The problem of difficulty starting the engine can manifest itself both when it is cold and after the engine has completely warmed up and reached operating temperatures. A common situation is that a hot petrol or diesel engine does not start after a short period of parking.

We also recommend reading the article about the design of the carburetor. From this article you will learn about the components and operating principles of this mixture formation device.

The car won't start - if it's an electronic problem

- Check the fuses: Not all cars have a fuse associated with the ignition system, but before you hang around the hood with everything else, just in case, check the fuses to make sure none are blown.

- Battery Corrosion: Over time, battery connectors can become dirty or slightly corroded, breaking the connection between the battery and the rest of the vehicle. Try cleaning the battery terminals with something metallic and then try to start the car again.

- A dead battery is the most common reason why your car won't start. If you have a battery tester, check its amperage. If you cannot check the battery power yourself, then note exactly how the car does not start: if a slight jolt still occurs when the starter is turned on, then the problem is most likely a dead battery. In this case, you just need to stop a passing car and “light” it.

- Faulty Ignition Switch: If the battery passes the test but the starter is still silent, it may indicate a faulty ignition switch. Turn the key to the first position. If the red warning lights on the dashboard do not light up (and the battery connectors are clean), then the problem is a faulty ignition switch. If they light up, wait a little or turn the key further (depending on the make and model of the car). The warning lights should turn off at this key position (most vehicles). And when you try to start the car, the lights should either dim (significantly) or turn off completely. If they do, then the ignition key should be fine. If not, then it is the ignition key or ignition switch that will need replacing.

- Starter connection failure: Corrosion can affect not only the battery, but also any other electrical components, especially those that are exposed to the elements, such as the starter. If you have a helper, you can check the connection by holding the tester lead on the wire that turns on the starter. This is the smaller of the two wires connected to the starter. Just make sure that no part of your body is near any moving engine parts - the starter can start spinning at any time. If the tester shows voltage, but the starter does not rotate, it needs to be replaced. If the starter turns freely when you turn the key, there is another problem.

Diesel engines

If the diesel engine does not start when hot, then the fault should be looked for in the fuel injection pump. Most often, the breakdown is simple and trivial - the oil seals and bushings have failed. The problem can be solved by servicing the pump. But the reason for the non-start may also be in the plunger pair - to solve this problem, a major overhaul of the pump is required.

The same problems are observed in the case of a faulty OPTS. To remove the plunger, the fuel injection pump from the rear is cooled, and then attempts are made to start the car. If the car starts, then the plunger pair is to blame.

If the car does not start when hot, the reason may be worn out oil seals, as well as the bushings of the injection pump drive shaft. There is a place under the seal from which the pump sucks air. This does not allow creating the required pressure in the plunger chamber. To treat and improve the situation, replace the oil seals and bushings.

Diesel engines have a temperature sensor that is used in the injector control system. It also affects startup. If it fails, the injection angle will change.

For both injector and diesel engines, problems in the ECU can significantly affect the normal operation of almost all systems in the car. If everything is in order, then perhaps the block is the reason for the non-start.

Poor starting on a hot VAZ 2114

The VAZ 2115 starts ideally in the cold and when starting hot. stops immediately. After cooling it starts without problems. What could be the reason?

Bad hot

launch. one of the diseases of VAZ cars. Therefore, the question is very common. This is due to the low quality of spare parts and some design features. It happens that the fuel pump is replaced with a new one, but it turns out to be faulty. In "troubleshooting" things change and the problem is discovered in the second round.

If the device does not start hot, we recommend checking the following algorithm:

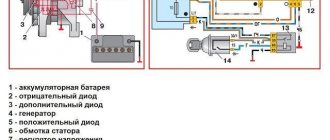

Topic for beginners. Make sure that the problem is related to the hot condition of the car. Check the battery charge, make sure that the alternator is charging (with a multimeter in voltmeter mode). Are there problems with the starter? If it turns, it doesn’t, or sometimes it turns poorly. take it to an electrician. For everyone else. It is advisable to start repairs with diagnostics. this will help you save money. Approximately 80% of the causes of the problem will be revealed by the diagnostician, the faulty part will be replaced and the car will drive away, and you're welcome.

The rest of the information is for the remaining 20% (diagnostics does not reveal problems) and those who do not have qualified specialists in the access area.

26 comments on “The VAZ 2114 car does not start when hot, but when driving everything is fine”

Ignition module! Try shooting it hot and cool.

I also had the same bullshit that the tags got confused over time

Look at the crankshaft sensor

Possibly the ignition switch.

try putting a cold cloth on it

So the fuel pressure

The sleeve (copper) in the bell is already broken and the starter stupidly bites (when it’s hot). This is only if everything is fine in the cold.

Antokha, it’s okay to start cold

Are the injectors clogged? try draining the fuel from the ramp and get to work

Measure the pressure in km, see Conditions

Miras, this is your 100% addiction. This happened to four last summer. Until it cools down a bit, does it start correctly? If you change it, it costs about 500 rubles. This is the reason

.

I had the same thing, only the reason was the fuel pump, I replaced it and everything is fine

Pennies are glued to the retractor, removed and cleaned, or a new retractor!

Andrey, that’s right, what kind of picture can I send?

Miras, here it is, I couldn’t take it off. There seems to be no way out without removing the starter itself. I poked for an hour and a half, went to work

Here with the starting ipos... First of all, understand, look, you shouldn’t change everything because of this.

what kind of starter do you have starter speed

the fuel pump does not create the required pressure, it seems to be checking

Crankshaft sensor see

Battery. It was exactly the same bullshit. I spent 2 months looking for the problem, they replaced everything, but it turned out to be the battery. I changed the battery and everything is fine

Where does a child's stimulating brain come from? The starter turns the engine, you can hear it perfectly

It's a shame that girls are smarter than boys. But aren't you ashamed?

see tags. the belt sound disappeared

Look at the sensor on the thermostat, this is the temperature, but it is also responsible for the rich and lean mixture of fuel, I suffered for a long time and for the first time changed 3 pieces (enough of the defects), I thought I could grab it from the sound, this is the sensor. if the belt fell, the sound would be different, because some valves are open, the starter would spin more easily, as if there were no compression. To check, try removing the chip from the sensor while it is hot and turn on the starter longer, it will start.

Too rich or lean mixture - air flow sensor

We mentioned above that problems with starting the car can arise due to a malfunction of the mass air flow sensor. mass air flow sensor. This element of the car is one of the most vulnerable to the environment, which is why they often talk about its breakdown. If it is very difficult to start the engine when hot, check the operation of this mechanism. This failure may also be accompanied by the following factors:

breakdown when pressing the accelerator pedal, lack of traction at certain moments; reduction in power or vice versa. an inexplicable increase in the potential of the unit; difficulty starting the engine and periodic moments of deformation; explosions inside the exhaust system when the accelerator pedal is sharply pressed; unstable speed due to periodic changes in mixture enrichment.

The fuel mixture of gasoline and air must have a certain consistency, which is formed by the mass air flow sensors and several other parts of your vehicle's electrical and electronic system. If these defects are faulty, you will have to change them and test the car, get the new equipment working.

