Many drivers, when changing tires from summer to winter and vice versa, think about whether they need to do an alignment after changing the wheels and rely on the opinion of more experienced drivers or servicemen.

But many, especially inexperienced car owners, when changing tires, listen to all kinds of advisers who claim that it is necessary to do a wheel alignment when replacing tires or wheels. Is it really?

Is it necessary to do a wheel alignment after changing tires?

In general, wheel alignment is not necessary after replacing the front tires. The only procedure that is necessary here is wheel balancing. Installing other tires of the same size does not affect the wheel alignment angles. However, there are several cases when this procedure must be performed:

- Old tires show signs of one type of wear. This most likely indicates that the positional settings of the drive wheels were violated during the operation of the car. And to avoid similar wear on new tires, you need to go to the wheel alignment stand.

- Tires of a different diameter were installed. In this case, due to a change in the distance from the axis of rotation of the wheels to the point of contact with the road, a slight deviation of the camber from the preset norm may appear.

- The tires were replaced after an impact that damaged the cord or bent the wheel rim. Strong dynamic loads on the suspension often lead to deviation of the pre-installation angles of the wheels from the norm. Therefore, you can do a wheel alignment after changing tires in such situations. You also need to additionally check the caster (the angle of inclination of the stand relative to the vertical axis). To do this, you need to contact a tire shop, where this procedure is carried out on a modern automated stand with a laser coordinate system.

- Simultaneously with the replacement of tires, any repair or adjustment work was carried out in the suspension or steering.

- The suspension has not been tested on the stand for a long time. Replacing tires is a convenient time to adjust wheel alignment.

Car owners often think about the question: how often do they need to do a wheel alignment? Ideally, experts recommend visiting the stand to check wheel alignment angles twice a year during the change of seasons: in late autumn before the onset of cold weather and in spring after the snow melts.

Also read our autoblog about how much it costs to replace an engine.

This is interesting: How much oil is in the Niva Chevrolet gearbox

Camber angle

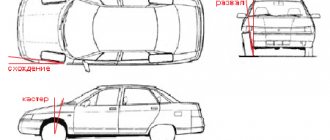

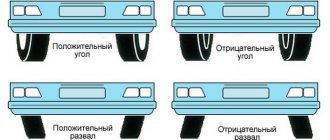

Camber angle (or simply camber) is the angle formed between the vertical and the plane of rotation of the wheel.

Average camber angle values:

- for the rear wheelbase – does not exceed 0°40′-1°00′.

- for the front wheelbase – does not exceed 0°15′-0°40′.

Structurally, vehicles vary and the initial camber angles vary. There are zero, negative and positive angles.

The principle of operation of silent blocks

Silent blocks are rubber-metal hinges that are the connecting element of the chassis system. They dampen the vibrations that occur, preventing their spread, and also give a certain degree of freedom to the parts connected to each other. This is one of the most important elements of a car’s suspension, requiring replacement if it malfunctions. The silent block consists of three parts: two metal bushings and a rubber or polyurethane gasket between them.

The exact mounting locations of silent blocks and their number are selected depending on the design of a particular car model. These elements are located on the front and rear axles. On the front axle, silent blocks are installed in the places where the lever connects to the hub and to the body, as well as at the attachment points of the anti-roll bar. On the rear axle, the places where silent blocks are placed are the levers and the attachment points for the torsion beam and shock absorbers. In addition, silent blocks can connect the steering rack with rods, as well as the body with the gearbox and engine.

The service life of silent blocks is usually 100 thousand km, but in bad road conditions this resource can be significantly reduced. After this, the silent block needs to be replaced. If extraneous noise appears in the chassis while driving, if there is a noticeable deterioration in the vehicle's handling, as well as in the case of typical tire wear and wheel play, you will most likely have to resort to repairs. In this regard, many people have a question: is it necessary to adjust the wheel alignment after repair? Let's try to understand this issue.

We recommend

“Computer diagnostics of a car engine: when is it needed and how is it carried out” Read more

Chassis and suspension malfunctions

When mechanical problems occur, the car pulls to the side much more than from the difference in tire pressure or different tread heights. The following faults cause the vehicle to be driven away:

- Worn tie rod ends. The ball pin does not turn well in the hinge, and sometimes it simply jams. A clear sign is that the steering wheel does not return to its original position on its own, the car continues to move in an arc.

