01/26/2022 159 177 117 VAZ 2115

Author: Ivan Baranov

Following the example of foreign automobile companies, it introduces advanced technologies into its vehicles. One such example is an on-board computer, designed to detect a malfunction in the machine using a digital code. We invite you to find out how the on-board computer of the VAZ 2115 is diagnosed - the error codes will also be deciphered in this article.

[Hide]

Diagnostics

There are two ways to set error codes for VAZ 2114 injector 8 valves. However, each method has unique advantages and disadvantages.

Self-diagnosis of VAZ 2114: error codes and their interpretation

The self-diagnosis method does not require the driver to have complex instruments or additional units. To complete the procedure, the car itself is enough.

The standard sequence of actions looks like this.

- Press the odometer reset button.

- Turn the ignition key to position No. 1 (turn on the on-board electrics).

- Release the mileage reset button. After this, the instrument arrows will make a full revolution and return to their place.

- Press the reset button a second time and release. The command displays the firmware version indicator.

- Repeat step No. 4 - this will display error codes on the on-board computer.

If the sequence of actions is performed correctly, all indicators will light up and the display will show a two-digit fault code.

Note!

A failure signal may be a lack of response from the indicator. In this case, it is necessary to check the circuit coming from the device.

The most common error codes for the VAZ 2114 panel, occurring in 90% of cases:

- 1 – microprocessor failure, flashing required;

- 2 – error code 2 VAZ 2114 indicates that there is an interruption or disruption in the wiring of the float sensor inside the gas tank;

- 4 – electrical wiring short circuit, voltage limit exceeded;

- 8 – error code 8 on the VAZ 2114 indicates a drop in voltage in the network, the battery may have run out;

- 12 – in the VAZ 2114, error code 12 indicates that the warning lamp is not functioning properly;

- 13 – open circuit of the oxygen sensor;

- 14 – error code 14 on the VAZ 2114 warns the driver that the engine has overheated or the antifreeze temperature sensor has shorted;

- 15 – short circuit or DTOZh has failed;

- 16 – exceeding the permissible voltage limit of the on-board network;

- 17 – BS voltage has dropped critically, battery discharge is allowed;

- 19 – DPKV does not respond or there is a short circuit on the line;

- 21-22 – incorrect response of the TPS, possible short circuit or wiring break;

- 23/25 – short circuit of the throttle position sensor;

- 24 – speedometer failure, power cords may be broken;

- 27/28 – CO sensor worn out or broken;

- 33/34 – problems with the mass air flow sensor, possible power loss or short circuit;

- 35 – IAC sensor has failed, can only be treated by complete replacement;

- 41 – incorrect phase distribution covered or shorted;

- 42 – the circuit has failed or the wires of the electronic ignition unit have been broken;

- 43 – mixture detonation sensor is faulty;

- 44/45 – there is a violation of the fuel supply to the engine, the system may trip, jerks appear during acceleration, and it picks up speed poorly;

- 51 – ROM is acting up;

- 52 – similar for RAM;

- 53 – potentiometer failure;

- 54 – break in wiring for octane corrector;

- 55 – excessive leanness of the mixture during acceleration;

- 61 – interruptions in the operation of the lambda probe.

In some cases, errors may be superimposed on each other if the failure is similar. For example, if errors 1 and 4 intersect, the panel will indicate "5".

It is important to know that after viewing, VAZ 2114/2115 error codes do not disappear on their own after repairs are performed. They need to be forced reset. To complete the work you will need a simple sequence of actions:

- turn on the car ignition;

- remove the terminals from the battery;

- wait 20-30 seconds;

- return the clamps to their place.

This also needs to be done if you are planning a trip to a service station. Having discovered the instructions from the on-board computer, the technicians will correct these problems, which will definitely be more expensive.

The disadvantages of an independent procedure include the low accuracy of the data. On-board diagnostics only show the general direction vector where the fault should be looked for.

