diagnostics, or check the engine for faults.

The first thing you can do when the light comes on is to stop and listen to how the engine is running: is there any vibration, or any extraneous noise or knocking. If you hear extraneous sounds, they will indicate the cause of the breakdown to an experienced driver. If the cause of the breakdown is not clear to you, the direct route is to the nearest service station.

If the cause of the light coming on is poor-quality fuel (this can be determined after diagnostics, after eliminating other causes), then the service technicians will tell you that it is worth changing the type of fuel you fill in the car or the place where you are used to refueling.

They also conduct a visual inspection of the engine for cracks, irregularities, and leaks. If you yourself discover a breakdown, then repairs are carried out according to the reason.

- Oxygen sensor. It is worth replacing it yourself, following the operating instructions for a car of a particular brand. If the replacement is not made in time, there will be excessive fuel consumption and the catalyst may break, the replacement of which will be much more expensive.

- A leak in the fuel tank is the cause of air getting inside, which means excess consumption. It is worth either replacing the lid or achieving a tight seal using gaskets.

- Candles. This is the main element that guarantees the combustion of the fuel mixture. If they do not work correctly, then the car will refuse to work at all. Replacing spark plugs is not difficult if you are already an experienced driver. You can change either only the spark plug that has already served its purpose, or all at once, in order to definitely avoid problems with the car. It’s worth buying a set of spark plugs specifically for your car at the store. If you are not sure that you will buy the right option and be able to replace it, then go to a service station, they already have the parts you need and specialists will be able to make the replacement quickly and affordably. When it comes to spark plugs, it is worth remembering that old-style cars require replacement every 20,000 km, and if the car is new, then it can travel up to 150,000 km on the same spark plugs. If you change spark plugs on time in accordance with the technical operation requirements of your car, then you can avoid catalytic converter breakdown and improve engine performance.

- Replacing the mass air flow sensor. This part regulates the amount of air needed for rapid ignition. When it is faulty, it results in excessive fuel consumption, an increased amount of carbon dioxide in the exhaust, poor acceleration, and a decrease in engine power. Most often, the breakdown is due to an incorrectly installed air filter or the filter's operating time has already expired. When it comes to changing a sensor, the costs are related to the price of the sensor itself, but the replacement service is not so expensive because it does not require much time and is simple in technology. Regular filter replacement guarantees long-term operation of the sensor .

Nuances in the operation of the “Check engine” light

The check engine light on the dashboard appeared in the early 90s. but then the work of the sensor was aimed only at monitoring the operation of the carburetor. That is, the light came on when:

- There was a blockage;

- The combustible mixture for engine operation was incorrectly prepared, etc.

Today, the work of a light bulb is much broader. There are no carburetors in new-style cars anymore. Injectors are installed instead. It is in connection with this new feature in the car that the light shows not only the wrong mixture. Thanks to it, the driver learns about:

- Business interruptions;

- Ignition problems;

- Poor gear shifting and more.

Bad fuel

Often residents of the CIS are faced with the fact that the “check” lights up after the car has been recently refueled. If at the same time there is a loss of power, the reason may lie precisely in the quality of the fuel.

Incorrectly selected, poor diesel fuel can cause detonation in the engine and disrupt the process of normal combustion. The electronic engine control unit records these changes and generates an error.

To solve the problem, it is often enough to simply dilute the already filled fuel with high-quality fuel. If everything is done correctly, after a couple of kilometers, the “Check Engine” will go out by itself.

In particularly advanced cases, the fuel will have to be drained completely and the fuel supply system will have to be flushed. If after this the “check” does not go out, the error will have to be reset through the program.

Fuel system tightness

The “Check Engine” warning is not always associated with serious malfunctions. Sometimes this light comes on when the engine is getting too little or too much fuel for some reason.

Therefore, the first step that the owner should take is to check the tightness of the fuel tank closure - perhaps its cap is cracked or loose. Such a banal reason often explains the appearance of a “check” on the instrument panel.

If the inspection shows cracks in the cover, it needs to be replaced urgently. If the cap is unscrewed, you just need to tighten it and drive a couple of kilometers for the “check” to go out.

