Shock absorber struts

This is the main element of the suspension, since it is with their help that vibrations are damped while driving on uneven roads. The struts on the Kalina consist of a metal body in which a telescopic shock absorber is located. The system is hydraulic and works in both directions. When repairing the Lada Kalina, special attention must be paid to the condition of the suspension elements. Not only comfort, but also safety depends on it.

Between the strut and the body there is a coil spring and an upper support bearing. A bracket is welded to the body on the rack, with which the steering knuckle is attached. Approximately near the middle of the rack there is a swing arm that connects to the steering end. A little higher is the lower cup, into which the spring rests.

How to check support bearings on Kalina

Before replacing the support bearings on the Lada Kalina, you should make a diagnosis and make sure that the “support” has failed , so check out the signs of failure:

- Clicks, knocks of Kalina’s “supports” (audible under the hood, when the shock absorbers are operating);

- A cracking sound is heard from the front side under the hood (when turning);

- Handling deteriorates, play at the steering wheel increases;

- You can feel the bumps in the road through the steering wheel.

If such signs are present, then there is a 99% chance that replacing the support bearing of the Kalina front strut is inevitable, but first make a diagnosis. 1. Place the car on a flat surface and open the hood. 2. Find the upper support, press this place with your palm. 3. Rock the car from bottom to top so that the Kalina front strut supports and shock absorbers work. 4. If you feel or hear knocking noises, it means it's time to replace the support bearing. 5. Ask an assistant to rotate the steering wheel and listen to how the unit works; when in good condition, the “support” functions silently.

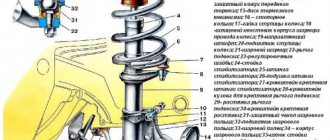

Front pillar elements

On the Lada Kalina car, the struts can be equipped with conical or barrel springs. It all depends on what equipment the car has. The lower coil of the spring rests against the support cup, which is tightly welded to the rack. The upper coil rests on the cup, which is attached to the shock absorber rod.

The rod is secured to the upper support bearing, which, in turn, is screwed to the body using three studs. Thanks to the bearing, the shock absorber rod rotates inside the support. This allows the wheels of the car to turn. A boot must be installed on the shock absorber rod, which protects the inner surface of the element from contamination.

Instructions for installing new springs, struts, support bearings and the supports themselves

First of all, we put the bump stop and boot on the new rack:

Then we tighten the new springs to the required moment and put them on the rack. It is important that the lowestmost coil falls exactly into the recess on the rack, so to speak, in its home place:

When the spring is sufficiently compressed, we proceed to the supports and bearings. We take the new support, turn it over and insert the support bearing. Typically, the bearing is marked “TOP”, meaning that this side should be inserted into the support:

Rotary mechanisms

When repairing the Lada Kalina, it is necessary to take into account the fact that after intervention in the design of the front suspension, it will be necessary to adjust the camber and toe of the wheels. A swing arm is installed on the shock absorber strut. Moreover, on two identical racks its position will be different. This lever has a hole into which the tie rod end is installed. Its length can be changed using a specially designed coupling.

The steering knuckle is secured to the front strut bracket using two bolts and nuts. The upper bolt has an oval washer, with which the camber of the wheels is adjusted. By rotating the bolt, you move the steering knuckle relative to the front strut. At the bottom it is secured by a ball joint to the wishbone of the suspension.

Signs of a support bearing failure

The first warning sign that something is wrong with the support bearing is most often a knocking sound coming from the area of the front right and left side members. Many suspension parts can creak and knock, but it is best to start checking with the support bearing. The most unpleasant sounds will appear when driving on uneven surfaces, when the car is heavily loaded, and also when making sharp turns. Also, the driver will probably notice a general drop in the car’s handling. Inertia occurs in the steering. The car may begin to “scour” along the road.

It is worth adding that most often manufacturers determine the service life of support bearings at 100 thousand kilometers. However, if the machine is operated in difficult conditions, parts may need to be replaced after 50 thousand. There are cases when the support bearing “flies” even after 10 thousand km.

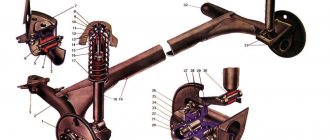

Suspension arms

The Kalina front suspension arm is kept from moving by a stretcher. This extension is secured at the rear edge to the lever with rubber-metal hinges. The front edge of this stretch is secured with a cushion to a special bracket, which is screwed to the car body. You can change the number of washers that are located in the rear and front mounts of this extension. This way you can adjust the angle of inclination of the wheel axis in the longitudinal direction.