Check using diagnostic equipment

You can identify error codes for VAZ 2115 and 2114 using a laptop with a special program. The tool is connected to the vehicle's test socket through a set of adapters. The wizard configures the software, and after diagnostics, one or more faults will be displayed on the computer screen in the form of a five-digit code.

The first part is the letter:

- B – damage to body panels;

- C – chassis or suspension malfunction;

- P – electrical, engine or transmission disorder;

- U – damage to the terminal for information exchange.

The second part is a single digit:

- 0 – typical indicator according to the SAE standard;

- 1/2 – conveyor failure code;

- 3 – reserve.

The next element is the breakdown group indicator:

- 1/2 – defect in the fuel/air line;

- 3 – ignition and related elements;

- 4 – catalyst;

- 5 – XO of the power plant;

- 6 – ECM and related wiring;

- 7/8 – transmission blocks.

The final two numbers point directly to the problem itself.

What does error 10 mean?

The driver of the VAZ 2114 sees error codes on the dashboard under the speedometer.

In the list of error codes 10 on the VAZ 2114, injector 8 valves do not exist. However, its appearance on the display is not uncommon. It means adding two known codes. To make sure that code 10 is not a glitch that arose as a result of errors stored in the computer’s memory, they can be reset by disconnecting the car’s power supply terminal from the battery. A de-energized control unit will clear the information stored in it. And if, while the car is moving, error 10 in the VAZ 2114 appears again, then you will have to understand its cause. For reference, we provide a table of codes 1-9, which can also turn out to be independent problems, or consist of codes that are similar in meaning. For example, the number 5 on the display indicates a problem with the temperature controller, and at the same time can be composed of codes 1 and 4.

Basic error codes for VAZ 2114 injector: decoding

Note!

The table is also relevant for version 2115.

Exhaust system – 0000

- 30 – open circuit of the oxygen sensor heater to the catalytic converter;

- 31 – also with a short circuit to the car body;

- 32 – similar with a short circuit to 12V;

- 36-38 – the same value as 30 only for the output sensor.

Air line defects – 0100

- 102/103 – Mass air flow sensor open circuit or signal violation;

- 112/113 – sensor lines t˚ overboard, impulse violation;

- 116 – engine overheating;

- 117/118 – damage to the DTOZH circuit;

- 122/123 – TPS line, short circuit or insulation failure;

- 130 – failure of the oxygen sensor in front of the catalyst;

- 131/132 – similar element, signal level violation;

- 133 – slow response of DK1 to commands;

- 134 – break in the power cable DK1;

- 136 – DK2 is broken;

- 137/138 – short circuit or violation of wiring DK2;

- 140 – fuse DK2 burned out;

- 141 – the heater of the same device is broken or damaged;

- 171/172 – excessively lean or enriched fuel mixture.

Error codes VAZ 2114 1.6 liters related to fuel supply - 0200

- 201/204 – break in the injector control line for all injectors in series;

- 217 – motor overheating;

- 230 – the fuel pump has failed or the corresponding relay has burned out;

- 261/264/267/270 – short circuit of the injector control circuit at +12 V, respectively, for each insert;

- 263/266/269/272 – failure or defect of the injector driver for each in series;

- 262/265/268/271 – Short circuit of highways to the car body.

Error codes on the VAZ 2114 on-board computer indicating a breakdown in the ignition system - 0300

- 300 – there are misfires;

- 301-304 – similarly for each cylinder, respectively;

- 326-328 – DDS is broken or there is no signal;

- 335-338 – failure, short circuit or interruption of the DPKV wiring;

- 342/343/346 – malfunction of the phase distribution sensor;

- 351-354 – open circuit for all pistons in series;

- 363 – the mixture in the cylinders does not ignite, emergency fuel supply cut-off.

Additional attachment that does not have a direct effect on the motor – 0400

- 422 – the catalyst may have clogged or the exhaust gas flow rate has dropped critically;

- 441 – failure of power supply to the adsorber purge valve;

- 444 – power failure above the specified element;

- 445 – short circuit of the gearbox to the car body;

- 480 – power wires to the main radiator cooler are damaged;

- 481 – failure of the coolant fan control circuit No. 2.