Poor engine starting or starting the second time

Low quality gasoline

There is no common method for assessing fuel quality. You have to use indirect signs, for example, a bad factory after refueling at an untested gas station. At the same time, while your car does not start, there is a high chance of the battery dying, “killing the spark plugs,” clogging the injector, and even destroying the engine in case of improper detonation.

If the engine does not start well when the engine is hot, the reason is probably due to unsuccessful refueling. The solution to this problem is the use of additives in the gas tank that improve the basic characteristics of gasoline.

To protect yourself from the consequences of refueling with low-quality fuel and keep the injector in good condition, we recommend that you always keep on hand the long-term injector cleaner Langzeit Injection Reiniger for gasoline engines and the long-term diesel additive Langzeit Diesel Additiv for diesel engines.

It is recommended to use these fuel additives when refueling at untested gas stations, as well as on highways.

Air filter problems

In winter, when there is a large temperature difference, a possible cause of problems such as icing of the air filter. Lack of air is also a reason that prevents the car from starting. In this case, it is recommended to immediately replace the air filter at the first sign of trouble. The procedure is quite simple and does not require special skills.

IMPORTANT! One of the key factors causing a vehicle to start poorly when cold may be incorrectly selected engine oil. If you fill in oil with a viscosity of 10W-XX and higher, and there is severe frost, the oil thickens and its pumpability in a cold system drops sharply, which leads to significant wear on the engine at start-up; As a result, the car will not start.

In winter, it is important to choose only high-quality oils from trusted manufacturers, as this guarantees that the oils comply with the declared parameters of “behavior” in the cold.

Low spark level

The second, common case is a low level of sparking.

This may happen for the following reasons:

- when spark plugs fail;

- if the electrical connections of the ignition system are broken;

- when the ignition coils fail

In this case, it is necessary to identify the causes and eliminate the source of the malfunction that prevents the vehicle from starting when the engine is cold.

Solution:

It is enough to replace the spark plugs and check all connections of the ignition system.

Fuel pump

Or rather, not only the fuel pump, but also the check valve in the fuel module. The fact is that for safety reasons, the ECU turns off the fuel pump after a couple of seconds if the engine does not rotate. This prevents fuel from leaking during an accident.

Therefore, if the check valve does not work correctly or the pump itself has reduced performance, then it does not have enough time to pump up the necessary pressure to start the engine. And you have to turn on the ignition several times and give the pump more time. Usually the second time the engine starts. Moreover, the colder it is, the more clearly this problem manifests itself, since in warm weather less fuel is required to start and the fuel itself evaporates more easily from the valves, thereby making it easier to start the engine.

In the fuel module, the function of a check valve is performed by the fuel pressure regulator. It maintains fuel pressure within specified limits and prevents fuel from flowing back into the tank when the fuel pump is turned off.

It is installed in the fuel module

Finding it separately is difficult, but possible. You can buy it using this link.

If the pump performance is weak, the pump itself must be replaced (the so-called bulb)

To check and diagnose this reason, it is enough to measure the fuel pressure. How to easily do it yourself is shown here

If the check shows problems with fuel pressure, then do not rush to immediately order a pump or pressure regulator. Remove the fuel module from the vehicle and inspect it. The fact is that sometimes connecting hoses burst and because of this, problems arise with fuel pressure

Crankshaft position sensor.

On vehicles where a camshaft position sensor (CPS) is installed, the engine can operate without a crankshaft position sensor (CPPS).

Therefore, if the DPKV is faulty or gives an incorrect signal, the engine will start anyway. But for this it will need more time, because the ECU needs time to switch to working according to the DPRV.

The most common cause of such problems is contamination of the crankshaft sensor with metal shavings.

Therefore, it is necessary to unscrew the sensor mounting bolt with a 5mm hexagon and pull out the sensor. After this, wipe it thoroughly

The car had problems starting with this sensor. After cleaning the sensor everything returned to normal.

For this reason, after starting the engine, a persistent smell of gasoline may be felt in the exhaust.

Camshaft position sensor

The ECU uses the sensor signal to coordinate fuel injection processes in accordance with the operating order of the cylinders. Based on the signals from the crankshaft and camshaft position sensors, the control unit sets the ignition timing and the cylinder into which fuel should be supplied.

Before the starter starts rotating the engine, the ECU has no idea what position the pistons and valves are in now and where fuel needs to be supplied, since there are no signals from the DPRV and DPKV yet. Therefore, if the DPRV signal is incorrect, the engine will not start the first time.

It is also worth noting that an incorrect DPRV signal is not always due to the fault of the sensor itself. Very often this is due to its wiring and incorrect installation of the sensor. The correct installation of the sensor is written in detail and shown here

For this reason, after starting the engine, a persistent smell of gasoline may be felt in the exhaust.

Air leak

Engine starting depends on the ambient temperature. The lower the temperature, the more air and fuel is needed at startup.

Therefore, before starting, the ECU analyzes the temperature data and, based on these readings, opens the IAC channel for the required number of steps.

At this moment, the ECU does not know about the presence of air leaks past the IAC channel. The control unit only takes values from its memory that at this temperature it is necessary to open the IAC for such and such a time and ensure the injection duration for such and such a time.

Therefore, when starting, we end up with excess air and the engine cannot start. Only after several attempts, when fuel vapors from previous unsuccessful attempts have appeared in the intake manifold and cylinders, will the engine start.

Therefore, in this case it is necessary to check the intake for air leaks. It is usually quite serious, so even a simple smoke generator will show it.

By the way, leaks most often occur through the crankcase ventilation valve and through the gaskets between the intake manifold and the engine.

Canister valve

The adsorber valve opens only when the engine is running. It provides purging of the adsorber, passing fuel vapors into the intake manifold.

If the valve is faulty or leaking, then when the vehicle is parked, fuel vapors can enter the intake manifold and engine cylinders.

Subsequently, when starting, we will get an excess of fuel and the engine either will not start the first time or will start with difficulty.

A distinctive feature of this reason is that after starting, dips in idle speed may be observed. And also a floating idle speed.

Accumulator battery

When it gets colder, many people are faced with starting the engine the second time. Very often the battery is to blame. And don't underestimate its importance.

This is especially true on vehicles with a Sirius ECU.

The starter seems to be turning, but the engine does not start. The whole reason is the voltage drop during startup. An old and weak battery cannot provide a stable potential difference. As long as the engine is warm and easier to start, there are no problems. And as soon as the car sits overnight in cold weather, starting problems cannot be avoided.

Therefore, if your battery is approaching its fifth year, then it’s worth thinking about its fault for poor cold starting.

Personally, I get rid of the battery after seven years of use, even if it is still “alive”.

Problems of domestic cars

Many domestically produced cars also have trouble starting when the engine is hot. The problem is in the design, but this time the gas tank. The fuel pump, which heats up during operation, should, in theory, cool down a little during operation. This occurs due to the liquid that moves through its body. During the summer heat, the liquid heats up, so cooling does not occur, which leads to disastrous consequences.

A faulty high-pressure fuel pump (HPF) stops working, which leads to a disruption in the fuel supply to the engine. Subsequent turns of the key and pushes will not help, but there are several “old-fashioned” methods. The device needs to cool down.