The stabilizer is connected to the front suspension arms. Its middle part is secured with brackets and rubber pads on the body. When one lever moves, movement is transmitted through the stabilizer to the second. This can significantly reduce the swaying of the car when driving on uneven roads, as well as reduce roll when cornering.

The new Lada Kalina practically does not need to be serviced; it is only advisable to occasionally check the alignment angles of the front wheels. It is also recommended to carry out suspension diagnostics from time to time in order to identify breakdowns in the early stages.

Tuning the Lada Kalina suspension

The condition and characteristics of the chassis elements directly affect the behavior of the car. Some owners are not satisfied with the standard chassis parts of the Lada Kalina, and they seek to improve it by installing elements with different characteristics. Many people are interested in increasing stability, which manifests itself in reducing body roll during high-speed maneuvering. This can be achieved by new shock-absorbing struts and springs with increased rigidity. Such components work out road unevenness in more detail and do not allow the body to make long-term vibrations. Excessive rigidity of the struts can cause driver discomfort, so this point should be taken into account when choosing analog products. We also note another negative aspect of stiffer racks. They can cause increased wear on other components in the chassis. Springs can be installed shortened. This improves aerodynamics, but reduces ground clearance and creates the risk of damage to the underbody, sills, as well as elements of the chassis and exhaust system. Also, non-standard springs give the shock absorbers reduced rigidity, which is noticeable on uneven roads. To adapt the car to different road conditions, owners tend to install shock absorbers with adjustable stiffness.

If we consider the chassis of the LADA Kalina in universal and “cross” body versions, then these designs are endowed with some differences from each other. The front suspension of the station wagon is identical to other body variations and requires serious modification so that handling and stability become a source of pride for the owner.

The “cross” version of the LADA Kalina is equated to “light” SUVs, therefore the elements of its chassis are reinforced and have greater rigidity. Also, due to the increased ground clearance, this modification exhibits better cross-country ability on country roads.

How to replace longitudinal tension

In order to adjust the longitudinal tilt angle of the axle, you must contact a service center. At the same time, they will definitely remove the stretch. Therefore, you should not change it yourself; it is better to do this immediately before adjustment. But, if you remove the old stretcher and install it in place, in order to minimize the error in adjusting the caster angles of the axle, you need to count and record the number of washers that were located on the rear and front edges of the stretcher before removal.

The replacement procedure is as follows:

- Remove the bracket that secures the suspension extension.

- Use a 24mm wrench to keep the extension from turning. And with the second key you need to unscrew the nut that secures the front end to the wishbone.

- Remove the washer from the brace and remove the rear edge from the hinge.

- Remove the adjustment washers completely.

Installation of the longitudinal extension is performed in exactly the reverse order. It is necessary that the chamfers on the adjusting washers face the extension. After replacement, it is necessary to adjust the wheel alignment angles. This is a mandatory condition if the Kalina suspension is being repaired.

Upper front strut support for Kalina - features of choice

As practice shows in most cases, the upper support assembly is replaced. There are three models of “supports” on sale, which you should pay attention to when purchasing. The photo below shows original sets of supports from three companies: SEVI. SS20 (SS20), ASOMI (ASOMI). The cost of products varies from 2000 rubles. up to 4000 rub. depending on the configuration.

Watch the spare parts review video:

How to replace the ball

The ball joint is one of the most important elements of the suspension of any car. It can be restored, but this is not recommended, since the quality of restored products is much worse than new ones. Even on the new Lada Kalina, the ball joint can fail.

In this case, it is necessary to repair the suspension. The following manipulations are performed for this:

- Completely remove the front wheel of the vehicle and raise the side to be repaired using a jack.

- Treat all threaded connections with penetrating lubricant.

- Unscrew the nut that is screwed onto the hinge pin.

- Remove the two bolts that secure the ball joint race to the steering knuckle.

- Install the puller.

- Tighten the puller bolt, thereby removing the pin from the hole in the lever.

How to check the silent blocks of the front control arms?

The rubber must not peel off or bulge from under the washers; its surface must be smooth, without cracks; large play is also unacceptable, since the result of these malfunctions may be the destruction of the hinge seats, in which case it will be necessary to replace the entire suspension arm, not individual parts. You can tell that the front lower control arm silent block has failed by the uneven wear of the tires. It is quite possible that the car will also be thrown from side to side at speed, and this already poses an immediate danger to all road users.

