January 11, 2018 Lada.Online 284 591 23

E-GAS or electronic gas pedal is installed on all Lada models (XRAY, Vesta, Largus, Granta, Kalina, Priora and Niva 4x4). Owner reviews about it are not reassuring; many complain that the e-gas pedal is “dumb” (less sensitive and informative than a conventional cable). Did you know that in some cases the electronic accelerator pedal can be adjusted to be more responsive and a little livelier?

We determine the model of the accelerator pedal; this can be done by the catalog number, which is glued to the side of the body. If you cannot access the sticker, you will have to remove the electronic gas pedal:

- Disconnect the block with wires next to the gas pedal;

- Unscrew three nuts using a 10mm wrench;

- Remove the housing and pedal assembly.

The manufacturer installs at least two types of electronic gas pedals on Lada cars (depending on the year of manufacture):

- Old model (catalog number: 11183-1108500);

- New sample (article: 11183-1108500-01).

Each block is modified differently. Attention! You do all further actions at your own peril and risk. In addition, you may lose your warranty.

Throttle adaptation for Lada Granta 127 engine

And if this is not done, then what will be interesting?

Or can you do this: install the battery, but since it’s cold now, don’t do the adaptation, and when it gets warmer, remove the terminal, then put it back on and do the adaptation?

Also, is it necessary to adapt the misfire function after this?

In general, everything is somehow not right. Okay adaptation. But these are +7 degrees. Drive in emergency mode all winter?

Added after 2 minutes As I understand it, it would be best to have an old battery with you. While I took this one out for charging, I quickly installed the old one to maintain the ECU memory.

Added after 1 minute Or you can also take an unnecessary battery from the UPS - it will be easier, but enough for support.

Source

Do-it-yourself throttle valve cleaning. — logbook Lada Granta Ice 2014 on DRIVE2

When I removed the air duct when replacing the speed sensor, I paid attention to the throttle valve. On it, 97,700 thousand kilometers away, deposits have accumulated, apparently from crankcase ventilation. According to the BC, the throttle position on a warm engine showed 4 (which is not good, it should be 1-2). For work you will need: hexagon number 5, a Phillips screwdriver (loosen the clamps), carburetor/throttle valve cleaner, rags and

Next, remove the air duct and the large crankcase ventilation pipe

Disconnect the terminal from the remote control (I also removed the terminal from the battery) Unscrew the 4 hex bolts. Two of which were searched for and unscrewed by touch. Unfortunately I didn't take a photo.

also from the air duct side

I did not change the rubber o-ring, it looks and feels like new.

Cleaned with carburetor and throttle valve cleaner. I bought the cheapest one that was in the store. I didn’t take any photos of the cleaning process either, I was distracted. Here is the end result:

Clean valve on all sides, remove all deposits

After installing it in place, I turned on the ignition for 60 seconds so that the damper determined the zero position. Acceleration from 1.5 thousand to 4 thousand rpm. per minute didn't.

Result: This may be self-deception, but the engine feels softer/quieter. According to the BC, the damper position at XX shows 1, very rarely 2.

Price: 150 ₽ Mileage: 97,700 km

Problem with idle float when starting on cold due to sticking of throttle 21127 and 21129.

Dear friends, today I’ll tell you about my experience in resolving problems with the throttle assembly. Very relevant, especially for owners of 21129 engines.

By the way, I have the firmware with the problem already fixed.

The occurrence and solution at the plant level in the case of the M74.5 ECU, it was like this. When the ignition was turned on on old versions of the ECU firmware, the micro-calibration time of the Throttle Unit (hereinafter referred to as the remote control) was, well, long, due to the fact that the owner did not wait for a 10-second pause during the ignition, this error occurred.

This problem can be fixed with firmware.

But not everyone, for example, in cars of 13-14 years, the remote control motor was of an old model, had a certain moment of jamming, then in 15 the remote control became “modernized” and this error went away altogether.

Firmware versions that have this problem:

I427DB02 I427DC03 I427DD04 I427DF04 I427DG05 I427GA01 I427GB02 I427GC03 I427GD04 I427GE05 I427GF06

Firmware versions that do not have this problem:

I427GG07 I427GKA1 I427GKA 2

Here is a photo of how to find out your firmware version, the firmware is interchangeable, at least install the oldest one on the new unit, at least the newest one.

Problem with floating XX when starting on cold

The car sits overnight, in the morning you start the revs, when it warms up, the revs begin to jump, +-300 revs, with the probability of stalling, you need to press the gas pedal lightly and everything returns to normal.