- Wet a cloth in cold water and apply it to the fuel pump housing until it cools down.

- Roll the car to a cool, sheltered place from the sun, open the hood. Wait a while for the unit to cool down. This usually takes 15–20 minutes.

An overheated fuel pump breaks down completely and cooling will not help it, so if after some time the car still does not start, you will have to replace the part. If the engine still starts when cold, then the problem is in the turbocharger.

A warm engine may not start due to poor quality fuel or the presence of unacceptable additives. This happens after changing the fuel. At the first start, everything may be in order, but then the engine stalls and does not want to start.

ECU software failure

If the car does not start when hot, but all sensors, spark plugs and wires have been checked, then it is worth diagnosing other components.

Sometimes it happens that the software in the ECU unit fails. To check, they are connected to the diagnostic connector in the car, and using a laptop and diagnostic programs, they detect faults. All that remains is to eliminate them by flashing them.

The starter turns, but the car does not start

This is the most common situation if the passage is from a VAZ 2114. The procedure for solving it must begin with answering the question of whether there is a spark. To do this, take an assistant, unscrew one spark plug, put an armor wire on it and very carefully (avoid touching live parts, hold the insulated part of the wire) apply the spark plug to the cylinder head cover. While the assistant turns the engine, watch the behavior of the spark plug. If there is no spark, you need to look for it.

If there's no spark

The ignition module is one of the key problems of the VAZ 2114 on the injector. It breaks often and sometimes a new one comes with a defect. You can read more about checking the ignition module in other material on our website

Please note that the problem may also lie in the chip that is connected to the module. The presence of power on it must also be checked.

DPKV is another reason why there may be no spark

Since this sensor monitors the firing phases of the cylinders, it is one of the key elements of the ignition system. Note that the probability of its failure is lower than that of the ignition module. It is checked by an electrician using an oscilloscope; garage methods do not provide an accurate assessment of the sensor’s condition (only replacement with a guaranteed working one)

DPCV is another reason why there may be no spark. Since this sensor monitors the firing phases of the cylinders, it is one of the key elements of the ignition system. Note that the probability of its failure is lower than that of the ignition module. It is checked by an electrician using an oscilloscope; garage methods do not provide an accurate assessment of the condition of the sensor (only replacement with a guaranteed working one).

KEY-DOP

ECU. “January” is a relatively reliable injector, but the “brains” can also malfunction from time to time. Often the problem with them is identified by a violation of the injection phases: for example, a spark is supplied only to cylinders 2 and 4, or only to cylinders 1 and 3. Sometimes the issue can be resolved by simply cleaning the contacts on the ECU chip; it is also subject to oxidation, which causes signal loss.

If there's a spark

Not often, but this problem does happen. By all indications, the car should start (gasoline splashes into the ramp, the starter turns, there is a spark), but the engine does not catch. There are also pitfalls here.

Injectors. In most cases, the problem is in them, it’s worth taking the car for diagnostics and cleaning it with ultrasound

If trouble strikes you on the road, pay attention to the candles. If the injector supplies the mixture, they must be filled with gasoline; if the spark plugs are dry, the probability of an injector malfunction is high.

However, keep in mind that injectors rarely fail suddenly and all at once

As a rule, before the car stops starting, the engine should be running

However, keep in mind that injectors rarely fail suddenly and all at once. As a rule, the engine should start running before the car stops starting.

Poor quality gasoline. It is assumed that a serviceable engine should start almost on water, unless it’s bad

work. In reality this is nonsense. There are enough examples of “dead” engines after refueling (both at “Uncle Ashot” and at completely official gas stations of well-known brands). Keep this in mind. If the car stops gripping immediately or a short time after refueling, you should not discount this option. The solution is to drain the gasoline and add another.

The VAZ 2115 does not start well when hot.

Lack of required pressure in the ramp. Here we return to problems with the fuel system. Perhaps the problem is the pump or problems with the TPS (unlikely). If you have January 7.2, the cause may be a malfunction of the mass air flow sensor. Unlike January 5.1, here this sensor is polled at startup and, if there is an error, the ECU may prevent the engine from starting.

Finally, we note that the reasons for non-starting in the presence of gasoline and spark may include the following:

- the phases are incorrectly set when replacing the timing belt, as well as its breakage or rotation - it’s worth checking;

- due to overheating, the cylinder head “started”;

- uneven compression in the cylinders, “stacking” of the rings.

Possible faults

No matter how trivial it may sound, if the injector does not start, it means something has gone wrong. The success and speed of repair depends on how quickly and efficiently the problematic link in the car’s design can be identified. To better understand the essence of repair activities, it would be a good idea to pay attention to potential breakdowns. The basic list of the latter is as follows:

- Malfunctions of the injector itself. In the event of a breakdown of this kind, as a rule, the car does not start either cold or hot. On top of that, the injector indicator on the dashboard or on-board computer constantly lights up, signaling its malfunction. It is much less common for the engine to work when the indicator is on, but in this case the car starts poorly and is extremely unstable. It is worth noting that the injectors in the injector most often become clogged or the ECU burns out, so it is advisable to check these components first;

- Ignition system failures. Here the list of possible faults is quite large. Often the candles that suffer are simply flooded. In the event of such a breakdown, the car starts and immediately stalls, but in the long term it stops even “grasping.” Other components of the ignition system (coil, module, distributor, crankshaft sensor, etc.) are noticeably less likely to suffer;

- Incorrect operation of the fuel system. In this aspect, injection engines most often suffer on three fronts:

- Fuel filters are clogged (the car “picks up”, but does not start; if the engine starts, it is extremely unstable);

- The fuel pump is faulty (its characteristic operating sound is absent when you turn the ignition key, the injector itself simply does not start both cold and hot, the starter turns).

- There is insufficient pressure in the fuel system (the engine starts up reluctantly both cold and hot, but if it starts working, it functions unstable);

- Engine problems. Perhaps the widest range of possible malfunctions. Often the reason lies in weak compression or incorrectly adjusted valves. In any case, with a “motor” starting problem, high-quality engine diagnostics are required, otherwise it will be very difficult to determine the cause of the malfunction.

In addition to the breakdowns described above that can break the operation of the injector, the problem may lie in more trivial things. An example of this is a weak battery charge or lack of fuel in the tank. Considering just such incidents, before repairing a car, it is extremely important to exclude the possibility of their occurrence, so as not to waste extra time and nerves.

What else is worth checking?

Other problems that may hinder hot-starting cars include:

- The main injector temperature sensor is broken. This problem only occurs in diesel engines.

- The pump drive is stretched, causing fuel injection to occur incorrectly and the combustible mixture does not meet the required characteristics. You can correct the injection yourself.

- The membrane in the fuel pressure regulator has broken. You need to check the membrane; if it is damaged, replace it.

- There may also be problems with sensors: idle speed, pressure in the fuel lines, crankshaft position or check valve in the fuel pump.

Injection cars

The carburetor is a more primitive device, and the reasons for its problems are simple. And you have to tinker with the injection power system much longer. There are other reasons here. If the injector does not start when hot, there are many reasons for this.

