VAZ distributor cover

The cover of the VAZ 2109 distributor (ignition distributor) is a device that distributes (distributes) high voltage current to the spark plugs in strict accordance with the established order of ignition of the cylinders. The distributor cap (ignition distributor) is the removable upper part of the ignition distributor itself; the distributor rotor is located under the cap. The VAZ 2109 distributor cover has built-in contacts through which high voltage current is supplied to the spark plugs in a strictly established order. As you can see, this is an important part of the ignition system, which should be taken into account and the condition periodically checked in order to avoid problems with ignition.

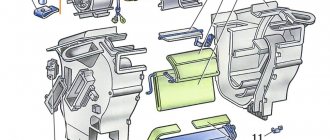

Design of the ignition system on classic VAZ engines

The engines installed on the VAZ 2106 differ in displacement, but have the same design.

The distributor, timing parts, front cover with marks and crankshaft pulley are interchangeable during repairs. There are contact (KSZ) and non-contact (BSZ) ignition systems. In the first case, the contacts open mechanically when the distributor shaft is turned by 90 0. The second option uses a Hall sensor and a controller that allows you to accurately determine the moment a spark is supplied to the cylinders. The simplest contact system consists of the following elements:

- Ignition switch, also known as a switch;

- Ignition coil with two windings to obtain high voltage;

- A mechanical breaker that opens the primary winding of the coil at the right moment;

- Rotor and contact cover for distributing voltage to the spark plugs;

- Centrifugal and vacuum regulators;

- Transistor to reduce the current in the primary winding and extend service life;

- Spark plug;

- High voltage wires.

Typical electrical wiring faults

Malfunctions, as a rule, boil down to the fact that electric current either does not flow to the spark plug at all, or if it does, it is in limited quantities. And this happens for the following reasons:

- When the current-carrying conductor through which the impulse passes breaks

- If there is a current leak, this means that the insulation is damaged, there is a breakdown of current on the side

- The resistance value exceeds the permissible value

- There are problems with the contacts (either with the spark plug, or with the distributor and ignition coil).

If a current-carrying wire breaks, then an internal spark occurs, in other words, a spark discharge is formed between the ends of the broken wire, which greatly reduces the voltage and also causes a parasitic electromagnetic pulse to occur. So:

- The resulting impulse, of course, negatively affects the correct operation of the vehicle’s electrical sensors

- Just one such defective high-voltage electrical wire often causes vibration and interruptions in the operation of the motor.

- In addition, a damaged high-voltage electrical wire leads to ignition in the cylinder with some delay or even every other time, then the synchronization of the operation of the cylinders and the engine as a whole is disrupted

Checking electrical wires

Anyone can check the wires, and do it with their own hands; this does not require electrical knowledge, or special hard-to-find tools or assistants, only the knowledge of what to do and in what order:

- First, you need to check the spark plug wires on the VAZ 21093 visually for visible damage (for example, cracks, kinks, etc.).

- Then you should make sure that there is no breakdown, this can be done even in the absence of any measuring instruments, it will be enough to look under the hood, with the engine running, when it gets dark, if there is a breakdown, then a spark will be visible while the engine is running on the broken electrical wire

- You can also check high-voltage electrical wires using a wire; you just need to take a piece of wire at night and strip the ends on both sides. Then you need to close one end of the wires to ground (this is the body of the machine), and take the other end with your hands and move along the entire length of each electrical wire, not missing joints and caps, etc. A spark will occur at the breakdown points

You can also measure the resistance of high-voltage electrical wires; for this we need a tester (multimeter):

- Turn on ohmmeter mode

- We remove the wire from the spark plug of the first cylinder, disconnect it from the distributor (see The device of the VAZ 2109 distributor: the difference between contact and non-contact ignition systems and adjusting the ignition timing)

- We connect the multimeter electrodes to both ends of the wire and check the readings

For serviceable electrical wires, the resistance varies from 3.5 to 10 kiloohms, it all depends on the type of electrical wires themselves. The resistance value is usually indicated on the insulation of armored electrical wires. When checking each wire, the spread between the values cannot exceed 2-4 kiloohms. If greater variation is detected, the wires should be replaced. By the way, the replacement is made as a set, that is, all together at once; the price here is not a reason to save money all together. In conclusion, we present to your attention the resistance readings for the most popular armored electrical wires:

- Tesla brands have a resistance of 6 kOhm

- Brands Slon (Elephant) with a range from 4 kiloOhm to 7 kiloOhm (where 4 kiloOhm goes to the 1st cylinder and so on up to 7 kiloOhm on the last cylinder)

- ProSport brands have almost zero resistance

- Brands Cargen (Kargen) with a resistance of 0.9 kiloOhm

Note: The resistance of armored electrical wires varies and largely depends on the thickness, length, and material used to make the wires.

What to do if the candles are flooded

How to start a car if the engine spark plugs are flooded. In the case where the spark plugs are wet from gasoline in an injection engine, you should unscrew the spark plugs, hold them on the fire with pliers (dry them), and turn the starter without installed spark plugs for about 10 seconds to ventilate the pistons. After this, the spark plugs are tightened and, as a rule, the car starts.

