Hi all! It is unlikely that anyone will argue with the fact that proper operation of the braking system is the key to the safety of every driver. Therefore, today we will continue this topic by talking about why the caliper is knocking, what to do in this situation and who is causing the noise.

Surely everyone knows that you should always monitor the degree of wear of the brake discs. We also talked to you about grooving brake drums, and also studied the nuances of grooving brake discs yourself. I don’t encourage you to do this yourself, but you must know the features and tasks of such procedures.

The caliper refers to the braking system of a vehicle. It comes in both front and rear. But in both cases, his treatment is carried out approximately according to the same scheme. And the reasons for the knocking are identical.

Possible reasons

To repair a fault, it must be found. Therefore, first we will look at the main causes of caliper knocking:

- Worn pads. Actually, it is not the caliper that is knocking, but the pads;

- The guides were taken out, as a result the caliper moves along them, while it knocks;

- The bolts holding the caliper have come loose.

Each of these problems has its own methods and repair methods. Let's look at them in more detail.

This is interesting: Lada Vesta fuses: where they are, replacement

The mount has come loose

This happens, but quite rarely. A common reason is traveling on poor quality roads. Vibration can cause bolts to become loose and unscrewed. Usually, this happens soon after a repair affecting the caliper. In this case, you or the master simply did not tighten the bolts. For prevention, always pull fasteners with a certain torque when assembling.

This will save you from problems. To eliminate this knocking noise, simply tighten the bolts. If one of them is lost, make sure it is not broken off and screw on a new one. The broken bolt will have to be drilled out.

Conclusion

. There are quite a large number of different mechanisms near the wheels. They periodically fail. Therefore, the question of what to do if the calipers are knocking is not uncommon. In many cases, this is a design feature that will be quite problematic to eliminate. But it is still quite possible.

Looking for the root of the problem

So, what causes such a characteristic ringing? The reason lies in insufficient pressure of the pads to the discs. As a result, a gap appears between them. On bumps, the pads vibrate and involuntarily come into contact with the surface of the disc.

This is what causes the haunting sound. What is noteworthy is that from the street it looks more like a ringing sound. And dull blows are felt inside. Sometimes this indicates a problem with the shock absorbers or ball joint. But don’t rush things and sort out the suspension. Perhaps your brake calipers are just rattling.

The caliper is knocking - what to do: how to eliminate the rattling noise with your own hands

Hi all! It is unlikely that anyone will argue with the fact that proper operation of the braking system is the key to the safety of every driver. Therefore, today we will continue this topic by talking about why the caliper is knocking, what to do in this situation and who is causing the noise.

The caliper refers to the braking system of a vehicle. It comes in both front and rear. But in both cases, his treatment is carried out approximately according to the same scheme. And the reasons for the knocking are identical.

Pads

Often, a metallic grinding sound is added to the knocking. This happens when the lining on the block has been removed completely. The knocking does not come from the caliper itself, but from the pads. The repair consists of replacing the pads. If you ignore the problem, your braking performance will be significantly reduced. But that's not all.

Having worn down to iron, the pads actively wear down the brake disc. A hundred kilometers in this mode and it will simply “cut off”. And you will have to buy a new disk at the store. It can also easily push out the working cylinders. This is fraught with jamming. The most common problem in this case is brake fluid leakage.

What to do if the pads rattle in the caliper immediately after replacement?

In this case, the culprit of the problem is a disk that is too thin. Typically its service life ranges from 120 to 200 thousand kilometers. With significant wear, neither lubricant nor additional plates will help restore the previous gap. There is only one way out of the situation - replacing the brake disc with a new one.

Some produce grooving of this element. But it is worth remembering that such an operation is performed only if the part is sufficiently thick. In our case, this operation can also cause harm.

If the calipers rattle, what should I do? If you install a new disc and pads, the problem should be solved. But if it remains, you can try replacing the clamping bracket.

