A capacitor malfunction can occur in three cases: 1.due to loss of part of the capacitance. 2. due to internal break 3. internal short circuit. If there is a short circuit, the engine will not work; in the second and first cases, the ignition system may not fail immediately. It will function, although the spark energy will be much lower than expected. This is evidenced by unstable engine idling and possibly difficult starting. Since the operation of the breaker in this case is accompanied by increased sparking, its contacts will quickly burn and wear out, gradually deteriorating the engine’s performance. Thus, the motor will “refuse” to start only some time after the capacitor fails. The situation can be temporarily corrected by cleaning the burnt contacts of the breaker.

I have a complicated cold start, i.e. it started up 3-5 times, and for the first 3-5 seconds it started up, then it picked up sharply and everything returned to normal, the air conditioner was from VAZ, after replacing it with the original old air conditioner, the cold start returned to normal, but considering that the old air conditioner was already 30 years old, I decided not to tempt fate and not torment the old capacitor, I ordered and installed an analogue HYUNDAI/KIA 27325-35610

price - 250 rubles.

The main malfunction of a capacitor in a contact ignition system is its breakdown to ground. In this case, the car engine may not start at all, or will start and stall, or suddenly stall while driving. Characteristic external signs of a malfunction are: strong sparking between the breaker contacts when starting the engine and a very weak spark or its complete absence.

There are several ways to check the capacitor on VAZ 2105, 2107 cars.

- Using a control lamp.

We disconnect the wire coming from the ignition coil and the capacitor wire from the distributor (they are attached to one terminal “K” of the breaker). We connect a test lamp between them, turn on the ignition and observe it. If it lights up, the capacitor is “broken” and must be replaced. No - OK.

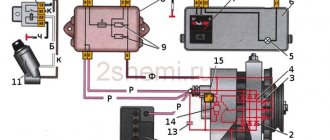

1 - ignition coil, 2 - distributor cap, 3 - distributor, 4 - capacitor.

— Using a wire from the ignition coil.

As in the method described above, we disconnect the wire from the coil and the capacitor wire from the terminal on the distributor. Turn on the ignition. We touch the tips of the wires. Sparking appears - the capacitor is faulty. No, everything is okay.

1 — ignition coil, 2 — distributor cover, 3 — distributor, 4 — capacitor.

- Using a high voltage charge and subsequent discharge to ground.

We turn the crankshaft so that the breaker contacts in the distributor close. We disconnect only the capacitor wire from the distributor. Turn on the ignition. We bring the tip of the central high-voltage wire from the ignition coil to the tip of the capacitor wire. Use a screwdriver to open the contacts of the breaker (or you can turn the distributor slightly by hand so that the contacts move apart). A spark will jump between the tip of the high-voltage wire and the tip of the capacitor wire - the capacitor will be charged with a high voltage current. We bring the tip of the capacitor wire to its body. The appearance of a discharge spark with a click indicates the normal condition of the capacitor. There is no spark - the capacitor is faulty.

Notes and additions

— The capacitor on VAZ 2105, 2107 cars and their modifications with a contact ignition system is installed on the distributor (30.3706-01) parallel to the breaker contacts and serves to increase the secondary voltage and prevent burnout of the contacts. It is charged when the contacts are opened and discharged through the secondary winding of the ignition coil, which causes an increase in the secondary voltage.

— Operating parameters of the capacitor of VAZ 2105, 2107 cars: the capacitance of the capacitor is measured in the frequency range 50 - 1000 Hz and is in the range of 0.20-0.25 μF, the insulation resistance at a temperature of (100±2)ºС and a DC voltage of 100 V should be more than 1 MΩ/μF.

Checking the capacitor VAZ 2107

The main malfunction of a capacitor in a contact ignition system is its breakdown to ground. In this case, the car engine may not start at all, or will start and stall, or suddenly stall while driving. Characteristic external signs of a malfunction are: strong sparking between the breaker contacts when starting the engine and a very weak spark or its complete absence. There are several ways to check the capacitor on VAZ 2105, 2107 cars.

- Using a test lamp.

We disconnect the wire coming from the ignition coil and the capacitor wire from the distributor (they are attached to one terminal “K” of the breaker). We connect a test lamp between them, turn on the ignition and observe it. If it lights up, the capacitor is “broken” and must be replaced. No - OK.