Experts first recommend checking the operation of the coolant temperature sensor. Due to a malfunction, it sends incorrect data to the ECU. This disrupts the fuel supply algorithms. Accordingly, the mixture becomes poorer.

Next, another popular place is the injectors. Often, due to defective injection, the engine will not start or starts with difficulty. To check the injectors, they are dismantled and then tested on a specialized stand.

It is also possible that the membrane in the fuel supply control system may be damaged. Fuel is supplied directly to the intake manifold. Due to this, the mixture is enriched. And this is not always good. The fact is that overly enriched fuel does not ignite well from a spark.

But that's not all. If the engine does not start when hot, and the DTS and injectors are in perfect order, it is worth conducting a more in-depth diagnosis. You need to start with the check valve on the fuel pump - if the valve fails, the pump will pump gasoline in the opposite direction. And after the engine stops, it will not be in the fuel lines until the next start.

Problems of domestic cars

Many domestically produced cars also have trouble starting when the engine is hot. The problem is in the design, but this time the gas tank. The fuel pump, which heats up during operation, should, in theory, cool down a little during operation. This occurs due to the liquid that moves through its body. During the summer heat, the liquid heats up, so cooling does not occur, which leads to disastrous consequences.

A faulty high-pressure fuel pump (HPF) stops working, which leads to a disruption in the fuel supply to the engine. Subsequent turns of the key and pushes will not help, but there are several “old-fashioned” methods. The device needs to cool down.

- Wet a cloth in cold water and apply it to the fuel pump housing until it cools down.

- Roll the car to a cool, sheltered place from the sun, open the hood. Wait a while for the unit to cool down. This usually takes 15–20 minutes.

An overheated fuel pump breaks down completely and cooling will not help it, so if after some time the car still does not start, you will have to replace the part. If the engine still starts when cold, then the problem is in the turbocharger.

A warm engine may not start due to poor quality fuel or the presence of unacceptable additives. This happens after changing the fuel. At the first start, everything may be in order, but then the engine stalls and does not want to start.

Checking this option is quite simple - cool the car. If you subsequently start it cold and hear extraneous sounds from the engine, most likely the problem is in the fuel. The engine does not start for other reasons:

- The presence of components in the fuel that do not allow the creation of a combustible mixture. In different cases the effect may be different, sometimes there is not enough spark to ignite, sometimes more air is required for ignition. Small inclusions also prevent the engine from starting.

- The fuel filter is clogged, which is why the pump cannot supply fuel. In such cases, thick smoke comes from the gas outlet. You need to remove the filter, clean it and put it back.

Fuel quality

If the car does not start well when it is hot, this may not always be due to breakdowns of any elements. Often the cause may be fuel. Poor quality fuel is one of the most popular reasons. But if the fuel is bad, the car will not start normally even when cold.

Gasoline or diesel fuel can sometimes contain additives that are not needed by the engine and are harmful to it. If diesel is frozen, it turns into jelly, and the pump cannot pump such a mass. It happens that the ECU system adjustments go wrong.

Carburetor engines

In the case of carburetor engines, there are few reasons for this behavior of the engine, and the symptoms themselves are extremely simple. But they may not be clear to most car owners. Most often, such problems only occur in very hot weather. So, the carburetor does not start when hot. What is the reason? Since carburetors are not equipped with an independent cooling system, they cannot be called reliable. When the engine stops working, this unit becomes seriously hot from the hot engine. The fuel that was in the float chamber evaporates under the influence of temperatures. As a result, air pockets form. To solve this problem, press the accelerator pedal one or more times - this approach will help remove air.

spark plug.Mass air flow sensor - mass air flow sensor

This sensor can cause problems when starting the engine. This element does not like negative environmental influences - it fails quite often. When the engine does not start at all when hot or starting is difficult, then the first thing to do is check this unit.

Failure of the mass air flow sensor is also indicated by failures when pressing the gas, weak traction at certain moments. The power drops or, on the contrary, increases sharply. The starting process is very difficult - the engine choke. Explosions can be heard inside the exhaust system. Engine speed is unstable. The combustible mixture must be prepared with a special ratio of air and gasoline. This proportion is formed by the mass air flow sensor.

VAZ 2114 takes a long time to start when cold. The car takes a long time to start when cold and when stopped

Why is the VAZ 2114 8-valve injector difficult to start?

For some reason, it seems that many drivers of this model will be interested in the question of why the VAZ 2114 8-valve injector does not start well. Finding the cause of this phenomenon is not as easy as it might seem at first. This is due to certain difficulties in troubleshooting in this model, since injection systems differ from carburetor systems. The algorithm for identifying possible problems will be built differently, adapting to the design features of the machine.

Why is the VAZ 2114 8-valve injector difficult to start?

, we will try to consider in this work. In a short article it is impossible to consider absolutely all possible problems; there are some that can only be identified with the help of diagnostic equipment. But, nevertheless, we will try to analyze as many such situations as possible in order to help all VAZ 2114 owners decide what to do in such a situation.

Why might the engine be difficult to start?

You can look for the culprit in such a situation in several directions. Among them, the most important problems are:

- Malfunctions in the ignition of a VAZ 2114 car

- There is no pressure in the fuel rail of the 8-cl VAZ engine

- Air leak into the VAZ intake manifold

- Timing belt marks are misaligned

Engine diagnostics using spark plugs

Let's look at the first option, why the VAZ 2114 doesn't start well. To do this, unscrew the candles and look at their color. If there is black dry carbon on the candles, we can say that the engine has been running for a long time on a rich mixture, which covers the candles with black carbon.

Why does black carbon appear on the spark plugs of an injection car:

- Malfunction of the mass air flow sensor

- The first oxygen sensor has failed

- Fuel pressure regulator is faulty

- Malfunction of fuel injectors

White carbon deposits on the spark plugs of an injection car appear due to a lean mixture, the reasons for the appearance:

- Everything is the same as with black soot

- Malfunction of the fuel pump or clogged fuel filter (check the mesh and fine filter)

- Air leaks through the air flow sensor pipe, the place where the regulator is attached to the XX joints of the manifold.

Checking the spark plug spark

The lack of a spark on one 8-cl spark plug of a VAZ engine will not affect the engine starting, it will be noticeable when idling, tripping and jumping revs. But if the ignition module of the VAZ 2114 is faulty, then the spark disappears in two cylinders 1-4 or 2-3. To check the spark plug spark, take out the fuel pump fuse, unscrew one spark plug or take a spare one, remove the high-voltage wires one by one, put them on the spark plug, then put the whole thing on ground (in this case, the valve cover) and ask a friend to crank the engine with the starter, so we check each spark plug. If there is no spark on one spark plug, most likely there is a defect in the explosive wires; if there is a spark in two or all spark plugs, it is highly likely that the problem is in the ignition module or the wiring to it.

The timing marks on the VAZ are not set correctly

Another reason why the VAZ 2114 does not start may be a mismatch of the timing marks. The reason for the mismatch of the marks may be weak timing belt tension, cut teeth, or the crooked hands of a mechanic at a service station.