What is a support?

supporto - support) - a unit designed for fastening, as well as for manual or automatic movement of a tool, for example in machine tools. Caliper

usually consists of a tool holder and intermediate parts such as slides that provide a given direction of tool movement.

Interesting materials:

How to add an action in Photoshop? How to add another artboard in Photoshop? How to add tools in Photoshop? How to add a brush in Photoshop? How to add a ruler in Photoshop? How to add a new tool in Photoshop? How to add a stroke in Photoshop? How to add a rectangle in Photoshop? How to add a transparent background in Photoshop? How to add sharpening in Photoshop?

Guides

The caliper is constantly subject to quite heavy loads. Therefore, problems with them are not uncommon. And on some Chevrolet models, this is a generic disease that appears after 20,000-30,000 kilometers. There are several ways to fix this problem:

- Replacing guides. This method does not always help. We buy a set of new guides and install it. If everything is in order, then the problem will disappear. But, she will return after some mileage. When the knocking occurs again depends on the characteristics of your vehicle. In some cases, the knocking noise is caused by wear on the guide seats. Dealing with such a malfunction is much more difficult. In this case, special rubber bands are installed on the pins. To do this, you will have to purchase special reinforced guides. But this pleasure is not cheap. Each set contains only 1 elastic band. Accordingly, one wheel will require from 2 to 4 sets. But, you will forget about the knock for quite a long time;

- There is a special lubricant for calipers. In general, this is a preventive measure. But, in some cases it helps to get rid of knocking. To use, pull the guide out of its seat and lubricate it thickly with lubricant. After that, we place part of the lubricant in the socket. We insert the pin into place and secure it. Depending on the degree of wear and the quality of the lubricant itself, one treatment should be enough for 500-10,000 kilometers. This lubricant is usually sold in small bags per guide;

- There is also a rather radical way to solve the problem. This is the addition of a spacer spring. To do this, you will have to drill holes in the caliper and brake cylinder block. After which, the parts are tightened using a spring. Suitable from VAZ drum brake repair kit.

This is interesting: How to add distilled water to a battery: how much liquid should be

Causes of knocking in brake mechanisms

The main reason why calipers rattle does not lie in the unevenness of domestic roads. Due to high mileage or untimely maintenance, the holes for the guides are broken. At least once every year it is recommended to check the presence of oil in them, as well as the wear of the rubber boots.

There are several main reasons why this phenomenon occurs:

It is better to start diagnostics by checking the condition of the pads. To do this, you can assess the degree of wear during driving. The car begins to brake worse; increased effort is required when pressing the pedal. Characteristic creaks and beating of the pedal also indicate that the pads must be replaced. Experienced drivers can determine the degree of erasure even by eye.

Installing the spring on the brake caliper

The frequency of replacing pads can be different for different brands of cars; most often it is done every 10-15 thousand kilometers. The sound of the pads on bumps is indeed somewhat reminiscent of the similar thunder of the calipers. Full application can cause the brake disc to wear out or even push out the brake cylinder.

Guides are also important components of the system. In practice, we often talk about wear and tear of the sockets in which they are placed. In the first case, you will have to go to the store for a new set. In the second, experienced car enthusiasts suggest resorting to special rubber bands, with which you can solve the problem on a budget and quickly. Such rubber bands are placed on the guide pins - this allows you to get rid of extraneous noise.

In some cases, it is possible to correct the situation by lubricating the guides. To do this, it is removed from the planting nest and processed thickly. For a certain time, this method helps solve the problem. For inexpensive brands of cars, in the old fashioned way, additional holes are drilled in the brake block and caliper - through them they make a tie with a spacer spring.

Poor fastening of the caliper itself is actually not so often the culprit of the situation. The fasteners unscrew when driving on unpaved or simply roads with poor-quality road surfaces. Another option is that a service station employee did not secure it properly during repairs or diagnostics of the brake system. In such cases, a good tightening of the bolts and nuts is sufficient to get rid of the knocking noise.