Starting the engine, the rpms are 1200, they begin to jump between 500 and 1400 and hang at 700.

Related problems:

— Jerking during a smooth start in first gear — Thoughts in part-load mode — The feeling when accelerating at 50% throttle that sometimes “as if you’re holding your ass”

How to diagnose physically: when disassembling the throttle, remove the plastic gear, twist the motor gear, if it rotates tightly or sticks, then the manual is for you.

It is necessary to remove the remote control, clean the valve (by the way, it was clean) with carburetor cleaner, then remove the cover, unscrew the motor and wash everything.

Source

Cleaning + lubrication of the throttle valve - logbook Lada Granta Perseus 1.6l. 8kl. 2015 on DRIVE2

At the beginning of this entry, I thank everyone who writes about their experience, especially with detailed photo reports. I’ve seen enough and decided to follow in the well-trodden footsteps of throttle valve cleaners. I have already driven 41,000 km. Up to 25,000 I filled in 95 TNK (2 times 92 - there was no way out) .After this mileage, it’s only 95 Lukoil. My consumption on 95 Lukoil is 8.2-9.5 liters with air conditioning. The city and a big traffic jam in the morning to work/in the evening from work.…

I bought a throttle valve cleaner at BB (on the way to my parents in the village) and got into the engine jungle.

*I wanted to buy Liqui Moly for 319 rubles in METRO, but a toad appeared and took me out of the hypermarket*1. Remove the pipes from the throttle body and mass flow sensor and move them to the side2. We take a hexagon (I don’t know which one exactly. My father has a whole set

3. We briefly remember all the relatives of the founder of the AvtoVAZ company and... voila, it’s in your hands!

puff-puff-puff - half of the bottle is missing (520 ml full). You can wash 100 ml economically. Next, use a rag to wipe the contact area of the throttle at the engine inlet. I unscrewed the cap and read from the guys that there is no lubricant on the gears. And so it was. Guys don't lie)

A little CV joint and we mount this nonsense in place (I didn’t take a photo, sorry)

Why is this and what does it give?1. Let's assume 3500 rpm and 3rd gear. release the gas pedal and your car seems to be rushing back. This procedure gives an almost imperceptible reduction in speed. In general, as it was from the factory.2. Work on xx without flaws

3. Smoother response to the gas pedal *by the way, I didn’t dare open it - the bolts are sealed*

Price: 142 ₽ Mileage: 41,000 km

When and how to do it yourself

When to do it

adaptation of the throttle valve zero and adaptation of the misfire diagnostic function:

- After replacing the ECU controller or resetting the controller using a scan tool.

- After replacing the throttle assembly.

Throttle zero adaptation procedure

:

- When the car is stationary, you must turn on the ignition, wait 30 seconds, turn off the ignition, wait until the main relay turns off.

Adaptation will be interrupted

, If:

- the engine turns over;

- the car is moving;

- the accelerator pedal is pressed;

- engine temperature is below 5 °C or above 100 °C;

- Ambient temperature is below 5 °C.

Adaptation procedure

Misfire diagnostic functions:

- warm up the engine to operating temperature (parameter value “Coolant temperature” = 60.90 °C);

- accelerate the car in 2nd gear until higher crankshaft speeds are reached (parameter value “Engine crankshaft speed” = 4000 min-1) and perform engine braking (“Engine crankshaft speed” = 1000 min-1);

- Perform engine braking six times in one trip.

This adaptation procedure is specified in the technological instructions for LADA cars.

How to adapt

After this, turn on the ignition for 30-40 seconds. Clicks will be heard, when they stop, turn off the ignition. Next, you need to wait 4 minutes for the main relay to turn off. For some reason it turned off earlier for us.

Now you need to drive in 2nd gear 6-7 times at rpm from 1000 to 4500. When you release the gas, you need the car to coast down to reduce engine speed. After the full number of repetitions, adaptation is completed.

How to install a horn signal with a compressor on a Lada Granta

Owner reviews

Owners of LADA XRAY who independently performed the throttle valve zero adaptation procedure note that the car stopped twitching and acceleration became smooth.

Some reviews from Drive2.ru (link to post):

Let us remind you that we previously published an information letter from AVTOVAZ, which tells us what to do in case of vibrations and jerks when starting off a LADA car.

Share on social networks:

Found an error? Select it and press Ctrl+Enter..

Source

Costly mistakes when repairing a car

Unfortunately, valuable experience in quality repairs is always built on a mass of expensive mistakes. Although no one has canceled banal laziness and sloppiness.