A discrepancy of more than two teeth will noticeably affect the operation of the engine of the fourteenth. With a slight deviation, the engine starts up a little worse, does not hold idle, and stalls when switching to neutral gear. If the deviation exceeds 4-5 teeth, the sound of the engine changes, air escaping under pressure through the valves that are not opened in time becomes audible, thrust noticeably disappears, and starting the engine is extremely problematic.

- To check, we need a “10” key; use it to unscrew the three bolts securing the timing case.

- Next, put the car in 5th gear and push it until the mark on the camshaft pulley and the rear cover match, you can also turn the pulley with the key to “17”

- We remove the protective plug from the clutch housing and see if the mark on the flywheel matches the mark; if not, then you need to loosen the tension roller and align the belt according to the marks.

Checking the crankshaft sensor VAZ 2114

Perhaps this is the only sensor without which a VAZ car will not be able to start at all. If, when the engine is cranked with the starter and the ignition and fuel supply are working properly, there is no seizure or ignition of the fuel, then the problem is in the DPKV. The cost of the sensor does not exceed 300 rubles; it is better to replace it. However, there is a way to check: checking the crankshaft sensor video

If after the performed operations it was not possible to determine the breakdown, please write your problem in the comments, I will be happy to answer your question!

When starting the engine, you have to turn the starter for a long time. What is the reason?

Main reasons

- Worn brushes in the starter. The malfunction is typical for used cars. You will need to remove the starter cover and replace the two brushes;

- Debris accumulation in the fuel tank. Garbage gets into the tank along with gasoline. These unwanted particles enter the fine filter and clog it. Accordingly, less fuel enters the combustion chamber, which is why you have to turn the starter longer.

- The air filter is clogged. Over time, the air filter can also become clogged. This leads to a lack of clean air for fuel.

- Vehicle age. Over time, compression in the cylinders may decrease. Due to low compression, gases leak into the crankcase and the engine cannot be started. This cannot be done without removing and overhauling the engine.

- Old spark plugs.

Is it possible to crank the starter for a long time?

Yes, you can do this, but be prepared for the following problems:

- Dead battery. Each unsuccessful attempt to start reduces the battery charge. In order for the battery to recover the expended energy, you need to start the car and let it run for a while. But if you can’t start, then soon the battery will simply run out. Then you will need to charge it, ask for a light, or try to start it with a pusher.

- Starter failure. Excessive operation of the starter leads to overheating. And this has a very bad effect on its details. Very often they break down, and then you can’t start the car at all. The bendix, which engages with the crankshaft, also suffers. If it fails to start, the splines or bearing may be damaged. So if you turn the starter for a long time, get ready to replace it.

The starter spins for a long time on a carburetor engine.

You can check a carburetor engine using spark plugs. To do this, unscrew them and examine the deposits on the electrodes.

- red color will indicate low-quality fuel. Most likely, it has a high metal content;

- light or black soot appears when the fuel mixture is too lean or rich;

- a slightly brown tint indicates normal engine operation.

The starter spins for a long time on an injection engine

A typical problem with an injection engine, due to which it takes a long time to crank the starter to start the engine, is an error in the on-board computer. This problem can be solved in two ways:

- By reflashing the on-board computer at a service center (or resetting errors);

- Resetting the on-board computer memory by disconnecting the battery. It is necessary to remove the wire from the negative terminal of the battery for 15-20 minutes so that errors are automatically deleted from the memory of the on-board computer, if they were recorded in it.

HBO for cars

A hot engine can also cause a breakdown in the case of an installed gas system. Since driving on gas has recently become profitable, many drivers switched to this type of fuel, however, they did not take into account some of the nuances of the new system. In hot weather, gas expands more, which leads to increased pressure inside the system and often causes damage. This is why it is bad to drive on gas in the heat.

The result is an extremely dangerous situation. To avoid this, try not to fill the tank to full gas in the summer, this will reduce the pressure in the system and the risk of breakdown. If a similar problem occurs, it is recommended to let the car cool down and then visit a service station. You should not repair the gas system yourself; the equipment should be adjusted by a specialist.

In such a situation, you need to act according to a certain algorithm, according to some instructions. The main task is to combine the mixture in order to allow the engine to start. To do this, when starting a hot engine, depress the gas pedal halfway, or even fully, depending on the situation and the carburetor itself. If you start pressing the gas frequently, you risk further aggravating the situation, because with each new press the pump will supply a new portion of gasoline to the carburetor, as a result you will simply “flood” the engine. Make several attempts, after starting, press the gas several times and continue your movement.

Prevention of injector breakdowns

Why the injection engine does not start and how to eliminate possible problems is now known to all readers of our resource. However, it is better to avoid such breakdowns, so let’s pay attention to ordinary procedures that, if carried out systematically, will help minimize the risks of all malfunctions. The simplest but most effective prevention consists of the following measures:

- Firstly, refuel exclusively at proven gas stations and only with high-quality fuel. Remember that most fuel system and engine malfunctions are caused by dirty gasoline;

- Secondly, change all consumables on time and only with high-quality products. The most important thing is periodic replacement of all kinds of filters and engine oil;

- Thirdly, periodically check the main components of the machine for stability. The list of the latter, naturally, includes the injector, elements of the fuel system, ignition and engine;

- Fourthly, never neglect routine diagnostics of your car at a service station. Surprisingly, even a delay of a couple of hundred kilometers can cause serious damage, which previously could have been eliminated with very simple actions;

- And fifth, always operate your vehicle properly. That is, you do not need to overheat, overload or negatively impact your car in any other way.

Perhaps this is where the most important information on today’s issue has come to an end. We hope the material presented above was useful and provided answers to your questions. Good luck in operating and maintaining your car!

Car enthusiasts do not know why the engine and injector start poorly when hot. Reaching operating temperature does not guarantee normal system operation. The design of the carburetor and the properties of the fuel affect the functionality, the temperature of the product sometimes remains low when the engine is already sufficiently warm.

How to properly start an injection engine in cold weather. (My experience)

We bought a new fuel-injected car. How to start it correctly. It would seem that it is clear to the “elephant”. But it’s still a good idea to look at the instructions once again to make sure your actions are correct.

Naturally, first of all, before starting, the gear shift lever must be moved to the neutral position and the key must be inserted into the ignition. Turn on the starter. When starting, do not press the accelerator pedal

.

If the engine does not start on the first try, turn off the ignition and after 40 seconds turn on the starter again. It is not recommended to turn on the starter for more than 10 seconds

. The engine did not start on the first two attempts.

Further actions: press the accelerator pedal all the way and turn on the starter for 10 seconds to purge the cylinders. After this, release the pedal and start the engine in the prescribed manner.

It is not allowed to start driving using the starter. Start driving in first gear.

In winter it is recommended.

When leaving the car in an open parking lot, before turning off the engine, you need to increase the crankshaft speed to 3000 for a minute. Before starting, turn on the ignition, pause for a few seconds so that the electric fuel pump raises the pressure to the operating value.

Further. Before starting and during starting, you need to depress the clutch pedal all the way, but do not press the accelerator pedal. If the engine does not start within 10 seconds, repeat the start after 40 seconds. The third attempt (after two unsuccessful ones) should be started with the accelerator pedal fully depressed to purge the cylinders.