- One of the steering rods was bent as a result of the impact and became several millimeters shorter. The toe angle of the front wheels is disrupted, tire wear on the affected side is accelerated, and the car is driven in the appropriate direction.

- The ball joint is stuck. The pin rotates around its own axis with great difficulty and does not allow the wheels to turn freely. At the last stage of wear, the hinge emits a loud creaking sound - a harbinger of final failure.

- The separator of one of the wheel bearings is destroyed. The balls scattered and ground into metal shavings, blocking the rotation of the hub. The car pulls towards the jammed wheel.

- After repairing the suspension, the alignment procedure was performed incorrectly or not done at all.

Advice. Not all reasons for a vehicle's deviation from a straight line are so critical. More prosaic moments also happen, for example, the bolts holding the hub have come loose. Hence the recommendation: before troubleshooting, check the reliability of the threaded connections of the suspension, chassis and steering rods.

How to diagnose these faults in a garage environment:

- Drive the car into an inspection ditch and check the steering rod ball pins. You need to grab the rod with your hand and try to rotate it around its axis. A serviceable hinge will allow it to rotate with little tension, a loose one will allow it to rotate very easily, and a jammed one will not allow it to rotate at all.

- The bent rod is also easy to notice from the inspection hole. The part must be replaced immediately, you can continue driving only after adjusting the camber - toe.

- To check the rotation of the ball joint, it is advisable to hang the front of the car and turn the wheels manually. Option two: diagnose play by alternately rocking the wheels.

- Wear and destruction of the bearing does not occur silently - the phenomenon is accompanied by a hum and grinding noise while the vehicle is moving. To check for damage, hang the wheel from the “noisy” side and spin it by hand. A broken bearing will immediately stop rotating or start grinding.

The bearing, which is in the initial stages of wear, moves the machine off the trajectory slightly. It is easier to guess about a malfunction by the buzzing sound. The damaged element is replaced immediately at the nearest car service center or on your own. If after replacement the car continues to deviate from a straight line, look for a breakdown elsewhere.

You can replace the rods and steering ends yourself (you will need a special puller), but you cannot drive further without adjusting the toe on the stand. By squeezing out the ball pins or unscrewing the tips, you will inevitably break the old settings.

What does incorrect wheel alignment lead to?

Everything is simple, if this parameter is disabled, then:

- The trajectory of the car is incorrect; it will pull to the right or to the left. Which is no longer safe.

- Increased tire wear on the wheel will require replacement more often.

- Incorrect position of the steering wheel in the car, which is also inconvenient.

To be honest, this is dangerous primarily due to the trajectory of movement, if at low speeds in the city you can hardly notice it, but at speeds of 60 km/h, the car may already be “wobbling” in different directions, that is, the steering wheel, you are holding straight - and the car is walking along the road. Well, the wear on the wheel will be simply enormous; even new tires can be ruined in a season.

Tire problems

The pressure difference in the front wheel cylinders is the most common reason for a car to easily pull away while driving. Diagnosis could not be easier - just measure the pressure with a pressure gauge and, if necessary, pump up the sagging slope. If the car pulls to the right, then low pressure should be observed in the right wheel and vice versa. Otherwise, you need to look for the problem elsewhere.

Equally common is uneven wear of the rubber on the wheels of the front axle. The reasons for the phenomenon are:

- a car enthusiast rarely monitors tire pressure;

- the wheels have not undergone the balancing procedure;

- in front there are tires with different patterns and sizes;

- slopes with a directional pattern are installed incorrectly;

- long driving with unadjusted camber angles of the front wheels.

Rubber of varying degrees of wear often ends up on one axle as a result of seasonal replacement. The owner of the “iron horse” did not mark the removed wheels according to their installation locations and next time he put them on at random. As a result, the rear and front axle tires got mixed up.

Reference. On front-wheel drive cars, the front slopes wear out much faster than the rear ones. If the wheels are mixed up and placed on one axle, the car will begin to pull towards a lower tread.

How to solve the problem of unevenly worn rubber:

- Choose a tire with high tread instead of a worn wheel. For example, install a spare tire.

- Balance the wheels, check and adjust the camber angles. Continuing operation and waiting for the differential to complete its task will increase the load on a tire of a larger diameter, causing the tread to quickly wear out.