Replacing the rear silent block of the front lever certainly requires attention and accuracy; it would be nice to have some skills in this area. But, in principle, if there are no special problems with the mechanics, then it is quite possible to carry out the operation yourself and not contact expensive service stations. Of course, you should start by diagnosing the problem; to do this, you need to jack up both suspensions one by one and remove the wheels. If defects are found on their surface, then the next step is straight to a specialized store for new parts.

The biggest difficulty may arise with how to press the silent block into the lever, but this issue can be completely resolved.

Replacing the lever

In order to replace the front suspension arm on the Kalina, you must perform the following manipulations:

- Unscrew the bolts securing the wheel, first lifting the side to be repaired.

- Remove the engine protection.

- Remove the bolts that secure the ball joint to the knuckle.

- Remove the bolt that secures the stabilizer link to the arm.

- Unscrew the nut that secures the transverse arm of the bracket to the body, and then remove the bolt.

- Write down the number of washers.

- The extension must be kept from turning using a 24mm wrench. Using the same exact key, you need to unscrew the nut that secures the rear edge of the extension.

- Remove the support washers from the rear edge. After this, you can dismantle the lower arm along with the ball joint.

- Remove the adjusting and thrust washers from the brace.

If it is necessary to replace the ball joint, it must be removed from the lever using a vice. Reassembling the entire assembly is done in reverse order. Tightening the threaded connections should only be done after the vehicle is installed on the wheels.

Replacing the front arm silent block - how to do it correctly?

Now, in order, about how the replacement process goes. First of all, you need to jack up your “iron horse” and remove the wheel. Next, you need to find the bolt on the front arm that secures the front silent block and unscrew it. We also unscrew the fastening nut of the rear silent block. Now we pull the stand along with the lever towards us; Having pulled it out, unscrew the bolts securing the lever to the ball joint and dismantle it. Next, you can proceed directly to the replacement; to do this, press out the rear silent block of the front lever using a small sledgehammer.

In order to press in a new part, you can also use a special device for replacing silent blocks, however, this does not mean that you need to immediately run to the store and purchase it, since in this case a hammer or sledgehammer will again be a faithful assistant. We assemble the lever in strict reverse order. Next, we install all the dismantled elements of the car in their places, but keep in mind that the front silent block can only be tightened with the car removed from the jack. And finally, don’t forget to restore the wheel alignment.

The suspension parts of the LADA “Kalina” wear out when driving on uneven roads and require periodic replacement. The Kalina anti-roll bar is a strong and durable part that requires replacement only as a result of an accident. The repair of this unit consists of replacing the bushings, the rubber of which does not withstand long-term use on our roads.

How to replace a rack

If there is a knock in the front suspension of the Kalina, then this may be the cause of failure of any element. Therefore, it is necessary to diagnose and check all components. If at least one shock-absorbing strut has become unusable, two need to be replaced at once. To do this, follow these steps:

- Raise the wheel using a jack and remove it.

- Disconnect the tie rod end from the lever on the rack. To do this, use pliers to remove the cotter pin and unscrew the nut with a 19mm wrench. After this, install the puller and remove the hinge from the hole.

- If you plan to install a new rack assembly, then you do not need to perform any unnecessary actions. But if you need to remove the spring, you need to unscrew the nut that secures the shock absorber rod in the support bearing.

- Loosen the three nuts that secure the upper support to the body.

- When installing new shock absorber struts, the toe-in of the front wheels will be disrupted. The installation angles can be adjusted only by eye, so that after repair you can go to a service station for adjustments.

- Remove the bolts that secure the strut to the steering knuckle.

- Remove both bolts and washers.

- Move the brake hose aside.

- Use a pry bar to move the steering knuckle down.

- Finally unscrew all the nuts securing the support bearing to the body.

Installation of the shock absorber strut is carried out in the reverse order. If you are not changing the struts, but are repairing them (replacing the inner race, oil, seals), then it is best to outline the position of the strut relative to the steering knuckle. This will avoid the costly procedure of adjusting wheel camber angles.

Lada Kalina - replacing the support bearing with your own hands

Before disassembling and removing the Kalina front strut with upper supports, be sure to study the structure of the unit. The diagram shows the serial numbers (articles) of the front suspension components.

To remove the support bearings of the front struts of the Lada Kalina you will need a set of tools: 1. A set of open-end or ring wrenches: 9, 17, 19, 22. 2. A 13 socket with a ratchet. 3. Steering wheel end puller, vice, torque wrench (if possible). 4. Jack. 5. Shock absorber spring clamps. 6. Pliers. 7. Hammer. 8. WD-40 lubricant.