After purging for approximately 5-10 seconds, slowly release the accelerator pedal, holding it in the position at which the engine starts to start.

If even after the third attempt the engine does not start, it means that the reason is something else, most likely either incorrect actions during the first two starts, or a malfunction of the battery, the density of which is lower than recommended at low temperatures. Recharge the battery and the engine will start.

Source

Possible faults

The wind cools the carburetor when the car is running; the air-fuel mixture does not form when the engine is turned off. A hot unit increases the temperature of the carburetor, gasoline slowly evaporates, the air filter becomes clogged, fuel lines, fluid passages become clogged, the amount of gasoline decreases and starting the car becomes difficult.

Test runs are repeated to remove blockages in the system, sometimes taking up to 30 minutes. Manual pumping of gasoline helps to cope with the problem.

Problems with injection systems:

- The coolant sensor fails and the operation of the automated system becomes difficult.

- Injector malfunctions rarely occur; holes appear, the pressure in the valve decreases, and the circulation of the working fluid becomes difficult.

- The air flow sensor is broken, the gasoline is oversaturated or insufficiently filled with oxygen, the fire is contained.

Stalls when hot, why and how to fix it

It is no less unpleasant when a hot engine stalls while the vehicle is moving. This phenomenon is often observed in the summer, when the air temperature is quite high. The reason for this is the appearance of gas plugs in the fuel pump. As a result of this, the fuel pump does not function correctly, and there is nothing left in the float chamber, since fuel simply does not flow into it. This problem is solved by cooling the fuel pump. To do this, take a damp cloth and wrap it around the fuel pump. But this method is only relevant for metal fuel pumps. It is not suitable for those models that use glass, since the glass will simply burst due to temperature changes. If, after a long cooling period, the hot engine still does not start, there is most likely a problem with the fuel pump in the car. To fix the problem, you need to check the fuel pump. If it is faulty, repair it or replace it.

In addition, a common reason for the engine stopping while driving may be poor quality fuel or a clogged fuel filter. To solve the problem, drain the fuel and replace the fuel filter.

The same problem can occur with the air filter; if it is clogged, air will not flow, and accordingly, the fuel-air mixture will flood the spark plugs. In addition, the engine will choke due to lack of air, in other words, the power will drop, the mixture combustion procedure will not be carried out and the engine will stall. To fix the problem, you need to replace the air filter.

If the vehicle stalls while driving and won't start, there may be a problem with the alternator. It may not charge, as a result of which the on-board network will be powered only by the battery, and, as we know, it will not last long.

In modern advanced cars, the reason may also be electronics and various sensors.

Typical reasons for difficulty starting a carburetor car

If the car suddenly does not start when hot, then with a skillful approach the problem can be solved.

However, this situation will continue as long as the motor is running. If the car is stopped, the temperature of the carburetor will begin to rise due to the fairly hot engine body. At this moment there are no longer any air flows, so it will not cool. The gasoline remaining in the float chamber will evaporate very rapidly as temperatures rise.

Fuel vapors will fill any cavities they can reach. This could be the intake manifold, the carburetor itself, the air filter and other parts. The levels of fuel remaining in the float chamber will drop below their normal level, and sometimes so-called gas locks may form in the power system.

How long this process will last depends entirely on how the fuel system of a particular car is designed, on the temperature of the engine and on the outside temperature. Other factors may also affect the duration. So, this effect can last for 5 minutes or 30 minutes.

If during these processes the driver suddenly wants to start the car, then due to the huge volume of fuel vapors that have accumulated in the cavities of the intake manifold, a too rich fuel mixture will enter the cylinders. This is the main reason why the engine does not start when it is hot.

What sensors can be located in the engine

Different motors may have different numbers of sensors, the health of which can have different effects on the start and operation of the power unit. Generally speaking, any indicator can affect the good start of the engine. But, if you take it apart, each sensor has its own purpose, and therefore not all of them can affect the start of the car’s heart. Let's consider each sensor separately and its purpose in the operation of the car.

So let's start from the beginning. A motorist poured fuel into a car. Many modern cars are equipped with a fuel quality sensor. Such sensors can especially be found on German and American cars that are not adapted for our region.

When bad fuel enters the fuel system, the analyzer determines how high-quality fuel has entered the car. If the “bodyaga” has been flooded, the engine may start with difficulty or may not start at all. This analyzer can be located before or after the fuel filter.

The second most important indicator that can affect engine starting is the coolant temperature sensor. It is the malfunction of this indicator that can lead to the fact that the power unit will take a long time to start. This is due to the fact that the electronic control unit thinks that the engine is hot and injects insufficient fuel. Typically, this sensor is the most susceptible to failure.

The next indicator that directly affects the normal start of the engine is the idle air control sensor. It determines how much of the fuel-air mixture is needed for normal engine operation at idle and during engine starting.

The knock sensor also affects the start of the unit. Typically, it is installed at the top of the engine and picks up the vibrations generated by the engine. If the sensor sends a signal to the computer that detonation actions can harm the engine, the control unit blocks the supply of the air-fuel mixture and the spark. In this case, the engine may crank the crank several times for the first time, and then stall and not start at all.

Throttle position sensor (TPS). This indicator monitors the position of the throttle, as well as the process of adjusting it to force air into the combustion chambers. The TPS is inextricably linked with the mass air flow sensor.

Crankshaft position sensor. It calculates the position of the crankshaft relative to the position of the cylinders. If it fails, the control unit receives stable data and forcibly stops the motor.

The oxygen sensor directly affects the formation of the air-fuel mixture, as well as fuel consumption. It measures the oxygen concentration in the exhaust gases, which directly controls the supply of fuel to the combustion chambers. The indicator reading varies from approximately 0.1 V (high oxygen - lean mixture) to 0.9 V (low oxygen - rich mixture).

And at the rear of the cylinder head there is a phase sensor. It determines the position of the 1st piston at top dead center. Designed and based on the action of a Hall sensor. This sensor regulates valve timing, namely the opening and closing of the exhaust valves.

Another representative of air indicators is the mass air flow sensor (MAF). It is located in front of the throttle valve and with its help the amount of air that enters the combustion chamber is controlled.

This indicator analyzes the position of the throttle valve to supply and regulate the amount of air supplied to the cylinders. Usually, when the sensor fails, the amount of forced air for different engine operating modes does not change, and the power unit simply suffocates when adding the amount of fuel and revolutions.

Additional sensors can be considered - a coolant temperature sensor located on the radiator and an electronics diagnostic sensor. These indicators are installed on cars with so-called “heavy electronics”, where all engine control processes are carried out by an on-board computer.

An integral part of the engine start control sensor is the power unit control unit. It is he who controls all the processes occurring in the engine, and also adjusts the settings for optimal starting. Failure of this element will result in the engine simply not starting.

Additional checks

So, if these methods do not help, then you should check the following components and devices. The first step after the main check is to check the crankshaft position sensor. It may send incorrect signals to the car's electronic control unit, and it will no longer be able to give the correct command to the injectors and other actuators, and the car's engine will not start.