How to dry the cylinders without unscrewing the spark plugs in the injector

Dry the cylinders in this order:

- The gas pedal is pressed all the way to the maximum.

- Turn the ignition key and turn the starter for about 10 seconds.

- Release the gas pedal.

If the gas pedal is pressed, the throttle valve is open, due to which air circulates and the spark plugs dry out.

In this simple way, you can start a fuel-injected car after filling the spark plugs with gasoline.

If the method of drying without dismantling the candles does not help, then you will have to dry the candles manually. Manual cleaning is better, since the electrode itself can also be quickly cleaned of carbon deposits and heated over a fire, and the gap can be checked.

Spark plugs are not expensive; those who don’t want to bother and clean them buy new ones that are appropriate for the given engine.

The service life of spark plugs is from 15 to 25 thousand kilometers.

If simple minor repairs and simple actions to eliminate this cause do not help, then it is necessary to carry out in-depth diagnostics: checking the ignition system, ignition coil, injectors, temperature sensor, Hall sensor.

ENGINE WILL NOT START: MAIN REASONS

If you are at least a little familiar with the structure of a car, you can imagine the number of elements that affect the reliable start and good operation of the engine. Accordingly, if the car does not start, the reasons for this are sometimes difficult to find even for experienced car enthusiasts.

Let's talk not only about such trivial things as a dead battery, but also less frequent breakdowns that affect the starting of the internal combustion engine. We will separately consider gasoline (carburetor, injection) and diesel engines.

The electromotive force that powers the starter, in our case, is the battery. An insufficient level of charging, characterized by a drop in voltage at the output terminals, will not allow the starter to develop sufficient force to start the engine. There may be several reasons connecting the battery and the engine not starting:

- oxidation of contacts. You can clean oxides using sandpaper. It is also worth checking all the important connections of the circuit: ground going to the engine, starter contacts;

- self-discharge The battery may discharge due to increased current leakage. If the leak is small, it can only affect startup during periods of severe frost. Be sure to check the current leakage on your car before winter;

How to understand that the car does not start because of the battery:

- the starter only makes clicking noises or does not respond at all to turning the key;

- The starter slowly turns the engine. If the engine does not start immediately, stop trying;

- After turning the key, the lights on the instrument panel do not light up. You can turn on the headlights. If they shine very dimly, the battery is guaranteed to be dead.

STARTER POWER

If turning the key does not cause any reaction, the problem may be hidden in the starting device itself. This could be brush wear, oxidation or broken contacts, a short circuit, excessive wear on the bushings, or a malfunction of the solenoid relay.

If, after turning the key, no power comes to the starter, the problem may be in the ignition cylinder itself or in the contact group. It is a rare case when the power is cut off by the standard immobilizer or alarm system. Some cars may have a secret algorithm for disabling the immobilizer. Otherwise, you'd better contact an electrician.

SUPPLY SYSTEM

To find the answer to the question of why the car won’t start, let’s start with the fuel supply system. Malfunctions that are typical for both injection and carburetor cars:

- blown fuses (for example, fuel pump);

- banal lack of gasoline. If, by coincidence, the gasoline level sensor is lying, and the warning light for the critical amount of fuel in the tank is faulty, the car will not move. Please note that the gasoline could simply be drained overnight;

- clogged mesh in the fuel tank, which prevents debris from entering the fuel line, clogged fine filter;

- fuel pump malfunction. On injection engines, it turns on when the key is turned to the 3rd position (On), and you can hear a characteristic buzzing sound;

- clogging of the filter element, which creates a barrier to the flow of fuel.

The best way to check if fuel is flowing is to remove the fuel line hose.

Vacuum regulator

The vacuum regulator, depending on how much the throttle valve is open and the load on the engine has increased, changes the angle of rotation, the maximum value of which for the VAZ 2109 should be in the range from 20 to 24 degrees according to the angle of rotation of the engine crankshaft.

Principle of operation:

- When the engine load increases and the gas pedal is pressed, the throttle valve opens;

- There is a decrease in vacuum in one of the compartments of the vacuum regulator;

- Reducing the vacuum in the chamber leads to movement of the spring-loaded rod;

- The moving rod pulls the plate along with it and rotates the breaker as the rotor rotates, thereby setting a smaller ignition timing angle.

- When the load decreases, the throttle valve closes, the vacuum in the chamber increases and the process occurs in the opposite direction.

Setting up SZ

If you have a VAZ 2109 carburetor, you will have to adjust the ignition system from time to time. This procedure is not the simplest; it requires following clear instructions. The operating procedure is as follows:

- We take the manual for our “nine” in our hands, set the contact gaps in accordance with the recommended values. Typically this is 0.45 mm.

- The ignition timing is set using special equipment, we miss this point.

- We connect the high-voltage wires and begin adjusting the torque in the middle of the stroke.

- Install the spark plug in the first cylinder and turn on the ignition.