How to remove the support bearing on Kalina - step by step guide

Replacing the Kalina front strut supports begins preparing the car. Place the car on a flat surface, if there is a lift or pit available. Engage first gear and release the parking brake. Dismantling sequence in order:

- We unscrew the wheel bolts, then raise the car with a jack or a lift as in our case.

- We gain access to the brake disc, but you don’t need to remove it, nor do you need to unscrew the hub locknut.

Reference data

Front wheel alignment angles under a load of 320 kg

Front wheel camber, hail

Front wheel toe-in, mm

Longitudinal inclination of the wheel turning axis, degrees

Installation angles of the front wheels of the equipped vehicle

Front wheel camber, hail

Front wheel toe-in, mm

Longitudinal inclination of the wheel turning axis, degrees

Tightening torques for threaded connections

Name of units and parts

Tightening torque, Nm (kgf-m)

Wheel bolts

Front wheel bearing nut

Bolts securing the ball joint to the steering knuckle

Nut securing the ball pin to the lever

Adjusting bolt nut (with eccentric) of the front suspension strut

Nut of the bolt securing the front suspension strut to the steering knuckle

Nuts securing the front suspension strut rod to the upper support

Nuts securing the upper support of the front suspension strut to the body

Nut of the bolt securing the front suspension arm to the body

Front suspension extension nuts

Extension bracket mounting bolts

Nut of the bolt securing the stabilizer bar to the front suspension arm

Nuts securing the stabilizer bar to the body

Bolt nut for the lower shock absorber mounting to the rear suspension arm

Signs of malfunction of the anti-roll bar LADA “Kalina”

Malfunctions of the suspension stabilizer appear when cornering and driving over uneven roads. The cause of the malfunction is broken bushings or poor tightening of the nuts of the clamps holding the stabilizer bar. This manifests itself as follows:

- there is a knocking noise under the hood when driving through potholes and potholes;

- the car begins to “go to the side” when driving in a straight line and you have to constantly adjust its trajectory (this is especially noticeable at speed);

- the car sways and rolls heavily when turning or braking;

- Excessive roll appears during maneuvering.

You can independently check the bushings and stabilizer mounts as follows:

- turn the wheels to the side until they stop, freeing up space in the wheel well;

- grab the Kalina stabilizer with your hand and pull strongly in different directions;

- If there is the slightest play, the stabilizer bushings must be replaced.

A more detailed analysis of the condition can be made by driving the car onto a pit or lift. This way you can determine exactly where the knocking is coming from and which part needs to be replaced.

What is needed to replace the Kalina stabilizer

To replace the anti-roll bar you will need:

- standard set of socket wrenches (socket wrenches can be used);

- WD-40 liquid;

- jack;

- special device (extension);

- hammer;

- stabilizer bushings “Kalina”;

- stabilizer's pole;

- stabilizer bar.

To access the mounts of the struts and stabilizer, you must place the car on a viewing hole or a lift.

Description of design

The front suspension is independent, with telescopic swivel struts, wishbones, longitudinal bracing arms and a torsion bar anti-roll bar.