Inspection of calipers

In 40 percent of cases, the front caliper rattles due to dry lubricant. Many car owners do not know that this part requires periodic maintenance. How often should you do it? Experts give the answer - lubrication is carried out every time the pads are replaced. The service life of the latter can range from 20 to 60 thousand kilometers, depending on the location (front or rear), as well as the driver’s driving style.

How to perform an audit? First you need to find a quality lubricant. It must be specialized - specifically for guides. Reviews do not recommend using grease for hubs, as well as copper and ceramic analogues. They dry out quickly and are not suitable for use in this location. A popular manufacturer of specialized lubricants for calipers is Liquid Moly. Typically this product is sold in vacuum bags. One is enough for two guides. The lubricant does not lose its properties at temperatures up to 200 degrees Celsius.

Note! If the piston boot is damaged, it must be replaced immediately. Otherwise, the rear and front calipers will rattle constantly.

The same work must be done on the adjacent brake mechanism. In order not to run to the store when you discover a damaged boot, it is recommended to purchase a repair kit in advance (in extreme cases, it will remain “in reserve”).

Clunking brake calipers+ [CURE*]

Yes.

Known disease on our machines. Getzevods know this disease after purchasing it almost from leaving the car dealership. On the forums, for treatment, they quickly write about tightening the springs, but for some reason no one tells how exactly this spring should be tightened. Actually this is what we will talk about. Character:

a dull metallic knock when driving over bumps, if you listen in the cabin with the windows closed. And a loud metallic clang if the windows are opened.

It should be noted that it can rattle for two reasons

: 1. Wear of the caliper guide bolt (the caliper itself rattles); 2. Fatigue (unclamping) so-called. springs holding the pads (the pads rattle directly).

Diagnostics:

Turn out the wheel. Use your hand to jerk the caliper up and down sharply. To check the springs, remove the wheel without removing the caliper; use your finger to move the pad sharply up and down, then the second one. When driving over bumps and braking, the knocking noise disappears.

We remove the wheel, unscrew the lower guide bolt with a 12mm wrench, if I'm not mistaken. We hang the caliper and, in order not to pump the brakes, we put a clamp on the piston through the damper. The clamp will not allow the piston to come out, in addition, if you install new pads, you can use a clamp to drown the piston a little (make sure that the clamp stop is in the center of the piston), just without fanaticism, at the same time open the lid of the brake expansion tank.

We remove the pads and springs and thoroughly clean the latter:

Now what to tighten up and squeeze out. Press with thin-nose pliers in several places, namely:

We compress everything wisely, without fanaticism. We focus on tactile sensations. We clean the seat. Install the springs. They should sit tight and securely. They should not slouch in their seats. If they slosh, repeat the tightening operation.

We clean the guide and lubricate it with special grease for calipers. It may be different. For example, based on copper grease or such as in the photo (see below), but it must be heat-resistant up to 1000 degrees. The consistency is viscous, almost viscous. I tried it with copper grease and didn’t like it. Over time it turns into plasticine (dries out?). It is better to change the guides with each pad replacement. With complete preventive maintenance of the brakes, it will also be necessary to lubricate the upper guide, as well as fill both boots (upper and lower) with this lubricant. We don’t go too hard when stuffing, especially with the lower boot, otherwise the lubricant may get on the disk (there is a threaded hole on the lower mount, through which the guide bolt fits, exactly above the disk, in my opinion. It got stuck in due time.). I liked the white grease (see photo), it retains the same consistency over time.

ATTENTION!

On the forums there are very often homemade products,

they say I went to a turner I knew and he turned me a bolt from rusty rawhide that was 0.1 mm thicker than hurray, I hammered it into place

.

Or: I screwed the foil onto the guide, hurray, the knock went away

.

Another thing: I wrapped some electrical tape around the guide bolt and the knock went away

.