- Turn the pulley counterclockwise 45°.

- We connect the ground to the spark plug, turn the pulley gradually in a clockwise direction until a spark appears between the electrodes.

- We look at the marks of the cover and pulley. They must be on the same level.

- To ensure that the marks coincide, we turn the distributor in the desired direction.

- If the marks do not match, the ignition will either be late or turn on prematurely, which is unacceptable.

- We rotate the pulley and distributor until we get the desired result, after which the distributor will need to be tightened, and then turn the crankshaft two turns.

- Check the result: if everything works fine, we finish the adjustment.

- You need to warm up the engine, then drive at a speed of 40-50 km/h, switch to fourth gear and accelerate sharply. If there is a knock, the ignition worked prematurely, we adjust it again.

At the service station, technicians can also carry out the adjustment, so if you can’t do it yourself, go there.

How to check the fuel system

It often happens in very humid weather that the fuel supply mechanisms break down. Water can seep into any crack and get onto the connectors of the injectors that spray gasoline in the combustion chamber, and into the gas tank through the O-ring of its neck cap. And even through the gasket of a submersible pump, which is installed directly into the tank.

Injectors are the easiest to diagnose. They are unscrewed and pulled out of the cylinder head. By pointing the injector nozzles away from the car, turn on the ignition for a couple of seconds, the pump starts working, and the nozzles should begin to spray gasoline. If spraying occurs, then everything is in order. It is worth checking the condition of the gasoline.

To do this check, unscrew the supply tube to the injector rail and, using a small, clean container, point the end of the tube into it. After turning on the pump for a few seconds, you need to assess the condition of the gasoline in the container for the presence of water. The appearance of water in the fuel means that the tank needs to be repaired. The flammable mixture is drained from it, allowed to dry completely and filled with clean fuel.

Rich mixture

The engine began to stall and stopped developing maximum power. When cold it may start and stall. In this case, the air-fuel mixture is to blame, where there is a lot of fuel and little oxygen.

It floods the spark plugs with gasoline and they refuse to work. From this you can judge the quality of the fuel mixture. If there is black soot, it is rich, if it is light, it is poor.

I wrote about this in detail in other articles, go to the channel, everything is written there, the link was above.

What to do

Look for the reason. There are several possible sources of problems:

- Mass air flow sensor

. It fails and the ECU receives incorrect readings for preparing the mixture. I wrote how to check it here. - The second lambda was covered with a “copper basin”

. There is also a separate article about it. - In the case of a carburetor, a high level in the float chamber

.

Why are the candles flooded?

Let's first look at the reasons why the spark plugs on the injector are flooded. To do this, consider the operation of a car starter.

Thanks to the operation of its pistons and valves, a mixture of gasoline and air is supplied to the combustion chamber, which is ignited by a spark generated by the spark plugs. After ignition, the starter turns off. Thanks to ignition, the engine cylinders start working. To successfully start the engine, you need a working starter, a powerful battery and a favorable ambient temperature.

At low temperatures, gasoline does not mix well with air. It is known that frosty air contains more oxygen. An increase in oxygen content requires the supply of more gasoline. The vehicle's electronic control unit sends a signal to the fuel injectors, which increases the fuel supply. Thanks to the starter, compression is created in the cylinders and at the same time a spark is formed to ignite the fuel mixture. But since the compression does not meet the standards and the spark is weak, the incoming gasoline will flood the spark plugs, preventing the mixture from igniting. This is the reason why candles are poured in cold weather.

The formation of a spark is influenced by the following factors:

- Gasoline quality. It should not contain many impurities and dirt, as this will affect the operation of the injectors.

- Engine wear. If the engine pistons are worn out, they do not create the necessary pressure and fuel may flood the injector.

- Quality of candles.

- Quality of injector and carburetor.

- Battery power: You should monitor its charging.

If the compression is ideal, the engine will start even with minimal impulse and fuel fluid will never fill the injector. But only a new car can boast of such compression. If a car, for example, such as a VAZ, is more than three years old, gasoline fills the spark plugs on the injector more often.

Preparation

As previously noted, you can do without such a device as a strobe light, but if you want to set up the ignition yourself, then there is still a reason to purchase it.

Before you start setting the angle, do the following:

- start the engine;

- heat it up to 90 degrees;

- increase the speed to 800;

- remove the pipe used to discharge the fitting;

- the dismantled tube is clamped with a finger - this will allow you to find out whether vacuum is actually occurring;

- if it is present, the speed is increased until it disappears;

- then the engine is turned off and the pipe is bent so that there is no gap left in it;

- use a wrench to unscrew the nuts securing the distributor;

- clean the inspection hole from dirt (it is located in the crater of the gearbox and is closed with a plug).

There is a special scale with which the set angle is determined. This should be discussed in more detail, since you need to set the ignition according to the marks. For this:

- Use a flat screwdriver to turn the flywheel until a long strip appears;

- in the future, during adjustment, you need to ensure that it remains clearly in the triangular cutout (this is the zero angle, that is, the starting point of adjustment).