Even ordinary machine repair operations can result in significant costs. And here the matter is not only in the attitude of the master or the owner himself to his car, but also in the mass of pitfalls of technical stones. Moreover, not all of them are mentioned even in the factory service manual.

Replacement of suspension and chassis elements

There are common cases when a client comes to the service center to replace suspension elements, and as a result, when returning the car, for some reason the ABS system malfunction lamp lights up on the instrument panel. Computer diagnostics will most likely indicate a malfunction of the wheel speed sensor, from which repair work was carried out. It’s strange, but the mechanic didn’t touch this electronic meter at all, but it has to be replaced. Where is the connection?

The most common cause of failure of the active wheel speed sensor of the ABS system is careless use of a hammer when replacing suspension elements.

The most common cause of failure of the active wheel speed sensor of the ABS system is careless use of a hammer when replacing suspension elements.

When and how to do it yourself

When to do it

adaptation of the throttle valve zero and adaptation of the misfire diagnostic function:

- After replacing the ECU controller or resetting the controller using a scan tool.

- After replacing the throttle assembly.

Throttle zero adaptation procedure

:

- When the car is stationary, you must turn on the ignition, wait 30 seconds, turn off the ignition, wait until the main relay turns off.

Adaptation will be interrupted

, If:

- the engine turns over;

- the car is moving;

- the accelerator pedal is pressed;

- engine temperature is below 5 °C or above 100 °C;

- Ambient temperature is below 5 °C.

Adaptation procedure

Misfire diagnostic functions:

- warm up the engine to operating temperature (parameter value “Coolant temperature” = 60.90 °C);

- accelerate the car in 2nd gear until higher crankshaft speeds are reached (parameter value “Engine crankshaft speed” = 4000 min-1) and perform engine braking (“Engine crankshaft speed” = 1000 min-1);

- Perform engine braking six times in one trip.

This adaptation procedure is specified in the technological instructions for LADA cars.

Adaptation using the example of some cars

Another method, which we will consider using the example of one well-known German brand, also involves adaptation without a computer. Here you should warm up the engine to a temperature of approximately 70-99°C. The battery voltage must be at least 12.9 Volts when the engine is not running. The action plan for how to adapt the throttle valve on a Volkswagen will be something like this:

- After warming up and turning off the engine, you should wait a short period (5-10 seconds).

- With the gas pedal released, turn on the ignition and wait 3 seconds.

- After 3 seconds, you need to press the accelerator pedal all the way 5 times and release it back. Act quickly, as you only have 5 seconds to do this.

- After the 5th exercise, you should wait a pause.

- After 7 seconds, press the pedal all the way again and hold it in this position until the “CHEK” indicator starts flashing (≈ 10 sec.), then it should remain on continuously (≈ 20 sec.).

- When the indicator lights up constantly, count to three and only then release the pedal.

- Start the engine (repeat if necessary), wait 20 seconds, then lightly accelerate (2000-3500). If the tachometer shows 700 rpm at XX (+- 50), it means that the adaptation was successful.

In this case, it is necessary to strictly adhere to the time intervals of each setting step. This is the only way the ECU training will go smoothly. But before that, it’s worth studying the adaptation features and the possibility of a manual procedure for your car. Perhaps only service station specialists can help.

Owner reviews

Owners of LADA XRAY who independently performed the throttle valve zero adaptation procedure note that the car stopped twitching and acceleration became smooth.

Some reviews from Drive2.ru (link to post):

Let us remind you that we previously published an information letter from AVTOVAZ, which tells us what to do in case of vibrations and jerks when starting off a LADA car.

Share on social networks:

Found an error? Select it and press Ctrl+Enter..

Source

Torque

To change the amount of torque, the electronic control unit can change one or more parameters:

- throttle opening angle

- boost pressure (if the engine is turbocharged)

- ignition timing

- fuel injection timing

- turning on/off cylinders

The amount of torque is constantly adjusted and depends on the following factors:

- engine starting conditions

- stable idle speed

- O2 content in exhaust gases

- restrictions on power and number of revolutions

- Automatic transmission (when shifting gears)

- traction control when braking

- forced idle when braking

- equipment operation (climate control, air conditioning)

- cruise control (whether the mode is on)

When and how to do it yourself

When to do it

adaptation of the throttle valve zero and adaptation of the misfire diagnostic function:

- After replacing the ECU controller or resetting the controller using a scan tool.

- After replacing the throttle assembly.

Throttle zero adaptation procedure

:

- When the car is stationary, you must turn on the ignition, wait 30 seconds, turn off the ignition, wait until the main relay turns off.