Failure, malfunctions in the SU speed control system – 0500

- 500 – speedometer sensor is broken;

- 506/507 – low or high speed of the vehicle;

- 511 – XX regulator – lines from the relay and ECU are interrupted;

- 560 – the battery is low or the power cable is broken.

- 562/563 – Short circuit on on-board wiring.

On-board network of auxiliary or main equipment – 0600

- 601 – ECM, ROM error;

- 615 – secondary starter relay, wiring damage;

- 616/617 – also with short circuit to ground or 12V;

- 627 – fuel pump control relay, possible line break;

- 628/629 – similar with a short circuit to the body or on-board system;

- 645-647 – compressor clutch, damage to the wiring with contact with the housing or other cables;

- 650 – the “Check Engine” lamp is broken, check the engine, there may be damage to the wiring;

- 654 – tachometer failed;

- 685-687 – malfunction of the main engine control relay, complete replacement of the part is required;

- 691/692 – problems with the main cooling fan relay.

Auxiliary systems – 1000

- 102 – breakdown of heater DK1;

- 115 – failure or malfunction of the above device;

- 123/124 – violation, too rich/lean mixture at idle;

- 127/128 – similar, only for partial load on the internal combustion engine;

- 135 – rupture of heating line DK1;

- 136/137 – incorrect fuel supply at low engine load, the throttle drive may be malfunctioning;

- 140 – discrepancy between measured and actual load;

- 141 – failure of heater DK2;

- 171/172 – incorrect information comes from the potentiometer;

- 301-304 – the ignition in the cylinder does not work correctly, consistently for all combustion chambers;

- 386 – incorrect sequence of testing the detonation channel;

- 410/425/426 – wiring of the canister purge flap, short circuit or line damage;

- 500 – the fuel pump relay line is damaged;

- 501/502 – similarly with a short circuit to the body or wiring;

- 509/513/514 – control center of the XX regulator, open or short circuit on board or 12V;

- 541 – damage to the wire of the BN relay, possible oxidation of the terminal;

- 570 – break in immobilizer control cables;

- 602 – no power to the ECM, oxidation of the pads is allowed;

- 606 – the bump sensor is broken, the part needs to be replaced;

- 616/617 – similarly with a change in signal level, there may be a short circuit inside the device;

- 2301/2303/2305/2307 - the ignition coils are shorted to 12 volts, in series for each piston.

Important!

Only the most popular error codes for the dashboard of the VAZ 2114 and similar models are listed here. There are other indices, but due to their low prevalence they are not mentioned.

Description of faults

| Serial number | Decoding |

| 1 | There are problems with the ECU. |

| 2 | The fuel level sensor is providing incorrect data. |

| 4/8 | There are problems with the machine's power supply. |

| 12 | The error lamp circuit is faulty. |

| 13 | Lambda probe – power supply circuit open. |

| 14/15 | Temperature sensor incorrect signal. |

| 16/17 | There is a short circuit in the on-board network. |

| 19 | DPKV incorrect data. At the same time, the car often does not start. |

| 21/22 | Typical TPS errors. Cleaning the damper is usually sufficient. |

| 23/25 | The intake air temperature meter has failed or is stuck. |

| 24 | Speed sensor is broken. |

| 27/28 | DC is faulty. |

| 33/34 | The air flow meter is not working properly. |

| 35 | The idle speed control sensor is faulty. |

| 42 | The ignition system circuits are broken or not working correctly. |

| 43 | The knock sensor is damaged. |

| 44/45 | The composition of the fuel mixture is incorrect. |

| 51/52 | ECU memory module errors, |

| 53 | CO2 setting sensor error. |

| 54 | The octane corrector is faulty. |

| 55 | The composition of the fuel mixture is incorrect. |

| 61 | The oxygen sensor has failed. |

Tidy 2115 stopped working

Occurs after power surges or moisture getting under the panel (condensation). If the device has completely failed, but other elements of the car are working, check the fuse and wiring of the element.

When only part of the panel does not show or the board lighting has failed, perform diagnostics of the illuminators and their contact groups.

