As the requirements for the engine power supply system became more stringent, carburetors, as the most complex components on the way of gasoline and air to the cylinders, underwent serious modifications and went from simple fuel sprayers to serious multi-tasking pneumohydraulic devices.

In Russia, this path ended with the creation of Solex-type carburetors; nothing more advanced was produced in our country; the time has come for fuel injection systems.

How did the Solex carburetor come about?

The evolution of carburetors for VAZ cars began with the use of fairly efficient Weber-type devices and continued in the Ozone family, which were the same two-chamber Weber, but with additional measures to improve environmental friendliness.

Especially during start-up and warm-up, as well as overall fuel economy through the use of a slightly leaner working mixture, where exhaust toxicity was simultaneously reduced.

However, with the advent of the promising front-wheel drive VAZ-2108 family, the further use of ozone had to be abandoned. They could not work normally on a transverse engine, and their efficiency reserves were exhausted.

The new carburetors were based on devices from Solex, a well-known French manufacturer that supplies many world brands of cars and motorcycles with its products.

This is interesting: How to replace power steering fluid

Initially, Solex carburetors were used on 1.1 and 1.3 liter engines of VAZ 21081 and 2108 cars; with the advent of an engine with an increased displacement of up to 1.5 liters, model 21083, a similar device was developed, differing only in calibrations, but giving rise to a whole family of power supplies including cars with a classic layout, as well as all-wheel drive Niva with engines up to 1.7 liters. Similar modifications were used for Muscovites, as well as in the later Volga.

Setting the fuel level

Adjusting the amount of fuel in the chambers of Solex carburetors is a common procedure and does not require special equipment. Although in industrial conditions this adjustment is made using a special template, which simplifies and speeds up the work. But at home it is possible to do without this template. To carry out adjustment work yourself, you need:

- screwdrivers (phillips, flat);

- ruler (preferably a caliper);

- a round rod with a diameter of 2 mm (wire or drill will do).

With such equipment, you can quickly complete all the work.

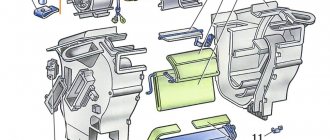

Solex 21083 carburetor design

A characteristic feature of the 21083 carburetor, associated with its purpose for a transverse engine arrangement, is a two-section chamber with two floats, which makes it possible to stabilize the mixture composition during acceleration, braking and sharp turns with variable acceleration.

Float chamber

Both floats are connected to each other by a common bracket, which presses upon the spring-loaded ball valve for supplying gasoline from the fuel pump during ascent. In this way, the fuel level, which is the base value for many settings, is kept constant. Small fluctuations do not greatly affect operation and are taken into account during calibrations.

The above-float space is balanced, that is, pressure is maintained in it after the air filter, so that its transition resistance does not affect the settings.

Idle system

Idle speed is provided in a less complex way than in Ozone; there is no completely autonomous system. Gasoline comes from the emulsion channel of the main metering system of the first chamber, after which it is mixed with air from the idle air jet, and the resulting mixture is sucked through the hole under the throttle of the first chamber.

The system also contains an electric forced idle valve that shuts off fuel during engine braking and a variable cross-section port in the wall near the edge of the throttle valve.

Main dosing system

Consists of two main fuel jets, two air and emulsion tubes, one set for each chamber. The mixture is formed in small diffusers installed inside the air flow through the large diffusers of the first and second chambers.

The flows are connected sequentially as the load increases, by alternately opening both throttle valves.

The qualitative composition of the mixture is determined by the ratio of the jet cross-sections and the fuel level in the float chamber. The quantity corresponds to the flow rate and vacuum in the diffusers.

Acceleration pump

To enrich the mixture at the moment of sharp opening of the throttles, due to inertial effects, it is necessary to use an additional accelerating pump. This is a diaphragm, driven through a rod from a cam on the throttle drive, injecting gasoline through nozzles into both chambers.