If everything is done correctly, then cylinders 1 and 4 move to the TDC position.

When the scale is poorly visible and you are not sure that you have found the necessary feature, then you can verify the correctness of the position in another way.

There are pulleys on the camshaft gears. They must coincide with the mark on the wall of the timing belt protective housing.

BTSZ device

The ignition system of the VAZ 2109 consists of:

- Switch 3620.3734;

- Spark plugs A17DVR;

- Distributor sensor 40.3706;

- Ignition coils 27.3705;

- Ignition switch;

- — A locking device that prevents the starter from being turned on again until the ignition is completely turned off;

- — Locking and anti-theft device.

Design features and operating principle

- The operating principle of the VAZ 2109 ignition system is based on the Hall effect.

- The sensor-distributor shaft receives torque from the engine camshaft and is located horizontally.

- Spontaneous shutdown of the ignition system occurs 2-8 seconds after turning the ignition key to the extreme left position and the engine is turned off.

- During the operation of the SZ, the switched current is equalized in the case when the voltage in the network varies from 6 to 18 V.

- At low engine operating frequencies, thanks to a special system built into the switch, the time of accumulation of electricity in the ignition coil is regulated, and the current is limited.

The ignition system of the VAZ 2109 operates at a voltage of up to 26 kilovolts, the duration of the spark discharge varies in the range of 1.6-2.0 ms and during this time 35 - 50 MJ of energy is released.

The operating order of the VAZ 2109 cylinders

Thus, the working cycle of the VAZ 2109 internal combustion engine is represented by the following sequential actions: 1. In the 1st cylinder, a downward movement occurs, the working stroke, that is, the combustion of the working mixture and the expansion of gases. 2. “Compression” occurs in the 3rd cylinder, the piston moves up. 3. In the 4th cylinder there is an “intake”, the piston moves down, and the working mixture is pumped into the cavity. 4. “Exhaust” is carried out in the 2nd cylinder; exhaust gases leave the cavity through the exhaust valves.

Now let's look at several cases of malfunctions in the operation of the VAZ 2109 engine. In order to find out the cause of the breakdown, you should use the following algorithm of actions:

• Start the engine and go to idle speed. Listen to the sounds of exhaust. If uniform, periodic popping noises are observed, then most likely the cylinder is not working due to suction, a faulty spark plug, reduced compression or lack of spark. • Inspect the spark plugs; there should be no traces of soot, oxidation or moisture. The gap between the electrodes should average 0.8-0.9 mm. • Replace the spark plug set. • Check the condition of the high-voltage wires of the ignition system. The insulation must be intact, and the contacts must not be oxidized or burnt. If the wires are damaged, they must be replaced. • Inspect the rotor and distributor cap. The lid must be intact, without cracks and clean, without traces of soot. The carbon contact must not be worn or damaged. The rotor must also be intact and have no signs of burnout. All faulty elements must be replaced. • If, after the actions taken, interruptions in the operation of the cylinders continue, then you should contact a service station for a full diagnosis and adjustment of the ignition system, which should be carried out on a stand. • It should be noted that normally the compression should be above 1.1 MPa. If fluctuations within 0.1 MPa are observed in one of the cylinders, then it is necessary to urgently repair the engine itself.

Thus, it is quite obvious that knowledge of engine operation will allow timely repair work and avoid serious breakdowns.

The engine does not start in cold weather, reasons

But flooding of spark plugs, unfortunately, is not the only factor that negatively affects the engine starting procedure at low temperatures. Every car owner should know about the most common of them - familiarity with the cause of problems of this kind often allows one to prevent the very possibility of their occurrence.

Problems with flooded spark plugs can occur when purchasing and installing a low-quality product. What we can recommend to car enthusiasts is that you should not choose consumables and spare parts for your car based on thoughts of maximum savings; purchasing a quality product at a higher price can often save you from many problems that arise during operation.

A weak spark can also occur if the spark plugs are heavily contaminated with carbon deposits, but the spark produced from them is not able to ignite a cold fuel-air mixture that does not contain flammable vapors.

High-voltage wires are damaged, how to check and fix them

You can also fill the spark plugs with gasoline if the high-voltage wires are damaged. The reason is that faulty wiring can produce an uneven spark.

poor quality fuel

The quality of the fuel is a very important factor on which the evaporation process depends. Practice proves that even at normal temperatures some types of fuel do not exhibit normal combustion; there is no need to say that at subzero temperatures they will evaporate and ignite.

Experts recommend paying attention to the quality of the fuel your car is fueled with and its suitability for the season. For use in the cold season, preference should be given to gasoline with the highest octane rating allowed for your car engine.

malfunction of the power system, how to check and fix it

Difficulties in starting a cold engine can also be caused by faults in the power supply system. A negative impact is caused by clogged or worn injectors, which, as a result of existing defects, can supply the wrong amount of fuel. Naturally, such violations will cause the candles to burn out.

To eliminate the problem, it is recommended to systematically monitor the condition of the engine components and systems, and eliminate any deviations noticed in a timely manner. Maintaining the power system involves regular cleaning and adjustment to the recommended settings.