All these miracle crafts are for the time being and depending on your luck, until the brakes jam. In addition, the brake units sometimes heat up to indecent temperatures - 300 degrees Celsius and higher ( what the hell is electrical tape?!

). Don't forget that good brakes are your life and the life of your loved ones. This is exactly the case when you don’t need to consider your unfortunate ingenuity smarter than a team of professional engineers.

If you understand the operation of our caliper, you will notice that the caliper in the lower mount runs horizontally along a special coupling, which is sealed in anthers. And the guide bolt itself secures this coupling to the body. It would seem, how can, for example, foil interfere with the movement of the caliper? And it's very simple! If the foil is wound unevenly (or the foil itself has an uneven thickness), then the coupling warps, which leads to this, i.e. to caliper jamming.

Let's return to our sheep. So, lubricate the guide bolt with thermal grease:

We put the pads in place. When seating the pads, you can just a little lubricate their fastenings where they touch the springs with the same lubricant.

Install the caliper and tighten the guide bolt. Do not overtighten the guide bolt!

Its tightening torque according to the documentation

is 22-32 Nm

! We put on the wheel.

Before leaving the garage, be sure to idle the brake pedal several times until the pedal feels very firm. If you open the expansion tank, don't forget to close it back.

SANGSIN brand pads

.

Front - code SP1047

.

Rear disc - code SP1117

. Amazing pads. They don't creak even once. They are soft, so they wear out quickly, but they are gentle on the disc.

Springs for the front pads can be ordered separately (piece by piece): code 5814432000

.

Change when replacing pads or during maintenance. By the way, the front guide bolts can also be changed more often, since the price is reasonable, code 5816232300

.

There is also a repair kit for guide bolt and piston boots - code 5816432000

(springs not included).

It’s more difficult with the rear springs; they only come complete with original pads for a hell of a price. Although it is reliably known that in the old catalogs there was a spring code, I could not find it. Rear pad kit code with springs - 583021CA10

.

Rear retaining springs separately, individually (found by chance from the article by vladimirblond repair of rear calipers and discs), code: 5824438300

.

Rear disc brake repair kit 5830328A00

.

*

After the operations are completed, the clang-clang-knock disappears. Unfortunately, this disease is chronic. Those. it will appear again in the future. But a season or two completely ensures quiet operation of the brakes. If you do not brake on uneven surfaces and do not brake sharply to the floor, the effect of the treatment will be prolonged. And finally, check your brake mechanisms so that they do not cause a baptism of fire.

PS

Blog - Hello comrade!

Many people are faced with a fairly common problem: caliper rattling. The main symptom is a metallic rattle, which disappears if you lightly press the brake and mainly appears on cobblestones or similar roads and is also clearly audible when you get into holes. The sound itself can be either sonorous or more dull. The main reason is the broken holes for the guides due to untimely maintenance. Although once a year it is necessary to check the presence of grease on the caliper guides, as well as the condition of the rubber boots.

How to eliminate knocking calipers

If the knocking has just appeared recently, an inspection of the calipers may help, that is, lubricating the guides with high-quality lubricant and checking the boots.

It is important to use high-quality lubricant special for guides. It is not recommended to use copper, ceramic or hub grease. These types of lubricants will jam the caliper guides under certain conditions. The optimal lubricant for guides is SLIPKOTE 211 DBC or similar. If the necessary lubricant is not available, as a last resort, use blue lubricant for the hubs, up to 170 degrees; without sudden braking, such lubricant will work normally. In principle, there were no problems with it on the Starex bead; the anthers did not swell.

How to get rid of knocking calipers on front-wheel drive LADAs

Owners of cars of different brands encounter extraneous noise from brake calipers, and LADA is no exception. Most often, drivers of Grant/Kalina, Largus and Vesta encounter this problem. The malfunction is less common on Priora and XRAY. Let's consider what can be done in this case.