The second thing to look at is the mass air flow sensor. It is just as important as other sensors in this vehicle system. The mass air flow sensor may be clogged or faulty. It is best to clean the sensor so that it is visually close to new; this is very important in order to determine whether the sensor is working.

The third thing to look at when the car won't start is the fuel line pressure regulator. As the name suggests, it regulates the pressure in the pipes that carry fuel to the injectors.

The fourth explanation why a warm car engine may not start is that the idle speed control is not working. It is needed to ensure proper engine operation during idling.

The fifth reason is high pressure wires. They conduct electric current to the spark plugs, which ignite the fuel mixture in gasoline engines. A faulty high pressure wire can be identified visually. If your high pressure wire has cuts, rips, or other damage, it is best to replace the wire.

The last thing to look at is the ignition system. In order to find out that the ignition system is faulty, you need to understand a little about the structure of the car. If it is discovered that the fault is in this particular system, it should be replaced immediately.

Stalls when hot, why and how to fix it

It is no less unpleasant when a hot engine stalls while the vehicle is moving. This phenomenon is often observed in the summer, when the air temperature is quite high. The reason for this is the appearance of gas plugs in the fuel pump. As a result of this, the fuel pump does not function correctly, and there is nothing left in the float chamber, since fuel simply does not flow into it. This problem is solved by cooling the fuel pump. To do this, take a damp cloth and wrap it around the fuel pump. But this method is only relevant for metal fuel pumps. It is not suitable for those models that use glass, since the glass will simply burst due to temperature changes. If, after a long cooling period, the hot engine still does not start, there is most likely a problem with the fuel pump in the car. To fix the problem, you need to check the fuel pump. If it is faulty, repair it or replace it.

In addition, a common reason for the engine stopping while driving may be poor quality fuel or a clogged fuel filter. To solve the problem, drain the fuel and replace the fuel filter.

The same problem can occur with the air filter; if it is clogged, air will not flow, and accordingly, the fuel-air mixture will flood the spark plugs. In addition, the engine will choke due to lack of air, in other words, the power will drop, the mixture combustion procedure will not be carried out and the engine will stall. To fix the problem, you need to replace the air filter.

If the vehicle stalls while driving and won't start, there may be a problem with the alternator. It may not charge, as a result of which the on-board network will be powered only by the battery, and, as we know, it will not last long.

In modern advanced cars, the reason may also be electronics and various sensors.

We recommend: How to determine that a valve in a car engine has burned out: signs and symptoms

The procedure for returning the car to “life”

Let's say you find yourself in circumstances where the injection engine starts poorly or refuses to do so at all. There is no need to hesitate in such a situation - it is advisable to immediately begin resuscitation procedures. If you don’t have time to figure out the exact reason why the car doesn’t start well, then you should quickly carry out the following algorithm of actions:

- First of all, we check the availability of gasoline and battery charge. Is there something missing? Fill it up and light it up. Let's try to start. If there is no result, proceed to the next step;

- Next, we quickly analyze under what circumstances the car malfunctions. If it takes a long time or is difficult to start when hot, we first check the spark plugs for overheating (light carbon deposits) and the functioning of the fuel system. Otherwise, when the car malfunctions both cold and hot, a more comprehensive approach is required. As a rule, the following procedures are sufficient: checking spark plugs, wiring the ignition system, assessing the operation of the injector and fuel system;

- Note that most motorists manage to solve the problem, so to speak, with little loss, that is, by implementing the actions described above. If you are not one of the lucky ones and your car still takes a long time, starts poorly or refuses to work at all, you will have to act globally. Here it is better to take the car to a service station or a convenient garage and check the compression, timing adjustment, clean the injector, assess the condition of the fuel system and ignition devices. If there are any malfunctions, they must, of course, be eliminated.

In general, there are no particular difficulties in repairing a non-starting injector. The main thing in the process of such work is to act competently, in accordance with the procedure and possible vehicle malfunctions described above.

What to do if the engine overheats?

In fact, there are many problems that can happen when driving a car, and engine overheating is one of the most annoying, but not really a big problem. Many factors can cause a car to overheat: generally, low coolant levels, hot, sultry weather, long drives and heavy traffic are some of the most common culprits. But what to do if the car overheats?

If you don't have an experienced mechanic or tow truck (free) near you, follow these simple steps:

- At the first sign of overheating, turn off the air conditioning and open the windows to avoid suffocation from the heat and humid air. This should be the first thing that will significantly reduce the load on the engine and help it cool down.

- If your car continues to overheat, turn on the heater and fan. This will transfer heat from the engine into the interior of the vehicle (and this technique will indeed do wonders for your overheated engine, but, alas, it will do very little pleasant for you!).

- If you are stopped in a traffic jam and the temperature gauge is rising, switch to neutral gear or park and increase the engine speed a little (just a little) - this will speed up the circulation of water and, thereby, cool it better.

- Try to use the brake as little as possible in the sense of accelerating as smoothly as possible - try to keep the revs just above idle, rather than accelerating hard and then braking just as hard repeatedly. In addition to the stress of constant acceleration, braking resistance also slightly increases the load on the engine and heats it up. If the traffic jam is completely creeping, start driving only when the gap between your car and the car in front of you becomes too large.

- If it seems to you that the car is about to start boiling, change over to the right lane of the road just in case, or even better - if time permits - stop on the side of the road, open the hood, and sit for a while, letting the overheated engine cool down. Usually, 30 minutes is enough to be able to continue driving again. At the same time, if you have a good new battery, then leave the key in the “On” position so that the cooling fan continues to work. Remember, do not open the radiator cap under any circumstances until the engine has cooled - this will not speed up the cooling of the engine, but is more likely to splash you with boiling water or coolant, and if your engine has already started to boil, do not add water until the engine is cool. It will get pretty cool again.

- If you need to add antifreeze while the engine is still slightly warm, add it slowly while the engine is in neutral or park.

While hot weather is the most common cause of an overheated engine, many other factors can also cause the same problem. If your car overheats in traffic in normal weather conditions, one of the following may be the culprit:

- Low water and coolant levels in the radiator.

- There is a leak in the cooling system.

If you cannot find the leak, then your thermostat is most likely faulty. Obviously, you can't replace the thermostat while standing on the side of the road. At the same time, you can drive without a thermostat at all as a careful and careful alternative to a tow truck and get to the nearest car service center or auto shop safely. Wait for the engine to cool completely and remove the old thermostat and connect the hoses directly without it. If the engine starts and runs well without overheating without a thermostat, then this is confirmation that the problem was in the thermostat.

Just don’t forget to install a new thermostat as soon as possible. Driving long distances without a thermostat can damage the engine.

Always keep a spare bottle of antifreeze (or water) in your car. Engines often overheat due to insufficient coolant in the system, and adding it will solve this problem. Plus, water (drinking) can be a lifesaver when you do the first two points above.