High voltage wires

Often, the main difficulty when repairing a carburetor VAZ 2109 is the reconnection of high-voltage wires that were previously disconnected from the distributor cover. It's also an ignition distributor.

The difficulty is that many people forget the connection procedure or simply do not know. But in practice, returning high-voltage wires is much easier than understanding the ignition module used on the injection VAZ 2109.

By following a few simple rules, you can easily return the wires to their rightful places.

- The ignition distributor cover is installed in its place, that is, on the distributor, only in a single position. Therefore, even if you wanted to, you won’t be able to confuse anything here. Otherwise the lid simply won't fit.

- There is an installation mark on the cover, which indicates the location of the wire socket from the first cylinder.

- The wires must be connected in the following sequence - 1, 3, 4, 2. Move counterclockwise when looking at the distributor cover from the side of the expansion tank.

Contactless - transistor ignition system (BTIS)

Now we have come close to the ignition system of the VAZ 2109. This VAZ car model is equipped with a non-contact ignition system, which has been used since the mid-80s.

In this system, the chopper mechanism has been replaced by a more modern non-contact sensor, which instantly and accurately determines the engine speed and angle of rotation.

Unlike earlier ignition systems, where their operation was based on the mechanical action of parts with each other, the principle of operation of the new ignition system is based on an electrical impulse, which is generated using a non-contact sensor. But first things first.

How to regulate

Practice shows that most often problems with the ignition system are observed in older models with a carburetor type of power plant.

To perform the setup you will need the following tools:

- Screwdriver Set;

- strobe light (you can basically do without it, but with its help you can set the angle more accurately);

- 10mm wrench (suitable for both socket and socket wrenches);

- tachometer (it is available in almost any car multimeter).

Why the engine may unexpectedly “start up” after rain, and what to do about it

The long-awaited summer greeted residents of the central region with rain and deep puddles. It rained so much that, they say, even the country estate of Prime Minister Mishustin was flooded. And what the private property of ordinary citizens had to endure is scary to think about. It wasn't just real estate that suffered from the weather: transport suffered just as much.

Moisture is generally the most dangerous enemy of a motor, but the problem in 2020 is not so much water hammer - such a puddle has yet to be found in the city - but the percentage of air/water, which over the past week in the capital has reached the level of an aquarium. It is clear that in such conditions the processes of oxidation and decay proceed much faster. However, the blues of a power unit from heavy rains do not always lie in rust, and some symptoms, localized at an early level, even allow everything to be solved with “little loss.”

The first step is to disassemble the air filter housing and carefully diagnose the condition of the filter element: if the canvas is wet or even damp, then the problem has been found. A wet filter allows air to pass through much worse, therefore the engine runs on lean fuel, abuses fuel and generally fails. The logic of further actions is clear: the casing itself must be dried, vacuumed from dust, and the filter must be replaced or, at worst, dried. If after all the measures described above the internal combustion engine’s well-being has not improved, you will have to roll up your sleeves.

The plug on the oil filler neck will tell you about the condition of the oil: if a white “sour cream-like” coating has formed on it, then water has gotten into the oil and you should speed up the replacement. Alas, today's engines are not ready, like their predecessors, to drive with such lubrication. If no emulsion is found, then the devil is in the candles and high-voltage wires. Let's start with the last ones.

The wire running from the ignition coil to the spark plug should not crumble in your hands, be bent or damaged. It simply must look amazing and sparkle with novelty, because the speed and other characteristics of fuel ignition in the cylinder directly depend on it. You don’t need to be a rocket scientist to fully diagnose it. Any gap - chip, tear, scratch - indicates the need for replacement. The only equipment you need is your eyes.

If nothing like this is visually detected, wait until evening and ask a friend to start the car, first opening the hood and concentrating on the front side of the engine. Broken high-voltage wires will “generate” fireworks no worse than New Year’s

Source

Features of the ignition module

Now let's talk about a more complex issue - the ignition module and its design features.

The design includes several components, each of which has its own nuances.

| Component | Peculiarities |

| Ignition coil | There are always two coils on a VAZ 2109. This mechanism is responsible for generating current |

| High voltage switches | Switch keys also work together. Through them, the current goes to the spark plugs, plus the controller regulates the time the current is turned on, which is calculated by receiving information from the crankshaft sensor |

| Electronic control unit | Responsible for distributing information in the form of electronic impulses |

| Frame | High-strength plastic is used for its manufacture, which largely ensures the durability and reliability of the device. |

Ignition coil

Location

Any work related to repair, testing, and maintenance of the ignition module will be impossible to perform if you do not know basic things - the location of the device.

You can find the ignition module (ignition module) in the engine compartment. Find the high voltage wires that go to the spark plugs. One end is connected to them, and the other goes to the module. The MZ is small in size and enclosed in a plastic housing.

Device location

Principle of operation

Initially, on carburetor cars, the system worked due to the presence of an ignition coil. With injectors everything is somewhat different.