The suspension strut consists of a housing in which a hydraulic telescopic coil spring shock absorber and an upper support are installed. A bracket for attaching the steering knuckle, a swing arm and a lower spring support cup are welded to the outside of the strut body. Depending on the vehicle configuration, the strut may have a barrel-shaped or conical spring. The spring's lower coil rests against the lower support cup, and its upper coil rests against the upper support cup mounted on the shock absorber rod. Also installed on the shock absorber rod is the upper support of the strut, consisting of a housing, a rubber cushion and a bearing. The support body is attached to the car body with three studs and nuts. The bearing allows the shock absorber rod to rotate in the support when the strut is turned, and the rubber buffer prevents the transfer of vibrations to the car body. The shock absorber rod is protected from dirt and dust by a plastic casing. In the event of a suspension breakdown, the stroke of the rod is limited by the compression stroke buffer. The strut pivot arm is connected to the steering rod through a ball pin. Changing the length of the rod using its connecting coupling allows you to adjust the toe-in of the front wheels. Tie rod adjusting sleeve : 1 - tie rod end; 2 — adjusting sleeve; 3 — steering rod The steering knuckle is attached to the strut bracket with two bolts and nuts. The upper hole of the bracket is made oval, and the bolt installed in it has an eccentric collar and an eccentric washer. When this bolt rotates, the steering knuckle moves relative to the strut, turning on the lower mounting bolt as if on an axle. Thanks to this, the angle between the strut and the fist changes, which in turn allows you to adjust the camber of the front wheel. A double-row ball bearing is pressed into the hole of the steering knuckle and secured with two retaining rings. The wheel hub is pressed into the inner ring of the bearing. At the bottom, the steering knuckle is connected to the wishbone of the suspension using a ball joint. The transverse lever is kept from moving by a stretcher, which is attached with its rear end through a rubber-metal hinge to the lever, and with its front end through a cushion to a bracket fixed to the car body. By changing the number of washers in the front and rear brace mounts, you can change the position of the lever, thereby adjusting the longitudinal inclination of the wheel steering axis. Attaching the steering knuckle to the rack : 1 - bracket for mounting the steering knuckle; 2 — rack body; 3 — bolt (eccentric) of the upper fastening of the steering knuckle; 4 — bolt of the lower fastening of the steering knuckle; 5 — steering knuckle Attaching the longitudinal brace to the transverse arm : 1 — rear end of the longitudinal brace; 2 — adjusting washers; 3 - thrust washer; 4 — rubber-metal hinge; 5 - wishbone of the suspension The ends of the anti-roll bar are connected to the wishbones of the front suspension of the car using struts. The central part of the stabilizer is secured through rubber cushions to the body with brackets. The movement of one of the levers is transmitted through the stabilizer to the second. This allows you to partially synchronize the operation of both sides of the suspension and thereby reduce the sway of the car on uneven roads and roll in corners. Front suspension : 1 — stabilizer bar; 2 — bracket for fastening the stabilizer bar; 3 — transverse arm bracket; 4 - wishbone; 5 — stabilizer strut; 6 — telescopic stand; 7 — ball joint; 8 — steering knuckle; 9 — longitudinal stretch; 10 — extension bracket After repairing any suspension or steering elements, be sure to check the alignment angles of the front wheels. It is possible to properly check and adjust the alignment angles of the front wheels only in a service company that has a special stand for performing adjustment work.

Lada Kalina - front strut support bearing: choice, price, characteristics

If you do change the support bearing individually by installing it in the old support, then you should buy from trusted manufacturers, a summary table of which and photographs are presented below. Catalog number (article) - 1118-2902840.

Table of recommended manufacturers

| No. | Manufacturer | Manufacturer's code | Price 2016, rub. | Equipment | ||

| Peculiarities | Retaining rings | Protective cap | ||||

| 1 | VBF Russia Analogue | 1118-2902840-01 | 700 | — Clip made of hardened steel; — Manufactured according to GOST; — Increased service life; — High-quality lubricant. | — | — |

| 2 | NPP "System Technologies" Russia Analogue | SS10113/11180-2902840-00 | 900 | — Silence; — Vibration damping; — Work at low temperatures; — Protection from dirt and dust. | — | — |

| 3 | AvtoVAZ Russia Original | 1118-2902840 | 750 | — Original product; — 1 year warranty; - Durability. | — | — |

Table of bearing sizes 8112Н and technical characteristics

| Characteristic | Unit | Value according to GOST (TU) |

| Inner diameter of the tight ring, d | mm | 60 |

| Outer diameter of the tight ring, d1 | mm | 85 |

| Free ring inner diameter, D1 | mm | 62 |

| External diameter of free ring, D | mm | 80 |

| Installation height | mm | 17 |

| Dynamic load capacity | kH | 41,5 |

| Static load capacity | kH | 95,0 |

| Nominal speed | rpm | 3600 |

| Axial clearance | mm | — |

| Steel type | — | SHH-15 |

| Hardness of steel and rollers | H.R.C. | 61-65 |

| Contact angle | hail | — |

| Torque | kN*M | 220 |

| Ring roughness | Ra | 0.32 |

| Number of balls | PC. | 24 |

| Ball diameter | mm | 8,731 |

| Mounting chamfer radius, r | mm | 1,5 |

| Weight | G. | 295 |

Features of Kalina's suspension

A detailed inspection of Kalina’s suspension reveals hydraulic shock-absorbing struts, which are attached to the steering knuckle in the lower part, being the basis of the entire structure of the unit. The bolt located in the upper part of the steering knuckle allows you to adjust the camber element.

In the assembly, the upper part passes through a hole that is located in the existing bracket. The body part is equipped with a mudguard, to which the top of the rack is fixed using three nuts. Due to the existing elasticity of this unit, high-frequency vibration is excellently damped. In this case, a characteristic swaying of the Kalina suspension strut occurs during the working stroke.

The front suspension of the Lada Kalina is telescopic and has complete independence.

Kalina's suspension, which is characterized by the presence of conical or coil springs, ensures a particularly smooth ride due to the presence of a stabilizer. This allows you to avoid compromising the lateral stability of the car. This function is also performed by levers that relate to transverse braces. The bearing for turning the strut must allow the wheels to turn.