— Using a wire from the ignition coil.

As in the method described above, we disconnect the wire from the coil and the capacitor wire from the terminal on the distributor. Turn on the ignition. We touch the tips of the wires. Sparking appears - the capacitor is faulty. No, everything is okay.

1 — ignition coil, 2 — distributor cover, 3 — distributor, 4 — capacitor.

- Using a high voltage charge and subsequent discharge to ground.

We turn the crankshaft so that the breaker contacts in the distributor close. We disconnect only the capacitor wire from the distributor. Turn on the ignition. We bring the tip of the central high-voltage wire from the ignition coil to the tip of the capacitor wire. Use a screwdriver to open the contacts of the breaker (or you can turn the distributor slightly by hand so that the contacts move apart). A spark will jump between the tip of the high-voltage wire and the tip of the capacitor wire - the capacitor will be charged with a high voltage current. We bring the tip of the capacitor wire to its body. The appearance of a discharge spark with a click indicates the normal condition of the capacitor. There is no spark - the capacitor is faulty.

Notes and additions

— The capacitor on VAZ 2105, 2107 cars and their modifications with a contact ignition system is installed on the distributor (30.3706-01) parallel to the breaker contacts and serves to increase the secondary voltage and prevent burnout of the contacts. It is charged when the contacts are opened and discharged through the secondary winding of the ignition coil, which causes an increase in the secondary voltage.

— Operating parameters of the capacitor of VAZ 2105, 2107 cars: the capacitance of the capacitor is measured in the frequency range 50 - 1000 Hz and is in the range of 0.20-0.25 μF, the insulation resistance at a temperature of (100±2)ºС and a DC voltage of 100 V should be more than 1 MΩ/μF.

More articles on car repairs

For clarity, the checks were made on a removed generator, but they can also be carried out on a car by disconnecting the wires from the battery and generator

Method four

The fourth option for checking the capacitor is related to starting the crankshaft. If strong current generation occurs during installation of the internal combustion engine, this is a sign of a faulty capacitor.

As for the malfunction, it is easy to determine when starting the engine. If there is a weak spark between the center armor wire and ground, but the contacts spark strongly, this indicates penetration. Such a capacitor can no longer work normally - it will have to be replaced.

This will allow you to test a system element in different ways. Each motorist, depending on his experience, chooses a more suitable option.

Forget about camera fines! An absolutely legal new product - Jammer for traffic police cameras, hides your license plates from cameras that are found in all cities. More details at the link.

- Completely legal (Article 12.2);

- Hides from photo and video recording;

- Suitable for all cars;

- Works through the cigarette lighter socket;

- It does not interfere with radios or cell phones.

Refined check

We check the negative valves by connecting the “plus” of the device to one of the mounting bolts of the rectifier unit, and the “minus” to the generator housing.

If the resistance is low, one or more valves are broken, or there is a short circuit of the stator winding to the generator housing.

To check the positive valves, we connect the “plus” valve of the device to terminal “30” of the generator, and the “minus” valve to one of the mounting bolts of the rectifier unit.

Low resistance means that one of the valves is broken

If the elements of the rectifier unit fail, we recommend replacing it as an assembly.

It is possible to replace individual diodes, but they will need to be repressed into the holder - an operation that requires care and skill.

Device and connection diagram

Inside the ignition system module (catalog number 2111-3705010) there are voltage converters and electronic components that distribute pulses based on signals from an external sensor. The elements are connected by jumpers, which are attached with tin-lead solder. The housing is made of dielectric material that does not collapse under the influence of vibrations and temperature changes. The outputs are equipped with contact plates to which mating elements of high-voltage cables are connected.

Ignition system diagram.

Connection instructions

- Install the coil onto the cylinder block and secure with screws.

- Connect the plug of the engine wiring harness.

- Connect the outputs of the coil to the spark plugs with high-voltage wires, observing the serial numbers of the cylinders. The numbers are printed on the module body. On the engine, the cylinders are counted from the accessory drive pulley.

- Connect the battery and crank the crankshaft with the starter to start the engine.

Capacitor check

To check the capacitor, a special device is used, but you can first assess the condition of the capacitor with an ohmmeter.