Adaptation will be interrupted

, If:

- the engine turns over;

- the car is moving;

- the accelerator pedal is pressed;

- engine temperature is below 5 °C or above 100 °C;

- Ambient temperature is below 5 °C.

Adaptation procedure

Misfire diagnostic functions:

- warm up the engine to operating temperature (parameter value “Coolant temperature” = 60.90 °C);

- accelerate the car in 2nd gear until higher crankshaft speeds are reached (parameter value “Engine crankshaft speed” = 4000 min-1) and perform engine braking (“Engine crankshaft speed” = 1000 min-1);

- Perform engine braking six times in one trip.

This adaptation procedure is specified in the technological instructions for LADA cars.

see also

Throttle error

Throttle valve malfunctions

DIY throttle valve repair

Cleaning the electronic throttle valve

The task of the throttle valve (hereinafter referred to as DZ) is to regulate the amount of air supplied to the intake manifold. Its position is adjusted in accordance with the position of the accelerator pedal. The damper drive can be mechanical (using a cable) or electronic (using an electric motor). The position of the remote control is recorded by a special sensor. It transmits the relevant information to the ECU, which in turn makes a decision on the amount of fuel supplied and changing the engine operating mode. You can read more about its structure and functions in additional material on our website.

Owner reviews

Owners of LADA XRAY who independently performed the throttle valve zero adaptation procedure note that the car stopped twitching and acceleration became smooth.

Some reviews from Drive2.ru (link to post):

Let us remind you that we previously published an information letter from AVTOVAZ, which tells us what to do in case of vibrations and jerks when starting off a LADA car.

Share on social networks:

Found an error? Select it and press Ctrl+Enter..

Source

Conditions for carrying out the idle speed adaptation process

Before starting training, a number of prerequisites must be met:

- travel by car for 10 minutes;

- ensure that the battery voltage at idle is at least 12.9 V;

- warm up the gearbox;

- The wheels of the vehicle must be straight, the steering wheel must be in the middle position;

- engine temperature – 70–95 °C;

- all devices that put a load on the car’s electrical network (heated windows, headlights, etc.) should be turned off;

- The automatic transmission selector is set to N or P.

Throttle adaptation for Lada Granta 127 engine

And if this is not done, then what will be interesting?

Or can you do this: install the battery, but since it’s cold now, don’t do the adaptation, and when it gets warmer, remove the terminal, then put it back on and do the adaptation?

Also, is it necessary to adapt the misfire function after this?

In general, everything is somehow not right. Okay adaptation. But these are +7 degrees. Drive in emergency mode all winter?

Added after 2 minutes As I understand it, it would be best to have an old battery with you. While I took this one out for charging, I quickly installed the old one to maintain the ECU memory.

Added after 1 minute Or you can also take an unnecessary battery from the UPS - it will be easier, but enough for support.

Source

Throttle Lada Granta 8 valve

Perhaps this is exactly the case when one should not interfere with a properly working mechanism, because...

There were no indications for surgical intervention in the Granta throttle assembly. The engine is running. Idle speed does not float. The throttle response to the electronic accelerator occurs as normal. Occasionally I noticed, standing at a traffic light, that the tachometer needle was trying to unobtrusively change its position, but the electronics quickly eliminated this incident. In early spring, one could refer to some amount of condensation that sometimes appears in the fuel system. Now, May. Warm. But sometimes the arrow still tries to “twitch”.

The situation is not annoying, but the mileage is under 17,000 km. indicates that behind the throttle it is not at all the same as it was in the first hundreds of kilometers.

I did not contact the “dealer” service station, where Grant was under warranty, to clean the throttle. After we “adjusted” the thermal clearances of the valves during maintenance-1, there was no desire to communicate with such “specialists”.

It’s high time for AVTOVAZ to check its dealers and subdealers for high-quality performance of work when undergoing scheduled maintenance of warranty vehicles. There are enough statistics. And those who are negligent will be punished with a ruble so that the desire to run an official car service will no longer exist once and for all.

If adjusting the “valves,” for me, still requires consolidating the experience gained, then with cleaning the throttle valve, everything is much simpler.

What you needed: *A 5mm hex wrench. *Star key T-20. *Brush flute. *Lubricant. *Thread lock. *New bolts with washers, made of stainless steel. *Phillips and slotted screwdriver. *Cheap degreaser. *Spray for cleaning carburetors and chokes. *Cotton rags. lint-free. *Disposable rag on a roll. *Rechargeable cylinders and a hand pump for them. *Garbage bag.

Using the “Open Diag” program, we take screenshots of the throttle position before starting cleaning.