When the second chamber is still closed, in order to avoid the accumulation of gasoline from the accelerator there, the throttle is installed with a small gap relative to the walls, through which additional gasoline escapes.

Economizer

When the load is sufficiently large, the throttle of the first chamber opens completely, the vacuum under it drops, and this change in pressure is used to further enrich the mixture.

This is done by the spring-loaded diaphragm of the power mode economizer, opening an additional channel for fuel supply to the nozzle of the first chamber. At low loads, the vacuum moves the diaphragm away from the ball valve and prevents the mixture from being enriched.

Econostat

The simplest carburetor system, operating under heavy loads, full opening of both dampers and maximum crankshaft speeds.

It consists of a sprayer and a single fuel nozzle that takes gasoline from the float chamber. It begins to suck in additional fuel with a large air flow, creating the necessary vacuum in the sprayer area.

Manual damper regulator (choke)

When starting a cold engine, the mixture must be enriched, so the carburetor is equipped with a manually operated air damper via a cable from the cabin. When the suction is pulled, the air in the first chamber is blocked, and the throttle is slightly open, which ensures the required composition.

After the first flashes, the vacuum increases, opening the air damper through the diaphragm to prevent excessive enrichment and flooding of the spark plugs.

All mechanisms can be adjusted to ensure optimal starting. On some modifications, manual drive is eliminated with the installation of an automatic starting system, activated by fully pressing the accelerator pedal.

Setting the fuel level

Adjusting the amount of fuel in the chambers of Solex carburetors is a common procedure and does not require special equipment. Although in industrial conditions this adjustment is made using a special template, which simplifies and speeds up the work. But at home it is possible to do without this template. To carry out adjustment work yourself, you need:

- screwdrivers (phillips, flat);

- ruler (preferably a caliper);

- a round rod with a diameter of 2 mm (wire or drill will do).

With such equipment, you can quickly complete all the work.

How to remove a Solex carburetor

To remove the carburetor from the car for the purpose of repair, maintenance or replacement, it is necessary to disconnect the mechanical, pneumatic, electrical and fuel fittings from it, and then unscrew the nuts securing it to the manifold flange:

- Remove the air filter housing by unscrewing the center cover nut and the four flange nuts on the carburetor top studs.

- Disconnect the electrical connectors of the limit switch and solenoid valve.

- Remove the return spring and disconnect the throttle cable.

- Disconnect the choke actuator.

- Loosen the clamps and remove the fuel supply and return hoses.

- Disconnect the hoses of the distributor vacuum regulator, crankcase ventilation and throttle heating unit.

- After unscrewing the four nuts of the intake manifold studs, remove the carburetor.

When reinstalling, special attention must be paid to the tightening of these nuts, since the lower plate of the housing is very easily deformed from excessive force, after which air begins to leak into the manifold.

Adjusting the ignition angle

Sluggish acceleration of the car and instability of the idle speed are also often associated with incorrectly set ignition; mainly, this function is performed in car repair shops using special equipment. But if desired, the adjustment is easy to make without the help of others, and also without a strobe, and quite accurately:

- with the engine stopped, loosen the three nuts securing the distributor (the third fastening is located at the bottom, it is not visible from above);

- we start the car, turn the distributor-distributor clockwise (to “”), and if the ignition was set later, the idle speed will increase noticeably;

- we select the best position of the distributor (the operation of the internal combustion engine should be smooth, without failures), reduce the speed with the quantity screw, turn off the engine, secure the distributor-distributor with one nut for now, and check the results of the ignition adjustment on the go.

If, under heavy load and sharp acceleration, the fingers begin to noticeably “knock” (engine detonation occurs), you should move the distributor a little to “minus”, then check the car again while driving. This way you can set the ignition quite accurately, and sometimes even better than with a strobe light.