We short-circuit the terminal of the capacitor to its body so that it discharges.

We connect the ohmmeter probes to the housing terminal and the wire tip (it is better to switch the ohmmeter to the upper measurement limit).

The arrow should deviate sharply towards zero, and then smoothly return to the end of the scale, to the “infinity” symbol.

If you change the polarity, the needle should deviate even more towards zero.

The engine is the heart of the car. It’s not for nothing that it’s so aptly said. For the proper functioning of the engine, the coordinated work and interaction of various components is necessary. The family of various ignition components is one of the most important. And the capacitor is an important link in this very system.

Signs of a faulty ignition coil

If, after turning the key in the ignition switch, you hear that the starter is turning, but the engine does not start, then, as a rule, this may mean that the ignition coil is not working correctly or has failed. Although there are many reasons why the engine does not start when you try to start it: spark plugs, explosive wires, problems in the fuel system (pump, fuel filter, clogged line), and so on...

When doubt falls on the capacitor

ATTENTION! A completely simple way to reduce fuel consumption has been found! Don't believe me? An auto mechanic with 15 years of experience also didn’t believe it until he tried it. And now he saves 35,000 rubles a year on gasoline! Read more"

The capacitor can fail in rare cases, but on the road the motorist must be prepared for anything. And the ability to test a capacitor for functionality with your own hands is included in the mandatory arsenal of skills of an experienced driver.

Diagnosing an auto-capacitor involves proving that sparking exists and is occurring normally. You should know that sparks appear unevenly and their color is dull red. When checking the capacitor, the entire distributor with the contact group is subject to diagnostics.

Note. Modern cars are equipped not with a mechanical distributor, but with an electronic switch. If a breakdown or failure occurs, the switch is completely upgraded.

Checking the distributor should begin with the cover. It is from here that, if there are microcracks, road debris penetrates, which leads to difficulties in supplying current. As a result, the impulse does not reach the SZ, they are inactive, and the entire power supply system of the vehicle is disrupted.

Causes of defects

Ignition coil failures can be caused by several factors, namely:

- Mechanical impact. Perhaps simple aging of the device led to corrosion of the insulation, which caused its destruction. Perhaps the body was damaged by an accidental impact and oil leaked out of the coil, which led to its overheating. In such cases, it is better to immediately replace the converter with a new one.

- Loss of contact. In the summer and off-season, oxidation may appear on the contact group due to moisture. This leads to a drop in voltage power in the spark plugs.

- Overheat. This defect is more common on individual-type coils. In the summer heat, as well as during long trips, it is unlikely that you will be able to control the temperature of the ignition coil. However, to avoid such situations, you can use high-quality devices and cooling fluids.

- Increased vibration. Also especially dangerous when using individual ignition coils. The main vibration affecting the device comes from the internal combustion engine cylinders. To reduce the impact of these forces, it is sufficient to promptly correct problems with the operation of the motor.

In principle, the coil is a durable and very reliable element, and the main reason for most breakdowns is simple aging, which leads to insulation failures and normal operation. Below are ways to check the integrity of the coils.

Capacitor diagnostic option first

Testing a capacitor involves having a meter called an ammeter, tester, or multimeter. The ends of the device are neatly connected to the contacts. The ignition is turned on, the contacts of the distributor must be open. At this moment you need to look at the multimeter readings.

The malfunction of the capacitor can be judged by the tester readings close to 0. In this case, the multimeter mode should be in the discharge position of 2-4 A.

Such multimeter readings indicate a complete malfunction of the capacitor. It is replaced with a new one.

Electronic ignition

Everything is a little simpler here. Let's see how to set the electronic ignition on a VAZ. Instead of a mechanical breaker, the system uses a commutator and a Hall sensor.

The procedure is quite simple. For safety, remove the negative terminal from the battery. Next, rotate the crankshaft until it aligns with the long mark - in this position, the piston of the fourth cylinder will be at TDC (top dead center).

Next, you need to remove the ignition distributor cap. The slider should be looking at the fourth cylinder wire. You can use a spark from a candle or a lamp. There is no particular difference in how to set the ignition on a VAZ-2105. The distributor is slowly turned in one direction and the other. When a spark jumps or a lamp flashes, you need to stop. Next, the distributor is turned quite a bit towards the minus side and secured.