Tidy does not light up

If the backlight does not function, as well as the dimensions on the left side of the car, check the corresponding fuse. When the insert is working properly, you will need to diagnose the mounting block for voltage.

Panel 2115 blinks

It happens when the device does not work correctly. The backlight blinks and the elements constantly jump. There are problems with contacts here. The pads may become loose or oxidized.

The solution to the problem is to clean the contacts from oxidation and tighten/replace the pads.

The temperature sensor on the device 2115 does not work

The solution lies in diagnosing the system and correcting breakdowns.

The arrows on the dashboard 2115 do not work

The fault lies with the blown fuse F3. Before replacing it, be sure to diagnose the wiring and eliminate problems and possible short circuits.

How to fix the problem

After diagnosis, the problem should be repaired. When reading a signal, it is necessary to check the circuit and devices following it. The most accurate method is to replace the damaged part with a known good one (new). This will eliminate the possibility of incorrect repairs. If the device is in working condition, the lines are checked; usually a primitive test is sufficient. However, if the control unit or relay fails, you will need a special tester and the ability to use it.

Separately, it is necessary to take into account that factory terminals and blocks become loose and oxidize over time. If the contact on the hitch deteriorates, the on-board computer or laptop program will say that the part is damaged, even if it is not.

You can prevent this from happening in the following way.

- Check the condition of the connectors once every 5000 km. The pads should sit in place tightly, without play. If necessary, elements must be replaced with new ones.

- Check plug connectors two to three times a year for oxidation. Oxides reduce the flow of electricity through on-board wiring, which leads to incorrect display of information.

- Experts recommend purchasing and using oil for electrical terminals. The liquid is similar in composition to transformer lubricants. The formula prevents water and oxygen from reaching metals, which prevents them from rusting.

Important!

You can diagnose VAZ 2114 error codes on the instrument panel and ECU yourself, only if you understand the essence of the process. If you don’t have confidence in your own abilities, it is recommended to contact a qualified technician.

Car diagnostics

Of course, it is impossible to detect a malfunction in the operation of a vehicle without diagnostics. This can be done using special equipment, which can be found at every specialized service station. But you can also check your car for faults on your own. Note that when checking the car yourself, the error codes will not be the same as when diagnosing on the equipment.

So, how can you independently diagnose the state of the VAZ 2115 on-board computer? This question came to the mind of every owner of these car models. Now we will tell you about this in more detail. But diagnosing the car is half the battle, because the resulting combinations of faults also need to be deciphered.

Self-diagnosis of VAZ:

- Find the odometer button on the instrument panel. You need to clamp it down.

- Then turn the ignition key to position 1.

- Having done this, the odometer button will need to be released.

- When you release the button, the arrows on the instrument panel will start jumping.

- Press and release the odometer button again. Numbers will appear on the speedometer indicating the firmware version of the on-board computer.

- Finally, hold and release the odometer button for the third time and you can see the fault combination. In the case of self-checking, error codes will be presented in two-digit form, in contrast to diagnostics on equipment, where faults are presented in four-digit form.

Pressing the odometer button to carry out self-diagnosis of the VAZ 2115

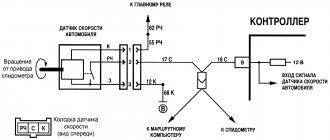

Diagnostic tool interface

When a list of detected errors is displayed, their explanation can be found in the test file that is usually included with the program. Decipher all errors that may occur in the event of a malfunction.

After deciphering the detected error codes, you should begin to eliminate them. First of all, it is worth checking the sensors, since the correctness of the readings and the operation of the ECU depend on their functionality. A faulty sensor may be causing the error message. For a more accurate diagnosis, additional checks of machine components may be required. Once you have fixed all the problems, be sure to run a test to make sure everything is working without errors.

Don't forget that all data is stored in the microcontroller's memory. Therefore, before a new scan, they must be reset.

To do this, turn off the ignition and turn off the diagnostic equipment. To reset the microcontroller, simply disconnect the negative battery terminal. Then the process is repeated - the laptop is connected and diagnostics are repeated. The process is repeated until all errors are eliminated.