- Place the rear slopes forward.

Avoiding the above-described manipulations is quite simple - pump up the cylinders in a timely manner, carry out balancing at intervals of 5 thousand km and visit the camber stand every 10-15 thousand km or after a strong blow to the suspension.

How to understand that the car is driving

On a flat road, having accelerated to 90 km/h and making sure that there are no other cars, simply let go of the steering wheel and look at the behavior of the car. If the car veers sharply to the left or right, then go to a car service center on the first free day. If the car smoothly moves to the right, then this is normal, because... there is a slope of the road .

If you steer the car to the left and the car moves smoothly to the left, then there is probably nothing wrong with the car and the alignment.

If the car still pulls to the right, and you steer to the left, but the car still steers to the right, then again there are 2 options:

- or it is necessary to do a wheel alignment;

- or crooked wheels.

In the first option, everything is clear, you need to go for diagnostics, change worn suspension elements and do a wheel alignment.

If you swapped the front wheels and the car began to pull to the left, but before that it was to the right, then the tires are to blame - 99%.

If the car drives straight, doesn’t rattle and doesn’t eat tires, then there’s no need to go to the wheel alignment after replacing the tires or wheels!

Toe angle

The toe angle is the angle between the middle plane of the wheel and the plane that is parallel to the longitudinal plane of symmetry of the vehicle, provided that the wheels are aligned for straight motion.

Average values of toe angles:

- for front-wheel drive: 0±10′.

- for rear-wheel drive: +15'±10'.

The sum of the angles for the left and right wheels forms a complete toe-in.

If the toe of the left and right wheels are equal, it is half toe.

The toe-in deviation tolerance for each wheel at car repair shops is ±5′.

The car pulls to the side after changing tires: reasons

If, after changing tires, the car begins to behave inappropriately, this is a consequence of incorrect settings of the elements of the car’s chassis. Usually the reason that the vehicle pulls to the side after replacing the ramps is one of these factors.

- Incorrect pressure. When installing new tires, car enthusiasts often forget about the need to check the tire inflation. If the car starts to drive crookedly, one of the tires may be flat.

- Tires installed incorrectly. Each slope has an inner and an outer side. There is a clear signpost for directional models. If the wheels on the same axle are positioned differently, the steering wheel will pull.

- Uneven wear. On the right side there is a good version, on the left there is a “dead” ramp, naturally the car will pull to the side.

- Problems with the brake mechanism. When replacing wheels, you can accidentally break the brake line, which will lead to the part jamming.

- Broken wheel alignment. The old tire could have gotten used to it and not react to the wearability violation.

After changing tires, the car pulls to the right when you let go of the steering wheel: what to do?

If the steering wheel moves to the right after changing tires, it is necessary to check the primary causes.

- Correct inflation - there should be equal pressure all around.

- Correct tire installation. Some craftsmen may mix up the wheels during installation.

- Brake system. A wedging caliper blocks the disc, which leads to slip.

- Uneven wear on the slopes. It is tedious to measure the tread depth with a caliper - it should be the same.

- Wheel alignment. Broken rods can cause the vehicle to roll away.

Axle angle (caster)

There are longitudinal angles of inclination of the rotation axis. They are adjustable. They can change the value under the influence of the weight of the cargo in the trunk of the vehicle. The tolerance for the left and right sides cannot exceed 0°15′-0°40′.

There are also transverse angles of inclination of the rotation axis. They are unregulated.

Usually, when they talk about the angle of an axle at a tire shop, they mean the longitudinal angle of the steering axis. It is located between the plane perpendicular to the surface of the road surface and the planes of symmetry of the wheel. Caster shows the deviation of the wheel position relative to the shock absorber strut.

Replacing ball joints

These parts directly affect the position of the wheels relative to the road surface, so after installing new ball joints, wheel alignment must be done. The reason for this is that when the old part gradually wears out, play appears, which you eliminate by adjusting the toe and camber. And if you decide to change the ball joints, the play disappears. Therefore, the wheels will stand differently and their position needs to be adjusted.

And also interesting: TRANSFER CASE AND SHANK SEAL OF FRONT AXLE NIVA 2121 21212302052 AvtoVAZ. Wholesale and retail.