The oxygen sensor (lambda probe) has failed

The oxygen sensor is involved in adjusting the proportions of the fuel mixture. It collects data on how much oxygen is contained in the exhaust gases, which is transmitted to the engine management system. Depending on this data, the ECU decides whether to enrich or lean the fuel mixture on gasoline engines.

In diesel engines, a lambda probe , together with a mass air flow sensor (MAF), helps to accurately determine the degree of exhaust gas recirculation for each operating mode.

That is, the purpose of the oxygen sensor is to transmit accurate data to the engine control system in order to make its operation more economical and environmentally friendly. Modern cars are equipped with 2-4 oxygen sensors.

Over time, the lambda probe becomes covered with a layer of used engine oil and begins to transmit erroneous data to the engine ECU. As a result, too much or too little fuel enters the chamber, which leads to malfunction.

The solution to the problem is to replace the faulty oxygen sensor, and it is better not to delay it, because a faulty lambda probe can damage the catalyst.

The mass air flow sensor has failed

The mass air flow sensor, together with the oxygen sensor, is involved in dosing fuel when preparing the air-fuel mixture.

When the mass air flow sensor fails, the proportion of formation of the fuel mixture is disrupted, hence malfunctions of the diesel engine, difficulties with cold starts, loss of power and increased diesel consumption.

Moreover, sensor failure may be caused by a violation of the air filter replacement regulations.

A faulty sensor needs to be replaced, otherwise problems with engine operation will not be eliminated, and the “Check Engine” warning will remain on the instrument panel.

The check light is flashing, the engine is shaking and not pulling, the car is shaking, the speed is floating

Typically, this situation occurs when driving, when the engine needs to suddenly increase speed. When idling everything is fine. Suspicion primarily falls on malfunctions in the ignition system. In this case, you should not experiment with a gasoline engine to check the spark in the coil, on the spark plugs and other manipulations. This can only be done using a multimeter. If the car’s behavior is limited only to the engine’s operation of not all cylinders, you need to carefully, cautiously, and slowly drive towards the nearest car service center. It is better to pay some money to professionals who are able to find and eliminate the cause than to damage the on-board computer or other delicate electronics due to your ill-considered actions. In this case, the costs will be much higher.

The check light came on after refueling

Bad gasoline is the cause of unstable engine operation

This problem may arise from a leak in the fuel system. One of the reasons is a poorly tightened gas cap or a defect in it. If necessary, the plug should be replaced. Another reason for the check to burn is refueling with gasoline with a low octane number or low-quality fuel. In the latter case, the gas station is changed. If the fuel is so bad that the car does not work stably, it needs to be drained. In all other cases, you can do this: dilute the fuel with high-quality gasoline, and reset the check engine readings to zero by removing the negative terminal of the battery for a few minutes.

If moisture gets inside the engine with injection, the injector after washing, heavy rain, or when crossing a river, drops of water can get on the high voltage wires, ignition coil, and wiring connectors. The danger here is that the malfunction will not appear immediately, but after some time. The consequences can be dangerous if the car is driven on the freeway. The “Check Engine” LED will light up, and the engine may suddenly rev up, lose throttle response, or even stall. It will help to remove moisture with a dry rag and dry all components of the power unit with warm air (using a hairdryer).

Vehicle malfunction at idle

If the VAZ 2114 power unit idles at idle, then:

In the first case, the fuel system is flushed and the injectors are cleaned. To carry out the last work, ultrasound is used. In the second case, you will need to replace the spark plugs, high-voltage wires, and diagnose the ignition coils. In the latter case, the valves are replaced or readjusted.

If the power unit stalls while running hot, then auto mechanics advise carrying out similar work as described above. At idle speed with a heated engine, one cylinder may not work due to malfunctions in the fuel mixture supply system or lack of spark. In this case, it is recommended to carry out the same work as in case of failures during cold running.

How to turn off the check engine LED. Reset error

On different brands of cars, the self-diagnosis process is launched in different ways. For some, by turning the ignition key and pressing the gas pedal a certain number of times at certain intervals. The engine fault light starts blinking and you need to count the flashes, convert them into an error code and find an explanation in the table. For others, an error code is displayed on the on-board computer display if you start the self-diagnosis process through a combination of buttons.