Causes of extraneous sounds in the chassis

Knocks and squeaks coming from the front suspension are direct evidence of damage to its elements. Note that the stern suspension makes itself known by malfunctions much less often. It is structurally simpler, and its main element is a torsion beam, which is held by longitudinal arms on the body and connected into one system with shock absorber struts.

To specify the malfunction, you should resort to a visual inspection of the suspension elements. In most cases, this practice bears fruit, and the identified worn part is replaced. There are cases where it is impossible to independently determine a breakdown visually. Here you will need to contact the service for a more thorough diagnosis. As an example, such a case may be a knocking rod inside the shock absorber strut.

Let's get back to the inspection. To do this, the Lada Kalina car should be hung with a lifting device or placed over a pit. In this case, you will need to stock up on a jack to hang each side of the car one by one. During diagnostics, each chassis element is checked individually. The rubber-metal liners of the arms and stabilizer struts, the integrity of the boots of the ball joints and steering tips are inspected. Attention is also paid to the racks. They are inspected for the absence of liquid leaks and the integrity of the anthers with bumpers.

When there is a violation of the integrity of these components, and also if, when the ball joint of the lever or tip is impacted with a pry bar, they emit a characteristic metallic sound, then they urgently need replacement.

Diagnosing the rear suspension is much faster. It does not have as many articulated joints as compared to the chassis of the front end. The inspection consists of assessing the condition of the racks. Also during this event, it is recommended to pay attention to the condition of the muffler hangers. Sometimes a dangling exhaust system pipe can produce knocks on the body and suspension components, misleading the owner.

Cases Kalina

Trunk volume Kalina hatchback

Lada Kalina 2 cross owner reviews

Causes of creaking and knocking car suspension

A creaking or knocking sound indicates malfunctions in the components of the Lada Kalina. The front suspension rattles more often. This is due to the fact that it is more susceptible to breakdowns than the rear one. Among the various components of the car, the malfunction of which can cause problems with the suspension and knocking in it are the following.

- CV joints.

- Shock absorbers.

- Bearings.

- Steering rod and reaction rod.

- Exhaust pipe.

- Rubber seal, etc.

Knocking can come from parts such as ball joints, silent blocks, front suspension arms, steering knuckle, mounting bolts. Without diagnostics, it is impossible to accurately determine the causes of creaking or knocking in the suspensions in order to effectively carry out repairs.

Only visual diagnostics of the Lada Kalina in the traditional way will help to identify why a knock is heard. A creaking or knocking sound from the suspension can only be associated with a broken rubber band, so there is no need to rush to use the services of a service station; this may take too much time and money.

If an independent visual inspection of the suspension did not reveal the real cause of the creaking or knocking noise, then the car must undergo a full diagnostic and subsequent repair. This will help identify the reasons why suspension knocking occurs.

It is important to know how you can independently diagnose all faults. It is easier to diagnose the rear rather than the front suspension, since the inspection is not complicated by the presence of a large number of complex controls.

Knocking in the front suspension on Kalina, reasons for the knocking

There are four main reasons for squeaks and knocks in the front suspension:

- Quality of the road surface. Yes, even the newest and most ideal suspension can knock and squeak on bad roads, even if this has not been observed before. To test this theory, drive a few hundred meters along a well-paved road. If there is no knock, then the suspension is ok. Otherwise, see the second reason.

- If the knock is accompanied by vibration in the steering wheel, then its cause is a faulty steering rack or thinning brake discs.

- The third reason is springs that have lost their tone, which is why the car body actually hits the suspension.

- A thin silent block designed to dampen knocks and vibrations when driving.

How to choose racks for Lada Kalina

Lada Kalina racks are divided by type and manufacturer. The area of application of the vehicle decides here. For good roads, it is better to install hard shock absorbers that hold the asphalt even at high speeds. Medium hardness options are suitable for riders whose vehicles drive in small towns where there is an abundance of primers. In rural areas, experienced car enthusiasts recommend installing soft racks.

Firms stand out among the popular manufacturers.

- SAAZ. A domestic brand that supplies products to the AvtoVAZ conveyor belt. The stands are quite soft and inexpensive. One of the disadvantages is the lack of stability when cornering.

- KYB or Kayaba. Rigid gas-filled struts meet the most modern vehicle control standards. Extreme stability, durability and reasonable price. The downside is that they are only suitable for normal roads.

- ASOMI and SS. differ from the stock version in increased reliability. There are no fundamental differences in the operation and efficiency of shock absorption. Used as an alternative to factory racks.