To make sure that extraneous noise while driving comes specifically from the brake mechanisms, you need to rock the caliper from side to side (you can do this without removing the wheel):

Front wheel brake diagram:

1 – wheel cylinder; 2 – fitting for bleeding the brake drive; 3 – sealing ring; 4 – piston; 5 – protective cap; 6 – retaining ring; 7 – caliper; 8 – pad guide; 9 – brake pads; 10 – protective cover; 11 – guide pin; 12 – guide pin fastening bolt; 13 – brake hose; 14 – bolt securing the cylinder to the caliper.

The sounds may resemble metallic knocking, rumble, clanging, strumming, etc. The first step is to contact your dealer with the problem. As far as we know, there are no AvtoVAZ regulations in this case. If the official representative refuses, you can try to get rid of the knocking of the calipers yourself using one of the suggested methods:

1. Fill the guide pins with refractory grease (it’s called “Grease for calipers”).

2. Replace the caliper guide pins with new ones.

3. Make a small groove in the guide fingers (using a lathe), onto which we put a ring made of oil-gasoline-resistant and heat-resistant rubber.

4. Make new guides (using a lathe), which will be slightly larger in diameter than the old ones.

5. Replace brake pads. It is better to choose ones that have a special rubberized coating on their outer side (survey for Vesta, Largus, Granta/Kalina/Priora).

6. Tighten the brake pad guide using a plastic clamp or spring (can be done without removing the wheel).

7. Fold the top of the noise reduction plate (number 4) down. This will get rid of the rattling of the calipers on Vesta:

This method is also shown in the video:

Information letter No. 19-18: When contacting owners of Lada Vesta cars, the effect of “noise from the brakes of the front wheels” emitted when driving on roads with broken surfaces is functional and cannot be eliminated under the warranty obligations of AvtoVAZ PJSC.

Have you encountered rattling noise from the calipers on your LADA? Did the official dealer help in this situation or did you have to fix it yourself? Let us remind you that knocking noises in the front part of the car can come from the suspension (for example, on Vesta from the anti-roll bar) or from the engine mount.

Problems with pads

To identify the reason why the brakes rattle, you should check the pads. A visual inspection may reveal that:

- counterfeit products;

- consumables are completely worn out;

- unsuitable pads are installed, for example, from another vehicle.

The most common noise in the caliper is fake. The main causes of knocking are shown in the table below.

Table - Origin of knocking noise from counterfeit pads

| Reason for knocking | Note |

| Delamination of friction material and support lining | Occurs when the manufacturer uses an adhesive mixture with poor adhesion. |

| Friction lining melting | Friction material particles stick to the disc, causing vibration and knocking as it rotates. |

| Baseplate geometry mismatch | There is a loose fit and uneven distribution of braking forces |

| Incorrect pad dimensions | There is a possibility of play in the seat |

Fake pads after 2500 km

If problems arise with the pads, they need to be replaced. In some cases, it is possible to modify the consumable, for example, if the geometry or dimensions differ from the required ones.

In this case, car owners are advised to remove excess parts of the friction material using a file. This should only be done as a last resort, since tampering with the braking system reduces road safety and violates the law.

Build error

If the pads begin to rattle after overhauling the brake system or replacing them, this may indicate an error occurred during installation work. At the same time, one should not exclude the risk of installing low-quality consumables, which cause extraneous sounds.

The most common error during assembly is poor fixation of the inner pad by the petals in the piston. In this case, you need to get it out by disassembling the caliper. Next, you should bend the petals further and mount everything in place.

What other components of the car should we look for the cause?

For those who are interested in what to do when rattling and other noises appear, the following instructions for action will be useful:

- Inspect and evaluate the condition of the brake pads by eye. Pay special attention to pads that have worn out more than half.

- Specifically find a bulge on the road, for example, any bump, and press the brake pedal. If after this the sound disappears, you can make a diagnosis - the problem lies in a faulty caliper.