Still others bridge certain contacts in the diagnostic connector for this purpose.

An excellent option that will help you save a lot of money on a trip to a car service center is to buy an OVD-2 car scanner or another brand. With its help, you can regularly check the operation of the engine to identify errors in order to understand which sensor requires replacement, or which adjustment has been violated.

Resetting errors by removing the battery terminal

You can reset errors in the on-board computer or ECU in the most accessible way - disconnect the terminal from the battery for a short time. The memory of electronic devices will be reset and the indicator should go out. But this should be done only after the error has been decrypted, detected and corrected. There are other ways to reset errors: using a scanner, installing special programs on a smartphone, closing the contacts in the diagnostic connector.

Checking the oil level and condition

The next most important reasons for the signal are considered to be overheating of the motor and a decrease in the level of lubricating fluid in the internal combustion engine. It is recommended to check the engine temperature. If there is no overheating, you need to check the volume and condition of the oil. After checking the level, it is necessary to add the missing amount of lubricant. Using a clean paper napkin, the quality and composition of the engine oil is checked according to the following criteria:

- Color.

- Consistency.

- Presence of mechanical inclusions.

- The smell of burning.

If everything is in order with the quality and quantity of oil, the engine starts to eliminate unusual sounds and noise when operating both at idle and under load.

If unusual noise effects of a running engine are detected against the background of a burning check, it is recommended to send the car to the nearest service company. Moving the car yourself is not recommended; delivery is carried out by towing or other convenient method. Further operation can lead to serious damage and costly repairs to the elements of the power unit.

Reset errors

There are quite a lot of cases when the Check Engine light comes on, and the problem that has arisen should not be ignored. However, after eliminating the problem, the light may still remain on. What does this have to do with?!

After detecting a problem, the ECU stores its code in memory (this has already been mentioned). However, if the situation is corrected, the code cannot go anywhere and therefore the indicator lights up again the next time the engine is started. Here you should erase error codes from the computer's memory. In the language of specialists, this procedure is called resetting error codes. There are several options for how this can be done.

Professional technique

This is the most reliable and effective way to get rid of the annoying indicator when the problem has already been solved. The procedure is performed in a car service center using special equipment. And today there are a lot of such places in every city, not to mention megacities.

Amateur performance

You can find special scanners for cars on sale in relevant specialized stores. Such a device can help out in different situations and therefore this purchase will be very useful for any vehicle owner.

Then the only thing left to do is download the necessary software for your smartphone (tablet or laptop - now every second car enthusiast has such gadgets). By connecting the device to the vehicle's OBD2 diagnostic connector, you can “read” all existing Check Engine errors.

Some software offers an alternative solution to the problem. Most minor breakdowns can be easily resolved by car owners. In other words, buying a car scanner has certain advantages, including savings. Finally, all that remains is to erase the errors, and the check will no longer bother and irritate you.

Originally folk technique

Some craftsmen know very well what to do to reset the error, using their own special method, which every experienced car enthusiast knows about. To turn off the light bulb, just follow a certain sequence:

- Start the engine.

- Open the hood and disconnect the positive terminal of the battery.

- Wait 60 seconds, then return the terminal to its place.

- The error code will be reset, which will be indicated by the indicator light going out the next time you turn on the engine.

- Another procedure may also help:

- Turn on the ignition, wait 3 seconds and proceed to the next step.

- Press the accelerator pedal 5 times, holding each position for 5 seconds. Release the pedal.

- After 8 seconds, press the gas pedal again and hold it for 10 seconds - the indicator will blink.

- Take your foot off the pedal and you can look at the display where error codes are displayed. Now press the accelerator pedal again for 10 seconds - the Check Engine light should go out.

- Turn off the ignition.

- To check, you can start the engine again and make sure that the indicator goes out and does not light up, as it should be.

It is worth noting that the last two methods only work if the problem is fixed. Otherwise, you shouldn’t be surprised that the Check Engine caught fire. And then visiting a specialist is only a matter of time.