FakeHeader

Comments 15

Do it of course. If the steering wheel is not level, don’t even think about it. After replacing the ball joint, you need to. My opinion!

Thank you, I did it not long ago, I said that maybe the ball mount is different and that’s why. Now the steering wheel is straight, half a year warranty and everything is like in a pharmacy.

It seems not... but it’s everyone’s business.

I was surprised myself, although I know that when replacing the ball joint there is no effect? Thanks for your feedback. Well, before the replacement, the steering wheel was exactly a hundred pounds! I changed the right one and leaned to the right ((

Steering rack and ends

It is also necessary to check this parameter when replacing them. After all, these are almost the very first culprits of incorrect wheel alignment. Moreover, if you simply removed the rack without making any changes to it, for example, simply changing the boot, or adjusting the clamp - this is one thing, the parameters may not be lost. But if the tips were changed, that’s completely different.

The steering tips regulate the toe-in; they are the ones that are “twisted” at stations, so when replacing them, procedures are mandatory - remember this! If it is not aligned correctly, there will simply be enormous wear on the tires of the wheel, and control will suffer, specifically.

Pressure

This is one of the most common reasons for a car to be driven away after installing other tires. Many people have a ready-made set of wheels that they simply change when the season changes. But very often they forget to check the tire pressure, which may decrease during storage. If the wheel on the front left has low pressure, then the car will move in that direction.

Also, this negatively affects the condition of the tires; driving on flat tires leads to accelerated destruction of the tires. Therefore, be sure to check your tire pressure. If you don’t have a pressure gauge, you can do this at any gas station absolutely free. There you can inflate the tires so that the pressure in them is the same.

Rubber wear

. Tires wear unevenly; even with the correct settings, each tire will have a slight difference. And if before this the car was driven for some time with a broken wheel alignment, then perhaps one of the wheels turned out to be worn a little more and completely unevenly. Carefully inspect the tire on the side where the car is steering. You may see that the tire on the outer circle is a little more worn. The only way to deal with this problem is by replacing the tire.

When replacing a CV joint

To be honest, the CV joint itself does not affect the car’s suspension, it is responsible for transmitting torque to the wheels, that is, replacing it should not affect the wheel alignment. However, I receive a lot of letters in the mail - that after replacing it, the steering wheel was not in the position it was in, or the car began to drift to the right or left. Why is that?

It’s very simple - when replacing a CV joint, craftsmen have to unscrew the fastening of the ball joint or often the steering end, or maybe both at once. You just can't remove the CV joint without removing these two (or one) ends (always different). They are difficult to remove, and often the hub simply sticks to the ball joint.

After replacement, they should be put back in their place, but you can inadvertently change the settings or break the tips! Because of this, it will pull or the steering wheel will not be in the correct position - we are going to “camber”. Also, after such a repair, we immediately check the ball and steering ends, perhaps due to incorrect removal actions you broke them. The moral is this - go to proven stations, and not to “Uncle Vanya” in the garage.

What I would like to say in conclusion is that the suspension of modern cars is a fairly durable mechanism (unless, of course, you deliberately kill it), it can travel many thousands of kilometers, usually problems begin closer to 100,000 km. Until this date, most likely you will not need to check the wheel alignment; replacing tires and even struts play practically no role here, so go for a ride - don’t be afraid of anything.

I’ll just give you one piece of advice right away, when buying a new car, it is advisable to immediately check the wheel alignment, before the first 2000 km - tell the mechanic that it seems like the car is dragging, and the steering wheel is not level, let them check (sometimes even this should be done at expensive cars, my friend has a new Tiguan, the settings were messed up, although I bought an expensive package).

Now there’s a useful video, let’s watch it.

And that’s all for today, read our AUTOBLOG.

votes, average: 3.73 out of 5)

Also interesting: Kenguryatnik on Chevrolet Niva: selection criteria, material, installation

Choosing wheels and tires: what to look for and how not to make a mistake

Car wheels and tires. At first glance, it seems that it could be simpler? But we would pose the question differently: what could be more important? Perhaps, it is the tires - these inconspicuous parts at first approach - that are the second most important in terms of safety (after brakes) and the first busiest part, which constantly works in difficult road conditions and on which the life and health of motorists depends.