- To get rid of the last doubts, it is better to dismantle the wheel. The caliper itself is rocked across its position and the size of the play is assessed. It should be no more than 1-1.5 millimeters.

Any calipers operate on brake fluid, which means there is a possibility of a leak. Most often, seals or protective anthers suffer from this. Dirt and water penetrate through worn boots onto the caliper and corrosion processes begin. A leak may appear in the rubber hose connecting the caliper to the brake line.

When you turn the steering wheel, the position of the caliper changes, and with it the position of the brake hose. Due to bending and temperature changes, rubber cracks and subsequently leaks. The fitting used to bleed the system may also fail. Because of this, it becomes airy and the pressure drops. The brake pedal either fails or reacts worse to pressure. All this reduces braking efficiency and road safety.

Getting rid of brake caliper knock using a spring

You can get rid of a leak in the caliper by timely checking this unit for the appearance of foreign stains. They are characterized by another “illness” - the so-called souring of the pistons. Rust gradually eats away at it and prevents it from moving freely in the nest. In practice, this immediately leads to the car moving to the side when braking. The sensitivity of the pedal is impaired, and the disc and pads begin to wear unevenly. This is why it is so important to inspect the condition of the anthers.

Front and rear calipers can break and knock with approximately the same probability. Souring of pistons, leakage of seals and clogged boots are typical for each of the car’s axles. In this case, the load on the front brakes occurs more often, so the operation of their components can occur faster. The rear ones can fail due to the handbrake mechanism located in their pistons.

The life and health of the driver, his passengers, and other road users largely depend on the efficiency and serviceability of the braking system. The caliper, as one of its elements, requires regular checking of its condition. The driver must pay attention to any creaks and other extraneous noises and respond to them in a timely manner.

How the brakes work

The serviceability and correct operation of the car's braking system determines whether you can drive it normally or not. The law prohibits driving a car with broken or jammed brakes, even if it is a minor problem. This is still unsafe for both you and other road users.

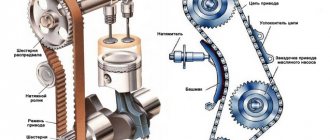

To understand possible malfunctions and understand why the front brakes jam, you need to have an idea of the principle of their operation. The braking system in modern cars consists of brake discs or drum pads, which mechanically, if necessary, slow down the speed of the car. The system works like this: the brake pedal is pressed, the piston in the main brake cylinder moves, “adjusting” the brake fluid, which, in turn, passing through the lines, affects the brake cylinders of the wheels. They press pads equipped with a friction mixture against the discs or drums. This leads to braking.

In addition, the brake system is equipped with an expansion tank for brake fluid and a vacuum booster, thanks to which you only need to press lightly on the pedal. There are quite a few car models equipped with a special electronic system (ABS) that prevents the wheels from locking during braking.

We recommend

Development on the steering knuckle

Front and rear disc brakes squeal their pads very often due to wear on the steering knuckles. As a result of prolonged use, the metal is “eaten” at the point of contact with the supporting plate. Upon visual inspection, small grooves may be found on the knuckle, which are signs of wear.

Initially, an extraneous sound appears on bumps, but subsequently it can accompany the entire period of movement of the car. When contacting a service technician with a question about what to do with a worn steering knuckle, the car owner receives two standard ways to solve the problem:

- Using welding, weld metal onto the worn surface.

- Replace the fist.

Both of these methods are very often unacceptable for car owners, as they are very expensive. There are artisanal ways to solve the problem. One of the cheapest and simplest methods is given below. It only requires plastic clamps.

- Clean the protrusions on the fist.

- Insert the tie into the ledge.

- Tighten the plastic tie. Do similar actions for the remaining protrusions.

- Trim off excess.

Since plastic ties do not have high strength, they need to be updated 1-2 times a year. For a longer lasting solution to the problem, it is recommended to use metal. You can fasten it, for example, as shown in the photo below.

We solve the problem quickly and effectively!