Video: Daewoo Matiz. Reset Check Engine Using ELM327 and Torque

Cylinder failure

https://www.youtube.com/watch?v=ephtWvjupAo

If the engine operates stable or unstable, it is recommended to check the cylinder. Its malfunction is associated with breakdown of the spark plugs, oxygen sensor and ECU. The cylinder can fail instantly or gradually. In the first case, the VAZ engine suffers, fuel consumption increases, engine power decreases, and vibration increases.

If the vehicle is not repaired in a timely manner, the engine may fail. This is explained by the fact that gasoline is constantly supplied to the broken cylinder, which is mixed with oil and goes into the crankcase. With a long process, the latter substance liquefies, losing its properties. The parts of the power unit begin to work in emergency mode, wearing out and forming chips.

Error code: VAZ 2107 diagnostics do not connect

If the check is flashing and the VAZ engine is shaking, then you must follow the following recommendations:

- start the power unit;

- open the hood lid;

- remove the wires from the spark plugs one by one.

The next step is to inspect the spark plugs for condition and performance. To do this, you will need to unscrew the spark plugs with a special key. If there is smoke on the head, and the electrode is clean and intact, then the motor tripping is due to dust getting into the cylinder. In this case, it is recommended to check the air supply system through the filter.

If the burn is on the entire head, and the electrode is completely burnt out, then detonation combustion has occurred and the ignition system has been emptied. If the head is covered with smoke, but the electrode is intact, then the mixture enters the ignition system late.

By assessing the condition of the spark plugs, it is possible to determine the exact cause of the failure of the cylinder. To check the performance of spark plugs, it is recommended to use the “spark” method. If it breaks through, then the check continues. If there is no spark, then the spark plugs are replaced with new analogues.

A good spark requires starting the VAZ and tracking the dynamics of changes.

Floating engine speed

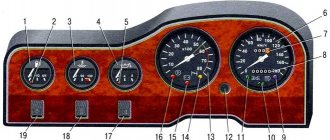

Engine speed problems can easily be identified by looking at the tachometer. Stable operation of the power unit at idle should not exceed 850 rpm. A small spread of 750 to 850 rpm is allowed. If the tachometer needle jumps chaotically—it goes down, then it goes up—there is a malfunction. This is a fairly common problem, and it is easy to identify why the speed of the Lada Granta is floating. It is enough to listen to the engine running - with unstable idle speed, the noise either decreases or increases.

Why are the revs jumping?

The cause of the problem is the specifics of regulating the operation of the power unit at idle by the control unit. It continuously reads data about the status of various engine systems from sensors. If the idle speed becomes unstable, the sensors are given a command to correct the functioning of the system.

A malfunction of the mass air flow sensor may be one of the causes of the problem. During operation, it becomes covered with a thin oil film, the formation of which will certainly lead to breakdown. When excess air is sucked through the inlet into the cylinders, idle speed is disrupted. As a result, the air flow sensor transmits incorrect information to the ECU about the excessive consumption of incoming air. The failure is displayed on the dashboard - a “check”, or engine error, lights up on the screen of the Lada Granta’s on-board computer. In this case, the control unit commands the valves to admit more fuel into the cylinders and equalize the ratio of air and gasoline to prepare the optimal mixture. As a result, the speed increases sharply, and the ECU realizes that there is too much fuel and gives the command to limit the supply. As a result, the speed drops sharply.

IAC (idle air control) can also cause jumps in engine speed, in which case a “check” will light up on the dashboard. The regulator is an electric motor with a cone-shaped needle. Its direct purpose is to adjust and maintain stable idle speed. A faulty regulator stops working normally, and the engine, left without it, begins to randomly increase or decrease speed.

Unstable idle may be caused by a problem with the oil pan ventilation valve. Engine operation is accompanied by the release of gases that accumulate in the pan. If there is a large amount of crankcase gases, they are discharged through the ventilation system through the intake manifold to the throttle assembly. With their help, part of the air-fuel mixture is formed in the combustion chambers. If the valve loses its normal throughput, then less gases enter to enrich the mixture, and the speed begins to float.