Decoding codes

As stated above, without deciphering error codes, diagnosing a vehicle is meaningless. Therefore, deciphering combinations should also be given attention. Especially if you don’t want to pay a lot of money to specialists at the service station for this. So, let's start with the combinations that appear during self-diagnosis of the car.

Self-diagnosis codes

| Combination | Deciphering the breakdown |

| 1 | Code 1 indicates a malfunction in the microprocessor. Sometimes the error is corrected by flashing the device. |

| 2 | The on-board computer reports incorrect operation of the gasoline level sensor in the fuel tank. There may be problems with the electrical wiring. |

| 4,8 | The voltage in the vehicle network is too high or too low. |

| 12 | Incorrect operation of the diagnostic lamp circuit. |

| 13 | The on-board computer stopped receiving a signal from the oxygen level monitoring device. |

| 14,15 | The control unit receives an incorrect signal from the antifreeze temperature sensor in the cooling system. In particular, the signal may be too low or too high. |

| 16,17 | When checking a car for errors, these combinations mean an incorrect on-board voltage indicator. it is necessary to carefully check the network for short circuits and breaks, since the voltage indicator is too high or very low. |

| 19 | The VAZ 2115 on-board computer receives an incorrect signal from the crankshaft position monitoring device. The circuit should be checked. |

| 21,22 | The VAZ 2115 control unit receives a very low or high signal from the throttle position control device. To eliminate the malfunction, you should check the functionality of the device itself, as well as diagnose the electrical wiring. |

| 23,25 | Intake air temperature control device. The control unit receives an incorrect signal from this sensor. The circuit should be checked, as well as the sensor itself. |

| 24 | The on-board computer stopped receiving a signal from the speed sensor of the VAZ 2115 vehicle. |

| 27,28 | These error combinations indicate the receipt of an incorrect signal from the CO sensor to the car control unit. It is recommended to check the circuit for opens and shorts or replace the sensor. |

| 33,34 | Mass air flow control device. These errors mean the receipt of an incorrect signal from the sensor, as a result of which it should be replaced. There is also a possibility of breaks in the circuit, so it makes sense to check the electrical wiring as well. |

| 35 | A malfunction has been detected in the operation of the idle air regulator. The sensor must be replaced to restore correct operation of the device. |

| 41 | The control unit receives an incorrect signal from the phase sensor. |

| 42 | This combination indicates a malfunction in the electronic ignition control wiring. Apparently, everything is in order with the ignition, but the circuit should be diagnosed. |

| 43 | The control unit received an incorrect signal from the knock sensor. You should check the device or diagnose the circuit for breaks. |

| 44,45 | In the injection system, the on-board computer recorded a lean or enriched composition of the combustible mixture. In this case:

|

| 51,52 | These combinations of faults indicate detected errors in the PROM or RAM devices. |

| 53 | The VAZ 2115 control unit stopped receiving a signal from the CO sensor. You should check the functionality of the device. |

| 54 | The signal from the octane corrector sensor has disappeared. |

| 55 | This combination indicates that when the car is moving, in particular when there is a high load on the VAZ 2115 engine, the combustible mixture in the injection system becomes leaner. In this case, the signs of failure may be the same as in the case of codes 44 and 45. |

| 61 | The oxygen sensor is broken. To restore system operation, the sensor must be replaced. |

Connecting special diagnostic equipment to the connector in the VAZ 2115 interior

Controller errors

The following are combinations of errors in the operation of controllers that arise when diagnosing a VAZ 2115.