As for the rear brake elements, there is no choice but to advise sorting out the contents of the drum. If you find play that you cannot get rid of, you will have to replace the drum. When the front pads are knocking, you can silence them quite simply. To do this, we will need a regular spring for the rear block of everyone’s favorite “eight”. You need to install it as shown in the photo. A slightly modified method of a similar type is demonstrated in the video, be sure to take a look. That’s all I have, no nail or rod for you, and most importantly – a quiet move!

Wear of guides and bushings

When the guides and bushings wear out, a knocking noise appears when braking, as well as on uneven road surfaces. In the most advanced cases, the pads rattle throughout the entire movement. To solve the problem, you need to purchase a special repair kit. It includes 2 boots, 2 guides, 2 bushings and special lubricant.

Instructions for eliminating pad knocking due to the guides are given below.

- Unscrew the two caliper guides.

- Remove the caliper.

- Knock out the bushing.

- Replace the bushing and reassemble everything in reverse order, using the elements from the repair kit.

Discs

Failed discs can also cause pads to knock. As a result of intense braking, the metal heats up. When driving through a puddle, water entering leads to deformations. Disc beating occurs. In this case, the knocking of the pads directly depends on the speed of the car. Elimination of runout is possible by boring, but provided that the deformation is not significant and the thickness of the disk is sufficient. Otherwise, it needs to be replaced.

The use of low-quality discs leads to their delamination. This causes damage to the pads and their knocking. The problem can be fixed only by replacing the disks with high-quality ones.

Car calipers are knocking: diagnostics and troubleshooting

A car's brake system without defects is the key to safe driving. The driver must be sure that when he presses the brake pedal, the car will start to stop with a certain intensity. Braking efficiency depends on a number of factors, but it cannot be achieved if there are defects in the brake system components.

Experienced drivers know the importance of timely replacement of pads and brake discs. But there is another problem that you may encounter: caliper knocking. If the calipers are knocking, it is necessary to identify the cause of the malfunction and eliminate it so that the brakes do not fail when the car is moving.

Is the caliper really knocking?

In fact, there are many elements in the car that can knock. These are the same engine valves and the notorious hydraulic compensators, the knocking of which we recently talked about. But the calipers also knock. Moreover, this phenomenon is quite common.

For some cars, such symptoms are quite common and their appearance is purely a matter of time.

The first step is to determine whether the calipers are actually knocking. Fortunately, there is no need to go to a car service center and spend money on expensive diagnostics. You can do it on your own. The knocking noise is most noticeable when the car is moving at low speed. It is worth intentionally driving through easy obstacles. The easiest option is to drive over a speed bump or drive onto the ground. And as soon as you press the brake, the knocking will disappear.

One of the disadvantages of the defect in question is the fact that it is not covered by warranty defects. Roughly speaking, if the car is under warranty, you will have to repair the calipers at your own expense.

What to do if the calipers are knocking? Proven Action List

Many car enthusiasts wonder what to do if the calipers are knocking and why this happens. Moreover, even owners of new cars suffer from this problem. This problem is certainly not terrible, but it is necessary to fight it. Otherwise, over time you may end up with completely ineffective brakes. In the worst case, they will simply jam. It should be noted that at all dealers this problem is not covered by warranty. Because of this, it makes sense even in a new car to fix the problem yourself. Moreover, there should not be any special problems with this. All methods and techniques are quite simple and effective.

Drum brake pads

Drum pads knock much less often. In most cases, the problem is due to excessive stretching of the springs of the mechanism. Elimination of chatter is carried out by rebuilding the drum brake. To do this, you must first purchase a special repair kit.

If knocking occurs immediately after replacing the drum pads, this indicates their low quality. The contact of friction material from a collapsing consumable on the drum leads to contamination of its surface, which causes impacts on the pads and their clanking.