- FENOX. Naturally, the Fenox brand produces some models of shock absorbers suitable for second-generation viburnums. Quite popular racks are characterized by an increased shelf life, increased strength and average dynamic characteristics. The manufacturer is often chosen by users who want to find a balance between stability, durability and machine control.

- Denckermann. According to buyers, this is a “foreign” analogue of Fenox products, which has similar parameters to the prototype. The only drawback is the low prevalence in certain regions.

Replacing Lada Kalina struts can be done independently, without contacting services. Due to the simple design of the units, the operation does not require specific tools or deep knowledge of mechanics.

Bearing replacement

No matter what kind of car the support bearing wears out, but if it uses a MacPherson strut, then the technology for disassembling the unit for replacement is identical, with the exception of some nuances regarding the suspension design.

Therefore, we will consider how replacement is carried out on a VAZ-2110 car, and then we will indicate the features of the operation on other models.

So, it has been revealed that the support bearing requires replacement. All work can be done in a garage, but some specialized tools will be required.

In general, you will need:

- Standard set of keys, hexagons, heads with collars and rods;

- Jack;

- Steering wheel end remover;

- Spring ties;

- Rags.

A new support will also be required, since on this car the bearing is included in its design.

Of course, you can disassemble the support itself to replace only the bearing, but most car owners prefer to replace the entire assembly.

Additionally, you can purchase a spring vibration damper that is installed between the upper cup and the spring.

Below we will consider the sequence of actions, and we will indicate small tricks that will make the work easier.

Disassembly and replacement is done as follows:

- We place the car on a level surface and immobilize it using the hand brake and wheel chocks;

- Take a 30mm socket and loosen the nut securing the drive to the hub. It is better to do this while the car is standing on all wheels (unscrewing this nut with the wheel removed is more difficult, since it will be more difficult to block the hub from turning). It is also worth noting that this nut is pinned, so it is difficult to tear it out of place and you cannot do without extending the wrench;

- We open the hood and, using a spanner wrench and a hexagon, tear off the shock absorber rod nut (the hexagon holds the rod itself, and the wrench loosens the nut. In this case, you only need to loosen it a little; it is strictly forbidden to twist the nut completely, otherwise the unheld spring will “shoot”). It is better to do this operation before removing the rack (it is much more difficult to remove the nut on a removed unit);

- After removing these two nuts from their place, you can continue disassembly. Jack up the required wheel and remove it;

- Unscrew the fastening of the ball joint of the lever to the rack;

- Using a puller, press out the tie rod end;

- Completely unscrew the nut securing the drive to the hub;

- Loosen the brake caliper mount (there is no need to disconnect the tubes from it), remove it from the disc and move it to the side;

- We take hold of the brake disc and pull it towards ourselves, pulling the hub from the splines of the drive shaft end switch;

- We go into the engine compartment and unscrew the three nuts securing the support to the car body. At the same time, we ask an assistant to hold the support so that it does not fall to the ground. After this, remove the assembly;

- We install the couplers and tighten the spring until its upper coil moves away from the thrust cup;

- We completely unscrew the nut securing the shock absorber rod and remove the support (after this you can check the performance of the shock absorber, check the condition of the boot and bump stop).

- Before installing a new support, we check the condition of the support cup, clean it of rust and dirt, install vibration dampers under it (if purchased);

- Before installing a new support, we install the spring correctly (the ends of the coils at the top and bottom should fit into special recesses in the cups);

- We install a new support and screw the rod securing nut until it stops;

- We remove the ties, constantly monitoring the position of the ends of the spring;

- We install the assembled rack on the car. After assembly work, it is necessary to additionally tighten the rod fastening nut.

Now about the features of the replacement with Priora, Kalina, X-Trail. Removing and disassembling the strut for these cars is the same as described above.

But it is not necessary to change the support itself on these cars (if the condition is satisfactory); after dismantling, it is enough to remove the bearing from it (installed on the side of the support cup), and put a new one in its place. And then everything comes back together.

Below is a table of the designation of support bearings according to GOST, designations (full, main, foreign analogues), their size and weight.

When carrying out replacement, special attention should be paid to safety precautions. You should not try to disassemble the rack without ties, since a “firing” spring can cause serious injury

Checking VAZ support bearings.

SIGNS OF FRONT STRUT DAMAGES

- The appearance of knocking noises when driving over uneven surfaces in the area of the pillar. This happens when the thrust bearing has become disintegrated and is not performing its function properly. This also happens if the coil spring bursts.