| Combination | Decoding |

| P0101-P0103 | These combinations indicate a malfunction of the mass air flow sensor. In particular, the signal may be increased or decreased. The device should be replaced. |

| P0112-P0113 | The intake air temperature sensor has been reported to have failed. It is necessary to check the electrical wiring, especially in places where the wires have been soldered. Apparently, the on-board computer is trying to inform you that a short circuit or break has occurred. |

| P0116-P0118 | These error codes indicate a malfunction of the antifreeze temperature sensor in the system. As a rule, in such cases, it is better to first check the electrical wiring, and if everything is in order with the circuit, then it is advisable to replace the sensor itself. |

| P2138, P2122, P2123, P0222, P0223 | These error codes indicate that the accelerator pedal position control device is not operating correctly. |

| P0201-P0204 | When such combinations appear, the on-board computer tries to inform the car owner that one of the injectors is not working correctly. In particular, an open circuit or short circuit may be detected in the system. |

| P0130 - P0134 | One of these combinations of numbers may indicate a malfunction in the functioning of the control oxygen sensor. To restore the operation of the sensor, you should check the circuit for breaks and short circuits, or you should replace the device. |

| P0136-P0140 | These errors indicate incorrect operation of the diagnostic sensor for monitoring the oxygen level in the injection system. As in the previous case, errors may indicate incorrect operation of the device or faulty wiring. |

| P0217 | Indicates overheating of the internal combustion engine. In this case, malfunctions may lie both in the operation of the motor itself and in:

|

| P0326-P0328 | The VAZ 2115 on-board computer informs the car owner about a detected breakdown of the knock sensor. In particular, such combinations may indicate not only the failure of the sensor, but also an incorrect signal coming from it to the control unit. |

| P0340-P0343 | Such combinations indicate a breakdown of the VAZ 2115 camshaft position control sensor. In particular, errors may mean:

|

| P0351, P0352, P2301, P2304 | These combinations mean incorrect operation of the ignition coils, namely, we are talking about an incorrect signal sent to the on-board computer. Also, these combinations may indicate a break in the electrical wiring or a short circuit in the circuit. |

| P0422 | The neutralizer device has broken down. |

| P0691, P0692 | The first cooling fan relay has failed. |

| P0693, P0694 | The on-board computer detected a breakdown of the second cooling fan relay. If the fuse is not replaced in a timely manner, the coolant may boil. |

| P0485 | The control unit receives an incorrect voltage signal from the cooling fan. |

| P0560-P0563 | The control unit has detected that the on-board voltage is too low or too high. |

| P0627-P0629 | These combinations may indicate either an incorrect signal from the fuel pump or a breakdown of the relay responsible for the operation of the unit. It is worth noting that if the fuel pump fuse breaks, operation of the vehicle will be impossible, since it will not be possible to start the engine. |

| P1602 | 1602 is a common VAZ error. Malfunctions have been registered in the operation of the engine control system controller. |

Reset error

Disconnecting the battery terminal to reset codes

If you have discovered and eliminated a malfunction, then it must be erased from the memory of the on-board computer. To do this, repeat the following steps:

- Stop the engine and turn off the ignition.

- Disconnect the terminals from the battery.

- Wait a few seconds and connect the terminals back to the battery.

Sources

- avtozam.com/vaz/2115/rasshifrovyivaem-kody-oshibok/

- vaz-russia.com/remont-vaz-2114/rasshifrovka-kodov-oshibok-vaz-2114.html

Designation of icons on the dashboard of the VAZ 2115

The following describes the warning lights and panel indications, which are indicated and numbered in the photo above.

| Number in order | Decoding |

| 3/4 | Turn signal indicators. They light up at the same time when the alarm is activated. |

| 7 | Minimum fuel level light. Lights up when the gas tank is empty. |

| 8 | Indicator for turning on external lighting. |

| 9 | The brake system is faulty. The brake fluid level and pad wear should be checked. |

| 10 | The high beam headlights are activated. |

| 12/15 | Information displays, basic information about the daily time and mileage is displayed here. |

| 13 | Emergency light activation key. |

| 14 | Check engine light. If it lights up, further movement is not recommended. |

| 16 | The battery is low. The operation of the generator should be checked. |

| 17 | The indication indicates that the handbrake lever is raised. |

| 18 | The warning light means that the engine oil pressure has dropped below normal. |

| 19 | This indicator is used exclusively on carburetor cars. The light indicates that the throttle valve is in the open position. |