- Initially, the ignition coil is turned on, generating a high voltage current. The coil operates on the principle of magnetic induction;

- Then the electronic control unit MZ is connected to the work, performing the functions of control, transmitting commands, and ensuring the flow of current required by the characteristics to the spark plugs;

- Next, the spark plugs activate the spark, ignition occurs, and so on.

MH malfunctions

The ignition module often shows the most basic sign of failure - lack of spark. But this is not the only indicator of a malfunction. These also include:

- Lack of dynamics when accelerating the car. Trying to quickly pick up speed, you can clearly feel failures in engine operation;

- The engine does not produce the usual power; in some cases, the engine is not able to pull the car uphill;

- The idle speed fluctuates;

- One of the pairs of engine cylinders refuses to work. Here, most likely, there is no current that should come from the ignition coil.

To eliminate problems with the MH, the first thing you need to do is check the spark plugs, and then make sure the other elements are working.

Disconnect and check

Checking the spark plugs

To check the condition of the spark plugs, which may cause the module to malfunction, you need to:

- Unscrew the spark plugs from their seats, having first removed the high-voltage wires. The elements are removed with a special key.

- Inspect the spark plugs for carbon deposits, mechanical defects, and poor clearance.

- Send defective spark plugs to a landfill and install new ones in their place.

If replacing or cleaning the spark plugs does not produce results, then the reason lies in other elements of the ignition module.

Checking the Ministry of Health

To check the node, follow these steps:

- Check the condition of the high-voltage blocks going to the MH. If there are breaks or insulation failure, a spark will not form. Perform the check with a tester;

- The normal voltage on high-voltage wires is 12 Volts with a small permissible deviation;

- If the wires are OK, check the module. There are several ways to make this work;

- The first method is the simplest - replacing the old ignition module with a new one, the functionality of which you are sure of. But this is not an economical option, since MH is not the cheapest pleasure. Buying it for a simple test is not particularly wise;

- The second method involves the need to move the MH. While the engine is running, move the module and knock on it. If the motor starts to work differently, then there is simply no contact. The problem is not serious, since the module can be disassembled and all contacts secured, after which the MH will work like new;

- The third method is the most accurate, but also difficult. You will need a tester or ohmmeter. Measure the resistance on the high-voltage wires. Pay special attention to the data on the ignition module terminals between cylinders 2 and 3 and between cylinders 1 and 2. A resistance of about 5.4 kOhm is considered normal. If there are deviations, the MH must be replaced.

In practice, the ignition module on a VAZ 2109 rarely fails completely. Most often, the problem is a violation of the integrity of high-voltage wires or loss of contacts. But if you had to deal with a breakdown of the MZ, it’s not worth repairing it. It's better to replace it right away.

Monitor the condition of the wires and the gap on the spark plugs. A gap higher than normal leads to premature wear of the MH.

Share with friends on social networks:

Carburetor engine does not start (reasons related to the ignition system)

The engine does not start or starts and stalls, reasons

— Battery is faulty

The battery could simply be dead. Its terminals or the tips of the power wires could also be oxidized. Oxidation can be removed with sandpaper, and the battery can be charged.

— Spark plugs are faulty

It is possible that the spark plug insulator is broken (current leakage to ground), or the gap between the spark plug electrodes is incorrect, or they are covered with black or oil deposits. To determine the malfunction, you need to unscrew the spark plugs and look at the carbon deposits on their electrodes. Check the gap. If the spark plug does not work at all, it may be flooded with fuel. See Spark Plug Problems. To determine the breakdown, you can perform a test by starting the engine in the dark (described in the Notes below).

— High-voltage wires are connected in the wrong order

If for some reason the wires were disconnected from the spark plugs or the distributor cap, it is quite possible that they were installed back with an error. Check the order in which the wires are connected.

— Incorrectly set ignition timing

If the timing is too early or too late, it is quite possible that the engine will not start or will have difficulty starting and stall. We set the ignition timing using a strobe or by ear by rotating the distributor until a stable idle speed appears within 700-800 rpm. For the required advance angles and the order of their installation, see “Setting the ignition timing on carburetor engines of VAZ 2108, 2109, 21099”.

— High-voltage wires are faulty

High-voltage wires may have damage to the protective coating (“breakdown”). The easiest way to check it is by the presence of a glow on them by starting the engine in the dark. You can also check their resistance using a tester. In addition, during a visual inspection we identify oxidized or damaged wire tips.

— Distributor cover is faulty

In the event of a “breakdown” of the distributor cover, it is necessary to remove it and inspect it. Traces of a “breakdown” are visible visually (dots, stripes). In addition, it is necessary to evaluate the condition of the contacts inside and outside the cover and the condition of the central contact “coal”.

— The ignition distributor (“slider”) is faulty

If the “runner” breaks down, it must also be removed and inspected. Traces of a “breakdown” are visible visually. An interference suppression resistor in the “runner” can also cause the engine to not start or to start and stall. Replace it with a piece of copper wire and restart the engine.