Methods for eliminating floating speed

Any cause of idle fluctuations can be neutralized in the following ways:

- Excessive air leak. The intake system needs to be checked for leaks. You can treat the hoses with WD liquid - there is a crack in the place where it instantly evaporates. You cannot seal it with tape or tape; only replacing it with a new part will help.

- IAC breakdown. The serviceability of the idle air control can be checked with a multimeter by measuring the resistance. If the readings are between 40 and 80 ohms, the regulator must be replaced.

- Malfunction of the oil sump ventilation valve. You can get to the part only after removing the pallet. The valve is dismantled, thoroughly washed in gasoline or kerosene and, after drying, installed in its place.

- Problem with DMRV. If the mass air flow sensor fails, it cannot be repaired; it can only be replaced with a new part.

- Problems with the throttle valve. If the problem is incomplete closure, the throttle assembly can be washed, for example, with carburetor cleaning fluid or the like.

It is quite easy to fix problems associated with floating engine speeds on your own, especially when you have minimal skills and experience. If you think that you cannot cope with such work, it is better to contact a service station.

Triples have arisen: reasons

If you notice that the car is jerking, and the check is tripping and burning, there is definitely damage, but there may be several reasons.

It all depends on the design of the engine installed in the vehicle, associated systems, sensors and other elements. For example, catalysts are installed on the injectors, which are necessary for cleaning exhaust gases. These components are expensive and capricious. Even minor engine malfunctions can damage the catalysts.

The fault can also be found in the spark plugs. Usually the reason is untimely replacement of a component or gaps between the electrodes. The check engine starts blinking when defects are detected in other important engine components.

Cylinder

Troubling may mean that one of the cylinders is not working properly. The fuel in it does not burn completely, entering the exhaust system. The residues will burn out in the area where the catalysts are installed, since the temperature in the unit is high. At the same time, they send a damage message to the ECU. The block will try to correct it, but will not be able to due to tripping. Therefore, fuel consumption will increase sharply. The engine will begin to function unsteadily, and the car's emergency lights will turn on.

This is necessary so that damage to the internal combustion engine and catalyst is reduced. In practice, this translates into the fact that the car begins to accelerate poorly. Often, engine thrust decreases and problems arise with spinning the crankshaft. Thanks to this mode, the catalysts do not melt or burn out.

But if the situation gets so bad that melting occurs, a plug will form in the exhaust pipe. It will block the exit of exhaust, so the masses will become more toxic. As a result, the power unit will work at 50% or will not start at all. The solution is planned repairs.

Valves

Because of this element, the engine begins to stall, especially in old-style engines that do not have hydraulic compensators. Under these conditions, it is necessary to adjust the valves, both on the damaged cylinder and on the “healthy” one.

Attention!

In cars with gas equipment installed, it is necessary to adjust the valves twice as often as in gasoline cars. There is no need to delay the procedure, because if the valve burns out, replacing it will be expensive.

Distributor

Due to damage to this element, the spark does not reach the spark plug or arrives late. This happens due to wear of the bushing, bearings and shaft. As a result, a gap appears between the contacts, causing cycles to be skipped.

Troubling appears when it is cold, but disappears almost completely after warming up. This also occurs due to thermal expansion as the gaps become smaller.

Air leak in the vacuum brake booster

Newer car models are equipped with sealed vacuum brakes. If this integrity is violated, air will leak into the system. It mixes with the fuel mixture, making it leaner. As a result, the mixture does not ignite well when it enters the cylinder. The spark plug becomes wet, a spark does not form and the fuel does not ignite.

This can provoke a slight adjustment of the engine, which will be noticeable in cold and hot conditions, even at idle speed. To make sure that the cause of the malfunction is air leaks, it is necessary to determine where exactly the depressurization occurred in the system.

Electronic components

The electronic control unit (ECU) is responsible for the operation of the new motors. Management in this situation is carried out on the basis of information coming from different sensors. Sometimes a failure or malfunction in their operation can cause the power unit to trip. Electronics reduce fuel consumption, but the power unit becomes less reliable, and its service life is also reduced.

Why does the injection 8 valve engine of the VAZ 2114 troit?