That is why the car owner must make special demands on tires in particular and wheels in general and take an extremely responsible approach to their purchase/change/update or improvement.

Yes, many will say: what is the wisdom of buying tires? After all, this is one of the simplest modifications that can be made by any car owner, even those far from the technical automotive part. But in order to choose the right tire, you need to know a number of nuances, and that’s exactly what we’d like to talk about today. Here's what you need to know before you go shopping for "shoes" for your car.

Brake problems

Problems with brake mechanisms appear both after pressing the pedal and while driving. The reasons are as follows:

- complete failure of one of the working cylinders, including on the rear axle;

- jamming of the working cylinder piston in various positions;

- fluid leakage from the brake circuit tube;

- failure of the hydraulic valve of the anti-lock braking system.

When the working cylinder on one of the front wheels fails, the car literally rolls away after sharply pressing the brake. If the car pulls to the left, it means the right cylinder is not functioning and vice versa. When the brake cylinder of the rear axle fails, the car does not pull away so clearly. The easiest way to find the “culprit” is by leaking brake fluid, inspecting each hub from an inspection ditch or simply looking under the car.

On cars with high mileage and worn calipers, the piston of the working cylinder may become stuck in the position of squeezing the pads. The wheel on the side of the faulty mechanism is continuously braked, and the car constantly moves in the same direction. It is easy to identify a breakdown: after driving 1–2 km, feel all the wheel rims with your hand. The “culprit” will be revealed by the heated rim.

If the piston of the working cylinder is frozen in a free position, then the vehicle will drift during the braking process - the car will drift in the direction opposite to the non-working mechanism. To finally make sure that the element is broken, hang the wheel from the suspicious side and try to spin it with the brake pedal pressed.

Diagnosing anti-lock braking system (ABS) problems in a garage environment is difficult. If fluid does not pass through one of the valves, you will have to disassemble the calipers and make sure that the cylinders are functioning normally. It’s easier to go to the nearest car service center, where technicians will check the brakes using specialized equipment.

Wheel angles

In order for the car to drive straight and not turn anywhere on its own, it is necessary that all its wheels are installed strictly at the correct angle. During suspension repairs, the previously set angles are lost and for this reason, before driving anywhere, it is necessary to go through the wheel alignment again.

This procedure includes adjusting the wheels vertically - camber, as well as adjusting them horizontally - toe. If you neglect this rule and set the wheels “by eye,” this will lead not only to rapid wear of the tire tread, but also to very poor handling.

When replacing shock absorber struts and stabilizers

Although the shock absorber struts are part of the front suspension, they are one of its main parts. However, they have practically no effect on “taxiing”; they do not affect steering rods, ball joints, etc. — when replacing a shock absorber, it is not recommended to unwind them at all. This applies to both front-wheel drive vehicles (MacPherson strut) and rear-wheel drive vehicles of our VAZs. We just remove the strut, there are three bolts on the front drive and two on the bottom and pull it out - install a new one and drive on.

The same issue applies to stabilizers; they generally have little effect on wheel alignment. These are generally bones that simply “collect” the suspension into a heap, making it work in a balanced and equal way. They can be changed in half an hour, with your own hands, after which you don’t need to do anything.

A few words about safety

More than the suspension, the only thing that affects driving safety is the brakes. To avoid getting into trouble, monitor their condition - change the pads on time and constantly check the amount of brake fluid. After replacing the pads, you need to bleed the brakes - this is not the law, but it’s safer and you’ll have peace of mind.

Keep an eye on the important components of the car - suspension, steering, brakes. A timely visit to the specialist will save you from many problems and costs.

When you feel that the car is not behaving normally, contact the station immediately, even if it is just a suspicion. It’s better to play it safe – it will get worse later. Timely maintenance will save you from accidents and the costs of future repairs.

If you find an error, please select a piece of text and press Ctrl+Enter.

Replacing the CV joint

The constant velocity joint is not part of the suspension and does not affect it, but when replacing it, the angle of the wheels is always adjusted.

When they take out the CV joint, they disassemble the fastening of the steering tip or ball joint. After installing a new part, the tip is twisted, which throws off its settings. Often it is completely broken. And if you don’t align, the car will drive to the side.

The angle of inclination of the wheels is also influenced by the condition of the steering tip itself. When replacing it or repairing the steering rack, the camber is also adjusted.