Throttle body adaptation grant 16 valves

Throttle learning is a technical term that owners of modern vehicles have recently become familiar with. This procedure is carried out on cars equipped with an ECU (electronic control unit) in case of unstable engine idling for a number of reasons, which will be discussed below.

The first ECUs (or controllers) began to be installed back in the late 80s. In this case, the opening of the throttle angle (TA) depended on signals from the sensors and the position of the gas pedal, which changed along with the force the driver pressed the pedal.

Modern cars are equipped with electronic accelerators on which electronic sensors are installed. It is from them that data on the degree of pressure (angle) on the accelerator is read. The corresponding information is supplied to the control unit. However, remote control training is also carried out on cars equipped with gas pedals that transmit force to the throttle valve mechanically.

Most modern cars made in Europe, America and Japan have both systems installed.

Withdrawal procedure

This job is simple: unscrew 3 screws and disconnect the plug with wires.

Now you need to disassemble it using a screwdriver. We see all the insides of the pedal body.

When we press it to the floor, it reaches the extreme position, when we release it, it moves back. But the pedal doesn't go all the way. You can move the slider a little so that it goes further than it is intended by the factory, but not all the way. Otherwise the pedal will not adapt. The electronic unit does not allow the fuel valve to open any further, and leaves it only at 50%.

In this case, the electronics will be able to adapt and set it to “zero”. In general, the slider must first be installed all the way, and then moved back about 10 degrees. Now we install the pedal in place and connect the ground to the battery.

Attention! Don't forget to connect the plug with the wires.

Signs of throttle adaptation

The throttle valve in its modern form is one of the last components to undergo electronic modernization. Instead of mechanical rods, a compact electric motor is installed on it, which serves as an actuator.

The signal to it comes directly from the throttle sensor. Together, this system allows you to control the engine correctly, supplying the required volume of fuel mixture to the combustion chambers in a timely manner. There are several signs by which you should start adjusting the throttle position.

For example, when you suddenly release the gas pedal, the engine does not go to idle and stalls; the following can also happen:

- Unstable engine operation at idle;

- a significant “freezing” of revolutions around the 1.5 thousand mark;

- drops in speed when gaining power;

- the “CHECK ENGINE” indicator lights up on the dashboard;

- difficult start at ;

- lack of response when pressing the gas pedal.

Depending on the engine type, there may be a slight loss of power, for example with engines with a V8 configuration. Also, fuel consumption almost always increases. These signs appear especially often on cars with a mileage of 30 thousand km or more, equipped with turbocharging.

Throttle assembly - removal, inspection, cleaning and installation of Lada Granta

The throttle assembly is non-separable, cannot be repaired and in case of malfunction it is replaced as an assembly. The need to perform work is determined by checking the technical condition of the engine control system.

To flush the throttle assembly, you need a means to clean the engine intake pipe. As a last resort, you can use a carburetor cleaner. If the problem cannot be eliminated using a cleaner, the throttle assembly must be replaced. After removing the throttle assembly, the gasket (O-ring) must be replaced. A product to clean and protect electrical contacts may be required.

To avoid damage to the electric drive, do not attempt to forcefully turn the throttle valve by applying force to it. When installing a new throttle assembly on a vehicle, special diagnostic equipment will be required in order to check the “calibration” of the throttle valve position in its extreme positions.

1. Prepare the car for work and disconnect the wire terminal from the negative terminal of the battery.

8. Using a multimeter in ohmmeter mode, measure the resistance of the throttle position sensors between terminals 1 and 4. A working throttle assembly should have a resistance in the range of 750–1250 Ohms.

When performing the following operation, hold the throttle assembly with the electric drive upward so that the cleaning agent cannot flow down the throttle valve axis towards the gearmotor and get inside the mechanism.

9. Using a cleaning agent, we wash away deposits from the inner walls of the throttle assembly and from the throttle valve.

10. Wipe the throttle assembly with a clean rag and blow it with compressed air from a compressor or foot pump.

11. Install the throttle assembly in the reverse order, replacing the O-ring with a new one.

Increased idle speed, dips and jerks when accelerating the car, loss of power - all this indicates problems with the throttle valve, which needs to be removed and cleaned, or replaced, if cleaning does not give the desired result, the unpleasant phenomena persist.

The procedure for removing the throttle assembly on a LADA Granta car

To remove the damper you need to perform the following operations:

- The wire is disconnected from the negative terminal of the car battery.

- The tightening that secures the ventilation hose going to the engine crankcase is loosened.

- The hose attached to the fitting of the air supply pipe is disconnected.

- The clamp connecting the pipe and the throttle becomes loose.