— Ignition coil is faulty

You can visually assess the condition of the ignition coil cover. Cracks in it are not allowed (especially around the central contact), as this is a sign of “breakdown”. You can check the coil more thoroughly using a tester. In case of its absence, temporary replacement with a known good one. See "Checking the Ignition Coil".

— Hall sensor is faulty

It is impossible to determine the health of the Hall sensor without a voltmeter (See “Checking the Hall sensor”). It is possible to replace it with a known good one and then restart the engine.

— The switch is faulty

Checking the serviceability of the switch without an oscilloscope is problematic. This can be done in advance using the voltmeter readings when turning the key in the ignition switch. See “Checking the switch of VAZ 2108, 2109, 21099 cars.”

— Low voltage wires of the ignition system are faulty

Visually inspect the low voltage wires of the ignition system. We check for kinks, abrasions, chips that have come off or are not fully installed. We check the presence of voltage at terminal B+ of the coil and terminal 30/1 of the ignition switch. To help, you can take the “Ignition system diagram for VAZ 2108, 2109, 21099 cars.”

— The ignition switch is faulty

Current is supplied to the ignition system through terminals 30/1 (brown wire - current comes from the generator) and 15 (blue and black - current goes to the coil). If the contact in the block on the lock is oxidized or leaky, the ignition system will be de-energized and the engine will not start.

Notes and additions

— A preliminary check of the ignition system consists of checking the presence of a spark on the spark plugs (the unscrewed spark plug with the connected voltage wire is placed on the engine ground, the engine is cranked with the starter, the presence and strength of the spark on the spark plug is visually assessed). For more details, see “Checking the contactless ignition system of VAZ 2108, 2109, 21099 cars.”

— General check of the ignition system elements for breakdown: start the engine in the dark and visually inspect the spark plugs, armored wires, distributor cover, ignition coil. If they malfunction, sparking or glowing will be noticeable.

More articles on the ignition system

Source

Adjusting the ignition yourself

To normalize engine operation and fix problems, you need to correctly set the ignition timing of your car. Only if these conditions are met can the engine operate correctly. To diagnose and correct errors in the ignition angle, you will need the following tools:

- strobe (desirable);

- tachometer. Most often, such a tool is built into the autotester, so there should be no problems with it;

- slotted screwdriver;

- wrench 10 (socket or open-end).

Having a strobe light will make all your work much easier, so it is better to purchase it for private use.

Before you start directly adjusting the ignition timing and angle, you need to do some preparatory work. First, place the key in the ignition and start the engine. Afterwards, you need to bring the system to a temperature of 90 degrees and increase the idle speed to 800 rpm (using a tachometer) using the fuel regulator knob on the carburetor body.

Hatch in the gearbox

After the engine has warmed up, remove the silicone tube that supplies vacuum from the fitting. You will find the adjusting lever on the panel of the ignition torque distributor, otherwise called the distributor. Its base is attached to the carburetor. Place the free edge of the silicone tube close to your finger to find out if there is a vacuum. If there is one, then the finger will stick to the tube. Reduce the number of revolutions until the vacuum disappears.

Flooding when there is a spark and the starter is rotating

Experienced motorists are faced with situations when a spark appears, the starter rotates, but the lower part of the spark plugs is filled with gasoline. Do not be deluded by the presence of a fire, since this event can occur irregularly under pressure and can be lost while the engine is running.

The cause of the event appears to be excessive pressure in the cylinders. It will be possible to identify the event and the factors that motivate it by monitoring the car on a stand that simulates a combustion chamber.

We recommend paying attention to the valve timing, because their failure will be the cause of wet electrodes. In fuel-injected internal combustion engines, motorists should check the operation of the bypass valve located on the fuel rail

If its malfunctions are ruled out, you will need to find out the gasoline pressure in the rail, because the manufacturer regulates this parameter. Sharp fluctuations and going beyond the specified interval (larger/smaller sides) can block the start of the internal combustion engine or stimulate flooding of contacts for spark ignition.

Diagnostics will need to be carried out for the sensors of the electronic control system and for the injectors. An example of a failure is when the coolant temperature sensor sends incorrect data. In such a situation, the control unit unreasonably over-enriches the fuel mixture. Much less often, the culprit of incorrect impulses is a failed electronic control unit or a malfunction of its software. In this case, problems will appear not only with the ignition.

What are the consequences of incorrect ignition settings?

If the ignition angle is incorrectly set, the engine may behave as follows:

- Ignition is too early, which leads to detonation. This will not only reduce the comfort of using your car, but also damage the cylinder, deform the pistons and rings.

- Early detonation and a large amount of fuel in the engine lead to the formation of a large amount of white gases in the power unit. Therefore, it can be determined by the white smoke coming from the exhaust pipe after starting the car.

- There are several seconds before acceleration occurs, that is, you press the gas pedal, but the car does not react to it immediately. In such a situation, it is especially dangerous to overtake on busy roads.

- Fuel is consumed faster because the engine needs more of it.

- Engine malfunctions often occur at idle.