As you know, the injection engine has replaced the carburetor engine mainly due to its efficiency, as well as the reduced amount of harmful emissions into the atmosphere. This became possible as a result of flexible adjustment of the operation of the internal combustion engine using the electronic control system of the ECM.

Note that the indicated “check” lights up for various reasons. In this article we will talk about why the check light blinks, the engine stalls, or the power unit is unstable in different modes, and such operation is accompanied by a lit internal combustion engine fault indicator.

Check the fuel filler cap

Many drivers, in most cases, when the “check engine” indication appears, will think about serious problems in the car’s engine, but will not even think to check the tightness of the fuel system, which may be compromised due to a defect or an insufficiently tightened fuel tank cap. This is a very common reason for the appearance of the “Check” engine icon.

Reason for the error: Leakage of the fuel system due to the passage of air through the filler cap of the fuel tank will increase the vehicle's fuel consumption, to which the vehicle's diagnostic system will generate an engine error by turning on the "Check engine" indication on the vehicle's instrument panel.

What needs to be done: If, when the “Check” indication appears, your car has not lost power, and there are no audible signs of engine damage (engine knocking, humming, creaking, etc.), then first check the gas tank for leaks. Your gas cap may be cracked or not tightened enough. If the cap was not tightened enough, then after tightening it all the way, continue driving the car for a while to see if the engine error disappears. To prevent a check engine light from appearing for this reason, check your fuel filler cap regularly. Remember that the cover must be replaced with a new one periodically!

Tips for restoring the performance of the power plant

If cleaning the engine compartment results in the engine being unable to start, the car owner should not panic and immediately call a tow truck. You can correct the situation right on the spot. It is enough to dry the places where liquid accumulates. It is recommended to adhere to the following instructions:

- Open the hood and visually inspect the power plant and other components. Any water found must be carefully removed;

- Remove the terminals from the battery and remove oxides;

- Wipe the high-voltage wires along the entire length;

- Unscrew the spark plugs and let them dry. Make sure there is no water in their planting areas;

- If there is a distributor, it must be dismantled. After this, remove the lid and wipe everything dry;

- Open the air filter housing and make sure there is no liquid in it;

- Check the status of the alarm.

If the above steps did not help, then the malfunction did not arise as a result of the engine being washed, but for other reasons. In this case, it is necessary to begin troubleshooting components and parts. For example, a cracked distributor cap could perform its functions when dry, but the appearance of moisture completely rendered it inoperable.

How to protect from water when washing

The best remedy is, of course, not to wash the engine. But how to remove oil stains? There are several ways. The most neutral one, which does not lead to consequences, is to buy a grease remover from dishes in a store, spray it on and wait a few minutes until everything drips down. Then use a compressor to thoroughly blow through all engine parts. But no moisture or water.

The second way is to mix a little gasoline with mallow - a product that many car mechanics use to wash their hands, pour this mixture into a spray bottle, spray it on the engine and also air dry.

What can cause the engine to run unstably?

Most often, the “check” can blink and the engine may run unstably when the fourth cylinder of the injector, which has 8 valves, fails. However, this formulation is incorrect, the reasons may be the following:

- problems with the spark plug;

- low compression in cylinders;

- the valves have not been adjusted for a long time (they do not fit tightly);

- the injectors are clogged or overfilled (they will have to be replaced);

- spark plug wire breakdown;

- ignition coil malfunction;

- The crankshaft sensor is not working correctly;

- the electronic control unit has failed;

- the timing belt is misaligned (or it has completely fallen off);

- Air filter contamination.

All these reasons lead to the failure of the cylinder and the appearance of characteristic signs of a malfunction.

In this case, problems can occur simultaneously or after a certain period. Pay special attention to the following signs:

- increased engine vibration during operation - the operation of valves, rotating parts of the power plant and transmission is disrupted;

- an increase in fuel consumption and a change in the nature of exhaust gases (they will contain unburned fuel);

- reduction in engine power and reduction in vehicle maneuverability.

Remember that the consequences of neglecting the condition of the engine appear very quickly. If you continue to use a faulty car, you may very soon need an expensive overhaul of the power unit or its complete replacement.