- The pipe is disconnected.

- The connector connecting the wires to the throttle assembly is disconnected.

- The bolts securing the throttle valve are unscrewed.

- The gasket located on the flange of the intake module is dismantled.

It should be noted that the gasket is disposable; when dismantling it, it is necessary to subsequently install a new element.

Source

Causes

The most common reason for an adaptation to be made is the consequences of throttle valve maintenance. As a result of operation, a large amount of deposits forms in this unit, therefore, after flushing, the position of the throttle valve changes, and the ECU continues to send signals about its condition until maintenance.

Over time, natural wear occurs on the resistive layer of the sensor potentiometer and the moving elements of the throttle valve; in this case, after adaptation, it will most often require replacement. It is necessary to conduct training if changes are made to the ECU settings (chip tuning), especially if operations have been performed to increase engine power.

The procedure is performed using special programs on computer equipment or without them (a strictly defined procedure, which will be discussed below) depending on the brand of car. Auto electricians must take into account the features of the model, year of manufacture, and type of ECU installed on the vehicle.

Instructions for cleaning the throttle body on LADA cars

In some cases, problems in engine operation may be associated with the formation of all kinds of deposits on the walls of the throttle valve. In this case, cleaning the throttle assembly (DU) can help. We'll tell you how to perform this procedure yourself. The remote control cleaning process is carried out similarly on all modern LADA cars (XRAY, Vesta, Largus, Priora, Granta, Kalina, Lada 4×4). You will find examples of work on specific LADA models in the comments.

It is not necessary to remove it to clean the throttle assembly. However, with the part removed, this can be done easier and better (see how to remove the remote control).

The book on repair and operation of the LADA Vesta car (and other LADA models) indicates that to flush the throttle assembly, you need a means to clean the engine inlet pipeline. As a last resort, you can use a carburetor cleaner.

We spray the cleaning agent not only on the throttle valve itself and the cavity around it, but also on all channels and hidden cavities. The use of soft rags is allowed. When cleaning the remote control with E-gas, make sure that the cleaning agent does not get into the electrical part of the unit. The process is shown in the video:

- Do not remove the throttle valve mounting screws. If they are then poorly tightened and tightened, the loosened screw can get into the engine cylinder and damage it.

- Use a coarse lint cloth or wire brush for cleaning.

- Do not touch the throttle on cars with an electronic gas pedal, so as not to reset the factory setting.

If it was not possible to eliminate the engine malfunction by cleaning the throttle assembly, then the throttle assembly must be replaced (if you are sure that it is the cause of the malfunction). When installing a new throttle body, special diagnostic equipment may be required to check the "calibration" of the throttle position at the extreme positions. This operation can be performed at a specialized service station. See also: Procedure for adapting throttle valve zero on Lada Vesta and XRAY.

Have you ever had to clean the throttle body yourself? What were the difficulties?

Need for maintenance

The prophylaxis procedure should not be carried out in the absence of obvious reasons. Before starting, you need to carefully evaluate the condition of the throttle valve. If there are no obvious signs of tar deposits and areas of coking, then the reason for unstable operation may lie elsewhere.

Also consider the mileage of the car. Experts recommend resorting to flushing no earlier than after 100 thousand km. But on some cars, for example, a Ford Focus, it may be necessary to flush it after 30 thousand kilometers.

You should know how to clean your throttle body to achieve the desired result. This requires a special carburetor cleaning solution, for example, Abro Carb & Choke Cleaner or similar products. The assembly must be dismantled; only in this case can the maximum effect be achieved, otherwise carbon deposits will remain inside the tubes. Disconnect all pipes from the throttle valve to gain good access to the inlet part of the assembly.

Remove carbon deposits delicately using a clean rag or soft brush. Do not use excessive force; you may damage the valve. The internal elements are coated with a thin layer of molybdenum, which novice car enthusiasts mistake for harmful deposits.

Throttle assembly - removal, inspection, cleaning and installation of Lada Granta

The throttle assembly is non-separable, cannot be repaired and in case of malfunction it is replaced as an assembly.

The need to perform work is determined by checking the technical condition of the engine control system.

To flush the throttle assembly, you need a means to clean the engine intake pipe.

As a last resort, you can use a carburetor cleaner.

If the problem cannot be eliminated using a cleaner, the throttle assembly must be replaced.

After removing the throttle assembly, the gasket (O-ring) must be replaced.

A product to clean and protect electrical contacts may be required.

To avoid damage to the electric drive, do not attempt to forcefully turn the throttle valve by applying force to it.