Adjustment, adjustment and cleaning

It is very undesirable to make changes to the calibration of the Solex carburetor, since this is a very accurate and balanced device with well-chosen characteristics.

All adjustments are of an operational nature and rarely change, but they must be checked preventively and adjusted if necessary:

- Adjusting the composition of the idle mixture is carried out using a gas analyzer, since the carburetor has great capabilities for ensuring minimal CO and CH emissions; it comes down to setting the permissible level of harmful gases with the “quality” screw at the nominal idle speed.

- The starting device is adjusted by changing the position of the cable sheath on the bracket so that the damper is fully open and closed in the extreme positions of the choke button.

- The fuel level in the float chamber is set so that when the top part of the carburetor is inverted and installed horizontally, the gap between the floats and the gasket is approximately 2 mm. After which the level can be checked by attaching the cap, starting the engine, turning off and removing the cap, the distance from the gasoline to the flange should be approximately 24 mm.

More subtle settings are available only to a qualified specialist, since changing some of them leads to disruption of others, so you can quickly bring the device to an inoperative state.

The same can be said about cleaning the carburetor. The use of a rough metal tool will lead to changes in the cross-sections of channels and jets. It is only allowed to wash the parts and channels of the housing with special aerosol carburetor cleaners after complete disassembly.

We set the quality of the fuel mixture

This carburetor adjustment on the VAZ-2109 can be done with your own hands and it is not necessary to visit specialists. The quality is very easy to set. To do this, the engine is thoroughly warmed up, and then using a screw to adjust the number of revolutions, the idle speed is set to about 900 per minute.

Next, the quality screw is tightened until the engine begins to operate intermittently. Then it is turned away again. It is recommended to unscrew until stable operation, namely until the speed stops increasing. In the position of the quality screw where the speed is highest, you need to stop and remove the high speed with the quantity screw.

Major Solex faults

Almost all malfunctions are associated with aging of parts and clogging of channels with poorly filtered or low-quality gasoline, as well as airborne debris passing through a defective air filter:

- fuel overflowing through a faulty float chamber valve, the engine starts poorly when hot, black smoke comes from the muffler;

- contamination of the jets of the main dosing system, the engine loses traction, starts poorly, shoots into the muffler or air filter;

- the tightness of the diaphragms of the starting system, accelerator pump or economizer is lost;

- general contamination of the carburetor when using low-quality fuel or getting water into it, power is lost, starting is difficult;

- the throttle valves are worn out, it is impossible to adjust the idle speed, failures in transient modes;

- non-flatness of the lower flange due to overtightening of the nuts, air leaks, loss of idle speed and power;

- clogging of the accelerator pump, failures during acceleration;

- The transition system of the second chamber is clogged, failures at medium acceleration modes.

Often the carburetor is blamed for problems created by the ignition system or gas distribution mechanics of the engine. Therefore, this technically complex device should be dealt with last, after making sure that all other systems are in full working order.

Adjusting the ignition angle

Sluggish acceleration of the car and instability of the idle speed are also often associated with incorrectly set ignition; mainly, this function is performed in car repair shops using special equipment. But if desired, the adjustment is easy to make without the help of others, and also without a strobe, and quite accurately:

- with the engine stopped, loosen the three nuts securing the distributor (the third fastening is located at the bottom, it is not visible from above);

- we start the car, turn the distributor-distributor clockwise (to “”), and if the ignition was set later, the idle speed will increase noticeably;

- we select the best position of the distributor (the operation of the internal combustion engine should be smooth, without failures), reduce the speed with the quantity screw, turn off the engine, secure the distributor-distributor with one nut for now, and check the results of the ignition adjustment on the go.

READ Replacing the fuel filter Passat b6

If, under heavy load and sharp acceleration, the fingers begin to noticeably “knock” (engine detonation occurs), the distributor should be slightly moved to “minus”, then check the car again while driving. This way you can set the ignition quite accurately, and sometimes even better than with a strobe light.