Most often, VAZ-2109 equipped with a carburetor are susceptible to ignition problems.

Distributor design

The distributor circuit assumes the presence of such elements as:

- low voltage current breaker;

- high voltage current distributor;

- centrifugal ignition timing regulator;

- vacuum ignition timing regulator.

The distributor circuit is designed so that at a certain moment the breaker opens the primary ignition circuit, as a result of which a high voltage current is created in the secondary winding of the ignition coil. Through the distributor, this current is transmitted to the spark plugs in certain cylinders. The regulators automatically adjust the ignition timing, which depends on the current operating mode of the engine.

The distributor breaker is an electromechanical part and consists of the following parts:

- shaft;

- movable contact plate;

- movable contact plate;

- capacitor;

- frame.

The breaker shaft consists of two main parts. On one of them, depending on the type of breaker, cams are installed, the number equal to the number of cylinders in the engine. This distributor device is not very reliable, since a large number of contacts, as well as the presence of moving parts, lead to regular problems with this unit.

The distributor device, as well as its use in general, are outdated from the point of view of modern electrical equipment, but in our country there are still a lot of carburetor engines, so the problem of the performance of this unit is currently relevant.

As for where the distributor is located in the car, most often it can be found under the hood next to the engine, near the cylinder head or on it. Although the exact location of the node depends solely on the model of the machine.

How does an ignition malfunction manifest itself?

If the unit in question is adjusted incorrectly, the following alarming symptoms are almost always observed:

- starting difficulties;

- black or gray exhaust color;

- instability of the engine at idle.

Meanwhile, the vast majority of car owners spend energy on carburetor prevention, mistakenly believing that this is where the cause lies.

Naturally, their work is wasted.

If the angle adjustment was made incorrectly, then the following are observed:

- too strong detonation of the fuel-air mixture;

- thick smoke from the exhaust pipe;

- loss of power;

- high fuel consumption;

- uneven work at XX.

All this leads to rapid wear of the engine as a whole.

Drops in the trunk

This often happens due to an incorrectly attached spoiler. Typically, bolts and double-sided tape are used for this. If it gets wet and moves away, water will begin to seep under the structure, which will penetrate inside the body and collect at the bottom of the trunk. A heated muffler will cause moisture to evaporate.

To eliminate the problem, it is necessary to degrease the surfaces and treat them with sealant. It is also worth checking the trunk seal, tail lights and all rubber plugs.

So, caring for the condition of the car should be comprehensive.

In the case of condensate, it is important to understand the mechanism of this physical phenomenon. And then finding the optimal solution will be much easier

Source

The car often does not start in wet weather. What could be the reasons?

Check the crankshaft sensor connector, most likely there is oxidation or a crack in the sensor. Accordingly, there will be no spark. The ignition coil is usually protected from splashes, except in basins, where it is quite possible that splashes will get on the coil connector. The coil itself and high-voltage wires do not suffer from moisture, unless you pour water into the wells.

1 Good answer

Thank you very much for your answer. Will watch

Spark plugs - high-voltage wires - ignition coils. Moreover, if the “problem level” has reached “won’t start”, and not just works uncertainly, then it’s the coils with a 99% probability

1 Good answer

Thanks for the answer! The car didn't start at all today. Will watch

How much gas does a car consume if it just sits running?

Conventionally, 1/2 of the engine volume per hour is considered. But this figure is from a warmed-up carburetor engine, near the injector, I think. it will be less. But it’s unlikely to be much less

4 Good answer

It was all about the candles)

1 Good answer

How to start an injection VAZ in severe frosts?

If the battery is good.

* Turn off all unnecessary consumers (heater, headlights, heated rear window, mirrors, radio)

* Turn on the ignition, wait 10-15 seconds for the fuel pump to create pressure in the rail

If it doesn’t start on the first try, wait a couple of minutes and repeat.

7 Good answer

What to do if the car fell into the water?

It was with such knowledge that people died. How about knocking it out with your elbow, well, if you have an iron elbow, then yes))) wait until the car is filled with water, Darwin Award)) it’s much easier to knock out the glass and immediately leave the car, oh yes, your elbow is not iron))) then take out the headrest and Here you have in your hands an excellent tool for breaking any atekl))

2 6 · Good answer

Why doesn't the car start the first time?

The car may not start the first time for the following reasons: 1) Weak battery charge (you can check either with special equipment, or try to turn on the light in the cabin and try to start the car - the lights in the cabin dim or go out when you try to start - low battery voltage). 2) Oxidation on the terminals - poor contact can affect the starting of the car, the problem can be easily solved - clean the terminals with sandpaper 3) Starter - if the battery and terminal are working properly, and when starting you hear clicks, metallic sounds - the problem is in the starter. 4) Power wires - damage to the power wires is possible; in this case, current does not flow to the spark plug. If there is damage, sparks are visible - the wires “break through”, replacement will help 5) Spark plugs - they may be flooded with fuel during unsuccessful starting attempts, or they may have carbon deposits on them that prevent the formation of a spark.

Source