Problems with poor starting of gas cars in warm weather

Many drivers, having read all the above arguments, will say that they are not valid for their car, since it has a gas installation. It became profitable to drive on gas several years ago, so LPG has found its way under the hood of many car enthusiasts. If in hot weather your car stalls and does not start when hot, you will have to let it cool completely, then start it and go straight to the service station. It’s better not to joke with this question for a number of reasons:

- due to high temperatures, certain seals could deteriorate and gas hoses could open;

- the working fluid of your car’s fuel system may leak for other reasons;

- expansion of gas in the tank at high temperature creates a certain pressure in the system;

- It is better not to fill a full gas tank in hot weather, limiting yourself to partial refueling;

- It makes sense to consult with a specialist if such a problem begins to occur on your car.

You shouldn’t joke with gas-powered cars at all - even the latest generation of LPG carries a certain danger. If your gas car does not start when hot, it is worth hiring a specialist to solve this problem. This way, you can easily obtain the necessary operating features of the power unit, and you will not expose yourself to the danger of incorrect operation of the fuel supply system. We invite you to look at the experts’ explanations about a poor launch during the busy season:

Prevention of injector breakdowns

Injection internal combustion engines are sensitive to fuel quality, so the requirements for consumables are increasing. Mechanical contaminants are well filtered, but gasoline contains resins that settle on the injectors. Deposits appear faster if the car travels short distances and does not warm up.

Replacing the fuel filter prevents contamination of the injector; the procedure is carried out once every 2-3 months. using cleaning additives.

The problem is solved by regular use of the product; if cleaning has not been carried out for a long time, dirt gets into the fuel channels, blocks access to the filter, and clogs the injectors, so prevention is carried out after flushing the injector.

A broken injector is determined by the method of sequential de-energization; if there are no changes in the operation of the motor, the problem will be identified. The voltage supply is determined by a simple tester, then the quality of operation of the injector valve is checked by briefly applying voltage to the terminal. Clicks indicate the serviceability of the part; operation of the device is restored after flushing the system.

Similar articles Why a car may have trouble starting in hot weather Why a car can have trouble starting in hot weather What to do if a diesel engine has trouble starting in hot weather

X

We recommend reading the article about why a cold diesel engine will not start. From this article you will learn about the main reasons and malfunctions that make it difficult to start a diesel engine after a long stay.

The most common answer to the question why a diesel engine starts normally “when cold”, but poorly, is the failure of individual elements of fuel equipment and electrical equipment. A hot diesel engine most often does not start for several reasons:

- injection pump;

- sensors;

- diesel injectors;

How to improve the launch?

It is recommended to keep the fuel-air mixture as lean as possible. At the moment of starting the engine, squeeze the gas to half. Sometimes you need to press the accelerator pedal all the way. But this should be done only once - otherwise the mixture may become over-rich.

If the spark plugs in the engine flood, you will have to unscrew and dry them yourself, using a hairdryer or any other available means.

Diesel

For a diesel engine, the primary cause is the high pressure fuel pump. Often the cause of the malfunction is quite simple - failure of the oil seals and bushings. In this case, routine maintenance of the unit will help. On the other hand, the reason may be hidden in the breakdown of the plunger pair, which actually leads to a major overhaul of the element.

Another element that will affect starting the engine when hot is the temperature sensor of the control injector. Failure of this electronic element will cause a changed injection angle. To fix the problem, you need to replace the sensor.

As for injection engines and diesel power units, a malfunction of the engine control unit disrupts the operation of all systems. To fix the problem, you will have to connect to the motor and carry out repair and diagnostic operations.

Diesel injectors are not sealed

The next reason why a diesel engine has trouble starting when hot is the lack of tightness of the injectors. After the engine is stopped, some of the fuel continues to flow through the injectors into the combustion chamber of the diesel engine. Excess fuel prevents the subsequent start-up of a hot diesel engine.

To diagnose this malfunction, the injectors are unscrewed from the cylinder block (BC). If the diesel injector is wet, then the problem is obvious. You can also unscrew the glow plugs in a similar way.

Wet spark plugs will mean that the injectors are leaking diesel fuel after the engine is stopped. In such conditions, try to start the diesel engine by first opening the throttle valve. This will relieve pressure in the working chamber. To eliminate the malfunction, it may be necessary to repair or replace the injectors with new ones. It is also possible to overfill fuel due to wear of the injector O-ring.

Finding out the cause of the problem

Now let's figure out how to quickly find out:

- The performance of the fuel pump, of course, is determined by its sound. If there is no sound, then check the wiring and provide 12 V supply to it. Pay attention to the pressure in the fuel system, it should be within 2 - 3 bar while the pump is running. If the fuel supply is stopped, the pressure in the system does not drop immediately. If the pressure drops sharply and there are no fuel leaks, then pay attention to the fuel pressure regulator. At least it can be silenced for a short time.

- Checking the ignition. To avoid burning the ECU, the spark plug must be connected to ground as best as possible.

- When checking the synchronization sensor, first of all, we pay attention to the integrity of the wiring and its shielding.

- As for the ECU, you need to try to move all possible connections. There is a high probability that something has come loose somewhere.

- Notice if the Check Engine light is on. If it lights up, then all is not lost and the ECU is still working. You need to know that it is not yet possible on VAZ cars without a tester to find out the error code and identify the location of the fault.

- If a suspiciously large number of error codes are displayed, then you need to pay attention not to the sensors, but to the fact that some part of your car has completely disappeared.

- You should also pay attention to the performance of the crankshaft synchronization sensor and the performance of the injector control system. But all this requires a special tester, and rarely does anyone carry this device with them in their car. Yes, and it is advisable for specialists to perform such work.

- But many people can check the voltage in the network. As a rule, when the engine is running it should be 14 V, when starting the engine 8 V, and when the engine is not running 12.5 V.

- Be sure to check the integrity of the camshaft drive belt and pulley. It's not hard to do.

- And the last hope. We disconnect everything possible from the ECU (electronic control unit), only leaving the crankshaft synchronization sensor. But again, if you know what you're doing. If you don't know, it's better not to interfere.

The engine still starts, but it is problematic:

- Check the air filter for clogging. If you have completely forgotten where it is, then everything is clear. Go ahead, buy a new filter, or at least clean the old one.

- Check the fuel pump as described above.

- When starting the engine, depress the clutch, this will make starting easier.

- Pay attention to what temperature the coolant sensor shows and what it actually is. Deviations should be within 5, 6 degrees.

- Again, check the car's voltage. What voltage should be, see above, paragraph 8.

- Pay attention to the quality of the fuel. Ask yourself the question, “Where did I refuel today?”

- We move all possible connectors. It’s corny, but sometimes it helps.

- We look at the camshaft drive belt.

These are the simplest actions that are available to many drivers. To conduct a more detailed diagnosis of the cause of poor engine starting, of course, it is better to contact a car service center. Professional equipment and devices will already be used there.

Gasoline pump

If the VAZ does not start when hot (especially if it is an old car), then, among other things, it may be that the fuel pump is too hot. This device is cooled by pumping cold gasoline from the tank. But when it's hot outside, gasoline can't be cold. As a result, the pump overheats, making starting difficult. In some cases, it is completely impossible to start the engine. This problem can be corrected by applying a wet cloth to the pump body and periodically cooling it with water. They open the hood, place the car in the shade, and allow the engine and all other components to cool normally. You can just wait until the temperature returns to normal. It is also worth remembering that if the pump has already been overheated, then it will no longer work normally.