Plate

Many manufacturers install special anti-squeak plates from the factory. They follow the contours of the block and are up to one millimeter thick. Many people do not see the point in installing these elements. But they have an effect. If the spring is not able to properly press the pads, this pad partially compensates for this gap. If the calipers rattle, what should I do? It is necessary to inspect the brake mechanism and check for the presence of an anti-squeak plate.

Causes of knocking noises

Since you can independently determine the knocking noise from the caliper when testing the suspension on uneven surfaces, you can also safely tackle the problem with your own hands.

There is nothing scary or difficult about this. This happens on a variety of machines, including:

- Toyota Corolla;

- Gazelle;

- Lada Largus;

- Ford Focus;

- VAZ 2110;

- Mercedes Sprinter;

- Renault Logan;

- VAZ 2114;

- Lada Vesta;

- Chevrolet Aveo (every 30 thousand km);

- Hyundai Solaris, etc.

The reason usually lies in one of 3 reasons.

This includes poor fixation of the element, wear on the guides, as well as wear on the brake pads. In the latter case, the pads themselves will actually knock, although the symptoms manifest themselves identically. In any case, you will have to go there and take appropriate measures.

Now we will consider each reason separately.

The pads are worn out

The first thing that should be checked when such symptoms occur is the pads.

There are two simple diagnostic methods that you can do yourself.

- While driving. If you feel that the car brakes worse with the same pressure on the pedal, plus there is a creaking noise when braking, the pads are probably seriously worn out. This also includes such a symptom as beating in the pedal;

- Visual method. You will have to get to the pads by removing the wheel and examine their condition visually. Worn linings indicate a problem. Even if they are not completely erased, it is better to treat the node immediately.

On every car, the pads must be replaced after a certain period. Usually this is 10-15 thousand kilometers.

If the pad is worn out, the driver will observe a sound reminiscent of a knocking sound from the caliper. Under no circumstances should the pads be allowed to wear excessively, otherwise this could result in damage to the brake disc. Also, such pads can squeeze out and cause jamming of the car brake cylinder.

Having dealt with the wear of the pads in the calipers, we move on.

The culprits are the guides

There is a rather important component in the brake system, called caliper guides. When they wear out, it is necessary to take measures to replace the components.

In fact, there may be 2 problems here.

- The guides themselves are worn out. If these elements are worn out, then there is no need to repair or restore anything. You just need to purchase new guides and install them in place of the old ones. Based on the video instructions, this will be quite easy to do;

- The sockets are worn out. The guides have sockets that also wear out over time. Special repair rubber bands will help you here. These rubber bands are put on the pin, thereby the guides stop causing knocking.

What you shouldn’t do is use the so-called collective farm method. It consists of drilling additional holes in the brake system cylinder block, as well as in the caliper itself, after which the elements are tightened. For this, a spacer spring is used.

In some cases, knocking noise due to the guides can be eliminated with lubricant. It is applied in a thick layer, after first removing it from the nest.

Sometimes lubricant helps to get rid of extraneous noise for a long period. For some, the sound appears again after 200-500 kilometers, for others it lasts several thousand kilometers.

Reasons for appearance

By purchasing new pads, we strive to return the brake system to maximum efficiency and forget about them for a while. However, having completed the installation procedure, during a test drive it is difficult not to notice the characteristic creaking of the newly purchased parts. Having asked any experienced driver, “What should I do?” - the answer will be - “Drive further and be patient until the pads rub in.”

When this stage is passed, another “pitfall” emerges, which already causes furious indignation even in the most balanced person. Now even the naive understand whether brake pads installed a few weeks ago can knock or not. The answer is obvious - there may be several explanations for this.

- An error was made when assembling all the mechanisms.

- If the rear brake pads are knocking on domestic classics, arbitrary disassembly of the springs, partitions and other elements located under the drum cannot be ruled out.

- Play between the block and the drum (for rear) or caliper (for front)

Often noise appears due to ordinary inattention. So, when replacing disks, the wheel bolts are chosen to be too long, which creates an unpleasant sound.