Using a carrier

Another way to check for operation involves using an ohmmeter or a portable lamp. The latter will even help identify the breakdown of the capacitor.

Here's how the diagnosis is carried out:

- The capacitor wire is disconnected from the breaker terminal.

- The current conductor laid on the coil is also disconnected.

- The carrying terminals are connected.

If the element is damaged, the lamp should light up.

Attention. To reduce the effect of charring of contacts and increase secondary. current, it is recommended to connect the capacitor synchronously with them.

It is fueled by a spark that jumps when it opens, even if the minimum gap is set. All known automotive power supply circuits are equipped with their own capacitor, the capacitance of which varies between 0.17 - 0.35 μF. For example, in VAZ models the capacitance of this device is close to 0.20 - 0.25 μF.

If the capacity suffers from deviation, this directly affects the minimization of the additional current. Discharging and recharging the capacitor does not solve the problem.

Third option for testing the capacitor

The method involves charging with high voltage current. It's done like this.

- The capacitor is fed with electricity directly from the coil.

- Then the discharge is carried out to ground.

If there is no discharge-spark between the electrical wire and the fuselage of the capacitor, we can talk about a malfunction of the capacitor. Yes, and one more thing - if the capacitor is working properly, a characteristic click will be heard.

Note. If after charging the device the spark does not appear again, this is another reason to make sure that there is a current leak from the capacitor.

Classification of misfire errors

If the ignition system is unstable, untimely ignition of the fuel occurs. The system counts the number of delays and can turn off idle cylinders. On most cars, the main sign of a problem is the light up of error P on the dashboard:

- P0301 - malfunction in cylinder 1;

- P0302 - in cylinder 2;

- P0303 - in cylinder 3;

- P0304 - in cylinder 4.

The main sign of a problem is the smell of fuel in the exhaust. Since the fuel has not ignited, it comes out in its original form and begins to emit a characteristic odor. Popping noises will appear, and the motor will lose power or start to stall.

How to check a generator capacitor

Using the example of generator 37.3701 of a VAZ 2108, 2109, 21099 car, we will check the capacitor installed on its rear cover.

Why is a capacitor needed in a generator?

— To protect the voltage regulator from the influence of current pulses in the vehicle’s on-board network and prevent the entire circuit from going into oscillation mode

— Prevent voltage sags

— Reducing the influence of high-frequency interference and current ripple on the operation of the voltage regulator

— Speeds up switching of the voltage regulator transistor, reducing energy loss and heating

So if the generator voltage regulator often fails, you should pay attention to the generator capacitor connected in parallel with the regulator contacts and check it.

How to check the generator capacitor?

To check, you need an ohmmeter (multimeter) with a measurement limit of at least 1000 kOhm or a known-good capacitor to check by replacement.

— Remove the capacitor from the generator

The tip of the capacitor wire is placed on the output bolt “30” of the generator and secured with a spanner nut at “10”. We turn it off with the key “10” and remove the tip.

The capacitor itself is attached with a screw to the back cover of the generator. Using a slotted screwdriver, unscrew the screw securing the capacitor and remove it from the generator.

— We measure the resistance of the capacitor

We connect the multimeter probes (in ohmmeter mode) to the terminals of the capacitor. Polarity doesn't matter. If it is working properly, when connecting the probes, the resistance will tend to infinity, then the resistance value decreases (several numbers will quickly flash on the multimeter screen), and then increases and again tends to infinity. If any other value appears on the multimeter screen instead of infinity, the capacitor is faulty.

Checking the serviceability of the generator capacitor 37.3701 of VAZ 2108, 2109, 21099 cars using a multimeter

Distributor rotor

It is located in the ignition distributor, under the cover. Consists of 2 plates: central and spacer. Models may be different, but the design scheme of operation is the same.

If the internal combustion engine spins poorly or does not start at all, and there is no spark at all 4 spark plugs, doubt immediately falls on the rotor (runner).

Checking the rotor is easy:

Finally, I would like to recommend it to all owners of cars equipped with an old ignition system. Change it to contactless as soon as possible. This way you will save your budget, time and nerves.

Source