When installing a new throttle assembly on a vehicle, special diagnostic equipment will be required in order to check the “calibration” of the throttle valve position in its extreme positions.

We prepare the car for work and disconnect the wire terminal from the negative terminal of the battery.

Using a Phillips screwdriver, loosen the clamp and disconnect the air supply hose from the throttle body pipe and pull the hose down.

By pressing the clamps, disconnect the wiring harness block from the throttle assembly.

Visually check the condition of the throttle assembly terminals and the wiring harness block.

To remove oxides, spray the terminals with a product for cleaning and protecting electrical contacts.

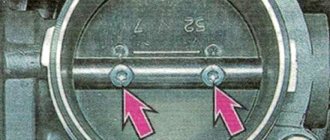

Using a 5 mm hex wrench, unscrew the four bolts securing the throttle assembly (one of the bolts is not visible in the photo)

Remove the O-ring from the intake manifold flange

Using a multimeter in ohmmeter mode, measure the resistance of the throttle position sensors between terminals 1 and 4.

A working throttle assembly should have a resistance in the range of 750-1250 Ohms.

When performing the following operation, hold the throttle assembly with the electric drive upward so that the cleaning agent cannot flow down the throttle valve axis towards the gearmotor and get inside the mechanism.

Using a cleaning agent, we wash away deposits from the inner walls of the throttle assembly and from the throttle valve.

We wipe the throttle assembly with a clean rag and blow it with compressed air from a compressor or foot pump.

We install the throttle assembly in the reverse order, replacing the O-ring with a new one.

Throttle learning idle

After flushing the unit or reflashing the ECU, the throttle valve should be trained to idle. To do this, fulfill the following conditions:

- check the voltage on the battery with the engine off, it should be at least 12.9 V;

- the coolant temperature should be in the range from 70 to 100 degrees;

- the steering wheel must be in a neutral position;

- The gearbox oil must be warmed up;

- all electrical consumers are turned off;

- automatic transmission handle in position P.

Failure to comply with the above requirements will lead to incorrect operation of the engine, so they must be followed. After warming up the engine, you must:

- turn off the ignition for 10 seconds;

- make sure that the accelerator pedal is in the up position;

- turn the key to the ON position for 3 seconds (do not start the engine);

- Press the gas pedal all the way 5 times within 5 seconds and release it for the last time;

- after 7 seconds, press the gas pedal all the way and wait until the “CHESK ENGINE” display lights up continuously;

- After pausing for 3 seconds, release the gas pedal.

Try to start the car, the attempt can be repeated several times. During stable operation, rev the throttle several times and the idle speed should return to the acceptable range.

The procedure for learning the throttle using a PC and car programs has its own specifics, depending on the brand of car, etc. Therefore, it makes no sense to describe the entire process in detail. But first you need to install special software on your PC, for example, VAG-COM for a VAG car group (or other) and drivers. The following is the standard connection order for all:

- turning on the ignition;

- connecting the PC to the car diagnostic connector with an information wire;

- launching software on a PC;

- conducting a test;

- receiving information about readiness for further work - the inscription: “The adapter is ready for work.”

Following a special algorithm, you will be able to coordinate the remote control and the ECU in the “throttle fully open/fully closed” modes for cars with both an electronic and mechanical gas pedal. In this case, the throttle valve training is carried out when the car is warm and the above requirements are met.

- Features of the Lada Granta throttle assembly

- Electronic gas pedal Lada Granta

- Malfunctions of the electronic gas pedal

- Cleaning the electronic throttle valve E-Gas Lada Granta 16V

Features of the Lada Granta throttle assembly

The throttle valve is turned by an electric motor through a gearbox. Both are built into the throttle body. When starting and warming up the engine, as well as during idling, the flow of air into the cylinders is regulated by opening the throttle valve. The throttle position is controlled by two sensors built into the throttle body.

The throttle valve opening angle is set by the electronic control unit (ECU) depending on the estimated amount of air that should enter the engine cylinders. This takes into account the operating mode of the engine (starting, warming up, idling, and so on), the temperature of the ambient air and the engine, and the position of the gas pedal.

Control commands are sent to the throttle assembly to the electric motor. At the same time, the ECU monitors the opening angle of the damper and, if necessary, sends appropriate commands to adjust its position. As a result of the fact that the ECU simultaneously regulates the amount of injected fuel and incoming air, the optimal composition of the combustible mixture is maintained in any engine operating mode.