- When hitting an obstacle, the car sways for some time due to the fact that the shock absorber itself does not dampen the vibrations.

- During a visual inspection, if you see that the strut is wet on a dry road, this means that the front shock absorber has lost its tightness. Oil leaks out of it.

REPLACING STRUTS ON KALINA VAZ 1117, 1118, 1119

- Wrenches for 17, 19 and 22, preferably ring ones. It is easier to remove old threads with box wrenches. You can, of course, use socket heads with similar parameters.

- A pry bar and a hammer will make it easier to separate the lower part of the shock absorber from the steering knuckle.

- Wheelbrace for removing and installing wheels.

- Pliers.

- An open-end wrench to hold the rod while unscrewing the top nut.

- A 13mm socket head with a wrench, or better yet, a ratchet (it makes it faster to unscrew and tighten the nuts).

- Spring ties.

It would be a good idea to prepare WD-40 lubricant or something similar, just in case the threads are too stuck and the nut or bolt cannot be unscrewed. You also need a jack, better than two, or some kind of reliable support, in case the car tilts and falls off the support. You will have to work hard with a hammer and a pry bar, the body will swing and therefore additional support is needed for insurance.

Video 2

Now you can safely unscrew the wheel nuts and remove the wheel. The brake hose is attached to the strut, so it needs to be released from the mount so that it does not interfere when we remove the strut. Now we will need WD-40; we need to treat all the bolts and nuts that will have to be unscrewed. The main thing is to spray on the lower nuts and bolts of the shock absorber that secure the assembly to the steering knuckle.

We remove the steering tip nut and hit the eyelet into which the ball pin of the tip is inserted with strong blows, while inserting a pry bar between the steering tip and its mount on the rack. If you have a special puller, you can press out the finger using it. Unscrew the two self-locking nuts securing the shock absorber to the swing arm. To do this, we use keys 17 and 19. It is better to use similar heads and knobs.

After removing the nuts, it happens that the bolts do not come out. They have to be knocked out. You must first knock them out through a wooden block so as not to spoil the thread, and then, using a punch with a smaller diameter, knock out the bolt when it is already sunk into the steering knuckle.

Video 3

DISASSEMBLING THE FRONT STRUT KALINA

Before you start disassembling the front strut on Kalina, you need to compress the springs so that they do not “shoot” when unscrewing the top nut. To do this, use spring ties. They come in different types, but the principle of operation is the same for all. For clarity, a photo of a spring tie of one type is given below:

Spring ties

We place the ties on both sides of the spring, put the hooks on the coils, then turn the pins with a wrench, evenly tightening them on both sides until the spring no longer rests against the gasket.

Next, unscrew the top nut of the shock absorber rod. Then you can easily remove the strut support on Kalina along with the bearing and other elements of the upper support. We remove the spring, and then remove the compression stroke buffer and protective cover from the shock absorber rod. To do this, you need to pull them up with a little effort.

All! We disassembled the old front strut of Kalina, now we can start assembling a new one...

ASSEMBLY OF THE FRONT STRUT KALINA

To begin assembling the Kalina front strut, we first put a protective cover on the rod of the new shock absorber, and then a compression stroke buffer, the so-called front strut bump stop.

Front strut bumper Lada Kalina (VAZ 1118-2902816-01)

We take new springs (if the old ones have become unusable), tighten them to the required height and install them on the shock absorber. We install it so that the lower outermost coil fits into the recess intended for it.

Front strut supports for Lada Kalina without bearing (VAZ 1118-2902822LV), with bearing (1118-2902820LV)

Reviews about the suspension

The owners highlight a number of positive points:

- The suspension is well suited for Russian roads, especially outside the city.

- On the highway, the suspension does its job well, and the car holds the road well.

- The suspension is moderately soft even at -30C.

- After a big hole, we had to change two wheels; we checked the suspension during maintenance - no complaints. On all previous cars with such a mileage it was necessary to completely “shake up” the suspension.

There are also negative points:

- On bumps the suspension is noisy.

- Compared to the Renault Logan, the Lada Granta's suspension is a bit harsh.

Let us remind you that you can get acquainted with the car in more detail from other reviews and tests of the Lada Grant.

Keywords: front suspension of Lada Granta | rear suspension of Lada Granta | front suspension of Lada Kalina | Lada Kalina rear suspension

Found an error? Select it and press Ctrl+Enter..

- Lada 4×4 snow blower is sold in Germany for 2.4 million rubles.

- Test drive Lada XRAY 1.8 with manual transmission from leading auto media

- Photos of Lada Priora Sport

- Lada 4×4 model range with photos and descriptions