The electric throttle body is sensitive to deposits that may accumulate on its inner surface. The resulting layer of deposits can interfere with the smooth movement of the throttle valve, jamming it (especially at low opening angles). As a result, the engine will operate unstably and even stall at idle, start poorly, and failures may also appear during transient conditions. To avoid this, as a preventive measure, deposits should be removed with special detergent compounds during regular vehicle maintenance. A large layer of deposits can completely block the movement of the damper. If flushing fails to restore the throttle assembly to operability, it must be replaced.

A malfunction or incorrect operation of the throttle assembly may be caused by a broken contact in its electrical circuit (oxidized terminals in the wiring harness connection block). In this case, it will be possible to restore operation by treating the terminals with a special compound for cleaning and protecting electrical contacts. There are other possible causes of the malfunction:

— no supply voltage is supplied to the throttle assembly;

— signals are not received from both throttle position sensors;

— The computer cannot recognize signals from the throttle position sensors.

In these cases, the engine control system goes into emergency mode. At the same time, the car retains the ability to independently move a short distance at a slow speed, which, in extreme cases, will allow it to be moved to a safe place

(move to the side of the road, leave the intersection, etc.).

The fact that the throttle assembly is operating in emergency mode may be indicated by a burning indicator lamp for a malfunction of the engine management system and an increased speed of the crankshaft at idle (about 1500 rpm, despite the fact that the engine is warmed up to operating temperature), the engine at this will not respond to pressing the gas pedal.

Each of the throttle position sensors is a potentiometer. During operation, gradual wear of conductive paths and moving contacts occurs. Over time, wear can reach such an extent that the sensor cannot function correctly. The presence of two sensors increases the reliability of the entire unit.

If only one sensor fails, the warning lamp will light up, but the engine management system will switch to backup mode. In this case, the engine will respond adequately to pressing the gas pedal, but with worse performance parameters

The reserve mode allows you to drive your car to the repair site under your own power.

Electronic gas pedal Lada Granta

On modern cars, instead of the usual cable drive for throttle control, a so-called “electronic gas pedal” is installed. In such cars, the throttle position is controlled electronically. When you press or release the gas pedal, information about this goes to the control unit (ECU) and only after processing and adjustment is a command given to the throttle module. The pros and cons of such a system, as well as signs of malfunctions, will be discussed in this article.

For those who are accustomed to mechanical drives, where pressing the gas pedal directly causes the throttle to move, driving a car with an electronic system will be unusual and unknown. To understand, you need to understand the principle of operation of the “electronic pedal” and its difference from a conventional mechanical one.

Getting rid of engine vibration part 2. Throttle revision

1 Cleaning and lubricating the throttle

Recently, the car has become very annoying with the behavior of the throttle. The car reacted nervously and with a slight delay to pedal presses, the idle speed fluctuated greatly, and releasing the gas was like a blow. I went for spring diagnostics for 299 rubles. Everything is fine, no electrical problems. I checked the spark plugs and changed the fuel. There was no effect, I tried to remove and clean the throttle, but knowing AvtoVAZ I decided to look at the condition of the E gas reducer. I bought a throttle cleaner and got to work. When I unscrewed the throttle nuts, the studs came out with them. The studs are held inside the plastic manifold by nuts; they fell out. I had to look for new ones and use thread glue. The damper was crap quite badly, especially around the axis of rotation. I slightly lifted the flap and turned it; it moved with little effort and stuck. A view opened up to the end of the damper; there was a lot of carbon deposits on it, which interfered with the passage of air at idle. Hence the sausages at low speeds. I washed everything, blew it with a cleaner from the heart. The biggest surprise was waiting inside the gearbox. We open it and see a completely dry gearbox. Not a drop of grease on the gears. The idler gear shaft has wear and plastic dust from the gear. And there’s actually an oval hole in the lid! I blew it out and lubricated it, very little lubrication is needed. A little inside the idler gear, a little into the cover and onto the drive gear of the engine. We close everything and put it in place. The result is excellent. Before cleaning and inspection: — Starting the engine was accompanied by vibration and floating speed. — Idle speed fluctuated greatly from 830 to 950 revolutions, sharply and with dips. — Acceleration up to 2500 rpm was sluggish, after 2500 it was like a kick. The car accelerated faster. — The release of gas was accompanied by a strong nod, which created discomfort in the flow. — The overall reaction to the gas pedal was very sluggish. — Squeaking sound when the ignition is turned on. After cleaning and inspection: - Now the engine starts, somehow abruptly, the speed is stable, vibrations are minimal - Idle speed has become more even, floating within 860 - 900 revolutions. — Acceleration is now smooth throughout. There is no such jerk after 2500. — The throttle release is smooth, the needle falls smoothly